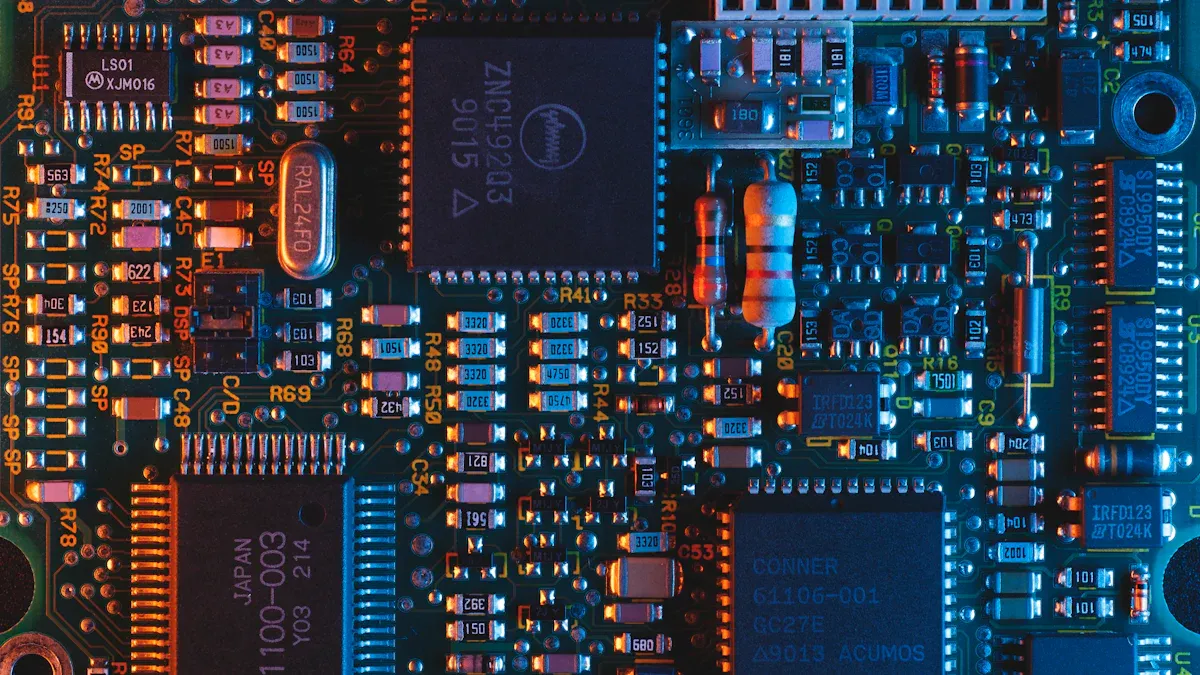

In today’s fast-paced electronics world, we want smaller, faster gadgets. SMD components, or Surface-Mount Devices, help make this happen. These parts allow makers to create small, efficient, and powerful devices. For example, the global SMD components market is growing 10% yearly from 2023 to 2030. This shows the rising need for tiny parts that save space, weigh less, and work better. From phones to smart devices, SMD components drive the cool tech you love.

Key Takeaways

SMD parts are tiny pieces used to make modern electronics. They help create smaller gadgets with more functions.

Using SMDs makes devices work better by lowering electrical noise. This is very important for fast tech like 5G.

SMD parts save money. They make production easier and cut labor costs with machines.

Fixing SMD parts can be hard because they are so small. Special tools and skills are needed to fix them well.

SMDs are important in many fields, like home gadgets, cars, planes, and medical tools.

Understanding SMD Components

What Are Surface-Mount Devices?

Surface-mount devices (SMD) are small parts used in electronics. They attach directly to the surface of a printed circuit board (PCB). Unlike older parts, they don’t need holes drilled into the PCB. Instead, they use surface mount technology (SMT) to stick on. This method skips wires, making assembly quicker and easier.

SMDs include resistors, capacitors, diodes, and integrated circuits. Their tiny size lets makers fit more parts on one PCB. This helps create smaller and stronger gadgets. For example, smartphones and laptops use SMDs for their slim designs and great performance.

Did you know? SMT started in the 1960s when IBM showed its use in small computers. By the 1990s, SMDs became the top choice for advanced electronics.

