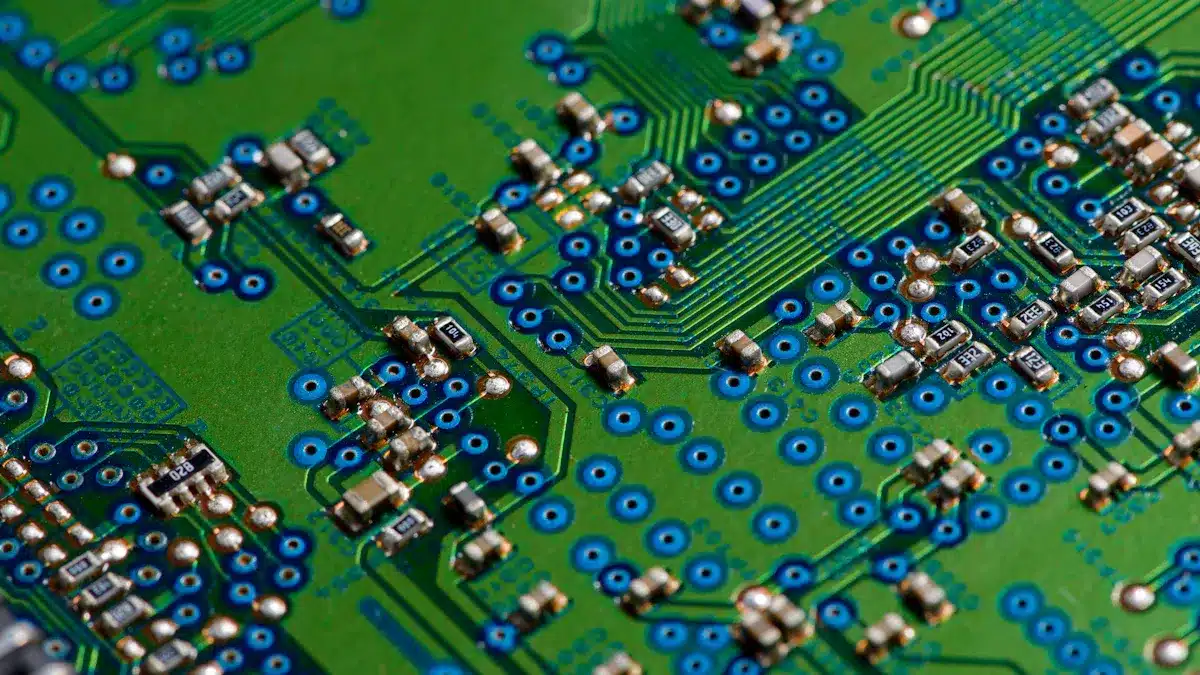

The world of electronics relies heavily on the ability to print PCBs, or printed circuit boards. In 2023, the global PCB market was valued at approximately $67.9 billion. This figure is projected to rise to around $92.4 billion by 2029, indicating a growth rate of 5.4%. As technology advances, the demand for innovative methods to print PCBs increases. The surge in IoT devices and sophisticated electronics is a key driver of this growth. Understanding these printing methods is essential for anyone involved in the electronics industry today.

Key Takeaways

Learn about different PCB printing methods. This helps you pick the best one for your project.

Stencil printing is quick and cheap for big production runs. However, it has trouble with complex designs.

Direct legend printing is flexible. It allows quick changes, making it great for small batches and prototypes.

Inkjet printing is low-cost for small runs. Photoengraving is best for making detailed and precise designs.

Think about production volume, design complexity, and budget when choosing a PCB printing method.

