In making advanced electronics, PCBA testing is key for quality. These tests check if parts work and find problems early.

The PCBA testing service market is growing fast due to high demand.

Smaller electronics are more complex, needing special PCBA testing to stay reliable.

Automated PCBA testing lowers mistakes and improves accuracy in fields like cars and planes.

Choosing the right PCBA testing for your product meets rules and boosts performance.

Key Takeaways

PCBA testing is important to make sure electronics work well. It finds problems early so bad products don’t get sold.

Automated tests, like Automated Optical Inspection (AOI), are fast and accurate. These tests are very important for industries that need high quality.

Picking the right test depends on your product’s design, how many you make, and your budget. Choosing carefully helps save money and improve performance.

Understanding PCBA Testing

What is PCBA Testing?

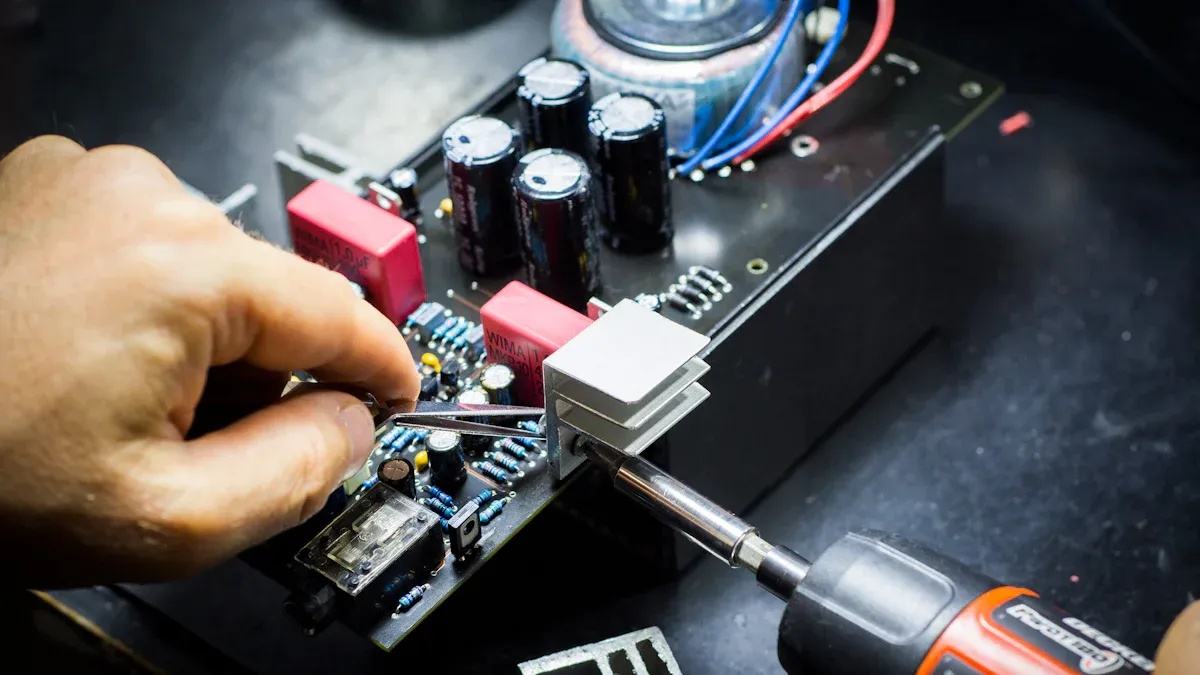

PCBA testing checks printed circuit board assemblies (PCBA) to ensure they work well. These tests confirm the electrical performance of the PCB and its parts. They find problems like broken circuits, short circuits, or faulty components. Unlike PCB testing, which looks at empty boards, PCBA testing examines the whole assembly. This includes solder joints and where parts are placed.

Test Aspect | PCB Functional Electrical Test | PCBA Functional Electrical Test |

|---|---|---|

What’s Tested | Empty PCB, traces, vias, pads | Full PCB assembly with all parts |

Key Focus | Connections, voltage, continuity | Part function and assembly quality |

Complexity | Simple, focuses on empty board | Complex, includes part interactions |

Why is PCBA Testing Crucial for Advanced Electronics?

