Robotics PCB assembly USA utilizes advanced robots to manufacture circuit boards, enhancing precision, speeding up production, and increasing output. In the USA, this technology drives innovation and supports the growth of electronics and manufacturing industries. By adopting robotics PCB assembly USA, companies improve efficiency and strengthen their global competitiveness. It represents a significant leap forward in automation and the creation of superior electronic products.

Key Takeaways

Robotics PCB assembly uses machines to make circuit boards faster.

This method cuts errors and boosts quality, helping big industries compete.

Using robots can save money by working faster and needing less labor.

Robots can work with small parts carefully, which is key for new gadgets.

Improving robotics is important to meet future needs and make things better.

Understanding Robotics PCB Assembly

What is robotics PCB assembly?

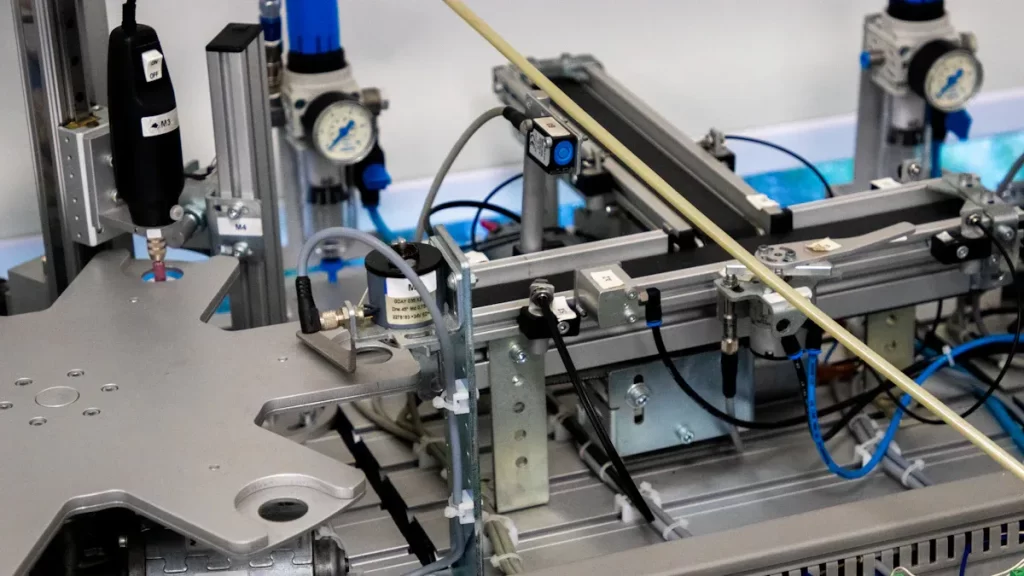

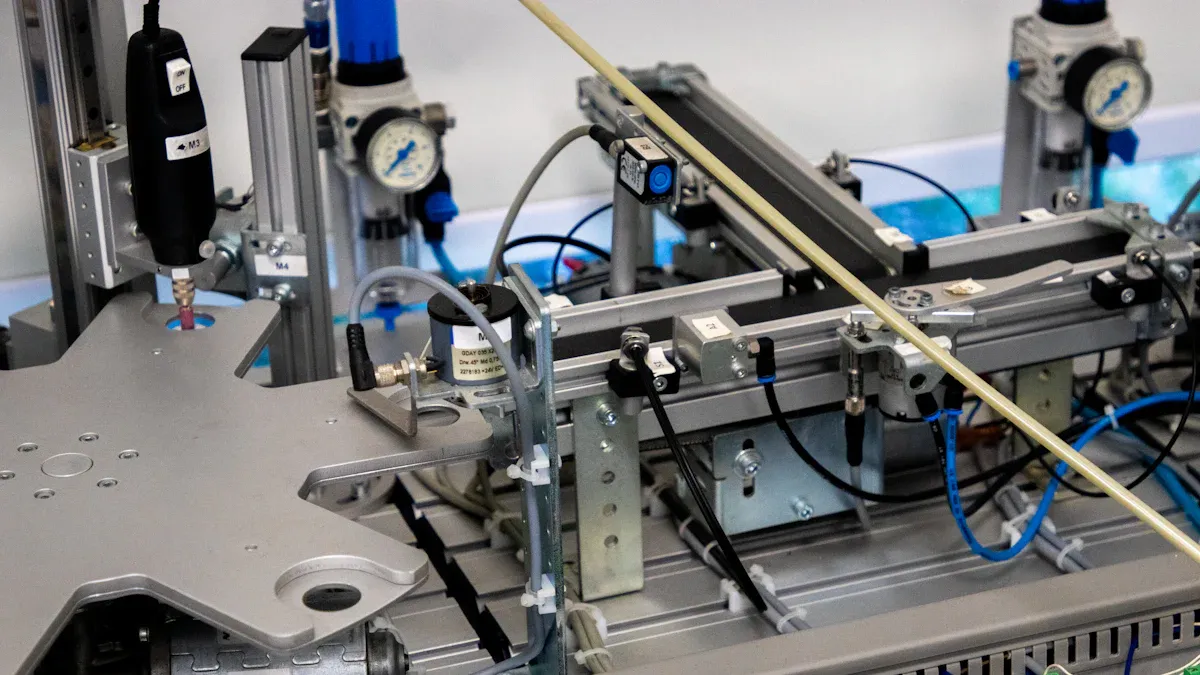

Robotics PCB assembly means using robots to make printed circuit boards (PCBs). These boards are like the “nervous system” of electronic devices, helping them work properly. In robots, PCBs are very important. They help power the robot and control its movements. Every part on the PCB has a job, like sensors that collect data or parts that help the robot move.

Tip: Think of a PCB as the “brain” of a robot. Without it, the robot can’t think or do tasks correctly.

Using robots for PCB assembly makes repetitive tasks easier. It also reduces mistakes, speeds up work, and keeps quality consistent. Adding robots to this process helps meet the need for better electronics while staying precise and reliable.

Key components and processes in robotics PCB assembly

Robotics PCB assembly uses important parts and steps to make sure robots work well in electronics production. Here are some key parts:

Power supply: Gives energy to the robot.

Control system: Works like the brain, telling the robot what to do.

Sensors: Collect information about the surroundings.

Actuators: Help the robot move and interact with things.

Feedback mechanisms: Let the robot adjust based on new information.