How SMD Components Differ from Through-Hole Components

SMDs are very different from through-hole components (THT), which are older parts. The table below shows how they compare:

Feature | SMD Components | THT Components |

|---|---|---|

Size | Smaller, reduces unwanted electrical effects | Bigger, increases unwanted electrical effects |

High-Frequency Performance | Better due to lower inductance and capacitance | Worse due to higher inductance and capacitance |

Strength | Less strong, easier to damage | Stronger, handles stress better |

Assembly Process | Automated, fits more parts | Manual, slower for large production |

SMDs are best for saving space and boosting performance. They work well in high-frequency circuits because they cause less electrical interference. But THT parts are still useful when strong connections are needed, like in heavy machines or airplanes.

Importance of SMD Components in Electronics

SMDs are key to modern electronics. Their small size helps make tiny, powerful devices. They are important in industries like telecom, cars, and consumer gadgets. For example:

5G networks need SMD power inductors for fast data speeds.

Electric cars use SMDs for battery systems and entertainment features.

In factories, SMDs power IoT devices for automation.

A report on in-mold electronics (IME) shows how SMDs improve car interiors and controls. This tech makes production simpler and less complex, proving SMDs are growing in many fields.

Special storage systems now handle SMDs better during production. These systems reduce mistakes and make manufacturing faster and easier.

Pro Tip: Use SMDs in high-performance circuits for better results and easier automated assembly.

Types of SMD Components

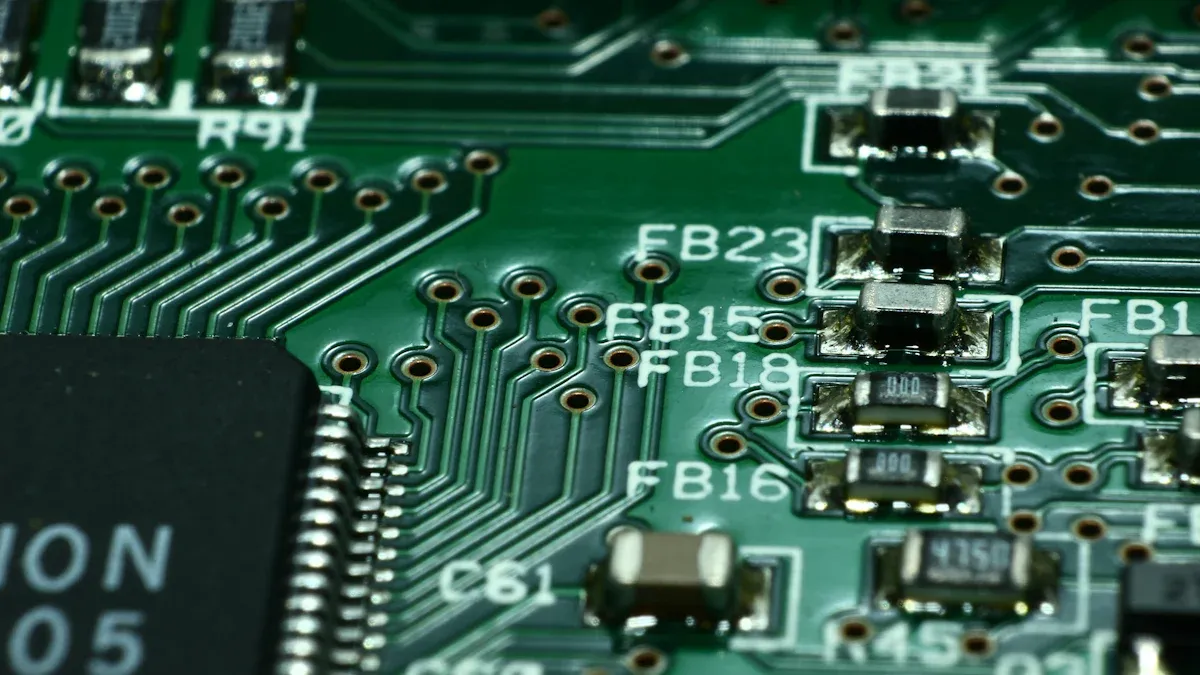

Passive SMD Components

Passive SMD components are very important in electronics today. These include resistors, capacitors, and inductors. They don’t create energy but store or release it. Their small size helps them fit into tight spaces on a PCB. This makes them perfect for small gadgets like phones and wearables.

How passive SMD components work depends on how they are mounted. Parasitic effects also affect their performance. For example, in RF circuits, parasitic capacitance can change impedance. The way these parts are placed and connected also matters. In high-frequency circuits, knowing these details helps improve performance and reduce problems.

Tip: For RF circuits, check the size and material of passive SMD components to avoid parasitic issues.

Active SMD Components

Active SMD components include transistors, diodes, and integrated circuits. These parts control electricity and boost signals. They help devices do complex tasks. Their tiny size and efficiency make them great for small gadgets like laptops and IoT devices.

