PCBA means Printed Circuit Board Assembly. It is an important step in making electronics. It means adding parts like resistors, capacitors, and microchips to a plain Printed Circuit Board (PCB). This process turns the PCB into a working device. Without PCBA, electronic gadgets would not work.

PCBA means a lot in today’s world because people want more electronics. For example:

The global PCB market was worth $75 billion in 2021. It might grow to $120 billion by 2030.

Consumer electronics, like phones and TVs, could be worth over $1.2 trillion by 2030.

These numbers show how PCBA means a crucial role in powering the devices you use every day.

Key Takeaways

PCBA, or Printed Circuit Board Assembly, turns a simple PCB into a working electronic device by adding important parts like resistors and capacitors.

Checking quality during PCBA production is very important. It makes sure each assembly is well-made, lowering mistakes and making devices work better.

Knowing the difference between PCB and PCBA is important. A PCB is just a plain board, but a PCBA is a finished assembly that works in electronic devices.

PCBA is very important for making better consumer electronics. It helps create new technology like 5G and IoT, which need small and efficient designs.

Using good PCBA methods can save money and improve how devices work. This makes gadgets faster, more dependable, and last longer.

What PCBA Means in Electronics

Definition of PCBA

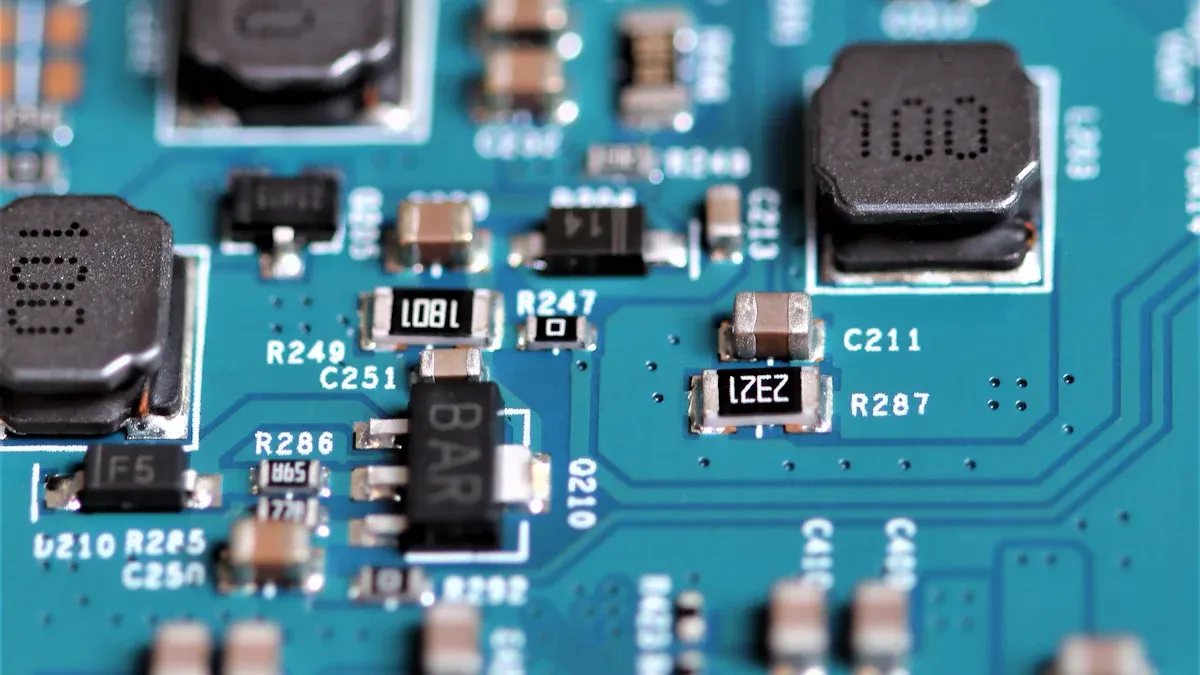

PCBA stands for Printed Circuit Board Assembly. It is a circuit board with all needed parts added. This process changes a plain PCB into a working unit for electronics. Parts like resistors, capacitors, and chips are placed on the board. These parts help signals and electricity move properly, making the board work.

Note: The IPC-A-610 standard sets rules for PCBA quality. The last step, Functional Validation Testing (FVT), checks if the PCBA works right.

