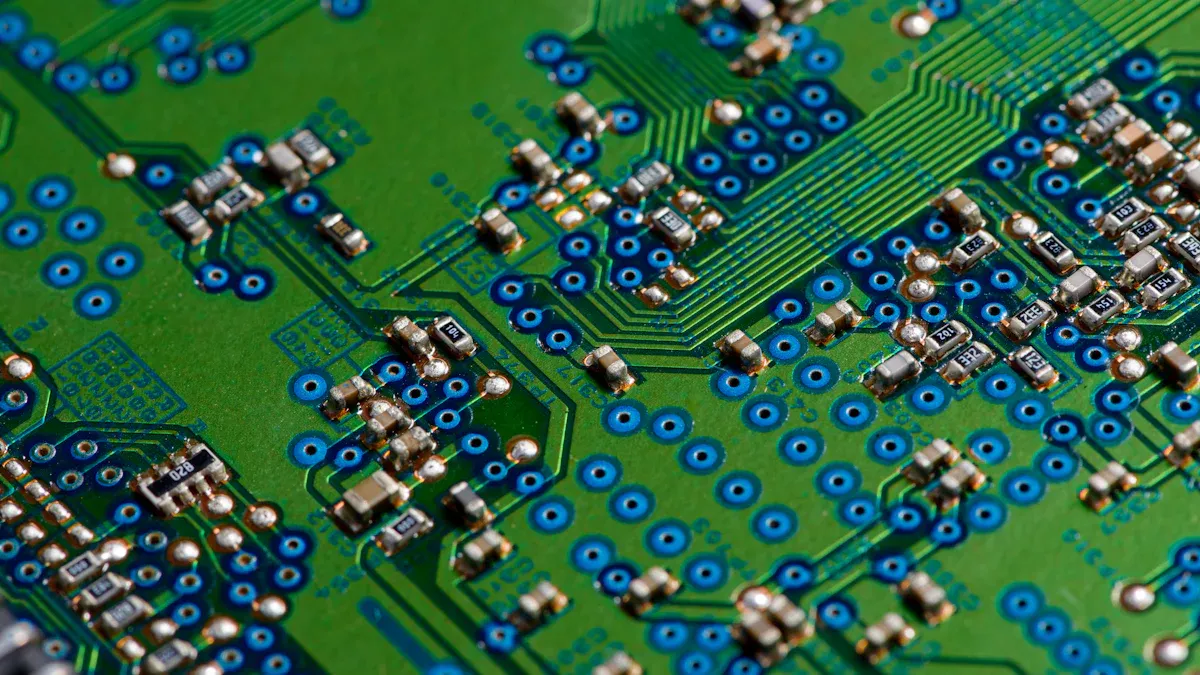

Ruggedized industrial sensor PCB assembly for harsh environments is crucial for ensuring that industrial sensors operate effectively in tough conditions. These specialized circuit boards are designed to tackle challenges that standard boards cannot manage. For instance, multilayer PCBs are more robust, better at heat management, and maintain signal clarity compared to single-layer boards. They also minimize material waste and require less energy during production.

Utilizing ruggedized industrial sensor PCB assembly for sensors in harsh environments guarantees their longevity and reliable performance. These PCBs are engineered to withstand temperature fluctuations, moisture, vibrations, and electromagnetic interference, making them exceptionally valuable in demanding settings.

Key Takeaways

Strong PCBs are important for sensors in tough places. They guard against heat, water, and shaking.

Using strong PCBs makes sensors work better and last longer. This means fewer problems and cheaper repairs.

Strong PCBs help sensors give better data by blocking interference and damage.

Spending on strong PCBs saves money over time. They make sensors last longer and cut delays in industries like oil, gas, and factories.

Taking care of sensors and PCBs is very important. Finding problems early stops big failures and keeps things safe.

Challenges rugged sensors face in tough environments

Industrial sensors work in places that test their limits. These tough sensors handle conditions that regular sensors cannot survive. Below are some common problems they deal with:

Temperature changes and heat stress

Extreme heat and cold can harm sensors. High temperatures can ruin coatings and damage parts inside. Cold weather can make sensors brittle and cause condensation. Outdoor sensors in rain, snow, or sunlight face quick temperature shifts. If a sensor goes beyond its safe temperature range, it might stop working. Industries like oil, gas, aerospace, and cars often deal with these extremes. They need sensors built to handle heat stress.

