By 2025, smart manufacturing PCBA has transformed PCB assembly completely. It is now faster, more accurate, and saves money. Tools like AI and IoT have enhanced production methods. Machines run all day and night, placing parts very quickly. They can place up to 40,000 parts every hour. IoT sensors predict problems early, cutting downtime by 70%. AI identifies tiny mistakes, ensuring better quality. This change has contributed to the PCB market growing by 10% each year. Utilizing smart manufacturing PCBA is now essential to stay ahead.

Key Takeaways

Smart manufacturing makes PCB assembly faster. Machines can place 40,000 parts an hour, boosting productivity.

AI and IoT tools find defects early. This lowers mistakes and keeps production quality high.

Real-time tracking helps businesses adjust quickly. Problems get solved fast, and resources are used better.

Automation saves money by needing less labor and cutting waste. It’s a smart choice for companies.

Green practices in smart manufacturing help the planet. They also bring eco-friendly customers and improve brand image.

Smart Manufacturing Technologies in PCB Assembly

AI and Machine Learning in PCB Design

AI and machine learning are changing how PCBs are designed. These tools study design needs and suggest better layouts, saving time. For example, AI-powered inspection systems find defects very accurately. This removes the need for manual checks, which can be slow and less reliable.

AI and machine learning also boost productivity by automating boring tasks. Smart vision systems now check parts placement and track progress. This accuracy lowers mistakes and improves product quality. Companies can now make better PCBs faster and meet deadlines easily.

IoT and Connected Systems in Assembly

The Internet of Things (IoT) has made PCB assembly more connected. Sensors watch every step, giving live updates on machines and conditions. This helps spot problems early, cutting downtime and saving money.

Connected machines also talk to each other, making bulk tasks easier. For example, cloud systems let machines share data and adjust settings. This feedback system avoids delays and keeps things running smoothly. Big companies like BMW use IoT to cut waste and work more efficiently.

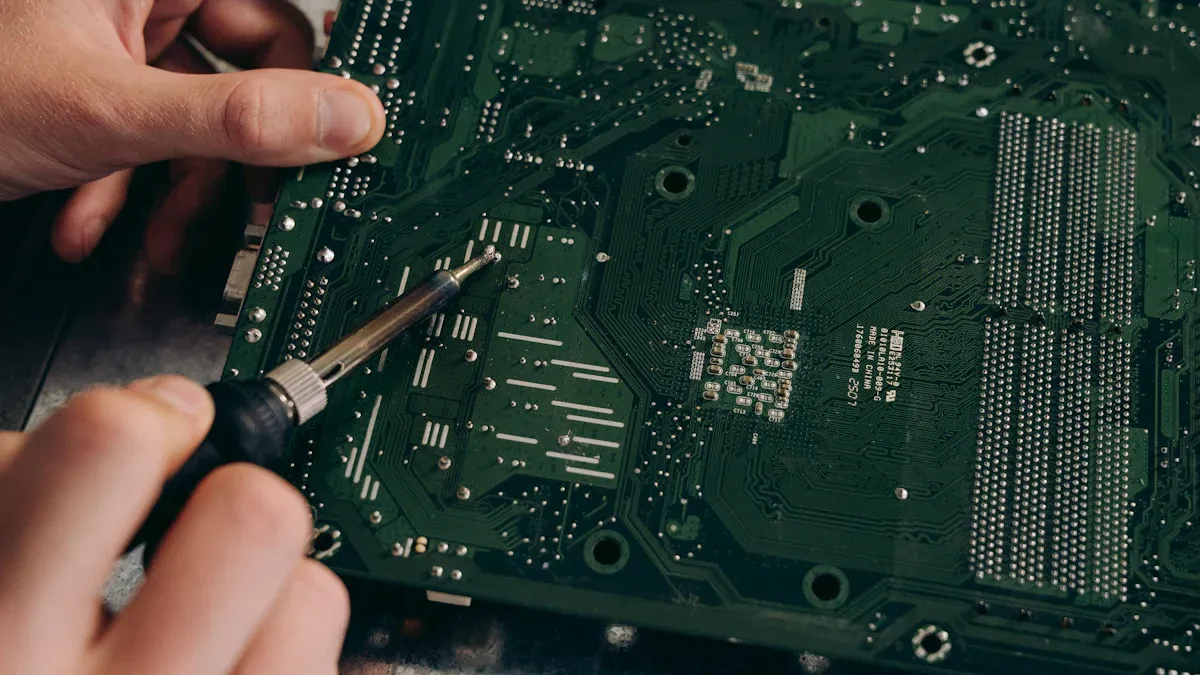

Robotics and Automation in PCB Manufacturing

Robots and automation are now key in making PCBs. Robots do jobs like sorting materials and placing parts quickly and accurately. This lowers mistakes and keeps product quality high. For big production, automation saves materials and reduces waste, cutting costs.

