Selecting the right custom printed circuit board maker is important for your project’s success. A good maker ensures steady quality, fewer mistakes, and faster delivery times. This helps lower rework costs and improves reliability during both testing and full production.

When looking at makers, think about things like clear cost details, quality checks, and customer help. These factors greatly affect your total project costs and schedules. Keep in mind, a very low price might mean lower quality materials, which can cause expensive problems later.

Key Takeaways

Pick a manufacturer that has a good reputation and experience. Check for positive reviews and quality standards like ISO 9001.

Make sure the manufacturer has great customer support. Fast replies and different ways to communicate can stop delays and confusion.

Choose a manufacturer that gives engineering help. Skilled engineers can solve design problems and make your PCBs better.

Focus on manufacturers with strong quality checks. Good inspection and testing can find problems early, saving time and money.

Search for customization choices and flexible production. This makes sure the PCBs fit your project needs and can change if needed.

Professionalism

When you choose a custom PCB manufacturer, professionalism is very important. Two main parts of professionalism are reputation and industry experience.

Reputation

A manufacturer’s reputation can greatly affect your project’s success. You should find manufacturers with good reviews and feedback from past clients. These details show how reliable and good the manufacturer is. Here are some signs of a trustworthy custom PCB manufacturer:

Quality Standards: See if they follow international rules like ISO 9001 and IPC standards.

Technical Capabilities: Make sure they can create multi-layer boards and flexible designs.

Delivery Capabilities: Quick sampling services and good international delivery are very important.

Testing Methods: Look for manufacturers that test bare boards to find problems early.

Production Flexibility: They should be able to go from prototypes to large production.

Design Optimization: A good manufacturer will give design for manufacturability (DFM) reviews and tips for thermal management.

Industry Experience

Industry experience is linked to product reliability and customer happiness. Manufacturers with many years of experience usually use quality management systems like ISO 9001 and Lean Six Sigma. These systems help make products more reliable and meet customer needs well.

Also, experienced manufacturers often work on improving quality all the time. This focus leads to happier customers. Talking regularly with clients helps manufacturers understand their needs better, which is key for providing reliable products.

Support

When you choose a custom PCB maker, support is very important. Good support helps with clear communication and solving problems. You want a maker that cares about customer support during your project. This can really affect how well your project goes and how happy you are.

Responsiveness

Being quick to respond is key in making custom PCBs. Fast answers to your questions can stop delays and mix-ups. Here are some problems that can happen if they are slow to respond:

More Revision Cycles: Delays in feedback can mean many changes, raising costs.

Longer Development Time: Slow timelines lead to higher labor costs and lost money.

Wasted Materials: Finding issues late can waste parts that were already made.

Customer Satisfaction: Delays and quality problems can make you unhappy, hurting future work together.

To avoid these issues, look for makers that are available 24/7. This way, you can contact them anytime there’s a problem, reducing downtime during important prototyping stages.

Communication Channels

Good communication is key for a successful project. Top custom PCB makers use different ways to talk to clients. Here are some common ways:

Phone

Email

Live Chat

Each way has its own purpose. For example, phone calls give quick help, while emails keep a record of questions and answers. Live chat gives fast help for quick questions.

To show how important these ways are, check out this table:

Communication Channel | Description |

|---|---|

Phone | Direct voice communication for quick help. |

Written communication for detailed questions and records. | |

Live Chat | Real-time help for quick questions and support. |

Having many ways to communicate makes it easier to solve problems quickly. This builds trust and helps create a good working relationship between you and the maker.

Engineering Support

When you pick a custom PCB maker, engineering support is very important. You need a partner with strong skills and help with design. These things can really affect how well your project does.

Technical Expertise

Technical skills are key in making PCBs. A smart team can help you with tricky designs and make sure production is high quality. Look for makers with skilled engineers. They should have the right degrees and certifications. Here’s a quick list of useful qualifications:

Degree/Certification Type | Description |

|---|---|

Bachelor’s Degree | Electrical Engineering, Electronics Engineering, or Computer Engineering |

Associate Degree | Electronics Technology or similar field (for entry-level jobs) |

Master’s Degree | Electrical Engineering focused on PCB design (for advanced jobs) |

Technical Certifications | PCB design certificates and special courses |

IPC Certification | IPC CID and IPC CID+ for professional recognition in PCB design and assembly |

Having a team with these skills means they know how to design and make custom printed circuit boards. This knowledge helps avoid costly mistakes and improves your project’s quality.