The process includes placing parts, soldering, and checking for mistakes. Cool tools like vision-guided robots and fast connectors help make everything accurate. For example, special modules manage energy, and fast connectors help parts talk to each other quickly.

Note: New ideas like ceramic materials and cooling systems make PCBs stronger and better at handling heat. This is great for tough jobs like robotics.

Benefits of robotics in electronics assembly

Robotics PCB assembly brings big improvements to electronics production. Here are some benefits:

Benefit | Description |

|---|---|

Production Speed | Robots make more products faster and with fewer mistakes. |

Quality Control | Robots with sensors check for mistakes to ensure good quality. |

Accuracy and Precision | Robots do tasks very accurately, meeting high standards. |

Real-time Monitoring | Robots use data to watch for problems and fix them quickly. |

Labor Efficiency | Robots can handle thousands of parts, freeing workers for harder tasks. |

Cost Reduction | Robots save money by lowering costs and boosting profits. |

Using robotics PCB assembly means faster production, better products, and lower costs. These advantages are vital for industries like electronics, cars, and airplanes.

Comparing Robotics PCB Assembly with Traditional Methods

Manual vs. robotics PCB assembly

When we compare manual and robotic PCB assembly, the differences are clear. Manual assembly depends on people to place and solder parts. This can cause mistakes and uneven quality. Robotic assembly uses machines that are precise and consistent. This reduces errors and makes production faster.

Aspect | Manual Assembly | Automated Assembly |

|---|---|---|

Error Rate | Higher because of human mistakes | Lower due to machine accuracy |

Consistency | Changes based on worker skill | Very steady, follows strict rules |

Production Speed | Slower, limited by human speed | Faster, machines work nonstop |

Cost Efficiency | Higher because of labor costs | Lower, saves time and money |

Quality Control | Uneven, more likely to have defects | Reliable, fewer defects and better quality |

Robotic PCB assembly gives better results by removing human errors. Machines follow exact rules, so products are always reliable and high-quality.