You’ll see active SMD components in power management and signal processing. For example, SMD transistors are used in switching circuits. SMD diodes are key for voltage control and rectification. They handle high frequencies and fast switching, making them vital for advanced tech like 5G.

Electromechanical SMD Components

Electromechanical SMD components mix electrical and mechanical functions. Examples are switches, relays, and connectors. These parts help connect and control electronic systems. Their small size fits well in modern gadgets without losing functionality.

Here’s a table showing examples of electromechanical SMD components in key uses:

Application | Example Component | Key Features |

|---|---|---|

Infotainment Systems | Vishay Dale CRCW-IF series | |

Telecommunication Base Stations | Ohmite LVK series | Up to 1W power rating |

Networking Equipment | TE Connectivity RN73 series | Tight tolerance, low TCR |

Smartphones | Samsung RC series | Compact sizes, high reliability |

Wearable Devices | Yageo RC0402 series | Small dimensions, high precision |

Tests like temperature cycling and vibration testing check if these parts work well. For example, in wearables, electromechanical SMD components must handle movement and temperature changes while staying accurate.

Note: Choose electromechanical SMD components with good tolerance and reliability for long-lasting performance.

Advantages of SMD Components

Miniaturization and Space Optimization

SMD components help make electronics smaller and more useful. Their tiny size lets more parts fit on one PCB. This allows gadgets like phones, watches, and laptops to have more features in less space. Surface mount technology removes the need for big, old-style parts.

Using SMD components helps create smaller products for today’s needs. For example, small satellites lower launch costs in space missions. These satellites stay reliable and work well despite their size. This space-saving design is important for industries like aerospace and telecom.

Fun Fact: Tiny electronics now fit into smartwatches and fitness trackers thanks to miniaturization.

Enhanced Performance and Reliability

SMD components make devices work better by shortening electrical paths. This lowers signal problems and improves signal quality. They are great for fast tech like 5G and advanced computers. Their design also reduces unwanted effects in high-frequency circuits.

These parts are also very reliable. SMD components handle stress better and last longer. For example, in factories, they work well in tough conditions without breaking. This makes them perfect for cars and medical tools where reliability is key.

Tip: Use SMD components in fast circuits for better speed and signal quality.

Cost Efficiency in Manufacturing

SMD components save money during production. Machines like pick-and-place systems make assembly faster and with fewer mistakes. This lowers labor costs and boosts efficiency, helping meet demand without losing quality.

Placing SMD components smartly on the PCB saves materials and time. Engineers pick common parts to cut costs and avoid delays. Using standard parts instead of custom ones makes production easier and cheaper.

Over time, SMD components save even more money. They last longer, need fewer repairs, and work well with automated systems. This ensures high quality in large-scale production.

Pro Tip: Work with SMT engineers to design cost-effective and easy-to-make products.

