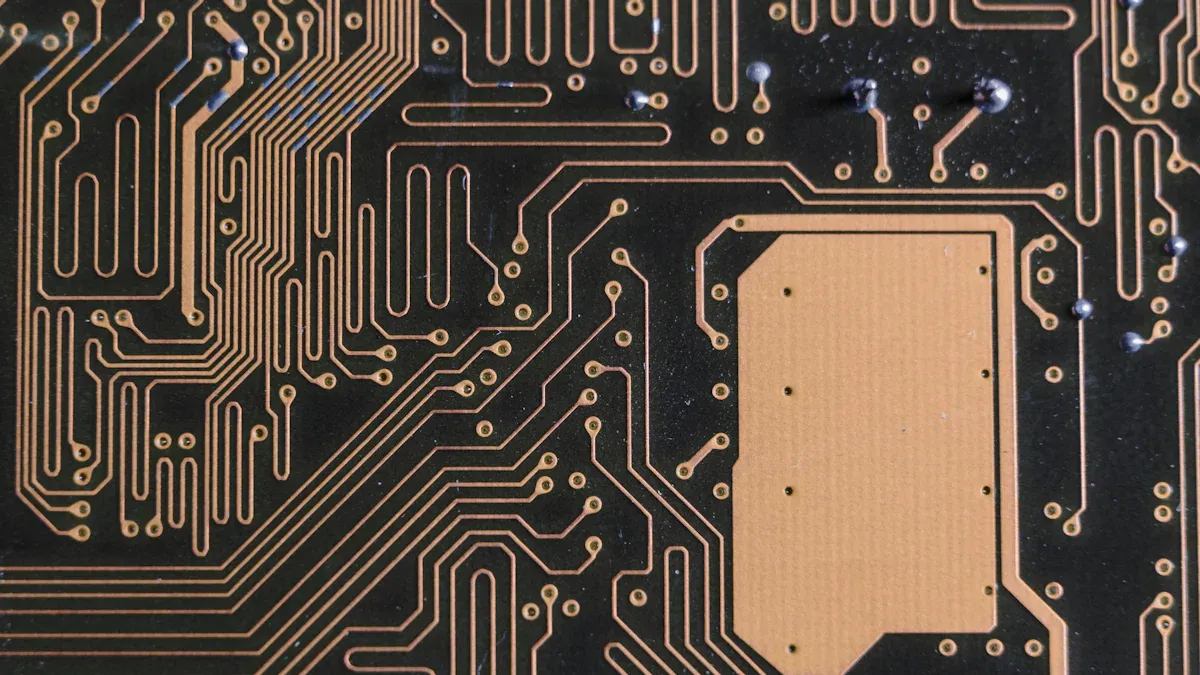

A PCBA prototype is an early model of a circuit board. It is used to test and check designs during product development. This helps you see if your design works before making many copies. Finding mistakes early saves money and time. Prototyping also improves how well your product works and lasts. Whether creating something new or fixing an old design, prototypes make it easier to create a great final product.

Key Takeaways

PCBA prototypes help test designs early to find and fix problems.

They save time and money by spotting errors early, cutting waste, and making products better.

Prototyping improves teamwork between designers and engineers for smoother work.

Different prototypes have special uses like testing ideas, functions, or production readiness.

Using feedback during prototyping makes sure the product fits customer needs and makes them happy.

What Is a PCBA Prototype?

What are PCBA prototypes?

A PCBA prototype is an early version of a circuit board. It includes the board and all needed electronic parts. This makes it work like the final product. You can use it to test and check your design. It helps find problems and ensures parts work well together. This step is important to make sure the product works right. It also lowers risks and keeps quality high.

How are PCB and PCBA prototypes different?

PCB and PCBA prototypes are not the same. A PCB prototype is just the board without parts. It checks the layout and connections. A PCBA prototype has all parts attached, so it works fully.

Here’s a simple comparison:

Feature | PCB Prototypes | PCBA Prototypes |

|---|---|---|

Production Tolerances | Lower production tolerances | Higher production tolerances |

Quality Standards | IPC1 | IPC2 |

Material Options | R4 only | R4, aluminum, flex-rigid materials |

Layer Capacity | Up to 8 layers | Up to 32 layers |

Surface Finish Options | HALS, ENIG | HALS, ENIG, ENEPIG, OSP, etc. |

Advanced Features | Lacks many advanced features | Supports advanced features |

Minimum Order Quantity | 5 to 100 | 1 to 10,000 |

Testing Capability | Basic function testing | Complex function testing |

Knowing these differences helps you pick the right one for your needs.

Why are PCBA prototypes important?