Cobots, or collaborative robots, are also very helpful. They work with people, mixing machine precision with human creativity. For example, cobots help build tricky PCBs while workers check quality. Automated systems also track parts in real time, saving storage space and improving workflow.

Automation is vital for quality checks too. Smart QA systems watch production and fix issues instantly. AI-powered maintenance predicts problems, reducing downtime and keeping production steady.

Digital Twin Technology for Process Optimization

Digital twin technology has changed how PCB assembly is improved. It creates virtual copies of real systems to test ideas. This lets you find problems and fix them before they happen.

With digital twins, designing PCBs becomes easier and faster. You can test designs in different situations without making real models. This saves time and reduces wasted materials. For example, new PCB software works with digital twins to plan every step. This ensures the process meets quality and efficiency goals.

Digital twins also help teams work better together. A shared virtual model keeps everyone updated and avoids mistakes. Teams can share information easily, which speeds up production. Digital twins also allow testing across different areas, improving the whole process.

Another benefit is predicting when machines might break. Virtual models use real-time data to spot issues early. This helps fix problems before they stop production. It keeps the assembly line running smoothly. In short, digital twins make PCB design and manufacturing much better.

Predictive Maintenance with Advanced Analytics

Predictive maintenance is now key in smart manufacturing. It uses data to check machines and predict problems early. This stops costly delays and keeps PCB assembly running well.

Sensors in machines collect data like temperature and vibrations. The system studies this data to find unusual patterns. For example, if a machine shows wear, it alerts you to fix it. This avoids sudden breakdowns and makes machines last longer.

One big advantage is saving money. Old methods check machines regularly or wait for them to break. Both are costly and wasteful. Predictive maintenance focuses on real problems, saving time and resources.

Real-time tracking also gives you more control. You can quickly adjust if a machine needs fixing. Tasks can move to other machines, keeping production on schedule.

When combined with digital twins, predictive maintenance becomes even stronger. Together, they give a full view of operations, improving efficiency and reliability.

Benefits of Smart Manufacturing PCBA

Faster and More Efficient Assembly Processes

Smart manufacturing makes PCB assembly quicker and smoother. Using advanced tools, production speeds up and delays drop. Machines finish tasks faster, improving how things run. Systems track progress live, finding problems and fixing them fast.

Big data tools help make better products with fewer mistakes. Machines share information easily, speeding up the whole process. New equipment collects data super fast, helping decisions happen quickly.

Metric | Description |

|---|---|

Faster Production | Smart tools and data make assembly quicker and smoother. |

Live tracking and data sharing improve product quality. | |

Lower Costs | Fixing problems early and saving time reduces expenses. |

These new methods make production faster and keep everything consistent.

Enhanced Precision and Quality Control

Smart manufacturing improves accuracy and checks quality better. Automated tools now spot mistakes early, making sure PCBs are high quality. These systems check thousands of parts in seconds, much faster than old ways.

New trends focus on reducing errors during production. High-tech inspection tools aim to make every PCB perfect. These systems help keep products reliable and meet high standards.

Better quality checks mean fewer mistakes and happier customers. Finding and fixing issues early ensures products meet industry needs.

Cost Savings Through Automation

Automation saves money by cutting labor costs and improving consistency. Many companies use smart tools to handle rising expenses. Automation can lower costs by up to half, making it a smart choice.

For example, automated systems reduce the need for workers and improve production. This helps businesses grow and work with new suppliers. By reducing waste and streamlining tasks, companies save money while keeping quality high.

Automation also prevents downtime with smart tracking and maintenance. These features keep production running smoothly and save resources. Using automation helps businesses stay competitive in PCB assembly.

Real-Time Monitoring and Adaptability

Real-time monitoring is a key part of smart manufacturing. It lets you see how machines and production are working instantly. With IoT sensors, you can check things like stock levels and product quality right away. This helps you fix problems fast and keep everything running smoothly.

Decision support systems (DSS) make real-time monitoring even better. They study how processes work and track important details. DSS can find problems early and suggest ways to fix them. For example, if a machine isn’t working as it should, DSS will show the issue and give solutions. This keeps products high-quality and avoids delays.

