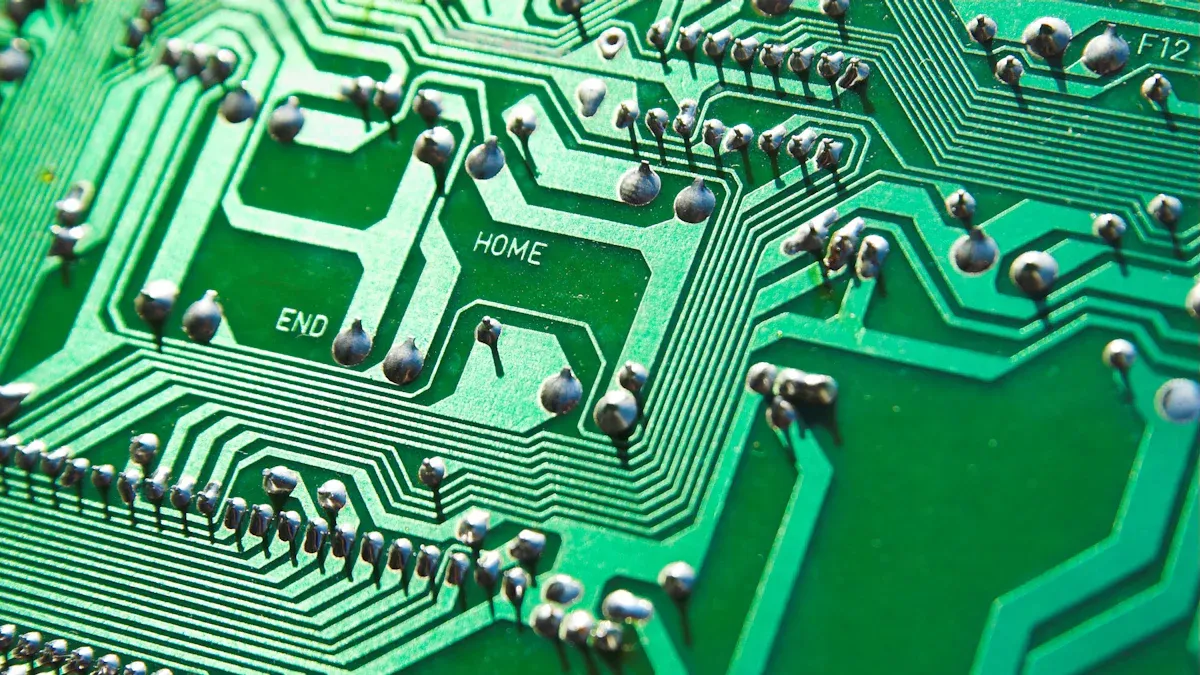

Printed circuit board assembly (PCBA) plays a crucial role in modern electronics. The pcba definition refers to the process of attaching components onto a printed circuit board (PCB) to make it functional. PCBA connects and secures components such as resistors, capacitors, and microchips, ensuring devices operate efficiently and reliably. In 2023, the PCBA market was valued at $68.4 billion, with projections suggesting it could grow to $105.8 billion by 2032. PCBA powers essential technologies, including smartphones and medical devices. For specialized requirements, custom PCBA provides tailored solutions, making it an indispensable part of today’s technology-driven world.

Key Takeaways

PCBA, or Printed Circuit Board Assembly, makes electronics work by adding parts to a PCB.

It’s important to know PCB and PCBA are different; PCB is just the board, but PCBA is the full, working circuit.

Checking PCBA quality with tests and inspections helps avoid mistakes and makes better products.

PCBA is used in many fields like electronics, cars, healthcare tools, and space tech, showing how useful it is.

Custom PCBA designs can be changed and grown, making them fit special needs and market changes.

PCBA Meaning and How It Differs from PCB

What Does PCBA Mean?

PCBA means Printed Circuit Board Assembly. It is the process of putting electronic parts onto a circuit board. This turns a plain PCB into a working part for devices. Parts like resistors, capacitors, and chips are added during this step. PCBA is the last step to make a working circuit. Without PCBA, devices like phones and laptops would not work.

The process includes attaching parts and checking connections. After this, the PCBA is ready to be used in products. This makes PCBA very important in making electronics today.

How Is PCBA Different from PCB?

