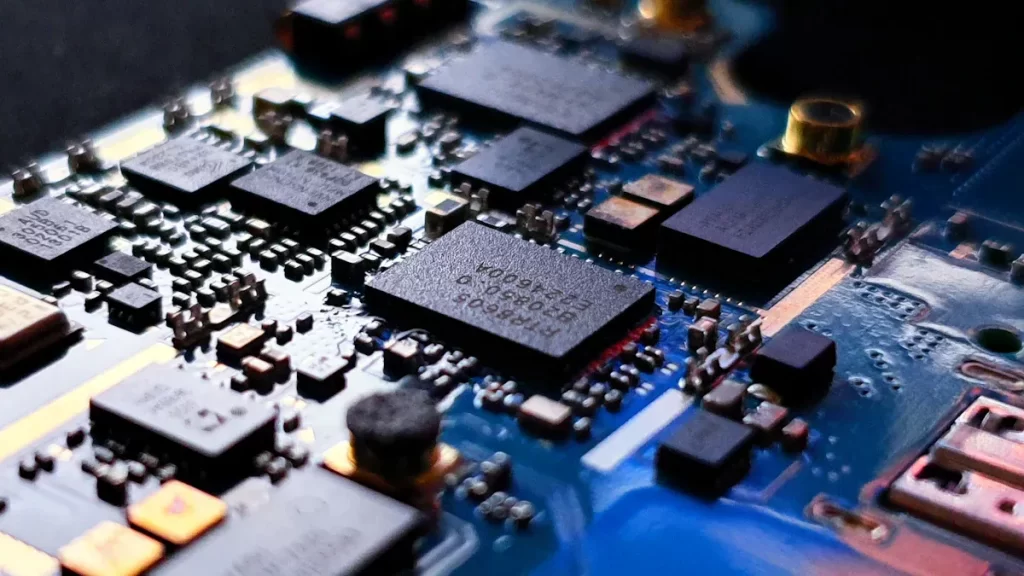

Printed Circuit Board Assemblies (PCBAs) play a crucial role in EV powertrains, particularly in applications like PCBA for EV powertrain control. They are essential for managing energy, connecting systems, and ensuring precise control. For instance, battery systems rely on multi-layer PCBs to enhance safety and longevity. Automakers now allocate 25–30% of their PCBA budgets specifically to EV designs, highlighting their importance in electric vehicles. Additionally, the demand for PCBAs capable of operating above 150°C has increased by 19% annually, underscoring their necessity in challenging conditions.

Key Takeaways

PCBAs help control energy and keep EV powertrains working safely.

They improve battery life and make sure it lasts longer.

PCBAs in battery systems save energy, giving cars more range.

They also help batteries charge faster, which saves time.

New ideas like bendable PCBs and sensors are changing EVs.

These changes make electric cars better and more dependable.

Key Applications of PCBA for EV Powertrain Control

Printed Circuit Board Assemblies (PCBAs) are crucial in electric vehicle (EV) powertrains. They help parts work together, manage energy, and control systems. Below are some key uses of PCBAs in EV powertrain control.

Electric Vehicle Battery Management System

The battery management system (BMS) keeps EV batteries safe and efficient. PCBAs manage energy flow and check battery health. They balance the charge in each cell, which saves energy and makes batteries last longer. This process, called cell equalization, ensures steady performance.

Heat and high currents can harm battery cells, reducing their capacity and charging speed. PCBAs track these issues to improve battery performance. They also store data to boost energy use and vehicle efficiency. Advanced BMS with PCBAs helps batteries last longer and stay safe.

Impact Area | Description |

|---|---|

Cell Equalization | Balances charge levels, saving energy and extending battery life. |

Cell Degradation | Heat and high currents lower capacity, affecting range and charging. |

Aging | BMS tracks cells to replace them, improving performance and range. |

Data Storage | Better lithium-ion tech improves energy storage and vehicle use. |

Capacity Management | New methods like battery swapping save time and improve user experience. |

Lifespan Extension | Advanced BMS makes batteries last longer and stay safe. |

Using PCBAs in the battery system improves energy use and reliability. These are key for more people to adopt electric vehicles.

Motor Control and Torque Management

In EVs, motor control and torque depend on PCBAs. They process signals to adjust motor speed and torque. This ensures smooth driving and better performance.

PCBAs also allow precise motor control, saving energy. By managing torque, they cut energy use and improve driving. For example, during regenerative braking, PCBAs turn motion into electricity to recharge the battery. This increases range and reduces brake wear.