PCB Printing Methods

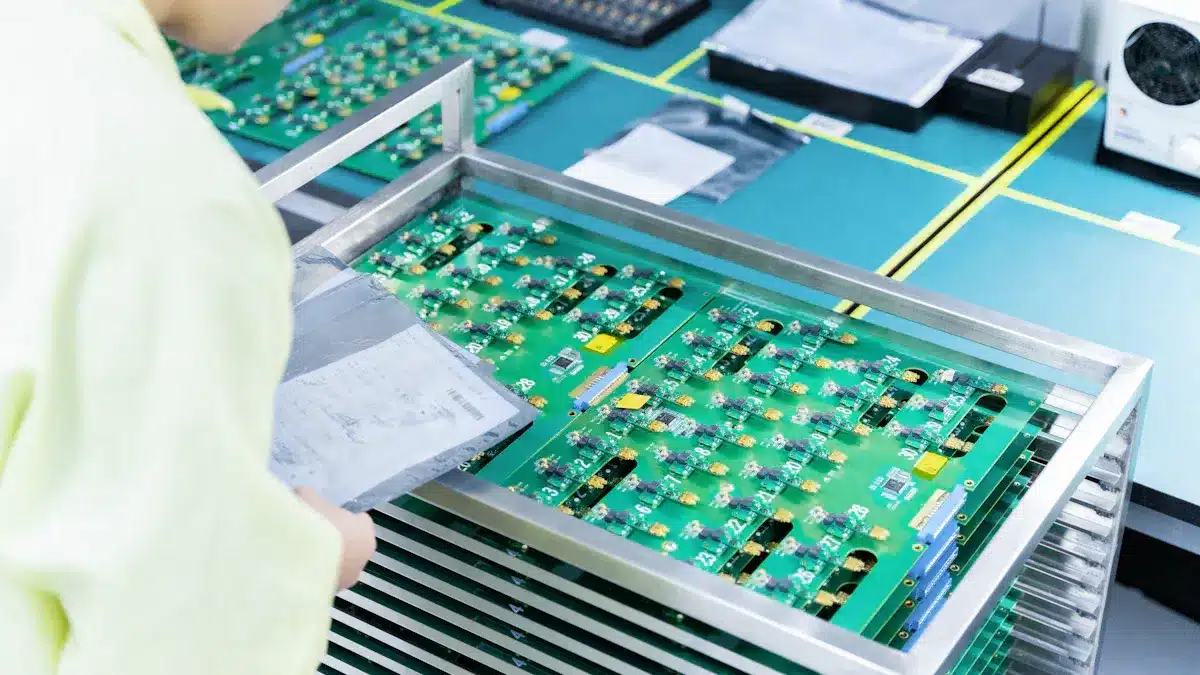

When you want to print PCBs, there are several methods to choose from. Each method has its own benefits and uses. Knowing these methods helps you pick the best one for your needs.

Stencil Printing

Stencil printing is a common way to put solder paste on PCBs. This method uses a stencil that matches the PCB layout. You place the stencil on the board and spread solder paste through it. This method works well for making many boards quickly.

Material Type | Description | Method of Creation |

|---|---|---|

Stencil | Usually made from stainless steel or nickel for strength and accuracy. | Laser cutting, Chemical etching, Electroforming |

Solder Paste | Made of solder metal and flux, it helps stick components in place. | N/A |

Stencil printing is great for large production runs because it is fast and cheap per board after setup. But, it can have trouble with complex designs, needing new stencils for changes.

Direct Legend Printing

Direct legend printing is a flexible choice compared to older methods like silkscreen printing. This method prints legends directly onto the PCB using high-quality inkjet technology.

Advantage | Description |

|---|---|

Can create fine details and small text clearly, which is important for complex designs. | |

Flexibility for Small Batches | Great for prototypes or small runs without needing stencils or setup. |

Quick Turnaround | Faster production with shorter wait times, often by 20-30% for small orders. |

Customization | Easy to change designs or add special markings for each board without extra work. |

Reduced Waste | Uses only the needed amount of ink, cutting down on waste compared to screen printing. |

This method is especially helpful for small batches, allowing quick changes without high costs.

Silkscreen Printing Methods

Silkscreen printing is an old method that puts ink on the PCB through a mesh screen. This method is good for making strong markings on the board. The type of ink used affects how long the markings last. For example, epoxy-based inks stick well and resist damage, making them good for tough jobs.

Tip: Keep a minimum line width of 0.15mm for clear reading in dense designs.

