PCBA test fixtures are essential tools in electronics manufacturing. These fixtures play a crucial role in identifying issues, verifying functionality, and improving product quality. Advanced testing methods, such as ICT and functional tests, are now capable of detecting even more problems. By utilizing a reliable PCBA test fixture, manufacturers can ensure high-quality PCBs, address defects early, and maintain customer satisfaction in competitive markets.

Key Takeaways

PCBA test fixtures are important for checking circuit board quality. They find problems early, stopping bad products from being sold.

Advanced tests like in-circuit testing (ICT) and functional testing help production. These tests spot issues fast, saving time and money.

Custom test fixtures are made for specific PCB designs. They make testing more accurate and dependable, helping manufacturers a lot.

Understanding PCBA Test Fixtures

What Are PCBA Test Fixtures?

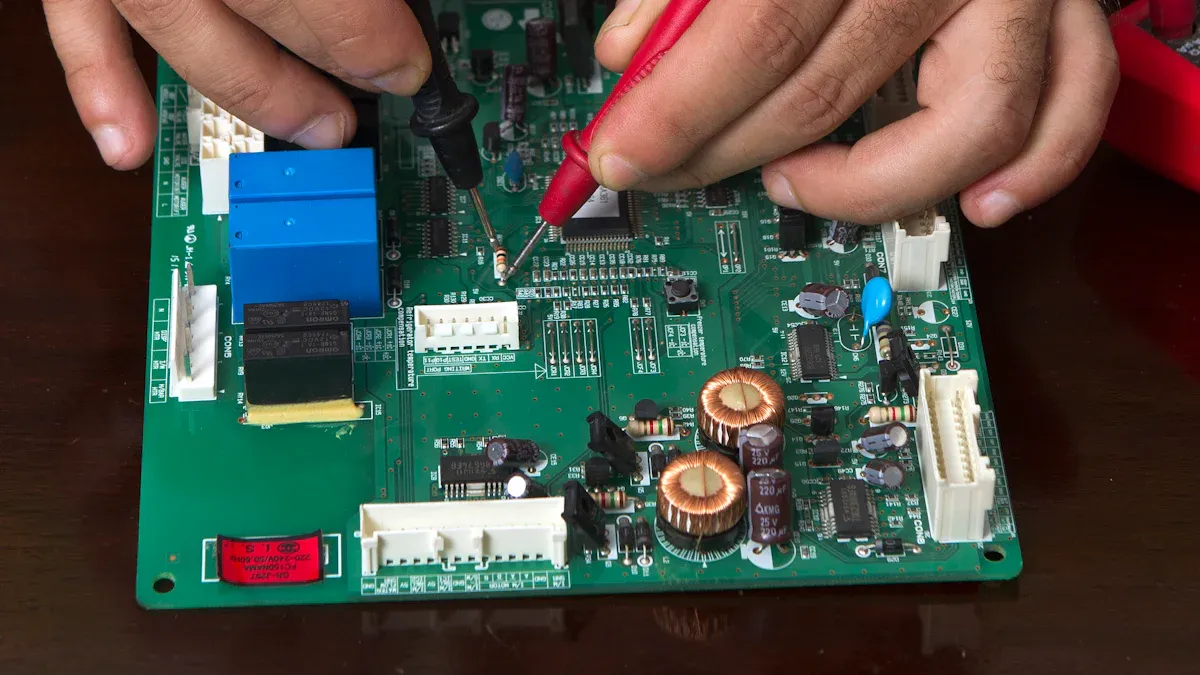

PCBA test fixtures are tools used to check circuit boards. They connect to the board using metal probes to find problems. These problems can include short circuits, open circuits, or broken parts. Test fixtures make sure the boards work well before moving to the next production step.

A test fixture has parts like RF launchers, lines, and a body. These parts hold the board steady and help with testing. Whether testing a few boards or many, these fixtures give accurate and repeatable results.

Purpose and Functionality of PCB Test Fixtures

The main job of a PCB test fixture is to check if the board works. It finds problems like bad soldering or parts that are not in the right place. Fixing these early stops bad products from reaching customers.

PCB test jigs also check if circuits work correctly. For example, in-circuit testing (ICT) uses a “bed of nails” to test many points fast. This method finds problems quickly and speeds up production. Functional testing is the last step to ensure all circuits are in the right place.

How PCBA Test Fixtures Support PCB Testing

PCBA test fixtures make testing circuit boards easier and more organized. They connect to the board through jigs that touch specific points. This setup helps with tests like checking connections, isolation, and functionality.