Components of a PCBA

A PCBA has many important parts that make it work. These include:

Resistors: Manage how much electricity flows.

Capacitors: Hold and release energy when needed.

Integrated Circuits (ICs): Handle tasks like data processing or signal control.

Connectors: Attach the PCBA to other device parts.

Conductive Tracks: Let electricity move between the parts.

To build a PCBA, makers use tools like the Bill of Materials (BOM), datasheets, and diagrams. The BOM lists all the parts needed. Datasheets explain details about each part. Diagrams show how parts connect, helping with building and fixing.

How PCBA Enables Functionality in Devices

PCBA is key to making electronic devices work. Adding parts to the board ensures the device functions well. Tracks and pads on the PCB connect the parts electrically. These connections let the device do its job, like showing data or sending signals.

A small mistake during assembly can cause problems. To avoid this, makers use tools like Automated Optical Inspection (AOI) to find errors. FVT also checks that the PCBA works as it should in the final product.

PCB vs. PCBA: Understanding the Difference

What Is a Printed Circuit Board (PCB)?

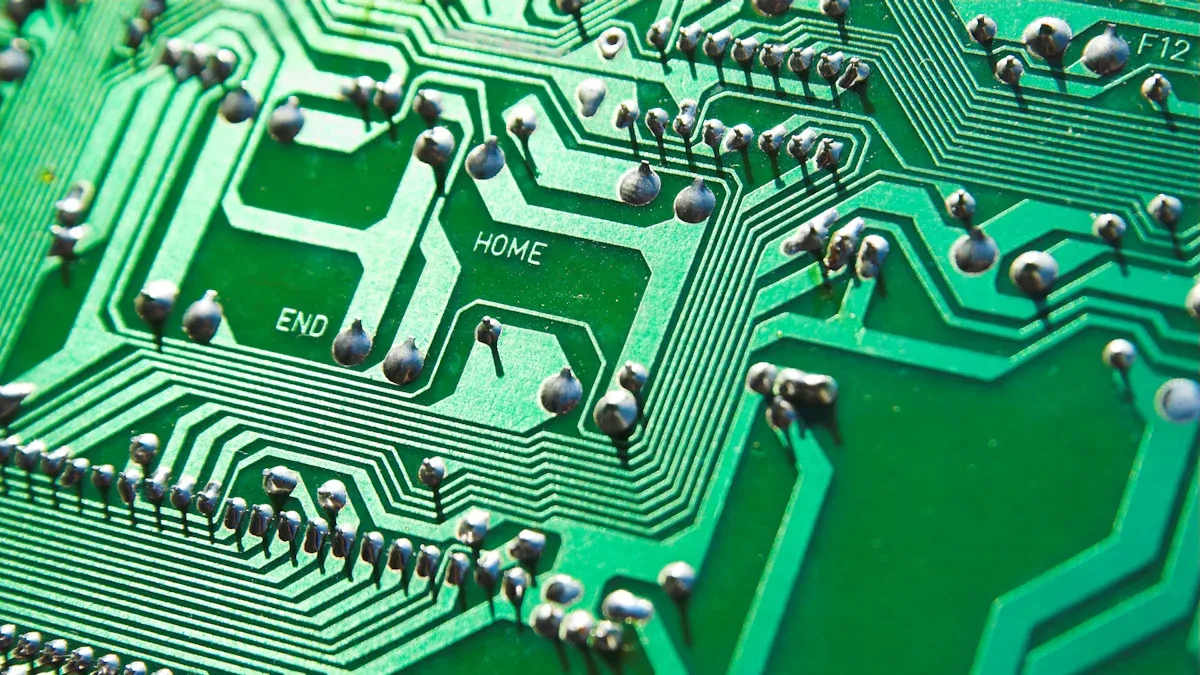

A Printed Circuit Board (PCB) is the base of electronics. It is a flat board made from materials like fiberglass. Thin copper layers are added to create paths for electricity. These paths link parts of a circuit, letting electricity flow.

PCBs come in various types based on their design and use:

Single-Sided PCB: Has one copper layer. It is simple and cheap.

Double-Sided PCB: Has copper layers on both sides for complex circuits.

Multilayer PCB: Has many copper layers, used in advanced devices.

Rigid PCB: Strong and common in everyday electronics.

Each PCB has important parts. A substrate gives support. A conductive layer connects parts. A solder mask protects the board. A silkscreen adds labels.