People often confuse PCB and PCBA, but they are not the same. A PCB, or Printed Circuit Board, is just the base. It is made of copper and insulating layers. It does not have any parts on it. A PCBA, however, has all the parts attached and is ready to use.

Here are the main differences between PCB and PCBA:

PCBs are empty boards; PCBAs are working circuits.

PCBs have copper and insulation; PCBAs have added parts.

PCBs are the base; PCBAs are the finished product.

Knowing these differences shows why PCBA is key to making electronics work.

Key Processes in PCBA Manufacturing

Component Placement and Soldering

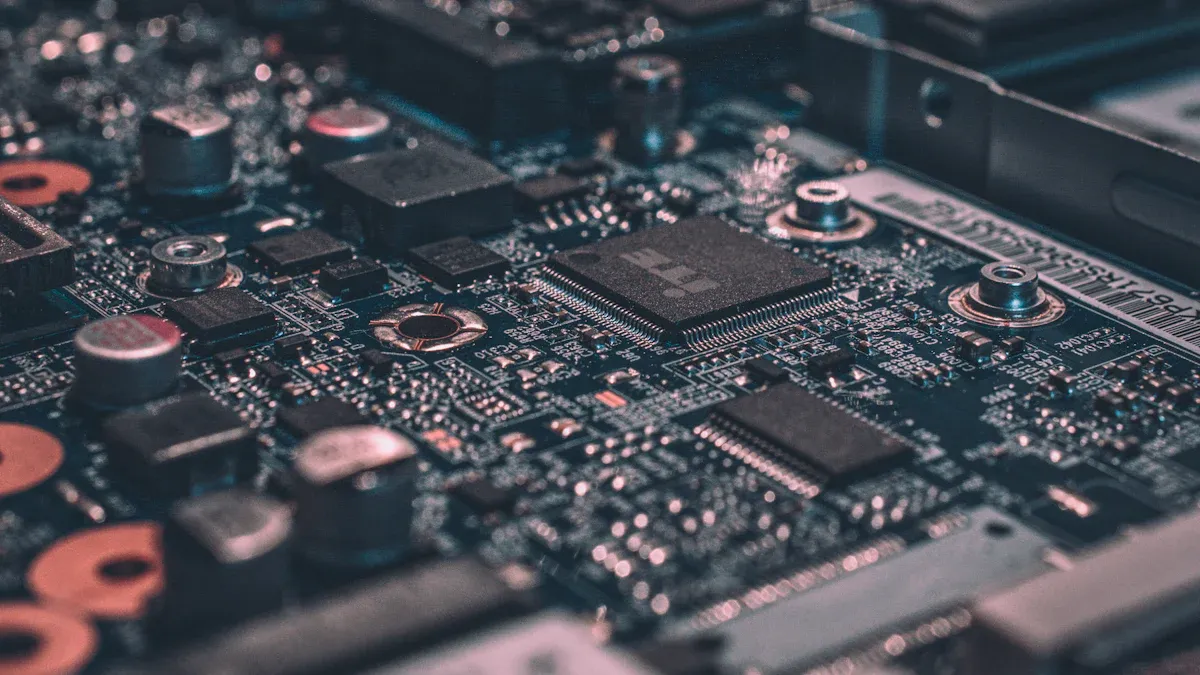

The first step in making a PCBA is placing parts on the PCB. This step needs accuracy so every part fits correctly. Machines are often used to place parts quickly and precisely. These machines add parts like resistors, capacitors, and chips to the board.

After placing the parts, soldering holds them onto the PCB. Two main soldering methods are wave soldering and reflow soldering. Wave soldering works well for parts with leads going through the board. Reflow soldering is better for flat parts on the board’s surface. Good soldering makes strong connections and avoids problems.

Inspection and Quality Control

Checking the PCBA is very important to ensure it works well. Special tools like automated optical inspection (AOI) and X-rays find mistakes early. These tools spot problems like misplaced parts or bad soldering.

Factories also use systems to watch for errors during production. This helps stop bad products from being made. For example, better checks can raise success rates from 95% to 99%. This means fewer broken parts and better quality.

Quality Control Step | What It Does |

|---|---|

Automated Inspection Tools | Finds mistakes automatically while making the PCBA. |

Monitoring Systems | Watches the process to catch problems right away. |

Full Testing Plans | Makes sure the PCBA meets all quality rules. |

Testing and Validation

Testing ensures the PCBA works as it should. During this step, each part and the whole board are checked. In-circuit testing (ICT) looks at single parts, while functional testing checks if the board works properly.