Advantages of robotics in industrial PCB assembly

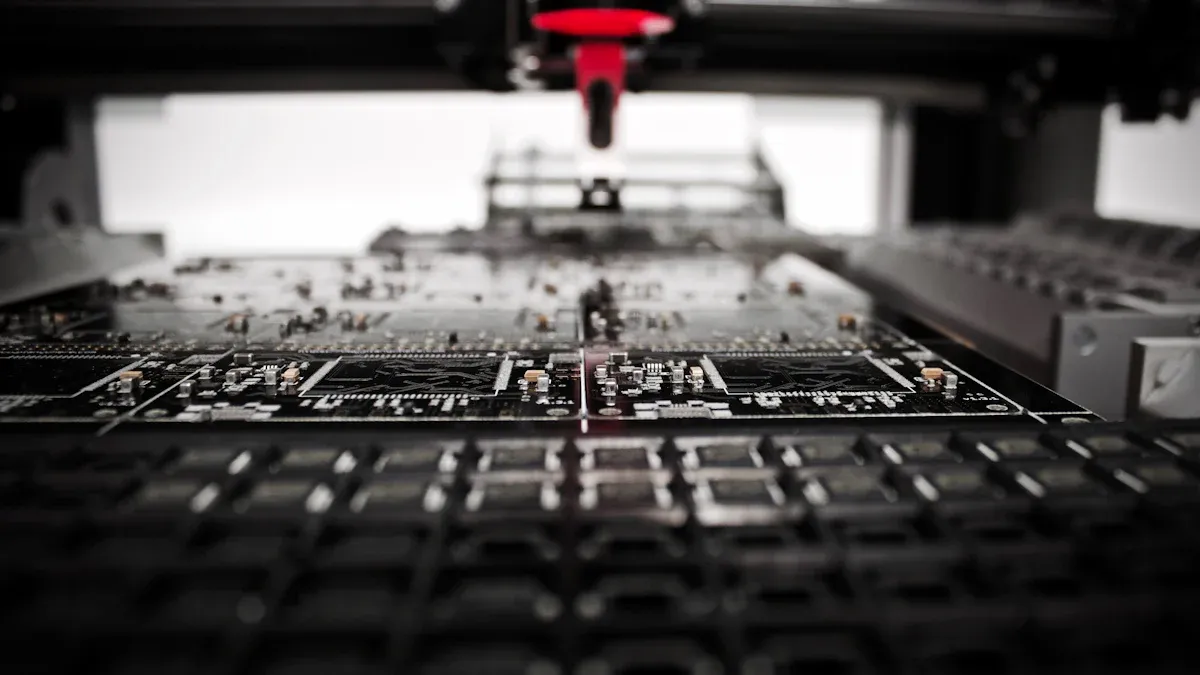

Robots bring many benefits to industrial PCB assembly. They work faster than people, making more products in less time. Robots are also very accurate, which is important for industries like healthcare and aerospace. With real-time checks, robots find and fix problems quickly, reducing waste and improving efficiency.

For example, the KR AGILUS robot uses smart vision systems to check parts in real time. It finds mistakes with 99.2% accuracy, much better than older methods. These improvements make robots essential for industries needing speed and precision.

Cost-effectiveness and long-term impact

Buying robots may seem costly at first, but it saves money later. Robots lower labor costs and reduce mistakes, which saves money over time. In one Siemens factory, robots cut PCB defects by 30%. This made products more reliable and cheaper to make.

Robots also use machine learning to improve processes. They use smart programs to work faster and more accurately. Over time, these benefits make robots a great choice for PCB assembly. They help companies stay ahead in a fast-moving market.

Applications of Robotics PCB Assembly in the USA

Electronics assembly in robotics and automation

Robotics PCB assembly helps improve robotics and automation in the USA. Robots need strong PCBs to work well. These PCBs control sensors, actuators, and systems inside robots. Using robots for PCB assembly makes these systems more precise and reliable.