Real-time monitoring also helps you adapt quickly. If something unexpected happens, like a machine breaking or demand rising, you can act fast. Smart systems let you move resources or change schedules without stopping work. This keeps your production steady and ready for changes.

Tip: Using real-time monitoring improves efficiency and keeps product quality high, which builds trust with customers.

Scalable and Flexible Production Systems

Smart manufacturing systems grow with your business needs. Scalability means you can add more machines or upgrade old ones easily. Modular equipment makes this simple and saves money compared to older methods.

Flexibility is also very important today. Smart systems let you switch between products or adjust production quickly. This is helpful for custom orders or when demand changes suddenly. You can set up your assembly line to meet specific needs and keep customers happy.

Modern systems also handle many products at once. Advanced software helps you manage different product lines together. This way, you can serve more customers without losing efficiency.

Feature | Benefit |

|---|---|

Modular Equipment | Add or upgrade machines easily as your business grows. |

Quick Reconfiguration | Change production quickly for new designs or demand changes. |

Multi-Product Support | Manage different products efficiently for more customer options. |

By using scalable and flexible systems, your business can grow and stay competitive. These systems make work smoother and prepare you for future challenges.

Note: Choosing scalable systems now can save time and money as your business expands.

Challenges in Smart Manufacturing Implementation

High Costs of Initial Investment

Starting with smart manufacturing needs a lot of money upfront. Machines like high-speed pick-and-place tools and IoT sensors are expensive. You might also need to upgrade your workspace for these advanced systems. For smaller businesses, these costs can be tough to handle.

Another challenge is paying for software and cloud platforms. These tools are necessary for automated PCB assembly but often have ongoing fees. While the long-term savings are worth it, the starting costs can stretch budgets.

To deal with this, you can look into loans or grants. Many programs help businesses switch to smart manufacturing. Careful planning can lower costs and make the change easier.

Integrating Smart Systems with Legacy Equipment

Adding new tech to old machines can be tricky. Older systems may not work well with modern automation tools. You might need special software to connect them.

Factor | Description |

|---|---|

Age of Old Systems | |

Data Quality Issues | Poor data from old systems can make AI less effective. |

Integration Problems | Some older systems need extra software to work with new tech. |

Custom Features | Adding specific features can make integration more expensive. |

Old machines might also have bad or missing data. Without good data, AI tools can’t give accurate results. Cleaning up data or improving your system can help fix this.

Customizing new systems to fit your needs can also be costly. But doing this ensures everything works smoothly and gives the best results.

Workforce Training and Skill Development

Smart manufacturing needs workers who understand robots, AI, and automation. Training your team is very important. Start by finding skill gaps and creating learning plans for employees.

Some companies already have programs to solve these problems. For example, Heroes MAKE America trains military members for manufacturing jobs. Community colleges also work with local factories to teach needed skills.

Skill Gaps: Find what workers know and what they need to learn.

Learning Plans: Create step-by-step training for each worker.

College Partnerships: Schools teach skills that factories need.

Government Help: Grants and programs support worker training.

Online classes are another great option. They let workers learn new skills while managing other tasks. By focusing on training, your team will be ready for automated PCB assembly.

Cybersecurity Risks in Connected Environments

Connected factories face serious cybersecurity problems. Adding IoT devices and smart tools to PCB assembly can open doors to hackers. Weak passwords, old security systems, and unsafe networks make it easier for attacks to happen. For instance, in 2020, Foxconn was hit by ransomware. Hackers demanded $34 million in Bitcoin, causing major factory disruptions. This shows how risky electronics manufacturing can be.

To keep systems safe, strong security steps are needed. Regular tests can find weak spots in your defenses. Firewalls protect internal systems, and endpoint security stops malware. Checking vendors ensures they follow data safety rules, lowering risks from outside sources.

Tip: Use blockchain to track parts. It prevents fake parts and secures the supply chain.

Protecting design data is also very important. Hiding or masking this data during teamwork stops unauthorized access. Following global rules like ISO 27001 and NIST Cybersecurity Framework makes systems stronger. For industries like defense, NIST 800-171 is key to protecting ideas and designs.

By fixing these issues early, you can keep your systems safe and running smoothly.

Managing Complex Data Streams

Smart factories create huge amounts of data. Handling this data can be hard, especially when mixing old and new systems. Problems like system mismatches, hard-to-access data, and team resistance may arise.