Power Electronics and Energy Conversion

Power electronics manage energy in EV powertrains. PCBAs in inverters and converters change DC energy from the battery into AC energy for the motor. They also reverse this during regenerative braking.

PCBAs make energy conversion more efficient, cutting energy waste and costs. They ensure high-power devices work well and support renewable energy use, making EVs greener.

Better Power Conversion: PCBAs improve energy conversion, wasting less energy.

Energy Optimization: They save energy, reducing losses in powerful devices.

Higher Efficiency: Power electronics cut energy loss, helping sustainability.

Renewable Energy Use: PCBAs connect EVs with renewable energy, boosting reliability.

Using PCBAs in power electronics improves energy use and sustainability. These are vital for the future of electric vehicles.

Benefits of PCBA in EV Powertrain Systems

Efficiency and Performance Optimization

PCBAs help EV powertrains work better and use energy wisely. They make sure energy flows smoothly and parts work well together. For example, in the battery system, PCBAs control charging and check performance. This leads to faster charging and longer driving ranges. They also cut energy waste and lower repair costs, making EVs more dependable and affordable.

Improvement Type | Description |

|---|---|

Increased Range | Better cell balance improves batteries, giving EVs more range. |

Faster Charge Times | Smarter monitoring helps batteries charge quicker. |

Decreased Maintenance Costs | Less energy waste means fewer repairs and lower costs. |

By saving energy and reducing waste, PCBAs make EVs more efficient and eco-friendly.

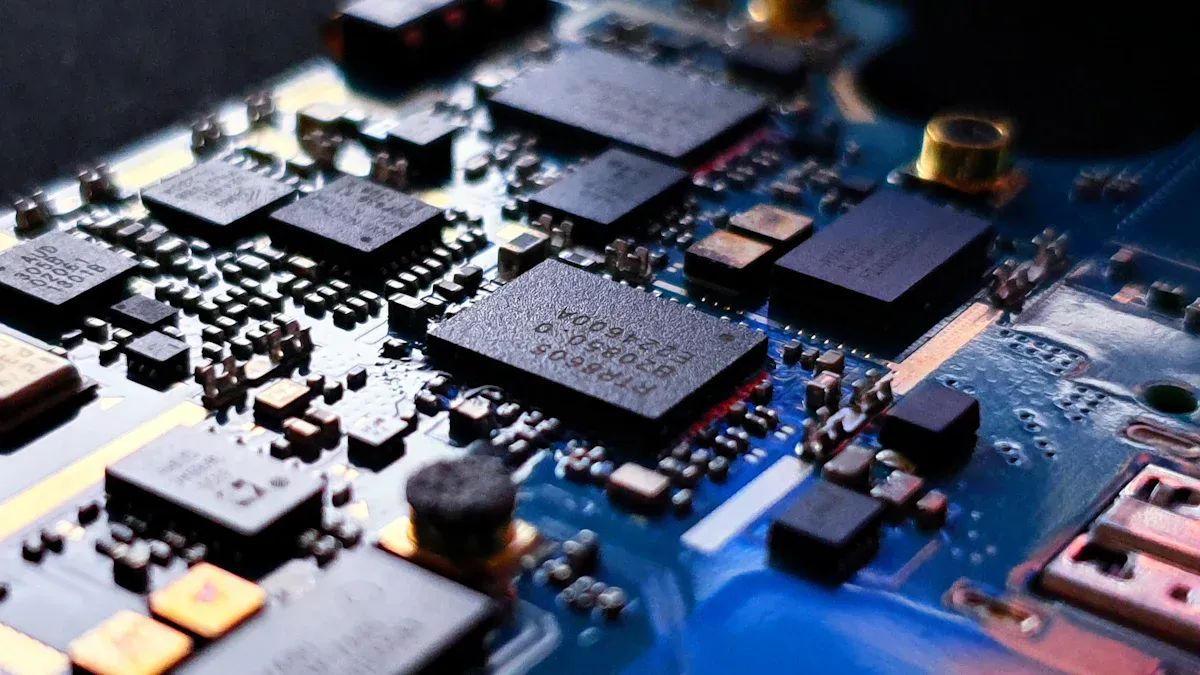

Compact Design and Space Efficiency

The small size of PCBAs is a big advantage for EVs. Multi-layer boards let makers add more features without taking up extra space. This is very important for electric cars. Smaller designs save room and improve how systems work. High-density connections in PCBAs allow better performance without making parts bigger.