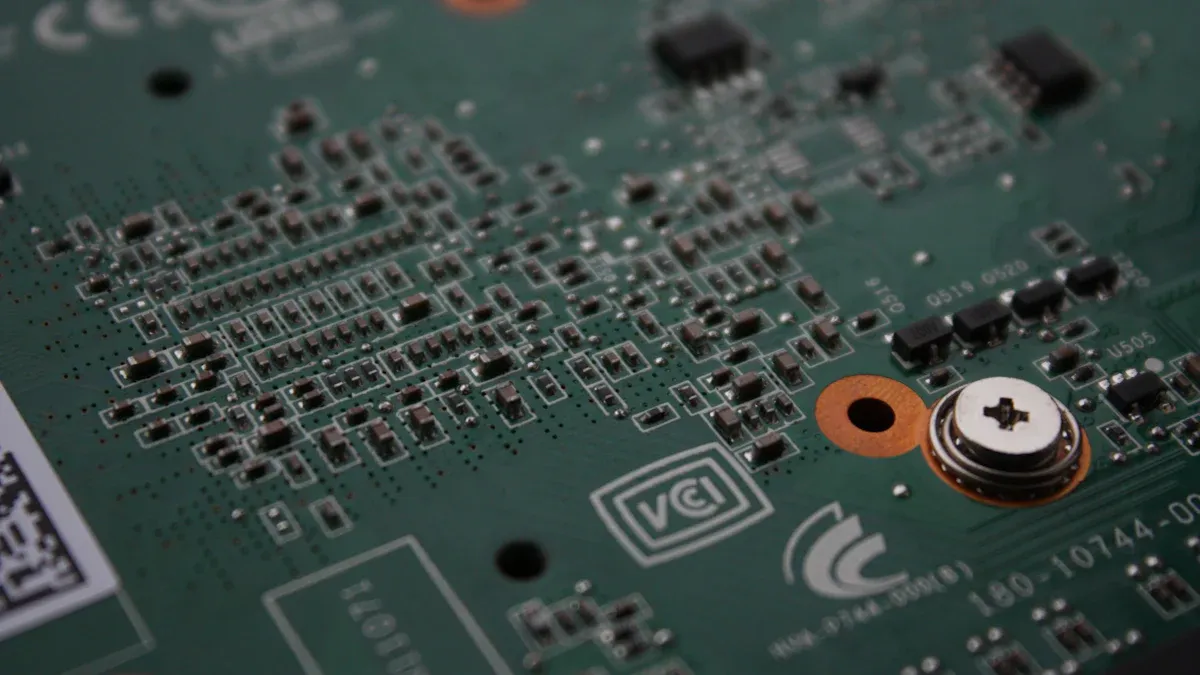

Compatibility with Automation

Automation has changed how electronics are made. SMD components are key to this change. Their design works perfectly with automated machines. This makes production faster, easier, and more accurate. Pick-and-place machines are built to handle SMDs. These machines place tiny parts on PCBs quickly and precisely.

SMDs make assembly simpler. Unlike older parts, they don’t need holes in PCBs. This skips a whole step, saving time and money. Automated systems use reflow soldering to attach SMDs. This method creates strong connections and reduces mistakes. The result is better-quality products.

The need for smaller, better electronics has increased the use of SMDs. Here are some facts about their growth:

The SMD market will grow from $65 billion in 2023 to $120 billion by 2032, with a 7% yearly growth rate.

Smaller, efficient parts are needed in industries like cars, gadgets, and telecom.

SMDs improve assembly and fit with smart manufacturing trends like IoT.

In cars, SMDs are used in electric vehicles and safety systems. They work well even in tough conditions. In telecom, SMDs support 5G, helping with faster speeds and better networks.

Tip: To get the most from SMDs, design your PCB for pick-and-place machines. Keep parts spaced and aligned properly.

Using SMDs with automation also cuts waste. Machines place parts exactly where needed, reducing material loss. This makes SMDs a greener choice for manufacturers aiming to lower their environmental impact.

It’s clear that SMDs and automation are a powerful pair. They simplify production and help create the advanced tech we use every day.

Challenges of SMD Components

Inspection and Assembly Difficulties

Working with SMD components can be tricky. Their tiny size makes spotting mistakes harder. Machines like pick-and-place systems help, but they aren’t perfect. You need special tools to place parts correctly on circuit boards.

Studies compare surface mount technology (SMT) with older methods like PTH:

Metric | SMT Components | PTH Components |

|---|---|---|

Inventory Accuracy | 74.8% | |

Rework and Scrap Costs | Higher | N/A |

Yield | Included | N/A |

Defect Rate | Included | N/A |

These numbers show SMT improves inventory accuracy but raises rework costs. Fixing mistakes is harder with SMD components. Careful monitoring helps reduce errors and improve assembly success.

Rework and Repair Limitations

Fixing SMD components is challenging. Their small size and many solder joints make repairs harder. Using too much heat or the wrong tools can damage the board or nearby parts.

Here are common repair problems:

Problem | Effect on Repairs |

|---|---|

Too many solder joints | Can harm chips, causing more damage or rework. |

Poor training | Leads to lower repair success due to lack of skill. |

Wrong tools | Makes repairs harder and less effective. |

Lack of preparation | Increases risk of damage during repairs. |

Heat control issues | Can harm nearby parts or cause oxidation. |

Hard-to-find problems | Small parts make detecting issues difficult. |

Skilled workers and good tools are key to fixing these issues. Training and advanced equipment improve repair success in electronics.

Need for Specialized Tools and Skills

Handling SMD components needs special tools and training. Regular soldering irons won’t work well. You need tools like reflow ovens, microscopes, and fine tweezers. These help manage the delicate parts.

Workers must also know how to handle these tools. Without training, they may damage parts or struggle with repairs. For example, controlling heat during soldering is very important. Too much heat can ruin parts or cause oxidation.

Investing in training and modern tools makes assembly easier. It reduces mistakes, saves time, and helps devices last longer.

Applications of SMD Components

Consumer Electronics

SMD components are crucial for making small and powerful gadgets. They are used in items like smartphones, tablets, laptops, and wearables. Their tiny size helps fit more features into smaller devices. This meets the need for portable and efficient electronics.

