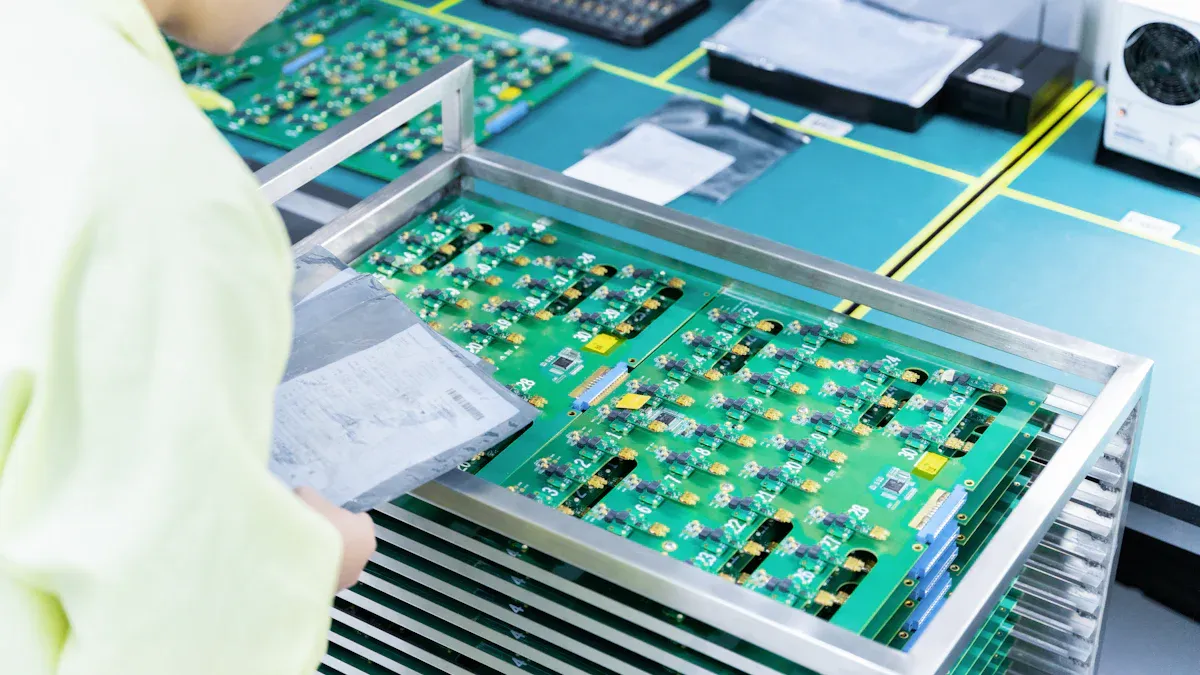

Manufacturing PCBA has special problems that affect quality and cost. Moving from prototypes to large production can cause delays. These delays often happen because of missing parts or design mistakes. You can solve these problems by using smart methods like Lean Manufacturing or Six Sigma. These methods use data to find problems and fix them. Experts in fields like cars and electronics show how good techniques and strict checks can keep costs low and quality high. Fixing PCBA problems early helps make production easier and results better.

Key Takeaways

Make designs easy to build. Simple designs lower costs and waste. They also make production faster and improve product quality.

Test and simulate designs early. These tools find problems before making real models, saving time and money.

Use good quality checks. Tools like SPC help find mistakes early and make products better.

Work well with suppliers. Good communication and trust ensure fast deliveries and better parts, keeping production smooth.

Train your team well. Skilled workers spot problems quickly, making better products and faster production.

Overcoming PCB Design Challenges

Making Designs Easy to Manufacture

Designing for easy manufacturing (DFM) makes PCB production simpler. It helps lower material costs, reduce waste, and improve quality. A simple design can save time and money during production. Avoiding complex designs makes the manufacturing process smoother and faster.

To do this, work with skilled designers and follow clear rules. Picking the right materials makes PCBs stronger and better at handling heat. Good heat management stops overheating and keeps products reliable. These steps make production easier and reduce the chance of problems.

Here’s how DFM helps your projects:

Reduces waste during production.

Improves product quality and reliability.

Speeds up time to market.

Makes manufacturing faster with fewer delays.

By focusing on DFM, you can solve PCB design problems early and prepare for smooth production.

Fixing PCB Layout Mistakes

PCB layout mistakes can cause delays and failures. You can avoid these by using careful planning and reliable methods. For example, connecting tightly to ground reduces unwanted signals. Smaller loops lower radiation and improve signal quality. Ground layers protect signal layers, keeping signals clean and strong.

Physical issues like bending or cracks can weaken PCBs. To fix this, use rounded corners and curved lines to spread stress evenly. Special coatings protect against water and shaking. Stress tests predict weak spots before they happen. These steps keep your designs strong in tough conditions.

Working with skilled designers helps catch mistakes early. Fixing errors before production saves time and money. It also ensures your designs meet high standards.

