Printed Circuit Board Assembly (PCBA), which is often referred to as PCBA meaning, is key to modern electronics. It connects parts to make working devices. The global market for PCBs may grow from $78.5 billion in 2023 to $120 billion by 2032. This shows the need for smaller, better, and smarter electronics.

Key Takeaways

PCBA is important for electronics, linking parts to make devices work.

The need for PCBA is rising in gadgets, healthcare tools, and cars.

PCBA helps by saving space, cutting costs, and being more reliable after tests.

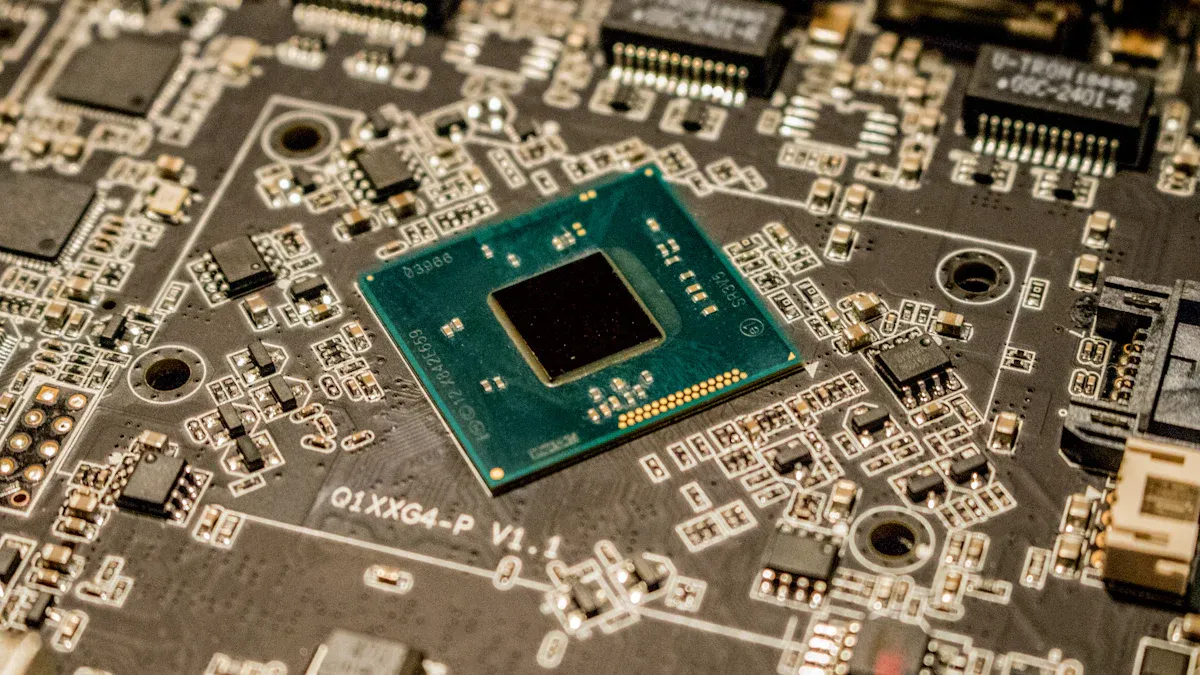

PCBA Meaning and Components

What is PCBA?

A Printed Circuit Board Assembly (PCBA) is a circuit board with parts added. It turns a plain PCB into a working electronic circuit. The PCB is like a base, and the assembly adds parts like resistors, capacitors, and transistors. These parts make the device work. Without assembly, the PCB cannot do any electronic tasks.

Rules ensure PCBAs are high-quality and safe. These include:

IPC-A-610: Checks for quality by looking at the board.

ISO: Makes sure quality systems are followed.

UL: Focuses on safety to avoid fires or shocks.

ITAR: Protects important technology and tracks it securely.

MIL-STD: Sets rules for military use and tough conditions.

Key Components of PCBA

PCBAs have important parts that help devices work:

Resistors: Manage how much current and voltage flow.