PCBA prototypes are key in making new products. They let you test your design early and fix mistakes. For example, a company making smartwatches used PCBA prototypes. They checked if parts worked together and tested a lot. This helped them launch their product faster and better.

Prototyping also helps you try new ideas and add new tech. The PCB market is growing fast, with big demand for better prototypes. Using PCBA prototypes saves money, works faster, and makes great products for customers.

Why Are PCBA Prototypes Important in Product Development?

Finding and fixing design problems

PCBA prototypes help find design problems during development. Testing a working model shows issues not seen in plans. This process lets you improve both ideas and physical models. Comparing these models with real-world results helps spot mistakes. This ensures your design works as expected and meets goals.

For example, testing a circuit board prototype can show wrong connections. It can also reveal parts placed in the wrong spots. Fixing these problems early avoids expensive mistakes later. Prototyping also proves your design works by testing it many times.

Saving money and working faster

Using PCBA prototypes saves money and speeds up production. Early testing catches mistakes before making many products. Buying parts smartly also helps save money. You can get good materials at lower costs.

Adding Design for Cost and Manufacturing (DFM) ideas makes production smoother. These ideas help fix cost issues early in the process. Using digital tools and automation also makes work faster and cheaper. These methods save money while keeping quality high.

Making better and stronger products

Prototyping makes your final product better and more reliable. A PCBA prototype tests how parts work in real situations. This ensures the circuit board works well and meets customer needs. Fixing problems early creates a product that lasts longer.

For example, testing a PCB prototype checks if it can handle stress. It also ensures it works well over time. Focusing on quality makes customers happy and improves your brand. Prototyping leads to stronger products and satisfied users.

Accelerating the product development timeline

Speeding up product creation is very important today. PCBA prototypes help you do this faster. Using prototypes early finds and fixes problems quickly. This saves time and gets your product to market sooner.

Prototypes let you test designs in real-life situations. You can check how parts work together and fix issues fast. For example, if a part fails, you can swap it without big delays. This step-by-step process keeps your project moving smoothly.

Prototyping also helps teams work better together. A physical model makes it easier to find problems and improve designs. This teamwork reduces confusion and speeds up decisions.

Another benefit of PCBA prototypes is testing how to make your product. You can check if your design is ready for mass production. Fixing factory problems early avoids expensive changes later.

Using prototypes also boosts creativity. You can try new ideas and tech without risking the whole project. This helps you stay ahead of others and make great products.

In the end, prototypes help you launch products faster while keeping them high quality. It’s a smart way to develop products successfully.

Types of PCBA Prototypes and Their Applications

Proof of concept prototypes

Proof of concept prototypes check if early ideas can work. They test if your product idea is possible in real life. For example, if you make a wearable device, this prototype checks if sensors collect data correctly.

Performance benchmarks help measure how well the prototype works. They show if the product meets its goals and works for users. These prototypes also find problems early, so you can fix them before moving forward.

Here’s a simple look at proof of concept success metrics:

Success Metric | Description |

|---|---|

Checks if the idea can work (Go/No-Go decision). |

Using proof of concept prototypes ensures your idea works and avoids costly mistakes later.