Tip: Ruggedized industrial sensor PCB assembly uses special materials and heat control methods. This keeps sensors working even in very hot or cold conditions.

Problems from water, humidity, and chemicals

Water and humidity can hurt sensors badly. Water can get inside and cause short circuits or mess up optical parts. Humidity can make sensors absorb moisture, which stops them from working right. Chemicals in factories can wear down sensor coatings and weaken them. For example, photoelectric sensors can be blocked by dust or water, making them less accurate.

Effect on Coatings | Impact on Sensor Performance | |

|---|---|---|

Temperature | Heat damage | Reduced effectiveness |

Humidity | Moisture absorption | Problems with functionality |

Chemicals | Coating damage | Weakened reliability |

Vibrations, shocks, and hits

Sensors in tough places face constant shaking and sudden impacts. Machines, mining tools, and factory systems create vibrations that loosen parts or break components. Accidents like bumps can also hurt sensors. Without strong protection, these forces cause failures and expensive repairs.

Rugged sensors are made to handle these problems. Their PCBs use shock-absorbing materials and strong connections. This helps them keep working even when hit or shaken hard. This toughness is vital for industries like mining and manufacturing, where machines face heavy stress every day.

Electromagnetic interference (EMI) and electrical noise

Electromagnetic interference (EMI) and electrical noise can mess up sensor performance. These issues often come from nearby devices, power lines, or the equipment itself. When EMI affects sensor signals, it can cause wrong readings or signal loss. This is why controlling EMI is so important in places needing accuracy.

Electrical noise can change the signals sensors need to work properly. For example:

Ground loops and EMI often create noise in vibration systems.

Weakly shielded cables pick up interference, ruining sensor data.

Analog circuits, which handle weak signals, are easily affected by noise.

In factories, electric currents can accidentally make noise in circuits. This noise moves through cables and lowers sensor accuracy. Without good shielding, even small interference can harm your equipment’s reliability.

To fix these problems, ruggedized industrial sensor PCB assembly uses advanced EMI shielding methods. These include special materials and EMI filters. Shielding blocks outside interference from reaching sensitive parts. This keeps sensor signals clear and accurate. By cutting noise, these PCBs help sensors give reliable data, even in noisy environments.

Note: Using EMI-resistant PCBs boosts sensor performance and lowers system failure risks from bad signals.

Features of ruggedized industrial sensor PCB assembly for harsh environments

Strong materials and protective layers

Ruggedized PCBs use tough materials to last in harsh places. They handle extreme heat, vibrations, and harmful chemicals. Protective layers keep them safe from damage.

Conformal coatings like acrylic and epoxy protect against water, dust, and heat. These layers stop environmental damage to sensitive parts.

Testing methods, such as vibration tests, check if PCBs can handle stress. This ensures they stay functional under tough conditions.

Choosing strong materials and smart designs makes PCBs more durable. For example, using high-strength materials and protective covers shields parts from impacts.

Did you know? High heat can crack solder joints and lower device life. Strong materials reduce these risks and improve performance over time.

Better heat control methods

Managing heat is key to keeping PCBs working well. Without good heat control, high temperatures can damage parts and cause failures. Ruggedized PCBs use advanced ways to handle heat.

High-Tg FR-4 materials and polyimide laminates resist high heat for long periods. These materials don’t break down easily in hot conditions.

Designs with ground planes and metal cores spread heat evenly. This stops hotspots that could harm parts.

Tests like thermal cycling and HALT check if PCBs can survive big temperature changes.

For instance, a car part maker built a control unit that works at 150°C. They used high-Tg FR-4 and ground planes, proving these methods work well.

Pro Tip: Good heat control makes devices last longer and prevents overheating problems.

Protection from water and chemicals

Water and chemicals can ruin PCBs in industrial settings. Ruggedized PCBs are made to resist these dangers and work reliably.

Special coatings or potting compounds block water, humidity, and chemicals. These layers stop moisture from causing failures.

Anti-corrosion features help PCBs last longer, cutting repair costs. With the right protection, industrial PCBs can work for 5 to 15 years or more.

Sealing parts and using corrosion-proof materials improve reliability in tough environments.

