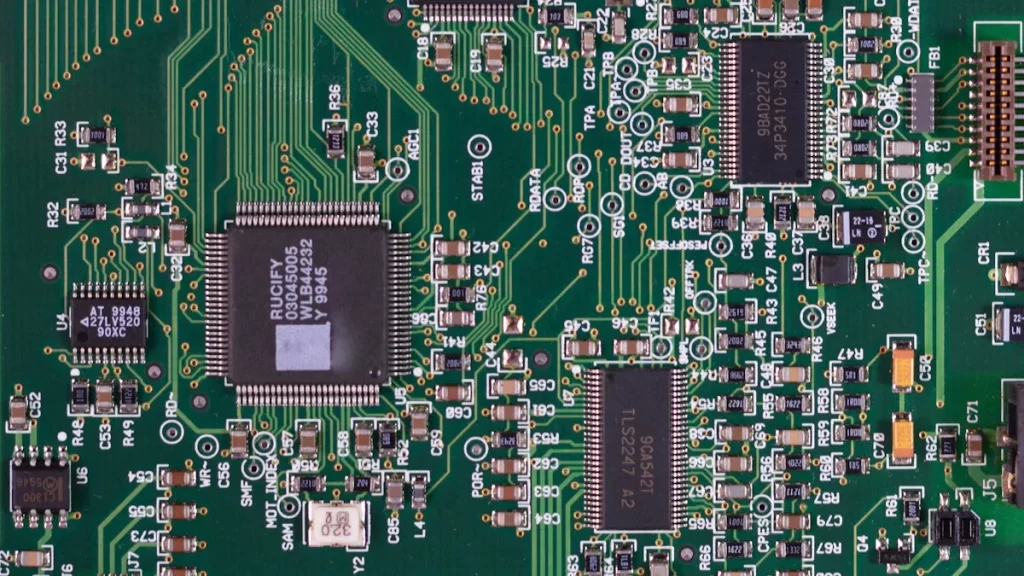

In factories, PROFINET circuit board assembly is very important. These assemblies help machines communicate with each other quickly and smoothly. Boards like the Siemens Simatic NET CP 1543-1 are robust and utilize smart technology. They can handle tough jobs and integrate well with new systems. Their sturdy design ensures longevity, even in harsh environments. Choosing the right PROFINET circuit board assembly enhances your system’s performance and durability.

Key Takeaways

PROFINET boards help machines talk to each other better. This boosts factory work and speeds up production.

Pick boards like Siemens Simatic NET CP 1543-1 for safe jobs. They have strong security and fit easily with current systems.

Get PROFINET boards that send messages quickly for exact control in automated tasks.

Choose boards that are tough and dependable. They should handle heat and shaking in factories.

Think about growth when picking a PROFINET board. Make sure it can adapt as your factory expands.

What is PROFINET?

Overview of PROFINET Protocol

PROFINET is a system that helps machines share data quickly. It uses Ethernet but improves it for factory use. Unlike regular Ethernet, PROFINET works with tools like PLCs and HMIs.

This system has changed a lot over time. Here’s how it grew:

Year | Event |

|---|---|

2000 | Plans started for a new system to replace PROFIBUS. |

2001 | The first version, called PROFINET CBA, was made. |

2003 | PROFINET IO came out, helping factories use it more. |

2006 | PROFINET IO became part of the IEC rules. |

2019 | TSN was added to make it even faster. |

These updates show how PROFINET keeps improving to meet factory needs.

Role of PROFINET in Industrial Automation

In factories, PROFINET helps machines talk to each other easily. It lets them work together at the same time, which is important for tasks like moving parts or controlling processes.

PROFINET connects devices to IoT systems for better data use.

It allows fast communication, which is key for quick production.

The system links different tools, making data sharing smooth.

Using PROFINET makes factory systems more reliable and efficient.

Why PROFINET is Preferred Over Other Protocols

PROFINET is better than other systems because it works faster and can do more. Here’s a comparison:

Feature | PROFINET | Other Protocols |

|---|---|---|

Basis | Ethernet technology | Different systems like CAN |

Standard | Open and follows IEC rules | May be private or open |

Performance | Great for fast tasks | Can vary a lot |

Applications | Factory work and process control | Depends on the system |

It handles both fast tasks and big data well, making it perfect for modern factories. Plus, its open design works with many devices, giving you more choices for your projects.