Testing finds problems before products are sold. This is very important for prototypes and devices used in fields like medicine or space. Fixing issues early saves money and makes products more reliable.

Small batch PCBA benefits a lot from careful testing. It ensures prototypes are high-quality, making it easier to move to full production.

Applications of PCBAs in Electronics

Consumer Electronics

PCBAs are essential for modern gadgets you use every day. Devices like smartphones, laptops, and gaming consoles need PCBAs to work well. These assemblies link parts like processors, memory chips, and sensors. This ensures the devices run smoothly. By 2030, the consumer electronics market could reach $1.2 trillion, showing the rising need for PCBAs.

PCBAs are also used in smart home devices like thermostats and cameras. The Internet of Things (IoT) market is growing fast, from 63 million US homes in 2023 to 93 million by 2027. PCBAs help these devices connect and automate tasks. Small batch PCBA production is often used to make prototypes. This ensures designs are good before making them in large numbers.

Automotive Industry

Cars rely on PCBAs for advanced systems. These include engine controls and entertainment features. PCBAs improve safety, efficiency, and user experience in vehicles. The automotive PCBA market may grow from $9.15 billion in 2023 to $13.39 billion by 2030. This shows more cars are using electronic systems.

Metric | Value |

|---|---|

Market Size (2023) | USD 8.87 Billion |

Projected Market Size (2031) | USD 13.58 Billion |

CAGR (2024-2031) | 5.48% |

Small batch PCBA production is key for car makers. It helps test and improve designs for electric cars and self-driving systems. Custom PCBA solutions also add features like driver-assistance systems and LED lights. These need accurate and dependable circuits to work properly.

Medical Devices

PCBAs are very important in medical tools where accuracy matters. Devices like pacemakers, MRI machines, and glucose monitors depend on PCBAs for correct results. The medical field uses PCBAs to create better healthcare technology. This helps improve how diseases are diagnosed and treated.

Medical PCBs must be reliable. For example, a device lasting 10 years needs 98% reliability to meet standards. Custom PCBA designs help meet these strict rules by focusing on specific medical needs. Small batch PCBA production is used to make prototypes. This ensures devices pass regulations before mass production.

PCBAs are also used in wearable health devices, which are becoming popular. These small devices track health data like heart rate in real time. As healthcare technology grows, the need for PCBAs in medical tools will keep increasing.

Aerospace and Defense

PCBAs are very important in aerospace and defense systems. These fields need high safety, strength, and strict rules. PCBAs are used in key tools like radars, communication devices, and navigation systems. They ensure these tools work well even in tough conditions.

To meet strict rules, makers follow special tests and certifications. For example, ISO 9001 and AS9100D ensure good quality. Tests like automated optical inspection (AOI) and in-circuit testing check if PCBAs work properly. The table below shows key quality control steps for aerospace and defense:

Aspect | Details |

|---|---|

Certifications | ISO 9001, ISO 13485, IATF 16949 |

Compliance Standards | IPC-JSTD-001, IPC-A-610 Class II and Class III |

Testing Processes | Automated optical inspection (AOI), X-ray, In-Circuit and Functional Testing |

Quality Control | Strict checks to make sure there are no defects |

Supply Chain Compliance | DFARS compliant and follows NIST cybersecurity rules |

Military standards like MIL-PRF-50884 and MIL-PRF-31032 are also followed. These ensure PCBAs meet defense system needs. Secure cloud systems protect designs and keep data safe. These steps make PCBAs a must-have for aerospace and defense.

Industrial Equipment

PCBAs are key parts of machines and automation systems in factories. They are used in robots, factory machines, and power systems. PCBAs improve how machines work, making them faster and more accurate.

Factories can be tough places with heat and vibrations. To handle this, PCBAs are made with strong materials and smart designs. Small batch PCBA production helps test designs before making many units. This ensures the final product works well in factories.

PCBAs are used to control motors, check sensors, and manage energy. For example, robots use PCBAs for smooth movements and quick data processing. In power systems, PCBAs control voltage and keep energy safe.

Small batch PCBA production also helps create custom designs for special machines. This allows unique solutions for different factory needs. As factories use more automation, the need for PCBAs will grow.