PCBA testing is important for making reliable advanced electronics. It finds problems early during production, stopping bad products from being sold. In industries like cars and planes, where accuracy matters, tests like in-circuit and functional testing ensure PCBs work perfectly under tough conditions.

Testing also helps meet industry rules and standards. For example, automated PCBA testing has made testing six times faster in car manufacturing. This saves time and improves product quality.

Key Benefits of Effective PCBA Testing

Good PCBA testing has many benefits:

Improved Reliability: It catches issues like weak solder joints early, ensuring steady performance.

Enhanced Efficiency: Automated tests cut manual work by 20% and boost speed by 10%.

Cost Savings: Finding defects early avoids expensive fixes and reduces waste.

Higher Quality: Detailed tests make sure PCBs meet strict quality rules.

Parameter | Description |

|---|---|

Testing Duration | |

Total Parameters Logged | 154 parameters tracked |

Observed Failure Modes | Sensor drift, part failures |

Benefits of Automation | Lower costs, better efficiency |

Using advanced testing methods helps save time and money while keeping your PCBs high-quality.

A Simple Guide to PCB Testing Methods

In-Circuit Testing (ICT)

In-circuit testing (ICT) is a trusted way to check circuit boards. It tests each part on the board to ensure they work. ICT uses a special tool called a bed-of-nails to touch test points. This method finds problems like broken circuits or wrong part values.

ICT is very accurate but costs more because of custom tools. It’s best for making many boards where the cost is worth it. ICT helps find problems early, saving time and money later.

Flying Probe Testing

Flying probe testing is a flexible option instead of ICT. It uses moving probes to test the board, not fixed tools. This method works well for small batches or test samples. It checks for broken connections, continuity, and part values without needing custom tools.

Flying probe testing is slower than ICT. It’s better for cases where speed isn’t a big deal. Even though it’s slower, it’s accurate and works for many board designs.

Functional Testing

Functional testing checks if the whole board works as it should. It tests how the board will work in real life. This test finds problems that other tests might miss.

Functional testing can be adjusted for different uses. It’s especially helpful for complex boards used in advanced devices.

Automated Optical Inspection (AOI)

Automated optical inspection (AOI) uses cameras and software to find defects. It looks for problems like bad soldering, misplaced parts, or missing pieces. AOI is quick and reliable, making it great for making many boards.

Evidence Type | Description |

|---|---|

Consistency | AOI keeps quality high, unlike humans who get tired. |

Positional Accuracy | AOI spots small placement errors for better accuracy. |

Speed of Inspection | AOI works fast and repeats checks, lowering costs. |

AOI is a key part of modern board testing. It ensures good quality and reduces mistakes made by people.

X-Ray Inspection

X-ray inspection is a strong tool for checking circuit boards. It looks at hidden areas like solder under parts. This method is great for finding issues in tightly packed boards.

X-ray inspection is very accurate but costs more. It’s used for important products like airplanes or medical devices. This test ensures the best quality for circuit boards.

Advanced Techniques in PCBA Testing

Role of Test Fixtures in PCB Testing

Test fixtures are important for accurate and reliable PCB testing. They help align the PCB with testing tools perfectly. This ensures tests give correct results every time. Fixtures also make testing the same for all boards. This reduces differences and keeps quality consistent.

Key Advantages of Test Fixtures:

Helps align PCBs correctly for testing.

Ensures all boards are tested the same way.

Makes results repeatable for fair comparisons.

For example, in-circuit tests (ICT) use fixtures to check small parts on crowded boards. Functional circuit tests (FCT) use them to test how the whole board works. Burn-in tests use fixtures to apply stress evenly to all boards. These methods ensure your PCBs are high-quality.

Automated Test Equipment (ATE) for Enhanced Accuracy

Automated Test Equipment (ATE) makes PCB testing faster and more accurate. ATE systems do tests automatically, so less manual work is needed. This saves time and lowers production costs.

Performance Improvement | Description |

|---|---|

ATE speeds up testing, cutting production time and costs. | |

More Units Tested | ATE tests many boards quickly, increasing production speed. |

Better Accuracy | ATE finds problems precisely, making boards more reliable. |

Using ATE means quicker tests and more boards tested. It’s a must-have for modern electronics production.

