PCBA prototyping plays a crucial role in electronics design. It aids in identifying mistakes early, which enhances performance and reduces costs. For instance, quick-turn PCBs deliver on time 98% of the time and exhibit fewer issues compared to traditional methods. Early testing in PCBA prototyping accelerates innovation, minimizes risks, and increases confidence in your designs.

Key Takeaways

PCBA prototyping finds design mistakes early. This saves time and money.

Testing prototypes makes products work better and meet safety rules.

Prototyping helps launch products faster by fixing issues quickly and avoiding delays.

Understanding PCBA Prototyping

What is PCBA Prototyping?

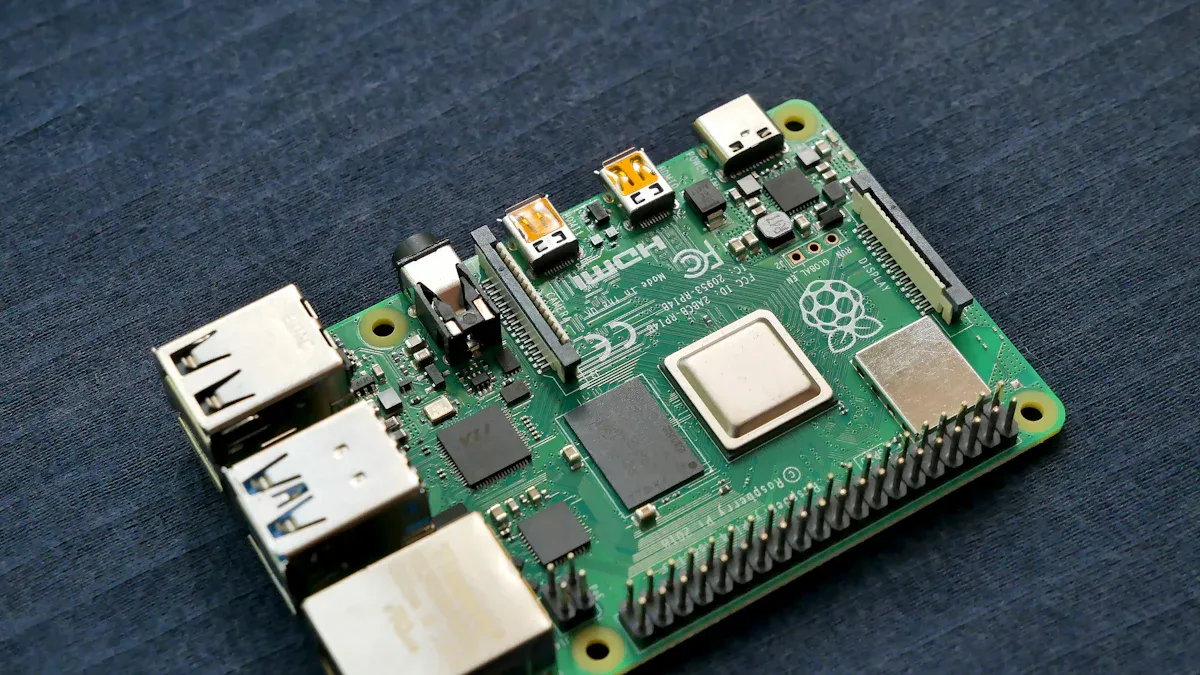

PCBA prototyping means building a working circuit board to test designs. A PCB is just a plain board with no parts. A PCBA has all the needed parts like resistors and chips. This lets you check how the design works in real life.

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Empty board for electrical connections | Board with parts, making it work |

Function | Holds parts and connects them | Does a specific job |

Components | None (just a blank board) | Includes resistors, capacitors, and chips |

Applications | Used for early testing and checking designs | Found in products like phones and computers |

Importance of Prototyping in Electronics Design

Prototyping is key to finding mistakes before making many products. Testing a prototype ensures it works well and meets rules. Virtual prototyping lets you test designs on a computer, saving time. Proof-of-concept prototypes show your idea works, helping you get support or funding.

How PCBA Prototyping Drives Innovation

PCBA prototyping helps create new ideas by testing quickly. For example, a startup used it to make smart home devices work with others. This helped them get funding. Car companies also use it to improve fuel use and safety. These examples show how prototyping helps meet market needs.

Benefits of PCBA Prototyping

Finding Design Problems Early

Prototyping helps spot problems before making many products. Testing ensures the circuit works as planned. Special debugging tools in prototypes make designs more reliable. Adding test pads to the PCB helps check circuits better. This makes moving from testing to production easier. Fixing big design issues early saves time and money.

Boosting Product Performance

Prototyping improves how well your product works. It lets you test heat, signals, and compatibility in real situations. Testing again and again ensures the product works where it’s used. For example, fixing a PCB design can make it last longer. This process creates stronger and better products that meet standards.

Speeding Up Market Launch

Prototyping makes product development faster, so you launch sooner. Quick testing and changes help fix problems early. This avoids delays from redesigning later. The need for faster product creation shows why prototyping matters. For example, the rapid prototyping market may grow to $2.5 billion by 2025. This shows how prototyping speeds up innovation and keeps you ahead.