Why it matters: Water and chemical resistance keep sensors working in places like factories or offshore sites where exposure is common.

By using these features, ruggedized PCBs ensure sensors stay strong and reliable, even in extreme conditions.

Shock and vibration resistance

In factories, sensors face constant shaking and sudden hits. These forces can loosen parts, crack joints, or break pieces. If sensors stop working, it can cause expensive delays and fixes. Ruggedized PCBs are built to handle these stresses. They keep sensors working even in tough conditions.

To resist shocks and vibrations, ruggedized PCBs have special features:

Reinforced connections: Strong joints and connectors keep parts in place.

Flexible PCB designs: These designs bend slightly to absorb vibrations.

Shock-absorbing materials: Rubber or silicone layers soften the impact of hits.

For example, mining machines create nonstop vibrations. A ruggedized PCB for harsh places helps sensors survive these forces. This strength is important to keep work going in hard environments.

Tip: Check your sensors often for damage. Fixing small problems early avoids big failures.

EMI shielding for signal integrity

Electromagnetic interference (EMI) can mess up sensor signals. It can come from machines, power lines, or even the sensors. Without good shielding, EMI can cause wrong readings or lost signals. This makes your systems less reliable.

Ruggedized PCBs solve this with advanced EMI shielding. These include:

Conductive coatings: Special layers block outside electromagnetic waves.

Ground planes: These layers inside the PCB absorb and redirect EMI.

EMI filters: Filters remove unwanted noise, keeping signals accurate.

In factories, precision is key. Ruggedized PCBs with strong EMI shielding keep signals clear. This ensures sensors give correct data, even in noisy electrical areas.

Did you know? Weak EMI shielding can cause random sensor problems. These are harder to find than total failures.

With these features, ruggedized PCBs improve sensor performance and reliability. They help systems run smoothly, even with shocks, vibrations, and EMI around.

Benefits of ruggedized PCBs for industrial sensors

Better reliability and steady performance

Ruggedized PCBs make industrial sensors more reliable. They use strong designs and manage heat well to work longer. For example, robots and control systems need these features to stay stable. Ruggedized PCBs handle tough conditions like heat and shaking, so sensors keep working.

You can count on ruggedized PCBs for steady performance in factories. Their tough build lowers the chance of breaking, even under stress. This means your machines run smoothly, with fewer stops and better productivity.

Longer life and lower repair costs

Ruggedized PCBs help sensors last longer and need fewer repairs. They are made to handle wear and tear, cutting down on fixes. For instance, they improve reliability by 47%, making sensors fail less often. This saves 25-30% in costs and reduces downtime by 30-50%.

Benefit | Improvement |

|---|---|

Reliability Boost | 47% MTBF increase |

Cost Savings | 25-30% |

Downtime Reduction | 30-50% |

Spending on ruggedized PCBs saves money on fixing and replacing sensors. They are a smart choice for keeping your sensors working longer.

More accurate data collection

Ruggedized PCBs help sensors collect accurate data by protecting them. Their strong design keeps sensors precise in tough places. For example, they block moisture, dust, and shaking, so sensors stay accurate.

Good designs also protect sensitive parts. Ruggedized PCBs stop outside problems from messing up sensors. This protection ensures sensors give correct data, which helps you make better decisions in factories.

Tip: Accurate sensors make factory work more efficient and improve results.

Increased safety and minimized risk of system failures

Ruggedized PCBs help make industrial sensors safer and more reliable. Their strong design keeps sensors working well, even in dangerous places. By stopping malfunctions, they prevent accidents and costly delays.

One way ruggedized PCBs improve safety is by finding problems early. For example:

Failure Mode and Effects Analysis (FMEA) spots possible sensor issues. It focuses on risks that could cause serious harm, like injuries.

FMEA suggests fixes to keep systems safe and working properly.

In one case, using FMEA lowered defect rates from 5500 PPM to 900 PPM. This made products much better.

Testing makes ruggedized PCBs even safer. These tests copy tough conditions to check if sensors can handle high voltage and other challenges. This reduces risks and ensures top performance. Better quality checks have also cut errors by 0.76%, making sensors more dependable.