Aspect | Data/Insight |

|---|---|

Market Growth Projection | Car PCB market may hit USD 17.08 Billion by 2032. |

CAGR for Multi-layer PCBs | Expected to grow fastest from 2024 to 2032. |

Drivers of Growth | More EVs, smart features, and advanced driving systems. |

Benefits | Smaller size with better performance and connections. |

This small design is key for EVs, where space is limited and valuable.

Durability in Extreme Conditions

PCBAs are built to handle tough conditions in EVs. They go through strict tests to ensure they work in heat, vibrations, and other challenges. High TG boards are especially important for parts like engine controls and battery systems. These boards stay strong even in harsh environments, keeping EVs reliable for a long time.

Functional Testing: Checks if the board works well in real use.

Environmental Testing: Simulates heat, vibrations, and other tough conditions.

With strong PCBAs, EVs stay safe and dependable, even in extreme situations.

Challenges in PCBA Design for EV Powertrains

Making PCBAs for EV powertrains is not easy. Designers must handle heat, high power needs, and long-term use. Solving these problems is key to building strong and efficient systems.

Managing Heat and Keeping Systems Cool

Heat control is a big problem in EV PCBA design. Too much heat can harm parts and lower performance. Good cooling methods are needed to keep systems steady. Copper-graphene materials can help move heat better, lowering temperatures by 25°C. Liquid cooling with special materials can also keep temperatures even during fast charging.

Research shows that PCBs near engines fail 12–18% more often in five years than cabin PCBs. Using halogen-free materials can cut harmful gas release by 60%. However, new soldering methods are needed to keep them reliable.

Problem Area | Findings |

|---|---|

Heat and Temperature Stress | Engine-area PCBs fail 12–18% more often in five years. |

Safer Materials | Halogen-free materials cut gas release by 60%, needing new soldering. |

Handling High Power and Energy Needs

EVs need high power, but this can cause problems. Uneven energy flow can weaken insulation by 40% in three years. High-CTI materials and protective coatings can fix this, making systems safer. Devices like IMDs can find energy leaks quickly, keeping systems protected.

Building Reliable and Safe Systems

EV systems must last a long time and stay safe. Strong materials like pure copper and heat-resistant laminates make PCBAs more durable. Compact designs improve how systems work and lower failure risks. Protective coatings shield parts from tough conditions, helping them last longer. Good heat control stops overheating, keeping systems steady.

Focus Area | Details |

|---|---|

Pure copper and heat-resistant laminates boost durability. | |

Protective Coatings | Coatings guard against tough conditions, improving lifespan. |

Heat Control | Cooling methods stop overheating, ensuring steady performance. |

By solving these problems, PCBAs can meet EV needs while staying safe and efficient.

Innovations Shaping the Future of EV PCBs

The fast growth of electric vehicles (EVs) is driving new ideas in printed circuit board (PCB) technology. These changes are making EV powertrain systems better, stronger, and ready for modern needs. Here are three important areas leading these changes.