Capacitors: Hold and release energy when needed.

Transistors: Work as switches or make signals stronger.

These parts work together to make the device run well.

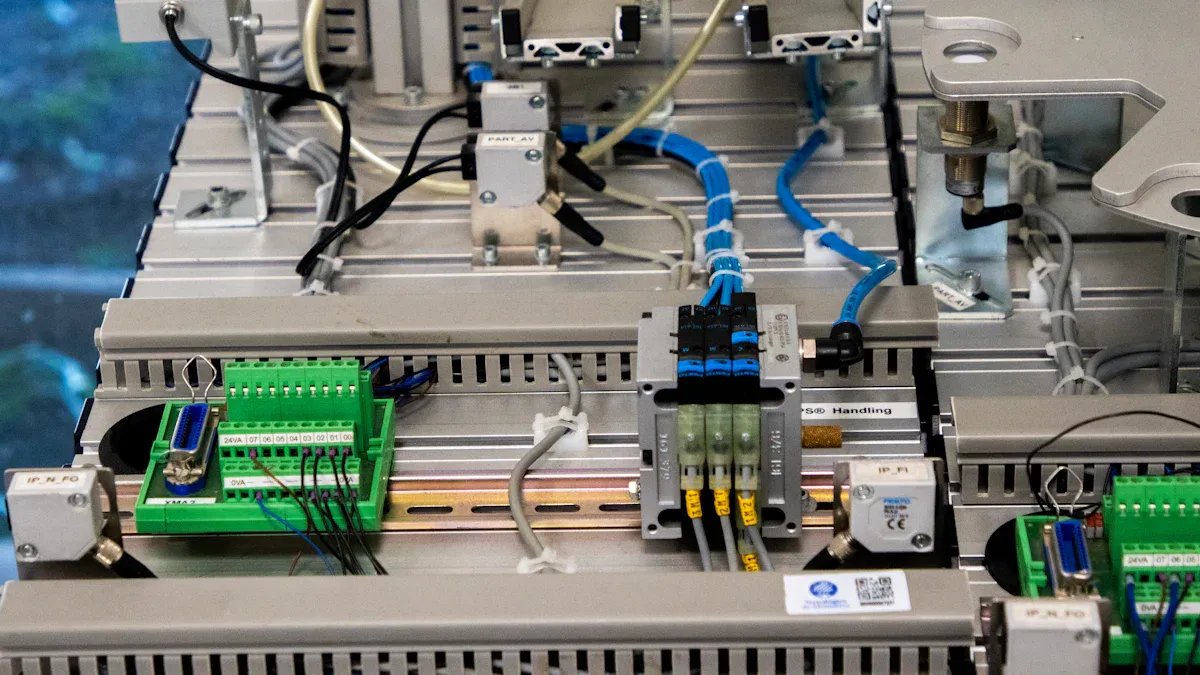

How PCBA is Manufactured

Making PCBAs involves steps to ensure they work well:

First Sample Test: Checks resistance and capacitance match the design.

Solder Paste Application: Adds solder paste to hold parts in place.

Component Placement: Puts parts like resistors and capacitors on the board.

Reflow Soldering: Heats solder paste to attach parts firmly.

Inspection: Uses tools and manual checks to find mistakes.

Final Quality Control: Makes sure it meets rules like IPC-610 before shipping.

Metrics like First Pass Yield (FPY) and Defects per Million Opportunities (DPMO) show how good the process is.

Applications of PCBA in Electronics

Role of PCBA in Consumer Electronics

PCBA helps make small and efficient electronic devices. Gadgets like phones, laptops, and smartwatches need PCBs to work. Over 70% of PCBs are used in electronics, computers, and telecom. This shows how important they are in daily life. Reports like “Printed Circuit Boards: Technologies and Global Markets” say PCBA demand is growing. By 2032, the market for these devices may reach $20 billion. This growth is due to better processors and smaller designs.