However, silkscreen printing has limits, especially for dense PCB designs. It needs careful planning to avoid crowding and keep things visible.

Inkjet Printing

Inkjet printing is a flexible method for making PCBs. This process loads PCBs into a printer and uses tiny ink drops to create the image.

Load PCBs into the printer bed and align them.

Jet tiny ink drops to create the image, usually between 10-40 picoliters.

Use curing systems like UV light to dry the ink quickly.

Add colors in more passes to make complex legends.

Inkjet printing is cheap for small runs since there are no setup fees. But for larger amounts, traditional methods might be cheaper.

Production Volume | Inkjet Cost | Screen Printing Cost |

|---|---|---|

$100 | $250 | |

5,000 boards | $5,000+ | $1,500 |

Photoengraving

Photoengraving, especially through photochemical etching, makes detailed and complex designs with very tight tolerances. This is important for jobs needing high precision, like mass-producing circuit boards.

Burr-free results

Ability to create complex designs

Fast prototyping

The dual-chamber photo engraving machine can etch down to 50μm, which is key for making detailed patterns in PCB manufacturing.

Comparison of PCB Printing Methods

Choosing the right PCB printing method depends on many things, like how many you need, how complex the design is, and costs. Here’s a quick comparison of the methods we talked about:

Feature | Stencil Printing | Direct Legend Printing | Silkscreen Printing | Inkjet Printing | Photoengraving |

|---|---|---|---|---|---|

Speed | Moderate | Moderate to slow | Slower, 2-5 minutes per board | Fast for complex designs | |

Cost for High Volume | Low per board cost after stencil setup | Predictable cost | Moderate | Higher for large runs | Moderate to high |

Flexibility | Limited, needs new stencil for changes | High, instant design changes via software | Limited | High, easy adjustments | Limited |

Design Complexity | Struggles with complex designs | Excels with varying pad sizes | Limited for high-density designs | Excels with complex designs | Excellent for intricate designs |

Upfront Costs | High due to stencil making | Low | Moderate | High equipment cost | Moderate to high |

Maintenance | Low maintenance | Low | Needs regular cleaning | Needs regular cleaning and calibration | Low maintenance |

Production Volume | Best for high-volume production | Best for low-volume runs or prototyping | Best for medium to high volumes | Best for low-volume runs | Best for high precision applications |

Choosing the right method helps ensure the best performance and cost for your PCB projects.

In conclusion, picking the best PCB printing method is very important for your projects. Each method has its own benefits for different needs. As technology changes, new trends in PCB printing will appear. For example, using AI and machine learning will make manufacturing faster. Also, 3D-printed electronics will change how you design and create printed circuit boards. This will help with quick prototypes and custom designs. Keeping up with these changes will help you make smarter choices in your PCB projects.

FAQ

What are printed circuit boards?

Printed circuit boards, or PCBs, are important parts of electronic devices. They connect electronic parts using pathways that conduct electricity. You can find them in devices like smartphones and computers.

How do I choose the right PCB printing method?

To pick the right PCB printing method, think about how many you need, how complex the design is, and your budget. Each method has its own benefits, so check your needs before making a choice.

Can I use multiple printing methods for one PCB?

Yes, you can mix different printing methods for one PCB. For example, you might use stencil printing for solder paste and direct legend printing for labels. This can improve both function and look.

What is the average cost of PCB printing?

The cost of PCB printing changes based on the method and how many you want. For small amounts, inkjet printing might be cheaper. Stencil printing is better for large orders because it costs less per board. Always compare methods to find what works best for your budget.

How long does it take to print PCBs?

The time it takes to print PCBs depends on the method you use. Stencil printing can be done in under 30 seconds per board, while inkjet printing usually takes 2-5 minutes. Complex designs might need more time for setup and drying.

See Also

Essential Guidelines for Choosing Quality PCB Assembly Services

Key Strategies to Enhance PCB Assembly Productivity

Selecting the Ideal PCB Fabrication Partner for Your Requirements

Crucial Advice for Picking the Perfect Main PCBA

Effective Solutions for Overcoming PCBA Manufacturing Obstacles