How PCBA Builds Upon PCB

A PCB is just a plain board without parts. A PCBA adds components to make it work. Parts like resistors, capacitors, and chips are placed on the PCB. These are attached using methods like Surface-Mount Technology (SMT) or Thru-Hole Technology.

The PCBA process makes the board functional. It allows the circuit to do tasks like processing data or powering devices. Without assembly, the PCB cannot work.

Key Differences Between PCB and PCBA

The table below shows how a PCB and PCBA differ:

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Plain board with copper paths | PCB with parts added, making it functional |

Function | Supports and connects electronic parts | Performs tasks like data processing |

Components | None | Includes resistors, capacitors, and chips |

Manufacturing | Adds copper paths and solder mask | Soldering parts onto the PCB |

Testing | Checks for proper copper connections | Tests if the board works correctly |

Applications | Used in early designs and prototypes | Found in finished products like phones and TVs |

A PCB is the starting point, while a PCBA makes it useful. Together, they are essential for modern electronics.

The PCBA Manufacturing Process

Overview of the Process

The PCBA process turns a plain PCB into a working board. It adds parts like resistors and capacitors. This process has several steps:

Design: Engineers plan the circuit and create design files.

Fabrication: The design is made into a real PCB using layers.

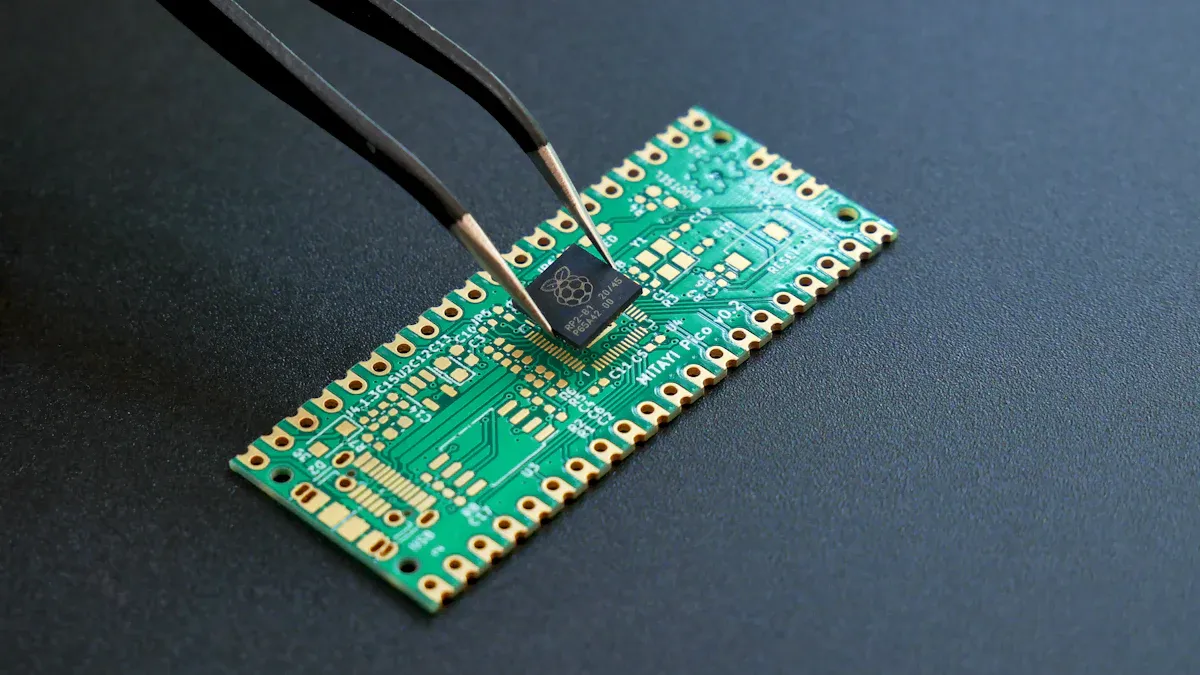

Assembly: Parts are added using Surface-Mount or Thru-Hole methods.

Testing: The board is checked to ensure it works properly.

Quality Control: Defects are found and fixed during inspections.

Each step is important for making a reliable PCBA. For example, during fabrication, extra copper is removed to show the circuit paths. A protective film keeps the needed areas safe.