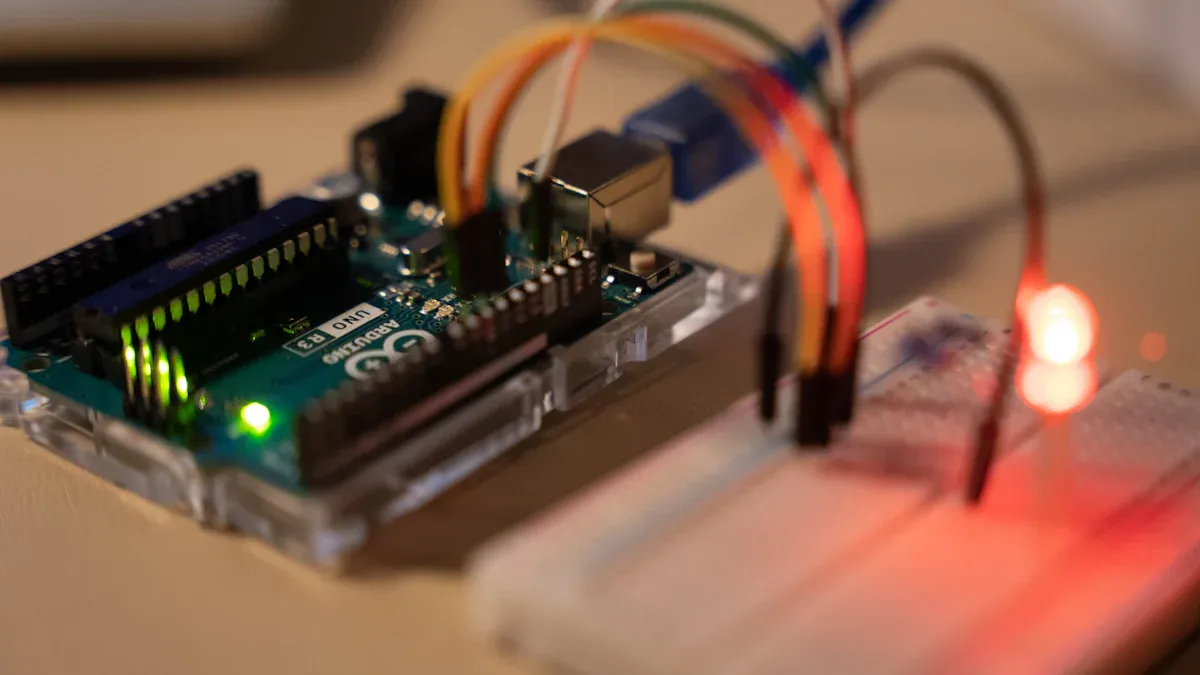

Functional prototypes

Functional prototypes test how the product works as a whole. They include all key parts and act like the final product. For example, if you make a smart home device, this prototype tests its connection and response.

These prototypes check how parts work together and meet user needs. They also find areas to improve, like saving power or making the design easier to use. Testing functional prototypes helps create products that meet customer needs and industry rules.

Pre-production prototypes

Pre-production prototypes prepare your design for mass production. They test how to make your product on a large scale. For example, in aerospace, prototyping helped make a lighter turbine blade that costs less to produce.

These prototypes reduce mistakes and improve production. In cars, testing a suspension part made it last longer and reduced warranty claims. In electronics, prototyping improved smartphone designs to meet customer needs.

Here’s a table showing pre-production prototype results in different industries:

Industry | Case Study Description | Key Outcomes |

|---|---|---|

Aerospace | Made a lighter turbine blade using rapid prototyping. | 15% weight reduction, faster development, lower production costs. |

Automotive | Tested a stronger suspension part with CAD and prototypes. | 20% longer lifespan, fewer warranty claims, happier customers. |

Medical Devices | Designed a surgical tool using user feedback. | Got FDA approval, showing the value of user input. |

Consumer Electronics | Improved smartphone design with prototyping and feedback. | Final product met customer needs for looks and function. |

Pre-production prototypes ensure your product is ready for production and stays high quality.

Applications of each type in product development

Each PCBA prototype type has a special purpose in development. Knowing how to use them helps make better products.

Proof of concept prototypes

These prototypes check if your ideas can work in real life. They are important for new designs to ensure they function properly. For example, if making a wearable device, this prototype tests if sensors and circuits work right. This step avoids wasting time and money later.Functional prototypes

Functional prototypes test how well your product works overall. They are great for testing quality by simulating different conditions. For instance, when creating a smart home device, this prototype checks its connection and response. It also shows areas to improve, like saving energy or making it easier to use.Pre-production prototypes

Pre-production prototypes get your design ready for large-scale production. They are helpful for showing your product to others and getting feedback. In fields like cars or planes, these prototypes ensure all parts work together smoothly. For example, testing a car’s suspension system with this prototype can find problems before mass production starts.

Here’s a table summarizing how each prototype is used:

Application Type | Description |

|---|---|

New Product Development | Prototypes test new ideas and features before full production. |

Prototypes check durability and quality under real-world conditions. | |

Modeling and Visualization | Prototypes show designs to non-technical people for feedback. |

Complex Multi-Component Systems | Prototypes test individual parts in detailed designs, saving time and effort. |

Using the right prototype at the right time makes development faster and better.

The PCB Prototyping Process

Design and layout creation

The first step is designing the circuit board layout. CAD software helps you draw the board’s structure. It shows how the board will look and work. Following rules like IPC-6011 and IPC-6012D makes designs strong and reliable.

IPC Standard | What It Does |

|---|---|

IPC-6011 | Sets general rules for printed circuit boards. |

IPC-6012D | Makes sure rigid boards meet quality standards. |

IPC-6013D | Checks flexible and rigid-flexible boards for performance. |

Once the layout is ready, you can move to the next step. This ensures your design works well and can be made easily.