For example, a “bed of nails” fixture tests many points at once, which is great for making lots of boards. Flying probe testing is better for prototypes since it doesn’t need a custom fixture. These tools help ensure boards meet quality standards, reduce mistakes, and improve reliability.

Types of PCBA Test Fixtures and Their Applications

In-Circuit Test (ICT) Fixtures

In-circuit test (ICT) fixtures check if a PCB works properly. These fixtures use many small probes to touch the board. This setup finds problems like broken parts or bad connections fast. ICT fixtures are great for making lots of boards quickly and accurately.

These tools are used in industries like aerospace and telecommunications. For example, aerospace companies use ICT to make sure systems are safe. Below is a table showing how different test fixtures are used:

Type of Test | Application |

|---|---|

In-Circuit-Test | Aerospace |

Functional Circuit Test | Medical |

Fatigue Test | Energy |

Fixture Test | Telecommunications |

Impedance Test | Others |

Functional Circuit Test (FCT) Fixtures

Functional circuit test (FCT) fixtures check if a PCB works in real life. These fixtures copy real-world conditions to test the board. They make sure all parts work together correctly, like power and signals.

Medical companies use FCT fixtures to test life-saving devices. These tests help keep devices safe and meet rules. FCT fixtures are also used in telecommunications to check network equipment.

Environmental and Stress Test Fixtures

Environmental and stress test fixtures test PCBs in tough conditions. These tests include heat, shaking, and moisture. Environmental Stress Screening (ESS) finds hidden problems by copying harsh environments. For example, military and aerospace industries use ESS to test durability.

To get good results, manufacturers check samples and calibrate tools. Reports from these tests show how products perform and meet standards. Common tests include heat testing, strength checks, and fire safety tests.

The Role of PCBA Test Fixtures in Quality and Efficiency

Ensuring Product Quality Through PCB Functional Tests

PCB functional tests are key to making good products. These tests check if each PCBA works as it should. By copying real-life conditions, they find problems missed earlier. This ensures the product is reliable before being shipped.

Manufacturers use different checks like solder paste, optical, and X-ray inspections. These, along with functional and in-circuit tests, spot issues during assembly. For example, machines check current, clock signals, and data speeds. Faulty boards are fixed to improve quality and reliability.

Companies with strict quality checks make better and more reliable products. This leads to happier customers and better performance.

Reducing Errors and Enhancing Reliability

PCBA test fixtures find problems early, reducing mistakes in production. Functional tests ensure all parts work well together, lowering failure risks. Tracking defects and performance helps fix issues quickly. Metrics like first-pass yield show how well production is going.

Reliability tests make products stronger. By testing in tough conditions like heat or shaking, you ensure PCBs can handle real-world use. This reduces errors and makes customers trust your products more.

Streamlining Production Processes with Testing

Testing makes production faster by fixing problems early. Before making many boards, manufacturers test prototypes to avoid big mistakes. This saves money and time.

For example, MacroFab worked with Somewear Labs to fix design problems. They solved size and signal issues to prepare for mass production. Testing like this saves resources and ensures high-quality products.

PCB test fixtures also speed up production. Tools like in-circuit fixtures test many points at once. This helps meet deadlines and stay ahead in the market.

Customization and Development of PCBA Test Fixtures

Adapting Fixtures for Specific PCB Testing Needs

Custom fixtures make sure each PCB is tested properly. They hold the board steady and connect to test points exactly. The design matches the board’s layout, electrical needs, and test locations. This accuracy gives dependable and clear results.

For instance, flexible fixtures can adjust to new product needs. They are a smart investment for long-term use. Functional test fixtures find problems early, lowering recall risks. Careful planning and setting test rules ensure cables and parts work well.

Aspect | Description |

|---|---|

Purpose | Custom tools that secure the PCB during testing. |

Functionality | Allow testing tools to connect with the PCB. |

Design Requirements | Made to fit PCB layout, test points, and electrical needs. |