Tip: Choose PROFINET if you need a system that's fast, reliable, and flexible for your factory work.

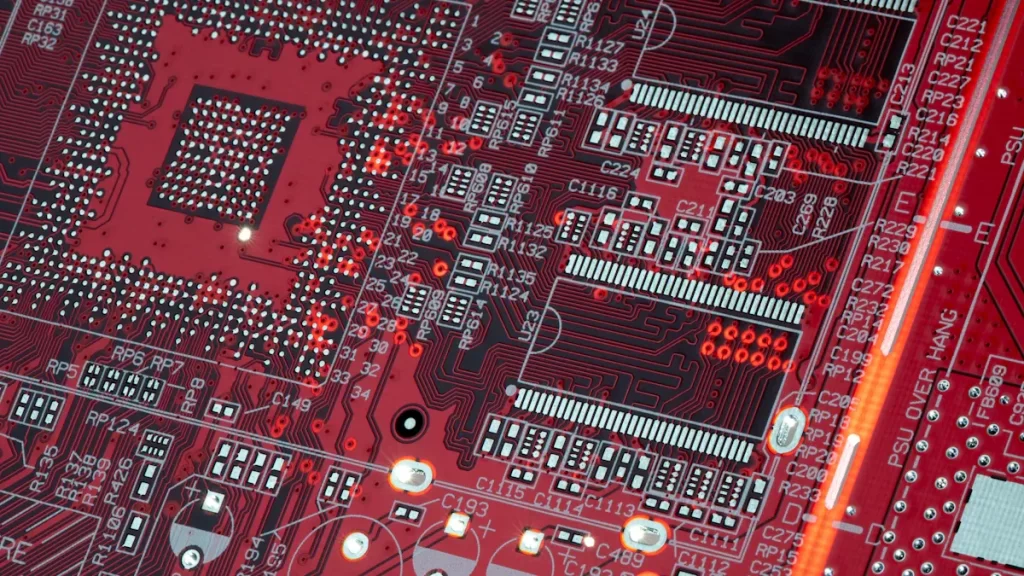

Key Features of PROFINET-Compatible Circuit Boards

Real-Time Communication Capabilities

PROFINET-compatible boards are great for real-time communication. This is very important in industrial automation. They use an Ethernet-based system made for quick and precise control. This makes them perfect for tasks like moving robotic arms or running machines. Timing is crucial for these jobs, and these boards handle it well. They send and receive data quickly, keeping everything running smoothly.

Real-time communication also boosts how well systems work. These boards can sync many devices so they work together perfectly. This is especially useful in industries where quick actions affect safety and productivity.

Note: Real-time communication isn’t just helpful—it’s a must for modern factories aiming to perform their best.

Reliability and Durability in Industrial Environments

Factories can be tough places with heat, vibrations, and electrical noise. PROFINET-compatible boards are made to handle these conditions. They use strong designs with features like grounding and shielding to block interference. Special techniques like differential signaling and opto-isolation help them stay reliable, even in noisy areas.

These boards are tested to match factory conditions. Tests include heat, moisture, and shaking to ensure they last. This means they keep working well over time, even in hard environments. Choosing these boards means picking a solution you can trust for years.

Compatibility with Industrial Systems

A key feature of PROFINET-compatible boards is how well they work with different systems. They follow global standards like IEC 61158 and IEC 61784. This ensures they can connect with many devices and setups. Manufacturers also offer flexible ways to add these boards to your system.

Here’s a simple look at their compatibility:

Feature Description | Details |

|---|---|

Compatibility Standards | Follows IEC 61158 and IEC 61784 for easy device connection. |

Certification Requirement | Must pass tests at approved PI Test Labs. |

Implementation Options | Provides flexible ways to fit into various setups. |

This high compatibility makes setup easier and saves time. Whether upgrading or starting fresh, these boards give you the flexibility you need.

Performance Metrics and Scalability

When picking a PROFINET board, think about its speed and growth. These features show how well it works now and in the future.