Use of PCBA in Medical Devices

Medical tools need PCBA for accuracy and safety. Devices like pacemakers, MRI machines, and pumps use high-quality PCBs. A 1% boost in PCBA reliability lowers costs and downtime. This is vital since small errors can risk lives. The rising need for PCBs in healthcare shows their role in improving medical tools.

Applications in the Automotive Industry

Cars use PCBA for engines, safety, and entertainment systems. Special PCBs control fuel, avoid crashes, and guide navigation. Electric and hybrid cars have raised the need for advanced PCBs. From 2023 to 2030, the car PCB market may grow from $9.15 billion to $13.39 billion. This growth proves PCBA is key in modern vehicles.

Importance in Telecommunications

Telecom depends on PCBA for networks and devices. Flexible PCBs are popular because they can bend and fit easily. The SAPCB Act suggests $3 billion for PCB production. This shows how important PCBA is in telecom. Reliable PCBs ensure smooth communication and data sharing, making them essential.

Advantages of PCBA in Electronics

Small Size and Space Saving

PCBA helps make small and efficient devices. It puts all parts on one board, saving space. This small size is important for gadgets like phones and medical tools. Flexible PCBs give more design options. They let makers create tiny, detailed products without losing quality. New methods like 3D printing make PCBs faster and cheaper to produce. They also allow for better customization.

Strong and Long-Lasting

PCBA goes through many tests to ensure it works well. These tests check how it performs in real-life situations. Below is a table of common tests:

Test Type | What It Checks |

|---|---|

Temperature Cycle Test | Checks if it works in hot and cold places. |

Heat and Humidity Cycle Test | Tests if it lasts in heat and wet conditions. |

Vibration Test | Makes sure it stays stable during movement or shaking. |

Impact Test | Tests if it can handle bumps and hits during transport. |

Electrical Test | Checks if it works well with electricity, like voltage and current. |

These tests make sure PCBs work well in things like gadgets and medical tools.

Saves Money in Production

PCBA helps save money when making electronics. Machines assemble parts quickly, cutting labor costs. Using standard parts lowers expenses with bulk buying. Making PCBs locally reduces shipping costs and improves supply chains. For example, laws like the CHIPS Act support local PCB production. This helps the economy and ensures good quality. These reasons make PCBA a smart choice for manufacturers.

Fits Many Uses

PCBA can be used in many industries. Tools like cloud computing and automation help test and make PCBs faster. AI and IoT improve designs and make them more accurate. For example, 5G helps share data quickly for better testing. These new ideas make PCBA ready for industries like telecom, cars, and healthcare.

Printed Circuit Board Assembly (PCBA) is crucial in modern electronics. It is part of the $95.4 billion PCB market, growing 5.2% yearly.

PCBA helps improve industries like cars, IoT, and healthcare.

It powers new tech, like electric cars and smart gadgets.

Segment Type | Description |

|---|---|

Automotive Industry | PCBs improve safety and entertainment in electric and smart cars. |

IoT Sector | Smart gadgets need strong PCBs for better connections and use. |

Multi-layer PCBs | These are popular for their use in advanced devices. |

The future of PCBA depends on automation and eco-friendly methods. Automation lowers mistakes and makes work faster. Sustainability follows rules and protects the environment. PCBA is changing technology and shaping the future of electronics.

FAQ

What is the difference between PCB and PCBA?

A PCB is just a plain board. A PCBA has parts added, making it work in devices.

Why is PCBA important in the medical and healthcare industry?

PCBA helps medical tools work accurately and safely. It is used in devices like pacemakers and MRI machines to improve healthcare.

How does PCBA benefit the consumer electronics industry?

PCBA helps make small and powerful gadgets like phones and laptops. It boosts innovation and improves how electronics perform.

See Also

Understanding PCBA Services And Their Significance In Electronics

The Essential Role Of PCBA Prototyping In Electronics Development

Choosing Between PCB And PCBA: Making The Right Decision

The Impact Of PCBA On Advancing Modern Electronics Technology

Why PCBA Test Jigs Are Crucial For Electronics Manufacturing