Precision | Needed for accurate and trustworthy testing. |

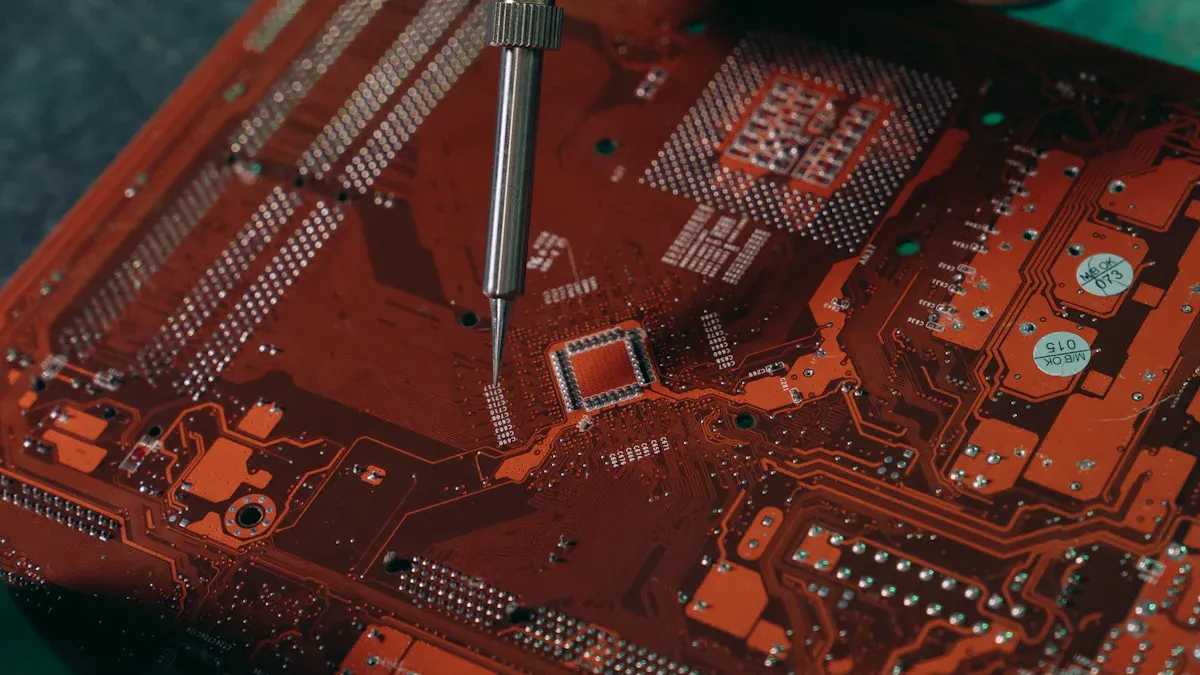

The Design and Manufacturing Process of Test Fixtures

Making a custom test fixture starts with studying the PCB. Engineers check its size, shape, and test points. Then, they create a fixture that fits these details perfectly. This makes testing smooth and mistake-free.

Modern tools like robots and smart systems help in production. Robots handle repeated tasks with great accuracy. Smart systems predict problems before they happen. These tools improve production and cut defects by up to 30%. Working closely with PCB makers ensures the fixture meets all needs.

Advantages of Custom PCB Test Fixtures

Custom PCB fixtures have more benefits than standard ones. They cost more at first but offer better testing and problem-solving. These fixtures are great for making many boards quickly and reliably.

Aspect | Custom PCB Test Fixtures | Standard Alternatives (Flying Probe) |

|---|---|---|

Upfront Costs | Higher | Lower upfront costs |

Test Coverage | Full testing and problem detection | Limited testing |

Throughput | Faster for large-scale production | Slower testing |

Fault Isolation | Excellent at finding specific issues | Less effective |

Economies of Scale | Lowers costs for big production runs | Not applicable |

Investing in custom fixtures means better testing, faster results, and lower costs over time. These fixtures also adjust to new product needs, making them a valuable choice.

PCBA test fixtures are important in making electronics. They make testing easier and ensure each PCB is high quality. Finding problems early saves money and speeds up production. These tools are flexible and help create dependable products that customers trust.

FAQ

How long does a PCBA test fixture last?

How long it lasts depends on use and care. If taken care of, most fixtures can handle thousands of tests. This keeps them working well for a long time. 🛠️

Can PCBA test fixtures work with different PCB designs?

Yes, custom fixtures fit different PCB layouts. They test unique designs accurately. This makes them useful for many electronics projects.

How do you take care of a PCBA test fixture?

Clean the probes often and look for damage. Replace broken parts quickly. Good care keeps tests accurate and makes fixtures last longer. 🧹

See Also

Understanding The Role Of PCBA Test Jigs In Electronics

Innovative PCBA Testing Methods For Modern Electronics Production

The Crucial Role Of PCBA Prototyping In Electronics

Enhancing Accuracy Through Automation In PCBA Testing

Understanding PCBA Services And Their Importance In Manufacturing