Quote: “A clear data plan is key. Use middleware and standard formats to share data easily.”

Big data tools help solve these problems. They find patterns in data, helping you make better choices. For example, studying production data can show where things are slow, so you can improve.

To manage data well, build a central system. Middleware connects old and new systems, making data flow smoothly. Standard formats make sharing and understanding data easier across platforms.

Note: Better data analysis improves how systems work and supports future growth.

By using smart methods, you can turn tricky data into useful insights for better decisions.

Future Trends in Automation and PCB Manufacturing

5G and Edge Computing in PCB Assembly

5G and edge computing are changing PCB assembly. These tools make data faster and reduce delays. Edge computing handles data near its source, improving speed. This is crucial for modern PCB assembly, where quick decisions matter.

The 5G edge computing market is growing fast. It is expected to rise by 47.8% yearly from 2025 to 2030. This growth shows the need for real-time data in industries like manufacturing. Using 5G and edge computing can make production lines more efficient and competitive.

Year | Market Value (USD Billion) | CAGR (%) |

|---|---|---|

2024 | 4.74 | 47.8 |

These technologies help machines work together better. They make assembly faster and more accurate. You can use them to improve workflows and cut downtime.

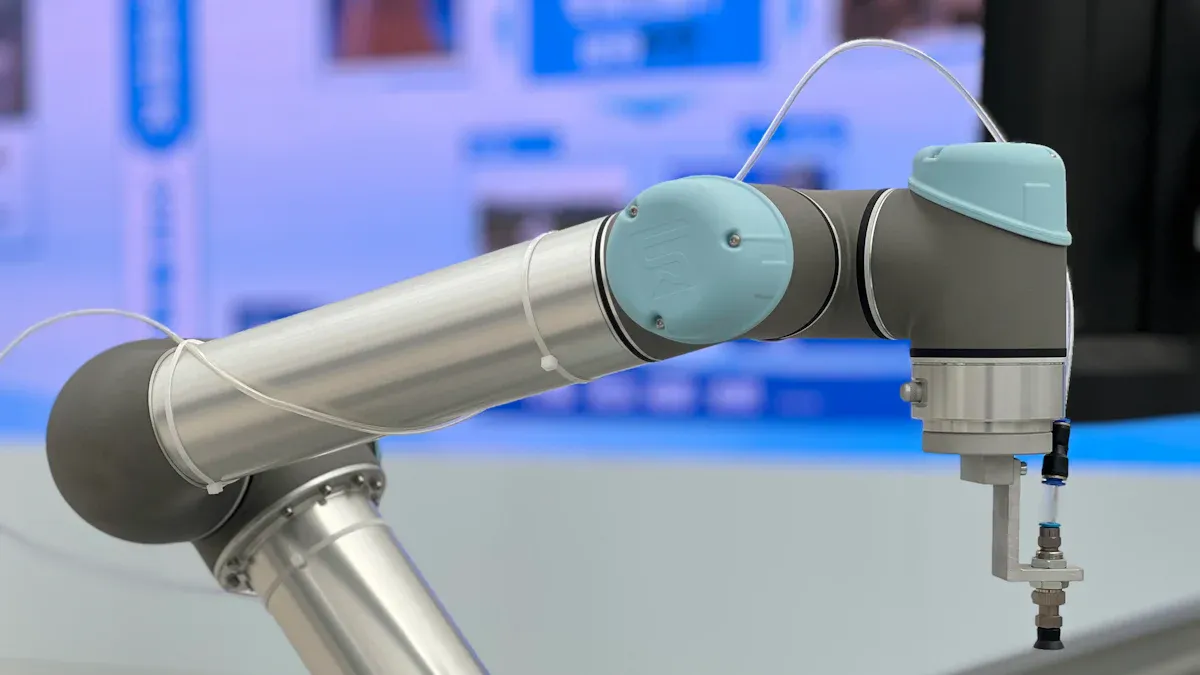

Collaborative Robots (Cobots) in Manufacturing

Cobots, or collaborative robots, are changing factory work. Unlike regular robots, cobots safely work with people. They mix machine accuracy with human creativity. This makes them great for building complex PCBs.

Cobots are simple to program and can do many jobs. For example, a cobot can solder parts while workers check quality. This teamwork boosts efficiency and lowers mistakes.

Cobots also make workplaces safer. They handle dangerous tasks, keeping workers safe from harm. Adding cobots to your factory can increase productivity and create a safer workspace.