Performance metrics tell how fast and smooth the board sends data. PROFINET boards are great at sharing data on time. This is important for tasks needing exact timing. For example, in a robot assembly line, the board must match movements perfectly. Fast data speeds and low delays make these boards perfect for tough jobs.

Scalability means your system can grow without big changes. Good PROFINET boards let you add or change connections, like Ethernet or RS-485. This makes it easy to upgrade or expand your system later. Boards with programmable controllers can also update to work with new technology, keeping them useful for years.

Reliability is key for both speed and growth. Factories can be rough with heat, shaking, and electrical noise. PROFINET boards use smart designs like shielding and grounding to stay strong. These features keep them working well, even in hard conditions.

By focusing on speed and growth, you can pick a PROFINET board that works now and later. This helps your factory stay fast and ready for the future.

Top PROFINET Circuit Boards

Siemens Simatic NET CP 1543-1: Specifications and Features

The Siemens Simatic NET CP 1543-1 is a trusted option for factories. It handles tough tasks and ensures smooth data sharing. The board uses advanced encryption to keep data safe, which is important for industries needing secure communication.

It works with Siemens TIA Portal, making setup and monitoring simple. The board supports real-time communication, helping machines work with precise timing. Its strong design allows it to handle heat, vibrations, and electrical noise. This makes it reliable for long-term use in harsh conditions.

If you want a board that’s easy to use, secure, and performs well, this is a great pick. It also works with many systems, so it fits easily into your current setup.

Hilscher CIFX 50E-RE: Specifications and Features

The Hilscher CIFX 50E-RE is a flexible board for modern factories. It supports many protocols like Ethernet and RS-485, making it adaptable for different needs. This board is great for tasks that need fast data sharing and protocol changes.

Here’s a quick look at its details:

Specification | Details |

|---|---|

Dimensions (L x W x H) | |

Interface | PCI Express, One-Lane Port |

Operating Temperature | 0..55°C |

Operating Voltage | 3.3V / max. 800 mA |

Features | Works with all PC card formats, Includes useful tools (OPC server & drivers), Supports major network protocols, Reduces product variety for easier logistics, Protocols can be updated with firmware, Same software interface for all protocols, One hardware for all Real-Time-Ethernet protocols |

This board can update its protocols, keeping it ready for future needs. Its sturdy design, with grounding and shielding, blocks interference, making it dependable in noisy areas. If you need a board that’s flexible, scalable, and strong, this is a smart choice.

Phoenix Contact FL SWITCH IRT: Specifications and Features

The Phoenix Contact FL SWITCH IRT is built for fast data sharing. It’s perfect for jobs needing quick communication, like robotic control. The board has backup systems to keep working even if the network fails.

It prioritizes important data, so critical tasks aren’t delayed. This is helpful for things like assembly lines. The board uses special designs like differential signaling to keep signals clear in tough environments.

This board is made to last, with strong connectors and durable parts. If you need fast and reliable communication for your factory, this board is an excellent option.

Ideal Use Cases for Each Board

Each PROFINET board has special features for certain factory tasks. Knowing these uses helps you pick the best one for your needs.

Siemens Simatic NET CP 1543-1

The Siemens Simatic NET CP 1543-1 is great for secure jobs. It works well in industries like food or medicine, where data safety matters. Its strong encryption keeps important information safe. This board connects easily with Siemens TIA Portal, making it perfect for factories already using Siemens tools. If your work involves controlling robots or fast assembly lines, this board offers the accuracy and dependability you need.

Hilscher CIFX 50E-RE

The Hilscher CIFX 50E-RE is ideal for factories needing flexibility. It supports many protocols, helping factories switch from older systems like PROFIBUS. For example, it improves monitoring and speeds up machine setup. Its firmware updates keep it ready for future needs. If your factory has different machines, this board makes connecting them easier and boosts productivity.

Phoenix Contact FL SWITCH IRT

The Phoenix Contact FL SWITCH IRT is best for real-time tasks. It’s great for car factories where timing is key. For example, it works well with bottling and packaging machines needing quick responses. It prioritizes important data, keeping operations smooth during busy times. If your factory needs synchronized processes, this board ensures everything runs on time.