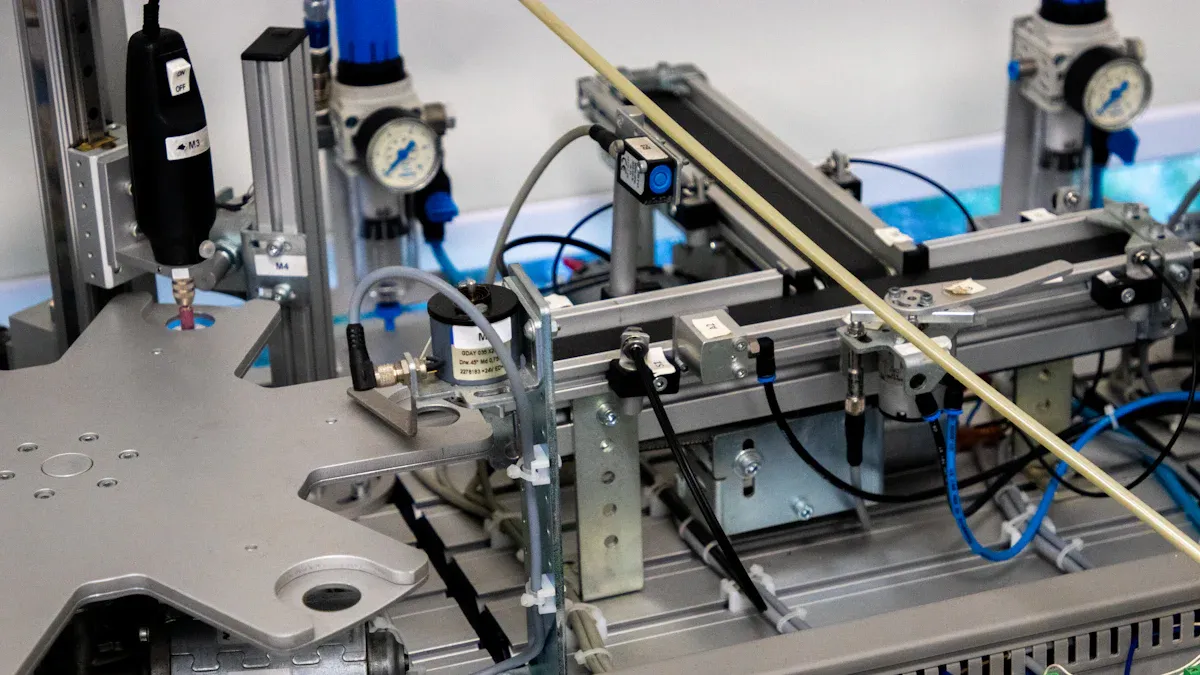

Component selection and assembly

Picking the right parts is very important. You need parts that fit your design and work well together. Machines like pick-and-place tools help put parts on the board.

After assembly, the board is tested to check if it works. Tests include checking signals, looking for hidden flaws, and testing under stress.

Test Type | What It Checks |

|---|---|

IST | Finds hidden problems. |

HAST | Tests how parts handle stress. |

X-ray | Looks inside the board. |

Dye-penetrant | Finds surface cracks. |

AOI | Spots early mistakes. |

Good parts and testing make sure the board works well. This avoids problems during production and saves time.

Testing and validation

Testing makes sure the prototype works as planned. It finds problems, checks how long parts last, and reduces warranty issues. Different tests check heat, strength, and rules compliance.

Goal | What It Means |

|---|---|

Finding problems early | Fixes issues before selling the product. |

Checking lifespan | Shows how long parts will last. |

Measuring MTBF | Predicts how long the product will work. |

Lowering warranty risks | Reduces defects that upset customers. |

Saving money | Cuts costs by fixing problems early. |

Testing ensures the prototype is strong and meets customer needs.

Iteration and refinement for final production

The last step of prototyping is improving the design. This stage fixes problems and gets the product ready for mass production. Small changes are made to improve how it works and is built.

Testing the prototype in real-life situations is very important. It helps find hidden problems, like parts overheating after long use. Fixing these issues now ensures the product works well later. A well-tested prototype means fewer problems during production.

This step also allows for design changes. You can quickly adjust the design to make it better or meet new needs. For example, if a circuit uses too much energy, you can change it to save power or lower costs.

Another key part is checking if the design is easy to produce. These checks find problems like hard-to-build parts or missing materials. Fixing these early avoids expensive changes during production.

By focusing on testing and fixing, you make a strong and flexible product. This process ensures the final product meets all goals and is ready for large-scale production. Improving the design now makes production faster and the product better.

Benefits of Using PCBA Prototypes

Better design accuracy and performance

PCBA prototypes help improve your designs step by step. Testing a working model shows problems not seen in early plans. This ensures all parts work as they should. For example, testing checks signal flow, power use, and overall performance. These tests make your design more accurate and meet needed standards.