Design Assistance

Design help can really make your project better. A maker that gives design support can help you dodge common problems. For example, they might offer Design for Manufacturing (DFM) feedback. This advice helps you spot issues early, stopping costly mistakes and delays.

Good customer support builds a strong bond between makers and clients. This keeps projects running smoothly and fixes problems quickly. Also, prototyping lets engineers check how the PCB works. Finding design flaws early stops expensive redesigns and makes sure the final product works well.

Quality Assurance

Quality assurance is very important for your custom printed circuit board projects. It makes sure the final product works well and meets the needed standards. Two main parts of quality assurance are inspection capabilities and testing procedures.

Inspection Capabilities

Inspection capabilities help find problems early in making the boards. A good manufacturer will use different inspection methods to check their products. Here are some common inspection methods used in the industry:

Inspection Method | Description |

|---|---|

Automated Optical Inspection (AOI) | Fast visual checks find defects like missing parts and bad solder joints. |

X-ray Inspection | Looks at hidden solder joints, giving real-time images and finding defects automatically. |

Dimensional Measurement | Makes sure PCBs meet size requirements using CMM to check dimensions and placements. |

Cross-sectional Analysis | Checks the quality of layers and plating through destructive tests to improve the process. |

These inspection methods help you find problems before they get worse, saving time and money. A strong quality system makes sure your custom printed circuit boards are dependable and meet your needs.

Testing Procedures

Testing procedures are key for checking how well your PCBs work and how reliable they are. Advanced testing methods can greatly lower the chance of product failure. Here are some important testing methods:

Failure Mode and Effects Analysis (FMEA): This method finds possible problems during making. It uses a risk priority number (RPN) to rank risks, helping with better quality control decisions. FMEA has been shown to lower defect rates and reduce product failure risks.

Design for Testability (DFT): DFT makes testing easier, allowing quick and effective fault finding. It helps designers spot and fix hidden errors, improving product quality. Finding faults early with DFT lowers the chance of production failures and extra costs.

By using these testing procedures, manufacturers show they care about improving quality. They regularly check quality data, train workers on new methods, and invest in better tools. This ongoing focus on quality helps make sure your custom printed circuit boards work well in their intended uses.

Customization

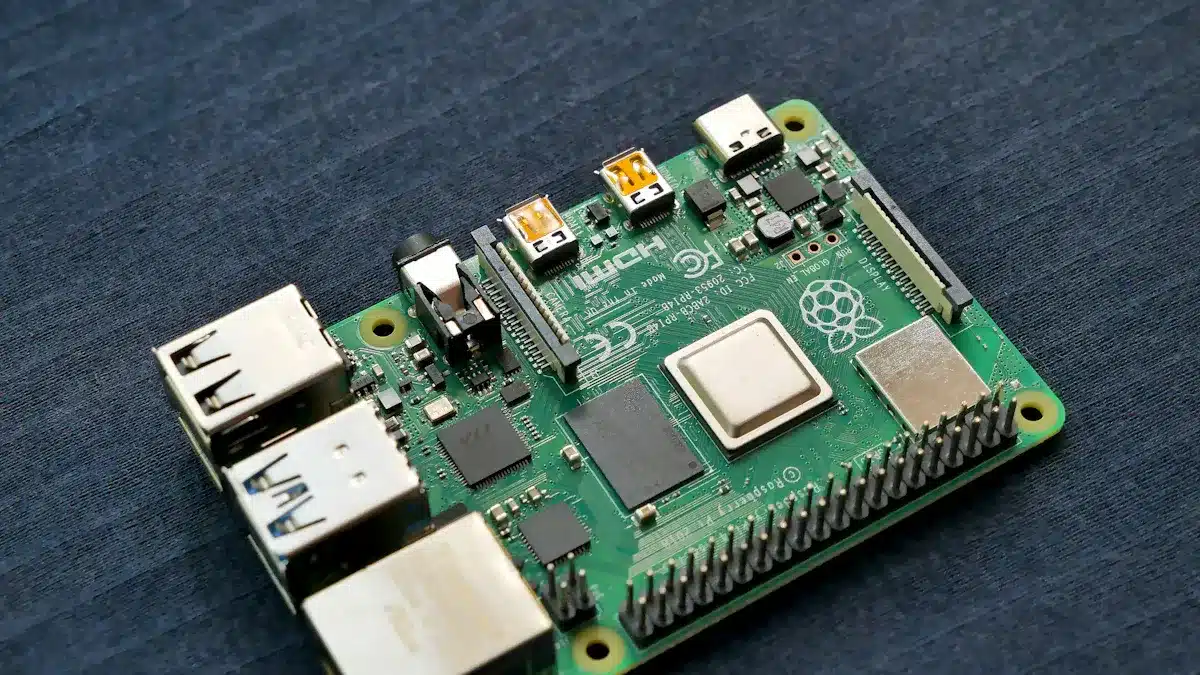

Customization is very important for your project needs when picking a custom PCB manufacturer. Being able to change printed circuit boards to fit your needs can really improve how well your electronic devices work.