AI-Driven Prototyping and Design

AI is improving how PCBs are designed and tested. AI tools study design needs and create better layouts quickly. This saves time and reduces mistakes during planning.

AI also allows virtual testing without making real models. This cuts waste and speeds up development. For example, AI can predict how a PCB will work in different situations. This helps find problems early.

Using AI-driven prototyping makes designing faster and cheaper. It ensures your designs meet standards and improves efficiency.

Sustainable Manufacturing Practices

Sustainability is now very important in PCB manufacturing. Factories can use eco-friendly methods to cut waste and save energy while keeping high standards. Using renewable energy like solar or wind power helps lower carbon emissions. Switching to lead-free solder and recyclable materials also reduces harmful waste and follows environmental rules.

Reducing material waste is another big part of sustainable PCB manufacturing. Smart software calculates exact material needs for each design. This saves money and reduces leftover scraps. For example, automated cutting tools use materials efficiently, leaving almost no waste.

Saving water is also crucial. Many PCB processes need water for cleaning and cooling. Closed-loop water systems recycle water, cutting down on usage. This saves resources and lowers costs at the same time.

Tip: Work with suppliers who care about sustainability. Look for certifications like ISO 14001 to match your green goals.

Sustainable practices help the planet and improve your company’s image. More customers now prefer businesses that care about the environment. By going green, you can attract eco-friendly clients and stay competitive in the PCB manufacturing market.

Fully Autonomous Production Lines

Fully autonomous production lines are the future of PCB manufacturing. These systems work without human help, using advanced robots, AI, and IoT. They bring unmatched speed and accuracy to production.

Autonomous systems handle every step, from moving materials to final checks. Robots with AI can find defects and fix them instantly. This keeps quality high and reduces the need for manual fixes. For example, automated optical inspection (AOI) systems check thousands of parts in seconds, spotting even tiny mistakes.

One big benefit of autonomous lines is they can run all day and night. This increases production and reduces downtime. Predictive maintenance tools watch machines and plan repairs before they break. This avoids costly delays and keeps production smooth.

Note: Setting up autonomous systems costs a lot at first. But over time, you save on labor and boost productivity, making it worth the cost.

Autonomous lines are also flexible. Machines can be reprogrammed quickly to make different PCB designs. This helps meet changing customer needs. In today’s fast-moving market, this flexibility is key. By using full automation, your business leads in PCB manufacturing innovation.

Smart manufacturing has changed how PCBs are made in 2025. It brings faster production, better accuracy, and saves money. Automation and live data tracking help reduce mistakes and improve stock control. These tools also let companies respond quickly to customer demands.

Description | |

|---|---|

More automation and better efficiency | Machines work faster and make fewer mistakes than people. |

Live data for constant improvement | AI studies data to fix problems and improve quality. |

Better accuracy with fewer mistakes | Smart tools check products carefully to meet high standards. |

Easier inventory control | Automated systems track supplies and lower costs. |

Faster response to customer needs | Flexible systems allow quick changes and custom designs. |

To stay ahead, businesses need to use these new tools. They should also focus on fixing issues like security risks and training workers. Acting now will help them succeed in the future of PCB production.

FAQ

What are smart factories, and how do they help PCB assembly?

Smart factories use tools like AI, IoT, and robots. These tools make production faster and more accurate. In PCB assembly, they save time and reduce mistakes. They also cut waste and downtime, making work cheaper and greener.

How do smart factories improve PCB quality?

Smart factories use machines to check for mistakes quickly. They watch production in real time to find problems early. This ensures every PCB is high quality. By reducing human mistakes, they make products reliable and consistent.

Can small businesses use smart factories for PCB production?

Yes, small businesses can use smart factories. These systems can grow or shrink based on needs. This makes them great for custom or small PCB orders. They work well for businesses of any size.

What problems might happen when switching to smart factories?

Switching to smart factories can cost a lot at first. Old machines may not work with new systems. Workers also need training to use the new tools. Cybersecurity and handling big data are other challenges. Planning and training can solve these issues.

How do smart factories help the environment in PCB assembly?

Smart factories use materials carefully to avoid waste. They recycle water and use clean energy like solar power. These steps save resources and protect the planet. This makes PCB assembly more eco-friendly.

See Also

Emerging Innovations in PCB and PCBA Development

Grasping the Essentials of PCBA Production Techniques

Essential Strategies to Enhance PCB Assembly Productivity

The Significance of Tailored PCBA Production in Electronics

Why PCBA Production Skills Are Crucial for Electronics Design