Emerging Technologies in PCBA Testing

New technologies are changing PCBA testing with smart ideas. For example, 3D Automated Optical Inspection (AOI) gives detailed views of solder and parts placement. Machine learning is also being used to predict problems before they happen by studying past data.

Burn-in testing is another advanced method. It puts boards under stress to find early failures. This is very useful for important products like airplanes and medical tools. These new methods make sure your PCBs are reliable and perform well.

Environmental and Stress Testing for PCB Reliability

Environmental and stress tests check if PCBs work in tough conditions. These tests copy real-world challenges to find weak spots and make PCBs stronger. Let’s look at three key testing methods that improve PCB durability.

Thermal Cycling and Temperature Testing

Thermal cycling tests switch PCBs between hot and cold temperatures. This mimics sudden temperature changes, called thermal shock. It checks if materials and solder joints stay strong. For example, these tests show if parts can handle extreme heat or cold, ensuring they last longer.

High-temperature tests check how PCBs work in heat during use. They find problems like material wear and electronic damage. Power cycling tests turn devices on and off repeatedly. This checks for heat-related wear and electrical strength.

Test Type | Description | Benefits |

|---|---|---|

Turns devices on and off to test heat and reliability. | Ensures parts last longer. | |

High Temperature Operating Life | Tests PCBs in high heat during use to find wear and damage. | Finds material and electronic problems. |

Temperature Cycle Test | Switches between hot and cold to mimic sudden temperature changes. | Checks material strength and solder joint quality. |

Vibration and Shock Testing

Vibration and shock tests see how PCBs handle shaking and impacts. These tests copy things like shipping bumps or machine vibrations. By shaking and hitting PCBs, you can find weak solder joints, connectors, or parts.

For example, vibration tests copy the shaking during transport. Shock tests copy sudden hits. These tests make sure PCBs stay strong in hard conditions.

Humidity and Corrosion Testing

Humidity and corrosion tests check how moisture and chemicals affect PCBs. High humidity can make materials swell, and chemicals can cause corrosion. Tests in controlled settings, like 81% humidity and 50°C heat, show weak spots.

The iNEMI creep corrosion test uses a sulfur chamber to copy real-world conditions. Results show prebaking PCBs stops corrosion, making them last longer. These tests ensure PCBs work well in wet or chemical-heavy places.

Aspect | Details |

|---|---|

Testing Methodology | iNEMI creep corrosion test uses a sulfur chamber. |

Environmental Conditions | Humidity at 81% and heat at 50°C with sulfur vapor. |

Findings | Corrosion links to field issues; prebaking stops corrosion. |

Environmental and stress tests, like thermal cycling, vibration, and humidity tests, ensure PCBs are reliable. These methods help make strong and high-quality products.

Choosing the Right PCB Testing Methods

Things to Think About: Design, Quantity, and Cost

When picking PCB testing methods, think about design, quantity, and cost. These factors affect how well your testing works. For example, a simple PCB with few parts may need only basic tests. But a complex PCB with many layers needs advanced tests like X-ray or functional testing.

Factor | Simple Design (1) | Medium Design (2) | Complex Design (3) |

|---|---|---|---|

Layers Count | 1-4 layers | 5-8 layers | 9+ layers |

Parts Density | Less than 10 parts | 10-20 parts | Over 20 parts |

Routing Complexity | Easy routing | Medium routing | Hard routing |

Special Features | None | Some features | Many features |

The number of PCBs you make also matters. Large batches work best with automated tests like in-circuit testing. This can cut mistakes by 30% (EIA, 2020). For small batches, flying probe testing is flexible and doesn’t need special tools. Balancing these factors helps you pick the best method.