The consumer electronics industry depends on SMD components for saving space and cutting costs. For example, smartphones use SMD resistors and capacitors to handle power and signals well. Fitness trackers and other wearables rely on SMD parts for accurate health tracking and reliability.

Fun Fact: Modern slim smartphones and tablets wouldn’t exist without SMD components.

Automotive Electronics

SMD components are vital in cars for safety and performance. They are found in sensors, lighting systems, and infotainment units. These parts can handle tough conditions like heat and vibrations, making them perfect for vehicles.

One example is SMD NTC thermistors, which meet AEC-Q200 safety standards. They help stop electric car batteries from overheating. Good thermal management improves both safety and performance in cars.

Key Uses in Cars:

Managing electric car batteries.

Advanced driver-assistance systems (ADAS).

LED lights for better visibility and energy savings.

Tip: Use automotive-grade SMD components for durability and safety compliance.

Aerospace and Defense Systems

Aerospace and defense need electronics that work in extreme conditions. SMD components are ideal because they are small and perform well. They are used in avionics, radar, and communication systems where space and weight matter.

For example, radar systems depend on SMD parts for processing signals and sending data. Satellites also use SMD components because their lightweight design lowers launch costs. Their ability to work under stress makes them essential for aerospace.

Sector | Example Uses | |

|---|---|---|

Consumer Electronics | Phones, tablets, wearables | Small, light, reliable |

Automotive | Sensors, lights, infotainment | Handles tough conditions |

Aerospace | Avionics, radar, communication | Compact, works in extreme environments |

Note: For aerospace designs, pick SMD components tested for extreme conditions.

Industrial and Medical Devices

SMD components are crucial for industrial and medical devices. These parts are small, reliable, and work well in tight spaces. They are used in factory machines and life-saving medical tools. Their compact size allows them to fit where space is limited but performance matters.

In factories, SMD components improve how machines and systems work. They are found in sensors, motor controllers, and power supplies. These parts collect accurate data and keep machines running smoothly. They also reduce electromagnetic interference (EMI) in places with many electronic systems.

Medical devices need even higher standards. SMD components meet rules like IEC 60601 for safe medical hardware. They also follow ISO 13485, which ensures quality in making medical devices. These rules guarantee safety and top performance for medical tools.

Tip: Use SMD components with ISO 9001 and FDA approval for reliable medical PCBs.

Electromagnetic compatibility (EMC) is very important in medical devices. SMD filters help devices meet EMC rules, stopping interference. This is key for tools like pacemakers and imaging systems, where small errors can be dangerous.

Picking SMD components with good certifications ensures safe and efficient devices. These parts meet strict standards, making them essential for modern industrial and medical technology.

SMD components have changed electronics by making devices smaller and better. They are important in industries like telecom, cars, and gadgets. For example, today’s smartphones use about 1,100 tiny ceramic capacitors. This shows how much we need small SMD parts. Also, Kyocera’s KGM03 Series MLCCs help 5G grow, with over 5.3 billion users expected by 2029.

Reasons why SMDs are growing:

Smart cities and self-driving cars need advanced sensors and systems.

People want smaller, sharper screens in their gadgets.

New screen types like OLED and LED keep improving.

These parts are key for new ideas, from smart cities to wearables. Their use in many industries shows how they shape future technology.

FAQ

What are SMD components used for?

SMD components help make electronics smaller and faster. They are found in phones, laptops, cars, and medical devices. Their small size lets more features fit into tight spaces.

How do SMD components improve performance?

SMD components make electrical paths shorter. This reduces signal problems and boosts speed. They work well in 5G networks, smart gadgets, and advanced computers.

Are SMD components hard to repair?

Yes, fixing SMD components is challenging because they are tiny. Special tools like microscopes and reflow ovens are needed. Training helps avoid damage during repairs.

Why are SMD components better for automation?

SMD components are great for automated assembly. Machines like pick-and-place systems handle them easily. Automation makes production faster and reduces mistakes.

Can SMD components handle tough conditions?

Some SMD components are made to last in harsh environments. They can handle heat, vibrations, and stress. You’ll see them in cars, satellites, and factory machines.

See Also

PCBA’s Impact on Elevating Today’s Electronic Innovations

The Essential Role of PCBA Prototyping in Innovation

Exploring Android PCBA’s Significance in Current Technology

Why Test Jigs Are Crucial for PCBA Production Today

Understanding PCBA Services and Their Importance in Manufacturing