The demand for humanoid robotics PCBs is growing fast. By 2030, this market may reach $7.91 billion, growing at 21.7% each year. This shows how important advanced PCBs are for robotics. Whether for factory robots or home helpers, robotics PCB assembly ensures top performance and durability.

Tip: Special materials like ceramics and cooling systems make PCBs last longer and work better in tough conditions.

Role in consumer electronics and automotive industries

Robotics PCB assembly is key for making smaller, smarter devices. As gadgets shrink, manual assembly becomes harder. Robots handle tiny parts carefully, ensuring high-quality results. For example, robots can screw or glue parts with great accuracy, boosting production by 25%.

In cars, robotics PCB assembly helps build electronic systems for safety and comfort. These include driver-assistance tools, entertainment systems, and electric car parts. Robots adapt easily to new trends like electric and self-driving cars. They can be reprogrammed for future needs, making production flexible.

Trend Description | Impact on PCB Assembly |

|---|---|

Robots make assembly faster and more accurate than humans. | |

High labor costs in the U.S. | Robots help cut costs for manufacturers. |

Advancements in robotics | Smarter robots improve assembly and lower costs. |

Note: Robotics PCB assembly saves money and keeps quality high, which is vital for electronics and car industries.

Contributions to aerospace, healthcare, and defense sectors

Robotics PCB assembly is crucial for aerospace, healthcare, and defense. In aerospace, PCBs are used in navigation, communication, and avionics systems. These systems must meet strict standards because even small errors can be dangerous.

In healthcare, advanced medical tools need high-quality PCBs. These PCBs are found in monitors, imaging machines, and surgical robots. Robotics PCB assembly ensures these devices work well, helping doctors save lives.

Defense electronics like radar and drones also rely on strong PCBs. These PCBs must work in harsh conditions. Surface mount PCB assembly services are vital for meeting these tough demands.

Example: A report shows rising demand for advanced PCBs in healthcare and aerospace. These PCBs are critical for tools like medical imaging and airplane systems.

Robotics PCB assembly helps these industries improve efficiency, performance, and innovation. This keeps them competitive worldwide.

Challenges and Advancements in Robotics PCB Assembly

Common challenges in robotics PCB assembly

Robotics PCB assembly faces many problems. Old technology and low budgets often cause delays. Some electronics makers use systems that are 18 to 24 months behind current trends. This makes it hard to keep up with new ideas in PCB assembly.

Upgrading old systems is another big issue. Many companies still use control systems from the 1990s. These systems are not flexible enough for modern robotics needs. Operations also get tricky because incomplete systems rely on outside vendors to fill gaps.

Here’s a list of key challenges:

Trend/Challenge | Description |

|---|---|

Outdated Technology | Makers use systems that lag behind industry trends. |

Insufficient Investment | Small budgets slow down upgrades and innovation. |

Complex Systems Upgrades | Old systems are hard to update for modern needs. |

Old Control Systems | Factories depend on outdated tech from decades ago. |

Fragmented Technology Stacks | Incomplete setups make work harder and less efficient. |

Mistakes in design or placing parts can cause defects. Problems like solder bridges or lifted pads may happen. Missing or repeated items in the BOM list also create confusion during assembly.

Tip: Fixing these problems means using newer systems and spending more on better technology.

Technological advancements driving innovation

New technology is changing robotics PCB assembly. Automation tools now make work faster and reduce mistakes. AI and machine learning help improve assembly lines. These tools study data to predict repairs and boost accuracy.

Industry 4.0 ideas, like IoT, allow real-time tracking of assembly. Predictive maintenance keeps machines running well and reduces downtime. Safer designs and quick setup changes make robotics PCB assembly more flexible.

Here are some exciting advancements:

AI and machine learning improve accuracy.

IoT helps monitor processes in real time.

Predictive maintenance reduces machine downtime.

Quality checks ensure consistent results.

Safety features create better working conditions.