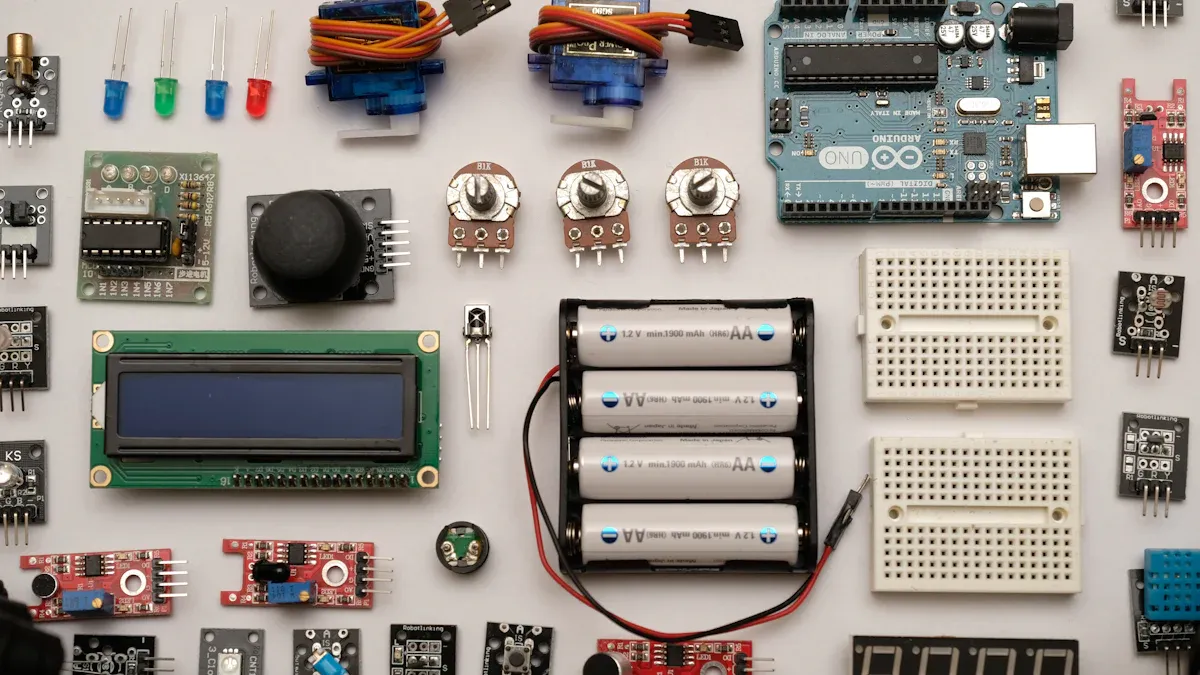

Flexible and Rigid-Flex PCB Technologies

Flexible and rigid-flex PCBs are changing how EV powertrains are built. Flexible PCBs can bend and fit into tight spaces. They are great for parts like wiring and batteries, where space and strength matter most.

Rigid-flex PCBs mix soft and hard designs. They are strong and flexible, making them perfect for tough systems like motor controllers. These PCBs also need fewer connectors, which lowers the chance of problems and boosts system performance.

Flexible PCBs work well in tight or moving parts.

Rigid-flex PCBs are strong and reduce part failures.

Both types handle heat and shaking, lasting longer in EVs.

As EVs improve, more of these useful PCBs will be needed.

Smarter Designs with Built-In Sensors

Adding sensors to PCBs is changing EV powertrain systems. These sensors check things like heat and energy in real time. With sensors inside the PCB, data is processed faster, and systems work better.

For example, some companies use sensor data to save energy, improving efficiency by up to 12%. Others, like GM, use smart electronics to adjust charging, cutting energy waste by 15%.

Feature | Benefit |

|---|---|

Built-In Sensors | Watch systems in real time for faster control. |

Energy-Saving Software | Boosts efficiency by 7–12% with quick adjustments. |

Smart Charging Electronics | Cuts energy waste by 15% with better charging rates. |

Smarter PCBs with sensors make EVs work better and use less energy.

Better Materials and New Manufacturing Methods

New materials and ways of making PCBs solve problems like heat and power in EVs. Special materials, like copper-sintered tech, cool parts 40% better. This helps with fast charging without losing performance. Insulated metal boards are also used to handle heat from EV powertrains.

Manufacturing is also improving. For example, 3D cooling designs use copper-graphene to lower heat by 25°C. These updates help PCBs handle high power and tough conditions.

Cooling Improvements: Special materials like copper-graphene cool parts better.

Higher Power Support: New designs handle more power safely.

Longer Lifespan: Water-resistant boards and anti-aging finishes last longer.

Car makers are also using eco-friendly materials to meet rules. These updates make sure PCBs stay strong and work well for a long time.

You help shape the future of electric cars by learning about the importance of PCBA in EV powertrain systems. As more people use EVs, the need for better PCBs increases. The worldwide EV market, expected to hit $823 billion by 2030, shows how important it is to have smart, reliable, and creative PCBA designs to solve new problems.

FAQ

What do PCBAs do in electric vehicles?

PCBAs help parts like batteries and motors work well. They manage energy and keep systems running smoothly.

How do PCBAs make EVs better?

PCBAs save energy and make systems more reliable. They also support features like regenerative braking, which helps cars go farther and protects parts.

Why is heat control important for EV PCBAs?

Good heat control stops parts from overheating. It keeps systems steady and helps PCBAs last longer in tough conditions.

See Also

Why PCBA Manufacturing Skills Matter in Electronics Design

Understanding PCBA and Its Function in Electronic Devices

Defining PCBA in Electronics and Its Significance

The Meaning of PCBA and Its Importance in Electronics

Exploring PCBA Definition and Its Essential Uses in Electronics