Prototyping also lets you try different setups. You can see how parts work together in real-life situations. This helps you make your product work better. A well-tested prototype ensures your final product works well and meets user needs.

Saving money by finding mistakes early

Finding mistakes early with prototypes saves a lot of money. Fixing problems during prototyping avoids costly changes later. For example, testing can show production or part issues. Solving these early stops delays in mass production.

Prototyping also cuts down on wasted materials. By fixing designs before full production, fewer defective items are made. This saves money and reduces waste. Early problem-solving keeps production smooth and cost-effective.

Better teamwork between design and engineering teams

PCBA prototypes help design and engineering teams work better together. A physical model gives everyone a clear idea to discuss and fix issues. This teamwork improves communication and keeps everyone focused on the same goal.

Numbers show how prototypes help teamwork:

Design checks take 60%-80% of the design process, showing teamwork’s value.

Over 50% of complex designs need fixes, which prototypes help reduce.

Prototypes also allow teams to share updates easily. They can focus on small changes instead of redoing everything. Giving unique IDs to design parts makes tracking easier. Using prototypes creates a smoother workflow, boosts teamwork, and reduces mistakes.

Better end-user satisfaction and product success

PCBA prototypes help make sure your product meets what customers want. By testing and improving designs, you can create products that work well and meet user needs. This step helps avoid problems that could make users unhappy or cause the product to fail.

Prototypes show how your product works in real-life situations. For example, testing can find issues like overheating or weak signals. Fixing these early makes sure your product works smoothly for users. A tested prototype also lets you add features that make it easier to use and more attractive.

Examples from different industries show how prototyping improves customer satisfaction. For instance, stealth cameras used in wildlife conservation helped stop poachers from harming animals. In electronics, home assistants were improved through prototypes and made ready for mass production. Medical systems fixed many errors during prototyping, leading to production-ready units. Silicon fabrication tools achieved almost perfect results, beating competitors by ten times. Similarly, reverse-engineering a pump led to a better microcontroller replacement.

Application | Description |

|---|---|

Stealth Camera Development | Helped catch poachers before they harm endangered animals in Africa. |

Next-Generation Home Assistant | Improved design and prepared for large-scale production. |

Medical System Re-engineering | Fixed many documentation errors, creating a production-ready unit. |

Silicon Fabrication Equipment | Created tools with near-perfect results, beating competitors by 10 times. |

Micro-controller Replacement | Redesigned a pump, leading to a better-performing replacement. |

These examples show how prototyping ensures your product meets technical needs and gives great value to users. By focusing on quality and usability during prototyping, you can gain customer trust and long-term success.

Tip: Always listen to user feedback during prototyping. It helps you learn what customers really want and ensures your product matches their needs.

PCBA prototypes are very important in making products. They help find mistakes early, save money, and ensure high quality. Testing designs before making many products avoids big errors and improves how they work.

Here’s a simple list of the benefits:

Benefit | What It Does |

|---|---|

Spots design problems early to make sure it works. | |

Fixing issues early stops wasting money and materials. | |

Testing Performance | Checks signals, power use, and heat control. |

Easy to Manufacture | Makes sure the design works with building and assembly steps. |

Using PCBA prototypes helps you make better products and succeed. Start using them now to create strong and affordable designs.

FAQ

What is the difference between a PCB and a PCBA?

A PCB is just the plain board with no parts on it. A PCBA has all the parts attached, so it works and can be tested.

Why should you use PCBA prototypes?

PCBA prototypes let you test your design early. They find mistakes, improve quality, and save money by avoiding big errors in production. Prototypes also make sure your product meets customer needs and industry rules.

How long does it take to create a PCBA prototype?

The time depends on how complex your design is. Simple ones take a few days, but harder ones might take weeks. Using clear plans and machines can make it faster.

Can you reuse components from a PCBA prototype?

Yes, some parts can be reused if they are not damaged. But for final products, it’s better to use new parts to ensure they work well.

What industries benefit most from PCBA prototypes?

Industries like electronics, cars, planes, and medical devices use PCBA prototypes a lot. These help them make safe, high-quality, and creative products.

Tip: Always test your PCBA prototype carefully. Early testing avoids problems later and saves money!

See Also

The Importance of PCBA Prototyping in Electronics Development

Defining PCBA: Understanding Its Significance in Electronics

Exploring the Definition and Uses of PCBA in Electronics

Key Advantages and Uses of PCBA in Today’s Electronics

Essential PCBA Components and Their Functions in Electronics