Additional Use Cases

Other PROFINET boards, like the SDS-3008 and EDS-510E, are useful too. The SDS-3008 is great for monitoring product lines and is easy to use. It helps switch from old systems without much IT knowledge. The EDS-510E works well in bottling and packaging networks. Its flexible design and high reliability keep operations running without stops.

Tip: Pick a PROFINET board based on your industry’s needs. Matching the board’s features to your tasks ensures better performance and long-lasting results.

Comparison with Alternatives

PROFINET vs. PROFIBUS

PROFINET and PROFIBUS are different in speed and use. PROFINET uses Ethernet, making it faster and more flexible. It works well with modern devices and IT systems. PROFIBUS uses a serial system and is better for older devices.

Feature | PROFINET | PROFIBUS |

|---|---|---|

Communication Type | Ethernet-based, TCP/IP or Real-Time (RT) | Serial fieldbus, master-slave architecture |

Speed and Bandwidth | Up to 1 Gbps | 9.6 kbps to 12 Mbps |

Topology | Flexible Ethernet-based (star, line, ring) | Bus or line topology |

Real-Time Performance | Superior with Profinet IRT | Lower precision real-time communication |

Device Compatibility | Modern devices, integrates with IT systems | Primarily legacy devices |

Installation and Maintenance | Easier with Ethernet setup | Needs special cables and parts |

Application Areas | High-performance systems | Older systems and simpler tasks |

Cost | Higher upfront, cheaper long-term | Cheaper upfront, costly upgrades later |

For modern factories, PROFINET is the smarter choice. It’s faster and supports advanced automation.

PROFINET vs. CAN Bus

PROFINET and CAN Bus are used for different jobs. PROFINET is great for factory automation and real-time tasks. CAN Bus is mostly used in cars for fast data sharing.

Protocol | Class/Type | Cycle Time | Typical Applications |

|---|---|---|---|

PROFINET | Class A | ~100 ms | Building automation |

PROFINET | Class B (RT) | ~10 ms | Factory and process automation |

PROFINET | Class C (IRT) | <1 ms | Motion control operations |

CAN Bus | N/A | N/A | Automotive systems |

For factory work, PROFINET is more precise and scalable. CAN Bus is good for cars but lacks the speed and flexibility for factories.

Why PROFINET Circuit Boards Are Better

PROFINET boards are faster and more adaptable than others. They allow real-time communication, which is key for automation. Unlike other systems, they connect easily with IT setups, making them future-ready.

These boards also support flexible designs, so you can build systems that fit your needs. Their Ethernet base makes setup easier and lowers maintenance costs. Plus, they’re tough enough for harsh factory conditions.

Choosing PROFINET boards gives you a reliable and scalable solution. They improve productivity and prepare your systems for future upgrades.

Factors to Consider When Choosing a PROFINET Circuit Board

Compatibility with Existing Systems

Picking the right PROFINET board means it must fit your setup. It should work well with your current tools to avoid extra costs or delays. PROFINET boards follow global rules like IEC 61158 and IEC 61784, so they connect with many devices.

To check compatibility:

Make sure the board supports your factory’s communication systems.

Confirm it has been tested with popular industrial devices.

Look for boards that can switch between protocols like Ethernet or RS-485.

Some boards have gateways to link old systems with new ones. This helps you upgrade without replacing everything. Boards with strong processors also handle future updates better.

Tip: Always pick a board that works with your setup to save time and money.

Performance Requirements

Performance is key when choosing a PROFINET board. It must meet your factory’s needs. For example, real-time communication is crucial for robots or automated vehicles.

Important performance features include:

Low Latency: Tasks need quick responses. Even a 50-millisecond delay can cause problems.

I/O Traffic: Low bandwidth is fine, but delays must be minimal.

Wireless Roaming: Wireless links should switch smoothly without delays.

Here’s a simple look at performance needs:

Performance Need | Details |

|---|---|

Communication Classes | PROFINET RT/IRT sends data fast without slowing down. |

Network Infrastructure | Must support RT/IRT without extra layers slowing it down. |

Adjustable Data Rate | Data speed can be changed to match your system. |

IO Cycle Parameters | Sets timing for data checks and error fixes. |

Boards with programmable controllers can update for new protocols. Testing ensures they work well even in tough conditions.

