The Industrial Internet of Things (IIoT) is transforming factories by connecting machines, systems, and workers. IIoT facilitates the collection of live data, automates tasks, and enhances work processes. For instance:

Factories utilizing shared data have reduced prototype to production IIoT manufacturing time by 23%.

Siemens’ smart factories have accelerated product creation by 50% and improved designs by 85%.

Additionally, tools like Schneider Electric’s EcoStruxure Plant Lean Management software streamline operations. They enhance efficiency by 5%, resolve issues more quickly, and decrease shift handover tasks by 33%. IIoT enables a seamless transition from testing to production, providing valuable insights and adaptable tools.

Key Takeaways

IIoT cuts manufacturing time by 23%, making work faster.

Automation with IIoT increases output by 20% or more. This makes production cheaper and easier to grow.

Predictive maintenance using IIoT lowers machine stops by 30-50%. This saves money and improves work speed.

Digital twins help create and improve designs faster. This shortens the time needed to develop products.

IIoT improves product quality by reducing mistakes by 49%. This makes customers happier and boosts sales.

How IIoT Enhances Prototype-to-Production Manufacturing

Real-Time Data for Faster Prototyping

IIoT helps speed up prototyping by using live data. It collects and analyzes data instantly, helping quick decisions and design changes. Digital twins, which are virtual copies of real items, let you test production ideas and improve designs. This has cut car development time from 5-7 years in the 1990s to just 2-3 years now.

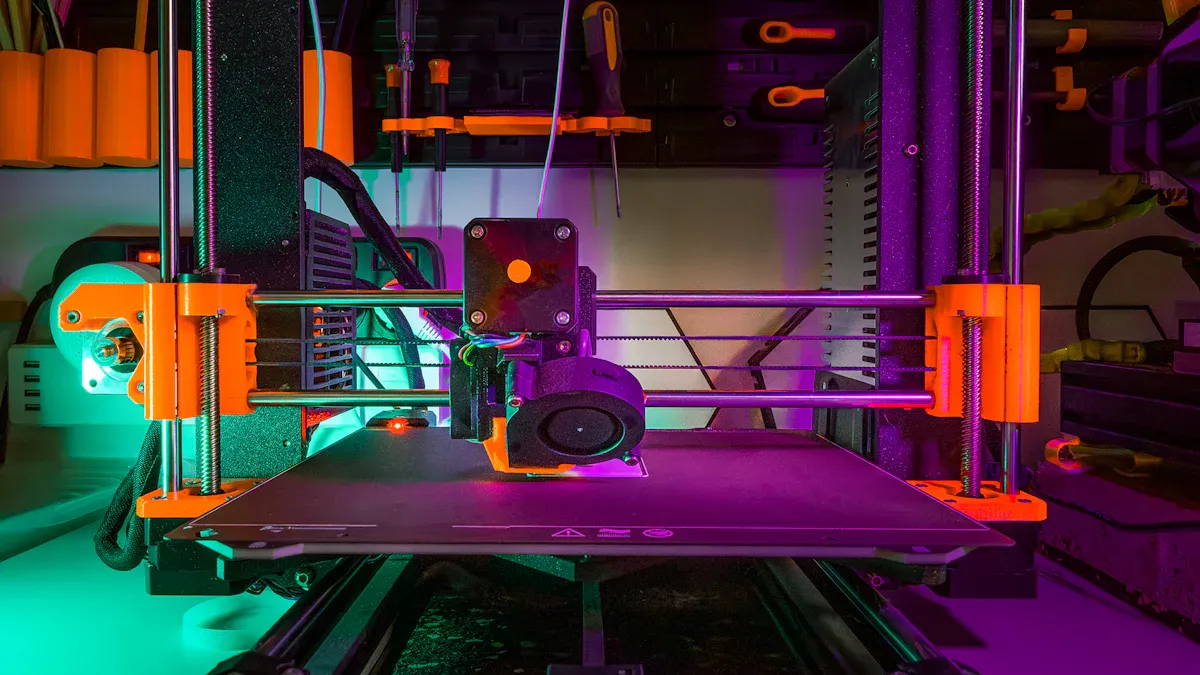

Digital manufacturing also speeds up prototyping. It shortens time-to-market by 30% and lowers planning and equipment costs by 40%. Production output increases by 15%. 3D printing, a key part of IIoT, saves up to 90% on raw materials. Programs like Protolabs’ Cool Idea Award help create smart products like security devices and water systems faster.

By watching data in real time, you can spot design problems early. This reduces mistakes, saves money, and makes moving from prototype to production smoother.

Automation for Scalable Production

Automation is key to IIoT, making production easier to grow. IoT tech automates tasks, improves workflows, and boosts productivity. For example, 6LoWPAN networks in ZephyrOS create energy-saving, stable connections in factories.