Saving Money with Prototyping

Prototyping stops costly mistakes in large-scale production. Using cheap materials early lowers financial risks. Quick changes let you improve designs without spending too much. Prototyping also allows custom designs for special needs. This helps make great products while staying on budget.

The PCB Prototyping Process

Design and Simulation

The first step is to design and test the circuit. You use special software to create the circuit board layout. Tools like SPICE help check circuits quickly. Advanced tools simulate heat and signal issues.

Simulation Tool/Methodology | Description |

|---|---|

SPICE Simulations | Quickly checks large circuit designs. |

Time and Frequency Domain | Shows how circuits work in different situations. |

Advanced Field Solvers | Tests heat, power, and signal problems. |

You can also test for heat and unwanted signals. These tests save time and make your design more reliable.

Fabrication and Assembly

After designing, you build and assemble the board. This includes:

Cutting and shaping the board.

Adding and soldering parts onto it.

Printing the circuit design on the board.

Cleaning and coating it for strength.

Machines like pick-and-place tools make assembly faster and more accurate. Talking with manufacturers ensures your boards meet your needs. Testing during this step checks the board’s quality.

Tip: Planning for easy manufacturing early saves money and time.

Testing and Validation

Testing checks if the prototype works correctly. Important measures include design accuracy and production success. A good prototype has 95% accuracy and 90% success, while poor ones have lower rates.

Metric | Well-Prepared Prototype | Poorly Prepared Prototype |

|---|---|---|

Design Accuracy (%) | 95 | 70 |

Manufacturing Yield (%) | 90 | 60 |

Testing Efficiency (%) | 85 | 50 |

Tests also include checking circuits and parts to ensure they work properly.

Iteration and Optimization

Prototyping involves testing and improving designs repeatedly. You fix problems by studying failures and updating the design. For example, changing parts or layouts makes the board better. Testing again ensures the prototype is ready for real-world use. This process creates reliable products.

Note: Learning from mistakes helps improve both quality and performance.

Overcoming Challenges in PCBA Prototyping

Common Challenges in Electronics Prototyping

Making electronics prototypes can face many problems. These issues include:

Testing carefully to ensure products work in real life.

Picking the right parts for specific uses.

Testing in tough conditions is also a big challenge. For example, testing only at 70°F may cause failures in hot or cold places. Ignoring things like moisture or signal interference can lead to expensive fixes. Meeting rules, like FCC approval for devices over 9 kHz, adds more difficulty. This can cost up to $10,000 and hurt budgets.

Solutions to Prototyping Challenges

You can solve these problems with smart strategies. Changing designs step by step helps improve prototypes. Companies using this method succeed 80% more often. Testing in different conditions makes products more reliable and cuts launch time by 43%.

Listening to customers also improves products. Dropbox used early user feedback to grow and get funding. Focusing on making designs easy to produce saves time and money. Fixing problems early avoids costly mistakes later.

Choosing Reliable Manufacturing Partners

Picking the right manufacturer is key for good prototypes. Check these factors when choosing:

Criteria | Description |

|---|---|

Budgetary Constraints | Plan costs, including setup and unit prices. |

Lead Time Requirements | Pick a partner who meets your deadlines. |

Quality Expectations | Look for certifications and strong quality checks. |

PCB Design Complexity | Make sure they can handle your design needs. |

Technology and Equipment | Check their tools for accuracy and reliability. |

Material Sourcing | Confirm they use good-quality materials. |

Communication and Support | Choose partners with good customer service. |

Engineering Support | Ensure they help improve designs for easier production. |

Teamwork is also important. Companies like Nextracker work closely with suppliers to improve processes. Using cloud tools can make communication better and help meet industry rules.

PCBA prototyping is crucial in today’s electronics design. It helps products succeed by testing and improving quickly. This saves money and lowers risks. Finding problems early speeds up development by 30-40%. This method encourages new ideas and keeps you ahead in a fast-changing market.

Key Point | Explanation |

|---|---|

Product Success | Testing early avoids expensive mistakes in production. |

Cost Savings | Smart prototyping uses fewer resources and boosts profits. |

Faster Development | Quick testing cuts time-to-market by up to 40%. |

Why Prototyping Helps:

Spots problems early, saving time and money.

Improves designs step by step for better results.

Tip: Using PCBA prototyping ensures your designs meet market needs effectively.

FAQ

What is the difference between PCB and PCBA?

A PCB is an empty board with no parts. A PCBA has all the parts added, so it can work and be tested.

How does prototyping speed up development?

Prototyping finds problems early in the design. Fixing these quickly helps launch products faster without delays.

Why is testing important in PCBA prototyping?

Testing checks if your design works correctly. It finds mistakes, makes it more reliable, and meets rules for safety.

See Also

PCBA’s Role in Elevating Today’s Electronics Industry

Why PCBA Test Jigs Are Crucial for Electronics Manufacturing

Choosing the Best PCBA Manufacturer for Business Growth

Benefits of Overmolded PCBA Compared to Other Encapsulation Techniques

Essential In-Circuit Testing Tools for PCBA You Should Explore