These improvements make PCB assembly faster, smarter, and more reliable.

Compliance with standards and environmental considerations

Following rules ensures robotics PCB assembly is safe and reliable. Mil-Spec and IPC Class 3 set high standards for quality. These rules are important for industries like aerospace and healthcare.

Compliance Standard | Description |

|---|---|

Mil-Spec | Defense rules for strong and reliable PCBs. |

IPC Class 3 | Military-grade PCBs tested for top quality. |

Environmental care is also important. Tests check how materials handle stress, heat, and moisture. Nano-coatings like parylene protect PCBs from water while letting heat escape. This meets MIL-STD-810H rules for tough conditions.

Note: Using nano-coatings improves PCB durability and makes them work better in harsh environments.

By following strict rules and using smart designs, robotics PCB assembly can meet the highest standards for quality and performance.

The Future of Robotics PCB Assembly in the USA

Emerging trends in robotics PCB assembly USA

Robotics PCB assembly is changing quickly due to new technology and market needs. Some key trends include:

The robotics PCB assembly market will grow from $1.5 billion in 2024 to $3.8 billion by 2033, with a yearly growth rate of 10.5% starting in 2026.

Automation in electronics is improving accuracy and lowering labor costs.

U.S. government programs, like the Advanced Manufacturing Partnership, support robotics in industrial PCB assembly.

Robots with vision systems are finding defects during large-scale production, improving quality.

These trends show how robotics is becoming essential for better PCB assembly processes.

Growth potential in industrial PCB assembly

Industrial PCB assembly in the USA has huge growth opportunities. The global PCB market is expected to reach $85.8 billion by 2027, growing at 5.1% each year. Robotics is helping this growth by using AI and IoT to handle hard tasks and analyze data instantly. This makes work faster and reduces delays.

Cobots, or robots that work with people, are becoming popular. They improve safety and help workers be more productive. As U.S. factories focus on smart manufacturing, companies are spending more on automation. This makes industrial PCB assembly quicker, more precise, and less expensive.

Importance of continued innovation and investment

Innovation and investment are key for robotics PCB assembly to succeed. Tools like AI, IoT, and vision-guided systems are changing the industry. To stay ahead, companies need to update old systems and use Industry 4.0 methods.

Government help is also important. Policies that encourage robotics and automation can keep the USA leading in industrial PCB assembly. By focusing on new ideas, manufacturers can make better PCBs while saving money and working more efficiently.

Tip: Spending on advanced robotics increases productivity and helps businesses stay strong in a competitive market.

Robotics PCB assembly in the USA helps industries grow and improve. It makes production faster, more accurate, and easier to scale. By encouraging new ideas, it helps American factories compete worldwide. As technology changes, this field can bring big improvements. Spending on robotics now keeps you ready for future industrial challenges.

FAQ

What is the main purpose of robotics PCB assembly?

Robotics PCB assembly uses machines to build printed circuit boards (PCBs). It makes the process faster, more accurate, and less prone to mistakes. This helps industries like electronics, cars, and airplanes make better products.

How does robotics PCB assembly save costs?

Robots cut down on labor costs and reduce mistakes in production. They work quicker than people, making more products with less waste. Over time, the money saved is more than the cost of buying robots.

Tip: Buying robots early can help you save money later.

Can robotics PCB assembly handle small components?

Yes, robots are great at working with tiny parts. They use special cameras and tools to place and attach small pieces. This is much harder for people to do by hand.

What industries benefit most from robotics PCB assembly?

Industries like electronics, cars, airplanes, healthcare, and defense benefit a lot. Robotics PCB assembly helps make reliable products like medical tools, electric car parts, and communication devices.

Is robotics PCB assembly environmentally friendly?

Yes, it creates less waste and uses less energy. Robots also use materials that are safer for the environment and follow green rules like RoHS. This makes the process better for the planet.

Note: Using robotics PCB assembly helps protect the environment. 🌱

See Also

Understanding PCBA Manufacturing and Its Importance in Industry

Exploring PCBA Services and Their Significance in Electronics

The Importance of Turnkey PCB Assembly in Production