Balancing Accuracy, Speed, and Cost

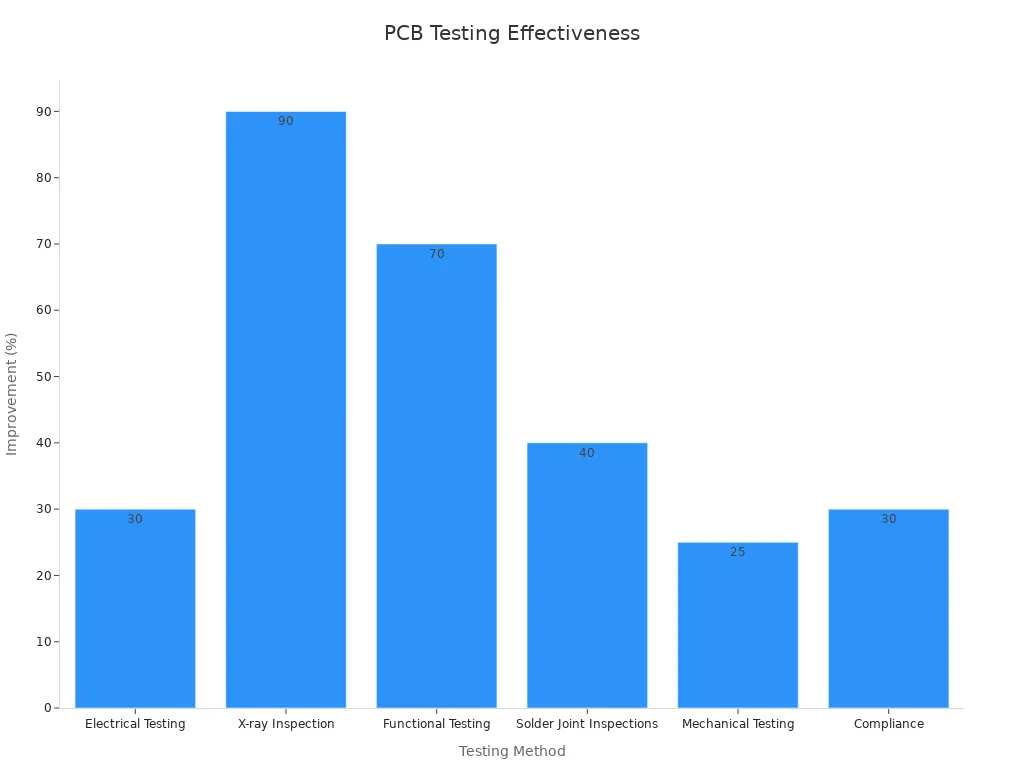

Testing well and fast can cost more money. You need to balance these with your budget. Automated optical inspection (AOI) and X-ray tests are very accurate. X-ray can find 90% of defects (IPC, 2021). But these tests can be pricey. If you need to save money, functional testing is cheaper and finds 70% of problems (Johnson, 2022).

Focus on what’s most important for your project. This way, you can test well without spending too much. It ensures your PCBs are good quality and affordable.

Matching Testing to Different Uses

Different products need different testing methods. For example, airplanes and medical devices need strict tests like solder joint checks. These tests lower failure rates by 40% (IEEE, 2020). Everyday electronics might use mechanical tests to avoid 25% of failures from physical damage (Consumer Electronics Association, 2021).

Knowing what your product needs helps you pick the right test. Whether it’s meeting rules for factory machines or making car electronics last longer, matching the test to the product ensures it works well.

PCBA testing is key to making sure products work well. Picking the right test finds problems and lowers failure chances. For instance, electrical tests find 80% of issues, and functional tests cut failures by 30%. Learning about new methods helps your products stay up-to-date.

Testing Method | Finds Defects (%) | Cuts Failures (%) |

|---|---|---|

Electrical Testing | Finds 80% | Cuts by 25% |

Functional Testing | Finds 70% | Cuts by 30% |

Solder Joint Checks | Cuts by 40% | N/A |

Following Rules | Cuts by 30% | N/A |

Physical Tests | Stops 25% | N/A |

FAQ

What is the difference between PCB and PCBA testing?

PCB testing looks at the empty board for electrical problems. PCBA testing checks the finished board, including parts and solder, to ensure it works well.

How do you choose the right PCBA testing method?

Think about your product’s design, how many you’ll make, and your budget. Flying probe testing is good for small amounts. For big production, automated tests like ICT are better.

Tip: Pick a testing method that fits your product’s needs. This helps it work well and saves money.

Why is automated testing important in PCBA manufacturing?

Automated testing makes things more accurate and faster. It avoids mistakes people might make. It’s very useful for industries like cars and planes, where quality matters a lot.

See Also

Understanding The Role Of PCBA Test Jigs In Electronics

Essential PCBA In-Circuit Testing Tools For Your Knowledge

Exploring PCBA Services And Their Significance In Manufacturing