Benefits of PCBA in Modern Electronics

Cost-Effectiveness

PCBA helps save money, making it great for electronics. It lowers costs by focusing on parts and production expenses. Custom PCBA lets you change designs and materials to cut costs. For example:

Good PCBs reduce errors, saving on repairs and warranties.

Machines handle testing, speeding up production and cutting costs.

Finding problems early avoids waste and costly fixes.

A study showed fixing issues early in PCBA saves more money. This method is especially helpful for small or short production runs.

Enhanced Reliability and Durability

PCBA makes devices work better and last longer. Tests like heat and vibration checks ensure they can handle tough conditions. For example:

Testing Method | Purpose |

|---|---|

Thermal Cycling | Tests if it handles changing temperatures. |

Vibration Testing | Checks if it survives shaking or movement. |

Burn-In Testing | Finds weak parts by stressing them. |

These tests prove PCBAs can last a long time, even in hard environments. Whether in medical tools or factory machines, PCBA keeps devices working well. This makes it vital for important industries.

Design Flexibility

PCBA allows creative designs for special needs. Custom PCBA helps make unique products faster. Using non-EOL parts gives more options than EOL parts:

Metric | EOL Components | Non-EOL Components |

|---|---|---|

Design Flexibility | Low | High |

This flexibility helps improve designs for cheaper and better products. Small batch PCBA also helps test ideas quickly, so products meet market needs faster.

Scalability for Custom PCBA Solutions

Scalability is very important for custom PCBA projects. Whether you need a few prototypes or many products, custom PCBA can adjust. This flexibility helps meet market needs quickly and effectively.

Custom PCBA companies like KKPCB and MacroFab are great at scaling. They can handle both small and large production orders. For example:

KKPCB delivers on time by adjusting to different order sizes.

MacroFab focuses on quality and tests every step carefully.

Good inventory management also helps with scalability. It reduces delays and waste, making production smoother. MacroFab uses smart inventory systems and has over 100 factory lines in North America. This allows them to handle any project size or difficulty.

Strong teamwork and clear communication make scaling easier too. Teams manage projects well, moving from prototypes to full production smoothly. Customer reviews and experience show which factories are reliable for tough jobs.

Scalable PCBA solutions are very useful in fast-growing fields like renewable energy. Flexible designs let you create new ideas while staying efficient. With the right partner, you can grow your production easily and stay competitive in changing markets.

PCBA has changed electronics by making devices reliable and efficient. It is used in many areas, like gadgets and aerospace. Its importance grows with new tech like 5G and IoT.

The table below shows how PCBA is growing in key industries:

Sector | 2023 Value (USD Billion) | 2032 Projected Value (USD Billion) |

|---|---|---|

Consumer Electronics | 12.0 | 16.0 |

Automotive | 6.5 | 8.5 |

Industrial | 4.5 | 6.0 |

Telecommunications | 3.0 | 4.0 |

Medical Devices | 3.66 | 4.07 |

As the market grows, custom PCBA offers great flexibility and scaling. These designs fit specific needs, making devices work better. Whether in cars, medicine, or factories, custom PCBA meets changing demands.

Using custom PCBA helps you stay competitive and eco-friendly. The future of electronics depends on smart and flexible PCBA solutions.

FAQ

How long does a PCBA last?

A PCBA’s lifespan depends on how it’s made and used. Good-quality PCBAs in safe places can work for over 10 years. Taking care of them and using them properly makes them last longer.

Can a broken PCBA be fixed?

Yes, broken PCBAs can be fixed. Experts use tools like soldering irons and magnifiers to repair connections or swap out bad parts. But sometimes, the damage is too much, and the whole PCBA needs replacing.

How do you pick a good PCBA maker?

Choose makers with certifications like ISO 9001. Check their skills, how they check quality, and what customers say about them. A good maker can handle big or small orders and delivers on time.

Are PCBAs good for the environment?

Today’s PCBAs use lead-free solder and materials that can be recycled. Makers also follow green rules like RoHS to cut down on harmful waste.

Which industries use custom PCBA the most?

Industries like cars, medicine, planes, and gadgets use custom PCBA a lot. Custom PCBAs help meet special needs, work better, and follow industry rules.

See Also

Understanding PCBA And Its Importance In Electronics

Defining PCBA And Its Significance In Electronic Devices

Exploring The Meaning Of PCBA In Electronics

How PCBA Enhances Functionality In Modern Electronic Devices