Custom Printed Circuit Board Options

You can find many options for custom printed circuit boards that suit different uses. Here are some common types:

Flexible: These PCBs can bend and fold. They are great for small electronic devices and odd shapes.

Rigid: Made from hard fiberglass, these boards are cheap but stiff. This makes them hard to use in tight spaces.

Rigid-flex: These combine both rigid and flexible PCBs. They are strong and flexible while being smaller and lighter.

These choices help you pick the best one for your project. This way, your design can meet both functional and visual needs.

Production Flexibility

Production flexibility is another key part of PCB making. It helps manufacturers change to different order sizes and design needs. For example, flexible printed circuit boards can be changed based on layer counts, materials, and parts. This ability makes them useful for many applications.

Imagine a manufacturer made a 300-foot flexible PCB for exact temperature readings. This shows how flexibility can meet special needs. Also, a vehicle heater project with fewer parts saved 40% in costs, showing the money benefits of flexible production.

With new technology, manufacturers can make PCBs in many sizes and shapes. This means they can meet different client needs well. By choosing a manufacturer that focuses on customization and production flexibility, you can boost your project’s success and efficiency.

Timely Delivery

Timely delivery is very important when choosing a custom PCB manufacturer. You need a partner who can always meet deadlines. This trust can really affect how well your project does.

Delivery Reliability

A manufacturer’s ability to deliver on time directly impacts your project. For example, MCL has a great average on-time delivery rate of 97 percent over the last year. This rate is much better than the industry average. Also, 99.6 percent of their on-time deliveries had no defects. This kind of reliability means you get your parts when you need them, helping your project stay on schedule.

Impact on Project Timelines

Delays in PCB delivery can mess up your project timelines. Problems in the supply chain can make lead times longer by as much as 30 percent. This situation forces you to look for other sources or deal with costly delays. Higher costs can happen as companies compete for limited resources, raising raw material prices.

When delays happen, they can hurt relationships with clients and stakeholders. You might face issues in project management, causing frustration and possible loss of business. To avoid these problems, think about manufacturers who focus on timely delivery.

Top manufacturers use different strategies to ensure timely delivery:

Early Collaboration: Work with manufacturers during the design phase to spot challenges.

Design for Manufacturability (DFM): Making designs simpler reduces complexity and lead times.

Standardization: Using standard parts and materials makes production easier.

By using these strategies, you can improve your project’s efficiency and success. Remember, timely delivery is not just about speed; it’s about creating a reliable partnership that helps you reach your goals.

Choosing the right custom PCB maker is very important for your project’s success. You need to think about some key things:

Quality rules

Customer help

Cost factors

Doing good research on makers can really change your project results. Checking their skills and quality checks helps you find trustworthy partners. Knowing about after-sales support lowers the chances of delays or problems. Always focus on your needs and look for makers that fit your project goals. This careful way will help make production easier and improve results.

FAQ

What should I think about when picking a PCB maker?

You should check their reputation, experience in the industry, support services, quality checks, and customization choices. These things can really affect how well your project does and how reliable it is.

How can I make sure my PCB maker delivers on time?

Look for makers with a good history of on-time deliveries. Ask them about how they produce PCBs and what they do to meet deadlines. This will help you stay on track with your project.

What kinds of PCBs can I change?

You can change different types of PCBs, like flexible, rigid, and rigid-flex boards. Each type is good for different uses, so pick one that fits your project’s needs.

How important is engineering help in making PCBs?

Engineering help is very important. It helps you avoid design mistakes and makes sure production is high quality. A maker with strong skills can help you with tricky design problems.

What are some common ways to check PCBs during production?

Common checking methods include Automated Optical Inspection (AOI), X-ray inspection, and measuring dimensions. These methods help find problems early, making sure the final product is good quality.

See Also

Tips for Finding the Right PCB Prototype Manufacturer

Essential Considerations for Selecting a Custom PCBA Manufacturer

Guidelines for Picking the Ideal PCB Fabrication Manufacturer