Ruggedized PCBs protect equipment from things like water, heat, and shaking. This lowers the chance of failures that could cause danger. For example, in mining or oil industries, a broken sensor could lead to big problems. Ruggedized PCBs reduce these risks and keep work safe.

Tip: Check your sensors and PCBs often to keep them in good shape. Regular care can stop problems before they happen and improve safety.

Ruggedized PCBs not only make sensors work better but also create safer workplaces. Their strength and dependability are important for industries in tough environments.

Applications of ruggedized industrial sensor PCB assembly for harsh environments

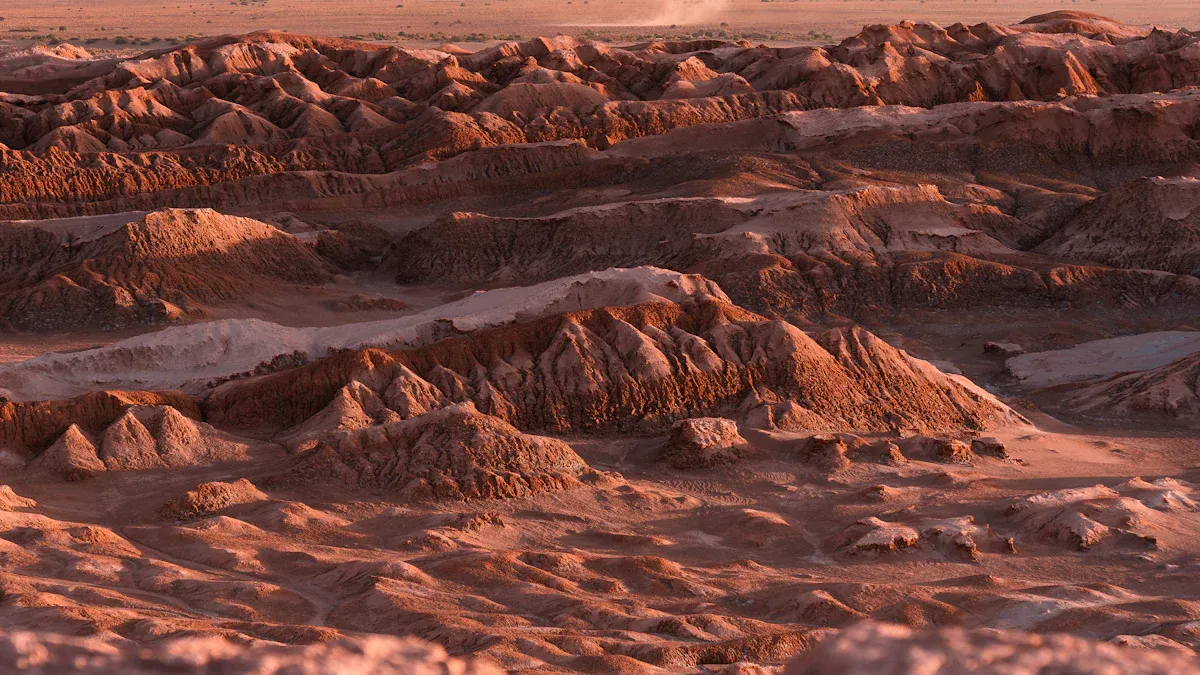

Oil and gas exploration and monitoring

Ruggedized PCBs are important in oil and gas work. They help sensors survive heat, shaking, and harsh chemicals. For example, LWIR sensors find leaks and check pipelines. These sensors measure temperature without touching, improving safety and efficiency. This makes them essential for exploration and monitoring.

Sensors also track vibrations in pumps and turbines. These machines face constant stress in oil and gas facilities. Ruggedized PCBs keep sensors working, reducing downtime and improving reliability. Wireless sensors are now used for remote vibration checks. Combined with predictive maintenance, they make operations even better.

Manufacturing and factory automation

Factories need sensors that work in tough conditions. Ruggedized PCBs protect sensors from heat, moisture, and vibrations. Temperature and humidity sensors check the environment to keep products high-quality. These PCBs ensure sensors stay accurate and safe from damage.

Automation systems also depend on ruggedized PCBs. Robots and conveyor belts use sensors to measure distances and detect objects. These sensors face constant shaking and impacts. Ruggedized PCBs make them stronger, lowering the chance of failures. This keeps production running smoothly and avoids costly delays.