Step | Description |

|---|---|

Sourcing Components | Parts are collected based on the Bill of Materials (BOM). |

Solder Paste Printing | Machines apply solder paste to the PCB pads. |

SMT Pick-and-Place | Machines quickly place small parts onto the PCB. |

AOI and Testing | Inspections check if the assembly meets quality standards. |

Surface-Mount Technology (SMT)

SMT is a common way to attach parts to a PCB. Parts are placed directly on the board without drilling holes. This method has many benefits:

Smaller parts make devices lighter and more compact.

More parts can fit, improving device performance.

Faster assembly saves time and lowers costs.

But SMT has some downsides. It is not good for big or high-power parts. Small solder joints can break under stress or heat changes. Even so, SMT is widely used because it is fast and cost-effective.

Thru-Hole Technology

Thru-Hole Technology uses drilled holes to attach parts to the PCB. These parts are soldered, creating strong connections. This method is great for big parts like connectors or transformers.

Thru-Hole is slower and takes more work than SMT. It also limits how many parts can fit on the board. However, it is still used when strength and durability are very important, like in military or industrial devices.

Quality Control in PCBA Manufacturing

Quality control makes sure every PCBA works well and lasts long. During production, tests and checks find and fix problems early. These steps are important for making reliable electronics.

Key Quality Control Metrics

Manufacturers use numbers to measure how good a PCBA is. These numbers show how well the process works and where to improve:

First Pass Yield (FPY): Shows how many boards pass tests the first time. Higher FPY means better quality.

Defect Rate: Counts how many boards have problems. Lower rates mean fewer issues.

Return Rate: Tracks how many products customers send back due to faults.

Failure Rate: Measures how often a product stops working during use.

Watching these numbers helps keep quality steady and improve production.

Inspection Techniques

To check if a PCBA works, manufacturers use different inspection methods. Each method looks for specific problems:

Visual Inspection: Finds clear issues like misplaced parts.

Automated Optical Inspection (AOI): Uses cameras to spot assembly mistakes.

X-ray Inspection: Looks inside multilayer boards for hidden problems.

In-Circuit Testing (ICT): Tests if each part works correctly.

These checks catch errors early and prevent bad products.

Common Tests in PCBA Manufacturing

Tests also check how strong and useful a PCBA is. The table below lists some common tests:

Test | Description | Criteria |

|---|---|---|

Visual and X-ray inspection | Finds outside and inside defects. | Pass/fail |

Peel test | Measures how hard it is to pull layers apart. | Pass/fail + specific value |

Solder pot and float tests | Checks how well solder sticks to holes. | Pass/fail |

Automated optical inspection | Spots assembly mistakes automatically. | Pass/fail |

These tests make sure the product meets rules and works well in real life.

Tip: Good PCBA production uses smart tools and strict checks. This reduces mistakes and makes electronics more reliable.

The Role of PCBA in Electronic Devices

Applications in Consumer Electronics

PCBA is very important in making electronics work. It changes a plain PCB into a working board by adding key parts. Gadgets like phones, tablets, and smartwatches need PCBA to function. For example, 5G technology has increased the need for PCBs. This helps devices communicate faster and connect better. In cars, PCBA is used in systems like battery control and engine timing, showing its many uses.

The table below shows how PCBA is used in different areas:

Sector/Technology | Description |

|---|---|

Telecommunications | More PCBs needed due to 5G advancements. |

Automotive | Used in battery systems, engine timing, and smart devices. |

Consumer Electronics | Phones, tablets, and smart gadgets depend on PCBA. |

Emerging Trends | Focus on flexible circuits and eco-friendly PCB production. |

Key Players | Companies like Quanta Computer and Apple suppliers lead in rigid PCB demand. |

Benefits of PCBA in Device Performance

Good PCBA improves how well devices work. Proper assembly connects parts securely, helping devices run smoothly. For instance, better designs improve electricity flow, signal quality, and power use. These upgrades make devices faster and more efficient.

Important performance measures include:

Metric | Description |

|---|---|

Electrical Performance | Better designs improve how electricity flows. |

Signal Integrity | Improved designs make signals clearer. |

Power Delivery | Good designs ensure power is used efficiently. |

Also, a well-made PCBA sends signals quickly without problems. This helps devices work well and meet user expectations.

Enhancing Reliability and Longevity of Devices

PCBA not only boosts performance but also makes devices last longer. Quality assembly lowers the chance of problems, keeping devices working for years. For example, a top phone maker cut failure rates by 30% with better PCBA methods. Similarly, a car ECU maker extended their product life by 20%.