Automation does more than scale production. Ayyeka’s system shows how IIoT boosts efficiency with real-time monitoring and secure data sharing. Here are some benefits:

Metric | Improvement Percentage |

|---|---|

Productivity increase | |

Lower operational costs | 15% or more |

Less equipment downtime | 50% or more |

More equipment uptime | 20-25% |

Better labor productivity | 15-20% |

Using IIoT automation ensures steady quality, cuts costs, and meets market needs.

Predictive Maintenance to Minimize Downtime

Predictive maintenance with IIoT reduces downtime and keeps work smooth. Unlike old methods, it uses sensors and data to check equipment health live. This finds problems early, avoiding expensive breakdowns.

Factories using predictive maintenance cut machine downtime by 30-50% and maintenance costs by 10-40%. McKinsey & Company says it lowers unplanned downtime by 10-20%. This boosts efficiency and makes machines last longer.

With predictive maintenance, your factory runs without interruptions. It raises productivity, lowers costs, and helps move from prototype to production easily.

Benefits of IIoT in Manufacturing

Better Product Quality and Consistency

IIoT helps make products better and more consistent. Sensors watch every production step to catch mistakes early. This reduces errors and keeps quality high. Companies using IIoT have cut defects by 49%. Fewer bad products mean happier customers.

IoT tools also study data to find defect patterns. Fixing problems early stops bigger issues later. A beauty company in Korea lowered defects by 54% with IIoT. These tools help keep standards high and deliver reliable products every time.

Quicker Time-to-Market

IIoT speeds up how fast products are made. Tools like digital twins and automation test designs quickly. This shortens the time from idea to production. The same Korean beauty company cut product launch time by 50%.

IoT platforms also improve teamwork by sharing information faster. Teams work better together, getting products to market sooner. Faster launches help meet customer needs and stay ahead of trends.

Improved Operational Efficiency

IIoT makes factories run better and smarter. IoT tools give live data to improve processes. About 43.1% of companies use IoT for process fixes, while 41.1% use dashboards to track progress. These tools show where to improve.

Factories using IoT have boosted efficiency by up to 82%. Better tracking also increases production efficiency by 20%. IIoT reduces waste, saves energy, and raises productivity. This makes operations cheaper and eco-friendly.

Applications of IIoT in Prototype-to-Production Processes

Digital Twin Technology for Prototyping

Digital twins are virtual copies of real products. They help test and improve designs before making physical items. You can try different materials and processes without wasting resources. This saves time and reduces mistakes.

Additive manufacturing uses digital twins to monitor and improve production.

Virtual tests find problems early and make designs better.

Companies using digital twins finish product development faster and succeed more often.

Tesla uses digital twins for car safety tests. They ran over 2 million virtual crash tests. This cut development time and earned top safety ratings. Digital twins reduce prototyping steps, save money, and speed up production.

Smart Factory Automation

Smart factories use IoT devices to automate tasks and track equipment. They improve productivity and reduce waste. Automation makes factories run better and use fewer resources.

Smart factories track energy use and equipment wear to save resources.

Connected devices and smart tools improve production and lower environmental harm.

Automation boosts productivity and cuts energy use significantly.

Smart factories collect and study data automatically. This helps fix problems quickly and lowers defect rates. Material waste drops, and quality improves. IoT in factories ensures steady production and meets market needs.

Improvement Category | Measurable Improvement |

|---|---|

Productivity Enhancements | |

Energy Efficiency | 10-20% reduction in energy consumption |

Material Utilization | Up to 30% reduction in waste materials |

Quality-related Savings | 20-35% reduction in quality-related costs |

Defect Rate Reduction | 25-45% reduction in defect rates |

Process Capability Index (Cpk) | Shift from 1.0-1.33 to 1.67-2.0 |

Smart factories make work faster, cheaper, and more reliable. They help businesses stay ahead in manufacturing.

Supply Chain and Inventory Optimization

IIoT improves supply chains and inventory management. It gives live updates on every step of the process. You can track items, check stock levels, and avoid problems.

Real-time tracking prevents delivery delays and lowers fuel costs.

Predictive maintenance stops breakdowns before they happen.

Monitoring inventory ensures proper storage and avoids waste.

Evidence Type | Statistic/Impact Description | Source Link |

|---|---|---|

Cost Reduction | Predictive maintenance can reduce overall maintenance costs by up to 30%. | |

Operational Cost Savings | Companies have reported operational cost savings in freight and logistics sectors. | N/A |

Efficiency Improvement | Real-time tracking and predictive maintenance lead to reduced fuel costs and transportation delays. | N/A |

IoT gives full control over supply chains, from raw materials to finished goods. This reduces losses, improves efficiency, and keeps production running smoothly.