Aerospace and defense systems

Aerospace and defense sensors must handle extreme conditions. Ruggedized PCBs help sensors work in high altitudes, strong vibrations, and fast temperature changes. For example, aircraft sensors monitor engines and weather. Ruggedized PCBs keep these sensors reliable during long flights.

Defense systems use sensors for radar, navigation, and surveillance. These sensors must work in deserts, icy areas, and other tough places. Ruggedized PCBs protect them, ensuring they stay accurate. This reliability is key for safety and mission success.

Mining and heavy equipment operations

Mining and heavy equipment need sensors that survive tough conditions. These places have constant shaking, hard hits, and rough materials. Ruggedized PCBs help sensors stay strong and reliable in mining tools.

These PCBs handle strong vibrations from drilling and digging machines. Shock-absorbing materials and strong connections stop parts from breaking. This strength keeps machines running and avoids delays.

Dust and dirt are big problems in mining. Sensors work in dusty areas where particles can cause issues. Ruggedized PCBs have special coatings to protect parts from dust and dirt. These coatings also stop damage from chemicals and water found in mines.

Tip: Check your sensors often for damage. Fixing small problems early saves money and time.

Ruggedized PCBs also make mining sensors more accurate. For example, load sensors in trucks need precise data to carry the right weight. These PCBs ensure sensors give correct readings, even under stress. This helps save money and improve work efficiency.

Using ruggedized PCBs makes mining sensors last longer and work better. They are key to keeping mining safe, productive, and reliable.

Renewable energy systems like wind and solar farms

Wind turbines and solar farms face changing weather. Sensors in these systems must handle heat, cold, and strong winds. Ruggedized PCBs keep these sensors working well in tough outdoor conditions.

In wind turbines, sensors check blade speed, vibration, and temperature. These sensors face constant movement and strong winds. Ruggedized PCBs use vibration-proof designs and protective layers to keep them working. This helps turbines run safely and efficiently.

Solar farms use sensors to measure sunlight and panel performance. These sensors deal with heat and UV rays for long periods. Ruggedized PCBs use heat-resistant materials and UV-proof coatings to protect parts. This keeps energy production steady and lowers repair costs.

Did you know? Sensors with ruggedized PCBs can last up to 15 years. This reduces how often they need replacing.

Ruggedized PCBs also improve sensor accuracy in renewable energy systems. For example, weather sensors in solar farms give important data for better energy use. With these PCBs, sensors provide clear and reliable information.

Investing in ruggedized PCBs ensures sensors in renewable energy systems work well. They are essential for getting the most energy and supporting clean power solutions.

Ruggedized PCBs are vital for keeping industrial sensors dependable in tough places. They handle problems like heat changes, water, and shaking. This helps sensors work well all the time.

Key Takeaway: Using ruggedized PCBs cuts downtime, boosts efficiency, and makes equipment last longer.

Picking ruggedized PCBs is wise for industries needing strong, precise sensors. They keep systems running reliably, even in the hardest conditions.

FAQ

What makes ruggedized PCBs special compared to regular PCBs?

Ruggedized PCBs are made with tougher materials and coatings. They resist heat, water, and shaking. They also have features like EMI shielding and heat control to work well in tough places.

How do ruggedized PCBs help sensors stay accurate?

Ruggedized PCBs protect sensors from things like noise and impacts. This keeps sensors giving correct data, even in hard places like factories or mines.

Can ruggedized PCBs work with photoelectric sensors?

Yes, ruggedized PCBs make photoelectric sensors stronger. They block dust, water, and shaking, helping sensors stay reliable and accurate in factories.

Are ruggedized PCBs worth the cost for industries?

Ruggedized PCBs save money by lasting longer and needing fewer repairs. They cut downtime and fix costs, making them a good choice for tough jobs.

Which industries use ruggedized PCBs the most?

Industries like oil, gas, aerospace, mining, and energy use ruggedized PCBs. These PCBs help sensors work well in extreme places, improving safety and work efficiency.

See Also

The Importance of Custom PCBA Production in Today’s Electronics

Exploring Flex PCBA: Benefits and Obstacles in Electronics

The Role of PCBA in Elevating Modern Electronic Devices

Understanding PCBA: Its Significance in Electronic Technology