Using Tools to Test and Simulate

Testing and simulation tools help solve PCB design problems. These tools show possible issues before making physical prototypes. For example, SPICE software checks signal quality and finds interference problems. This keeps signals clear and reduces errors.

Advanced tools calculate impedance and check power flow. They make sure designs work well in real-world situations. Programs like Ansys CoDesigner for Altium Designer help simulate signal behavior and power use.

Testing early with these tools avoids costly mistakes and improves performance. Using simulation data in your design process creates reliable PCBs that meet industry needs.

Tackling Manufacturing Defects in PCBA

Improving Quality Control Steps

Manufacturing mistakes can hurt your PCBA production’s success. Better quality control makes sure products work well and meet standards. A strong system checks every step, from design to assembly.

Tools like Statistical Process Control (SPC) track data to find problems early. This stops defects before they happen. Root Cause Analysis (RCA) helps find the main reason for issues. Fixing these causes leads to lasting improvements in quality.

Here’s a simple look at key quality metrics:

Metric | What It Means |

|---|---|

First Pass Yield (FPY) | Percent of products passing tests the first time; higher is better. |

Defect Rate | Percent of failed products; lower means better quality. |

Return Rate | Percent of items sent back by customers; high rates show problems. |

Failure Rate | How often products fail during use; lower is better. |

Reliability Metrics | Measures like MTBF (Mean Time Between Failures) show product dependability. |

Cost of Quality (COQ) | Tracks costs for quality checks and fixing failures. |

Process Capability Index (Cp/Cpk) | Shows how stable and consistent the manufacturing process is. |

Always aim for improvement. Let your team suggest better ways to work. Train them on quality rules. These actions lower defects and make customers happier.

Making Soldering Better

Soldering is an important part of PCBA production. Bad soldering can cause weak connections and product failures. To improve soldering, focus on temperature, materials, and steady processes.

Good soldering materials make strong, reliable connections. Automated machines keep temperatures steady, avoiding overheating or cold joints. Regular machine checks ensure they work properly.

Test early during soldering to catch problems fast. For example, X-ray checks find hidden soldering issues like gaps or misalignments. By improving soldering, you reduce defects and make better PCBA products.

Using Automated Inspection Tools

Automated inspection tools help find and stop defects. These tools use advanced imaging to spot problems you can’t see by eye.

Automated Optical Inspection (AOI) scans PCBs for errors like misplaced parts or bad soldering. X-ray tools check inside layers and connections. These systems give accurate results and reduce manual checks.

Adding automated inspections to your production saves time and ensures quality. Early testing with these tools catches problems before products are sold. This approach improves quality and helps your PCBA production succeed long-term.

Solving Supply Chain Problems in PCBA

Building Strong Supplier Partnerships

Good supplier partnerships help solve supply chain problems in PCBA. Reliable suppliers provide quality parts on time, avoiding delays. To build trust, communicate clearly, pay on time, and plan long-term. These actions create teamwork and shared success.

Benefits of managing suppliers well include:

Benefit | What It Means |

|---|---|

Saving Money | Lower storage and shipping costs improve your budget. |

Happier Customers | Fast delivery and good products keep customers loyal. |

Quick production and adapting to changes give you an edge. |

Focusing on supplier relationships makes your supply chain stronger and PCBA production better.

Handling Component Delivery Times

Managing delivery times keeps production running smoothly. Late parts can slow work and raise costs. Using a Manufacturing Execution System (MES) helps fix these problems. MES tracks parts, improves workflows, and ensures on-time delivery.

For example, PCBasic’s MES helps make small batches quickly. It also solves problems like late deliveries and bad parts, making production faster. Using tools like this reduces delays and keeps PCBA production steady.

Reducing Risks with Backup Suppliers

Having backup suppliers helps avoid supply chain problems. Relying on one supplier can cause trouble if they run out of parts. Using multiple suppliers ensures you always have what you need.

Common problems include not enough materials, too few parts made, or slow shipping. To fix this, use several suppliers and keep extra important parts in stock. These steps lower risks and make your supply chain stronger.

Watching supply chain data can also show risks early:

Metric | What It Shows |

|---|---|

Costs | |

Delivery Time | Long waits for parts slow production. |

Stock Levels | Using many suppliers helps avoid running out of parts. |

By following these tips, you can solve supply chain problems and keep PCBA production running smoothly.

Improving Teamwork in PCBA Manufacturing

Better Communication Between Teams

Good communication helps teams work well in PCBA manufacturing. Sharing clear information avoids mistakes and keeps production smooth. When everyone knows their job, work gets done faster. A learning environment also helps teams share ideas and improve.

Here’s why clear communication matters:

Keeps everyone updated and working together.

Uses each person’s skills for team success.

Shares knowledge to make things better over time.

Focus on open communication to solve problems and build a strong team culture in PCBA processes.