Real-World Examples of IIoT in Manufacturing

Automotive Industry Innovations

IIoT has changed how cars are made. It makes factories work better and saves money. Predictive maintenance helps avoid sudden machine breakdowns. It also lowers repair costs. Watching machines in real time finds problems early. This keeps everything running smoothly.

Car makers have seen big improvements:

Improvement Type | Percentage Change |

|---|---|

Less unplanned downtime | 40% |

Lower maintenance costs | 25% |

Fewer product defects | |

Better production efficiency | 20% |

Watching processes closely helps fix problems early. This reduces mistakes and improves machine performance. Fewer errors mean better products and faster production.

Consumer Electronics Advancements

IIoT has improved how electronics are made. Factories use IoT tools to make production lines faster and waste less. One company boosted production by 20% and cut material waste by 10%.

Here’s how IIoT helps electronics factories:

Performance Metric | Improvement Percentage |

|---|---|

Lower maintenance costs | 30% |

Less downtime | 70% |

These changes make production quicker, cheaper, and better for the planet.

Aerospace and Defense Applications

IIoT helps make planes and defense tools faster and better. It improves supply chains and speeds up production. Digital tools connect every step of the process. This gives live updates and clear tracking.

Supply chains work 16% better.

Products are made faster.

A Deloitte study says 78% of people think digital tools improve tracking.

These tools help factories avoid delays and keep quality high. They make aerospace and defense production more efficient and reliable.

Steps to Use IIoT in Manufacturing

Setting Up IIoT Systems

To use IIoT well, follow clear steps. First, check your current tools and find areas where IIoT can help. Look for things like fixing machines before they break or watching data live. After finding these areas, pick tools like sensors or data platforms that match your needs.

Good connections are key for IIoT. Make sure devices talk to each other easily by setting up strong networks. Then, connect IIoT tools to your factory systems without causing problems. Test the setup on a small scale first to ensure it works. Train your workers to use and take care of the new tools.

Following these steps helps you get the most from IIoT. It makes factories run better, saves money, and gives a clear view of production.

Solving Problems with IIoT

Using IIoT can be tricky. Security is a big worry because connected devices might seem risky. To fix this, use strong security tools and follow safety rules. Sometimes, connecting new tools to old systems is hard. You’ll need good tools to find and fix these issues fast.

Training workers is another challenge. Learning new systems takes time and can slow work at first. But training helps machines work better and reduces downtime later. By solving these problems early, you can fully enjoy the benefits of IIoT.

Problem | Effect |

|---|---|

Fear of risks from connected devices slows IIoT use. | |

Connection Problems | Need better tools to fix issues when linking systems. |

Worker Training | Workers need time to learn IIoT, which may slow work. |

Working with IIoT Experts

Teaming up with IIoT experts makes things easier. These experts know how to set up systems that fit your needs. They help you plan, check your current tools, and find what’s missing. Working together ensures you pick the right tools and manage data well.

Experts also help connect IIoT tools to your factory smoothly. Their help improves how things work, lowers machine problems, and uses resources better. With their support, you can switch to smart factories faster and stay ahead in the industry.

IIoT is changing how factories work. It connects prototyping and production with live data, smart tools, and automation. These technologies make work faster, easier, and more creative. Using IIoT helps you stay competitive and meet new challenges. If you ignore it, others may get ahead with better and quicker methods. Start using IIoT now to improve your manufacturing process.

FAQ

What is IIoT, and how is it different from IoT?

IIoT means Industrial Internet of Things. It connects machines and systems in factories. IoT focuses on consumer devices like smart homes. IIoT improves factory work, making it faster and more efficient.

How does IIoT make factories better?

IIoT uses live data and smart tools to improve work. It lowers downtime, boosts product quality, and reduces waste. Watching processes closely helps find and fix problems quickly.

Can small factories use IIoT?

Yes, IIoT works for small businesses too. Affordable tools like cloud systems and sensors make it easy to start. Small factories can begin with one area, like machine maintenance, and grow over time.

What problems come with using IIoT?

Challenges include keeping data safe, connecting old and new tools, and training workers. Solve these by using secure networks, picking the right tools, and teaching your team how to use them.

How do you start using IIoT in a factory?

First, find areas to improve, like cutting downtime or fixing quality. Pick tools like sensors or data systems that match your needs. Test them on a small scale, train your workers, and expand slowly.

See Also

The Importance of PCBA Prototyping in Electronics Development

Key Phases Involved in the PCBA Manufacturing Workflow

Strategies to Enhance Efficiency in PCBA Production Processes

Essential Advice for Overcoming PCBA Manufacturing Obstacles