Note: Pick a board that matches your needs to avoid problems and keep things running smoothly.

Cost and Budget Considerations

Cost matters when picking a PROFINET board. High-quality boards may cost more upfront but save money later by lasting longer and needing less maintenance.

To choose wisely:

Compare the price with long-term benefits like reliability and upgrades.

Look for boards with parts you can replace instead of buying a whole new one.

Choose boards with strong connectors and durable designs to avoid frequent replacements.

Cheaper boards might lack features like real-time communication. But spending more now on a future-ready board can save money later.

Tip: Balance cost and features to get the best value for your money.

Scalability for Future Needs

Scalability is important for factory automation systems. When picking a PROFINET board, make sure it can grow with your factory. A scalable board lets you add devices, update protocols, and use new technology without replacing everything.

Modular Communication Interface Design

A modular design helps with scalability. Boards like this can switch between protocols like CAN, Ethernet, and RS-485. This makes it easier to connect both old and new devices.

Programmable controllers make boards even more scalable. These controllers let you update firmware to support new protocols. For example, if your factory uses a new standard, you can update the board instead of buying a new one.

Testing for compatibility is also very important. Boards that pass these tests work well with popular industrial devices. This saves time and prevents costly mistakes during setup.

Tip: Choose boards with protocol converters. These help connect old systems to new ones, making upgrades easier and cheaper.

Comprehensive EMI/EMC Design Strategy

Scalability isn’t just about adding devices. It’s also about keeping the system reliable as it grows. Electromagnetic interference (EMI) and compatibility (EMC) can cause problems in larger systems.

To fix this, PROFINET boards use grounding, shielding, and filters to block interference. Features like differential signaling and opto-isolation improve noise resistance in busy environments.

Strong connectors and tough PCBs make boards last longer. These parts handle heat, moisture, and shaking. Signal tests ensure the board works well in tough conditions, keeping communication stable as your system grows.

Future-Proof Hardware Platforms

Future-proofing is key for scalability. Boards with strong processors can handle future upgrades. This keeps your system useful as technology changes.

For example, boards with extra memory and faster processors can handle more data and harder tasks. This makes it easier to add tools like IoT devices or AI systems.

By choosing a board with future-ready hardware, you save money over time. It keeps your factory ready for new tools and challenges.

Note: Scalability isn’t just about growing now. It’s about being ready for the future. A scalable PROFINET board helps your factory stay competitive and prepared.

PROFINET boards are key for today’s industrial automation. They help machines share data quickly and work well in tough conditions. Boards like Siemens Simatic NET CP 1543-1, Hilscher CIFX 50E-RE, and Phoenix Contact FL SWITCH IRT each have special features for different tasks.

Tip: Pick a PROFINET board that fits your tools, works fast, and can grow with your system. These choices make your automation setup strong and ready for the future.

Choosing the right board boosts efficiency and gets your factory ready for new challenges.

FAQ

What makes PROFINET better than other protocols?

PROFINET is faster and works well with modern devices. Its Ethernet design allows quick data sharing, perfect for automation. It’s also scalable, so you can easily upgrade as your system grows.

Can PROFINET boards connect to older systems?

Yes, many PROFINET boards have gateways or converters. These tools link older systems like PROFIBUS to newer PROFINET setups. This way, you can upgrade without replacing all your equipment.

How do I pick the best PROFINET board for my factory?

Think about your factory’s needs. Look for boards that match your current devices, support real-time communication, and allow future upgrades. For example, Siemens Simatic NET CP 1543-1 is great for secure tasks, while Hilscher CIFX 50E-RE is very flexible.

Are PROFINET boards tough enough for harsh conditions?

Yes! PROFINET boards are made for tough places with heat, shaking, and electrical noise. Features like shielding, grounding, and strong connectors keep them working reliably in hard environments.

Do PROFINET boards work with wireless systems?

Yes, some PROFINET boards support wireless connections. They let devices switch between access points without losing data. This is helpful for factories with moving robots or automated vehicles.

Tip: Check the board’s details to ensure it supports wireless before buying.