Using Teamwork Software Tools

Teamwork software tools make working together easier in PCBA manufacturing. These tools help with communication, tasks, and sharing files. For example, quick chats fix problems fast, and task lists keep everyone responsible.

Feature/Benefit | What It Does |

|---|---|

Quick communication tools | Helps teams solve issues fast by chatting in real-time. |

File sharing and updates | Makes sure everyone has the latest files and resources. |

Task tracking | Lets teams see progress and know who is doing what. |

Works with other systems | Combines tools to make work simpler and faster. |

Better teamwork and info sharing | Speeds up decisions and keeps everyone on track. |

Clear project goals and accountability | Encourages team members to take responsibility for their tasks. |

Faster work processes | Cuts down on extra emails and meetings, saving time. |

These tools improve teamwork, manage heat better, and make processes more efficient for better results.

Setting Clear Documentation Rules

Clear rules for documentation keep PCBA manufacturing organized and high-quality. Standards like ISO 9001 and IPC help meet industry rules. Writing things down and checking often shows where to improve and stay on track.

Standard | What It Means |

|---|---|

ISO 9001 | A global rule for quality that focuses on customer needs. |

AS 9100 | Made for aerospace, adding extra rules to ISO 9001. |

IPC Standards | Sets rules for making strong and reliable PCBs. |

Using these standards helps fix problems, manage heat, and succeed in PCBA projects. Updating documents and checking them often keeps your work competitive and high-quality.

Staying Competitive in PCBA Manufacturing

Using Advanced Manufacturing Technologies

To stay ahead in PCB assembly, use advanced technologies. These tools make work faster and reduce mistakes. For example, machines can assemble parts automatically. This speeds up production and lowers human errors. Faster production means quicker delivery of better products to customers.

These technologies also cut costs and improve product consistency. Using better materials and automation makes products more reliable. Reliable products make customers happy. Below is a table showing how these technologies help:

Benefit | Description |

|---|---|

Better Efficiency | Faster workflows and smarter processes save time and resources. |

Higher Quality | Fewer defects and stronger products make customers trust your work. |

Lower Costs | Less waste and smarter operations save money and increase profits. |

By using these tools, you can fix signal problems and meet industry needs.

Making Processes Sustainable

Sustainability is important for PCB assembly. It helps the environment and supports long-term success. You can recycle materials and use low-energy methods to cut waste. Removing extra steps in production saves energy and lowers pollution.

Throwing away circuit boards is hard because they don’t break down easily. This can harm the environment. Recycling and eco-friendly practices help solve this problem. The table below explains key steps for sustainable practices:

LCA Component | Description |

|---|---|

Decides what the assessment will focus on. | |

Collecting Data | Tracks materials and energy used during the product’s life. |

Checking Impacts | Studies how the product affects the environment. |

Learning from Results | Uses findings to improve eco-friendly methods. |

Environmental studies look at pollution, climate change, and health risks. These help you make greener choices while keeping products reliable.

Training Your Team

Your team is key to PCB assembly success. Training them keeps them skilled and ready for new tools. Skilled workers can spot problems early and avoid costly mistakes.

Teach both technical skills and quality rules. For example, show them how to test products early. Early testing makes products stronger and more reliable. A trained team also brings new ideas to improve your work.

Investing in training helps your team make better products. It also keeps your business competitive and successful over time.

Solving PCBA manufacturing problems needs focus on design and quality. Managing supply chains and teamwork also helps improve production. Planning ahead and working together make processes easier and results better. Using new tools and training workers keeps you ahead in the industry.

Track success with these key measures:

KPI | What It Shows |

|---|---|

Cycle Time | How long one production cycle takes |

Yield Rate | Percent of products that meet quality rules |

First Pass Yield | Items passing checks the first time |

Customer Satisfaction | How happy customers are with your products |

Follow these tips to boost quality and efficiency. For tough problems, ask experts for advice and support.

FAQ

What is the biggest problem in PCBA assembly?

The biggest problem is keeping quality high during assembly. Problems like bad soldering, misplaced parts, or weak connections can happen. You can fix these by using strict checks and automated tools.

How can PCBA assembly be made faster?

You can make it faster by using advanced machines, improving workflows, and automating tasks. These steps cut mistakes, speed up work, and give steady results.

Why is Design for Manufacturability (DFM) important?

DFM makes sure your PCB design fits with how it’s made. It lowers mistakes, cuts waste, and makes assembly easier. This saves time, money, and improves product quality.

How do automated inspection tools help in PCBA assembly?

Automated tools like AOI and X-ray find problems early. They are more accurate, reduce human mistakes, and ensure good products. These tools also save time by making checks faster.

Why is training workers important in PCBA assembly?

Training teaches workers to use new tools and methods. Skilled workers can spot and fix problems quickly. This keeps assembly smooth and products high-quality.

See Also

Essential Advice for Selecting a Reliable PCBA Manufacturer

Key Strategies to Enhance PCB Assembly Productivity

Effective Techniques to Improve Your PCBA Engineering Skills