The table below shows how PCBA helps devices last longer in different industries:

Industry | Case Study Description | Result |

|---|---|---|

Consumer Electronics | Top phone maker reduced device failure rates | 30% fewer failures |

Automotive | ECU maker extended product lifespan | 20% longer lifespan |

Aerospace and Defense | Military system cut maintenance costs | 25% lower maintenance costs |

By ensuring strong assembly and good connections, PCBA reduces defects and makes devices more durable. This makes it a key part of modern electronics.

Why PCBA Matters in Modern Electronics

Impact on Innovation and Miniaturization

PCBA helps make electronics smaller and smarter. As gadgets shrink, they need tiny and efficient PCBs. Flexible PCBs let makers design unique shapes without losing performance. These are important for wearables, phones, and small devices.

IoT has increased the need for tiny PCBs. IoT gadgets need boards that fit sensors, processors, and connectors in small spaces. Better semiconductor technology also helps. Tiny parts now improve how devices work while keeping them small.

Trend | Description |

|---|---|

Flexible PCBs | Fit into different shapes while keeping performance strong. |

Integration of IoT | Need small PCBs for sensors and wireless modules. |

Miniaturization Advances | Tiny parts make devices smaller and more powerful. |

Contribution to Cost-Effective Manufacturing

PCBA lowers costs and speeds up production. Design for Manufacturing (DFM) makes layouts simpler and parts standard. This saves money. Machines like pick-and-place systems help assemble boards faster and cheaper.

Outsourcing PCBA to experts also cuts costs. Contract manufacturers have tools to make good boards for less money. For example, companies using automation and outsourcing saved 22% on labor and made products 30% faster.

Case Study | Key Actions | Results |

|---|---|---|

DFM Optimization | Made layouts simpler and used standard parts | 18% lower costs, faster production |

Automation | Used machines for assembly and soldering | 22% less labor cost, 30% faster output |

Outsourcing | Worked with expert manufacturers | 15% cost savings, better responsiveness |

Importance in IoT and Smart Devices

PCBA is key for IoT and smart gadgets. By 2024, there will be 24 billion IoT devices, like smart home systems and wearables. These need small, strong PCBs to work well. Wearables like fitness trackers use tiny boards with sensors and wireless parts.

5G technology has made advanced PCBs more important. Fast connections are needed for IoT devices. Electric and self-driving cars also rely on strong PCBs for safety and power. As tech grows, PCBA will stay important.

By 2024, 24 billion IoT devices will exist worldwide.

Wearables could reach $160 billion in sales by 2028.

5G and electric cars need better PCBs for top performance.

Tip: Using PCBA helps your devices keep up with new tech like IoT and 5G.

PCBA is crucial in making electronics work well and last long. It turns a plain PCB into a useful and dependable part. Devices like phones, cars, and smart gadgets need PCBA to perform properly. Flexible methods help meet what customers want. Advanced tools make sure the process is accurate and steady. In industries needing safety, tracking data keeps quality high. These improvements make PCBA key for new ideas and future technology.

FAQ

What is the difference between SMT and Thru-Hole Technology?

SMT puts parts directly on the PCB surface. It is faster and works well for small devices. Thru-Hole uses drilled holes to attach parts. This makes stronger connections. SMT is common in modern gadgets. Thru-Hole is used in tough devices like industrial machines.

How does PCBA improve device performance?

PCBA attaches parts securely and connects them properly. This helps signals flow better and saves power. Devices work faster and more reliably with good PCBA. Proper assembly makes electronics perform their best.

Why is quality control important in PCBA?

Quality control checks if every PCBA meets standards. It finds problems early to avoid failures later. This step ensures you get strong and reliable electronics. Good quality control means fewer issues in finished products.

Can PCBA be used in flexible electronics?

Yes, PCBA works with bendable PCBs for flexible devices. These are great for wearables and curved gadgets. You’ll see this in fitness bands and foldable phones. Flexible PCBA makes unique designs possible.

What role does PCBA play in IoT devices?

PCBA combines sensors, processors, and wireless parts in IoT gadgets. This helps them connect and work smoothly. PCBA is found in smart homes, wearables, and connected cars. It powers the technology behind IoT devices.

See Also

Understanding PCBA: Its Importance in Electronic Devices

Exploring the Definition and Significance of PCBA

The Importance of PCBA Services in Electronics Production