Circuit board connectors are very important in electronic design. They help move power and signals. This ensures that devices work correctly. Connector failures cause about 40-50% of all device failures. This is especially true in military uses. There are many types of connectors. These include board-to-board and wire-to-board options. Choosing the right one for your project is very important. Each type of connector has a special purpose. So, making a smart choice is key for good performance.

Key Takeaways

Circuit board connectors are important for linking printed circuit boards (PCBs). They help devices work correctly.

Picking the right type of connector is very important. This includes options like wire-to-wire or board-to-board. It affects how well the device works and how reliable it is.

Think about things like voltage ratings, environmental conditions, and space limits when choosing connectors for your project.

Regular maintenance is key. Check for loose connections and clean them. This helps PCB connectors last longer.

Making smart choices in connector selection can boost the efficiency and lifespan of your electronic devices.

Overview of Circuit Board Connectors

Definition and Purpose

Circuit board connectors are key parts in electronic devices. They connect printed circuit boards (PCBs) and link PCBs to outside cables. This helps power and signals move well. Here are some main jobs that circuit board connectors do:

Enabling Interconnection Between PCBs: They make strong connections, ensuring good signal and power flow.

Providing Connections Between PCBs and Cables: They connect outside devices to PCBs for communication and data sharing.

Supporting Debugging and Programming: During product testing, connectors help check and confirm designs.

Adapting to Complex Environments: They can handle tough conditions, making sure devices work right.

Facilitating Modular Design and Efficient Production: Their design helps with easy and compact assembly.

Ensuring Stability and Reliability of Data Transmission: They keep connections steady for clear data transfer.

Importance in Electronics

Picking the right circuit board connector is very important for how well electronic devices work. Good connection reliability makes sure the contacts fit together well. This leads to steady signal flow and power supply. Connectors that fit better offer more stability, even if they shake or move.

Choosing the wrong connector can cause big problems. You might have weak connections that stop devices from working, issues with signal quality, or dirt that harms parts. Sometimes, it can even create safety dangers, like fire risks. So, knowing what your project needs is key for making smart choices.

By choosing the right PCB connectors, you improve how well your electronic devices work and last longer.

Types of PCB Connectors

Wire-to-Wire Connectors

Wire-to-wire connectors let you join two wires directly. They are used in many places, especially in cars and factories. These connectors make sure power and signals connect well. You can often find them in devices like sensors and control units.

Tip: When picking wire-to-wire connectors, check the current and voltage ratings. This helps ensure they fit your project’s needs.

Industry | Application Description |

|---|---|

Automotive | Used to connect electrical parts like sensors, lights, and control units, needing to be strong. |

Industrial | Found in machines and automation systems, where reliability is key to avoid downtime. |

Consumer Electronics | Seen in devices like smartphones and laptops, needing small and high-performance designs. |

Board-to-Wire Connectors

Board-to-wire connectors connect a printed circuit board (PCB) to outside wires. They are important for moving power and signals from the PCB to other parts. These connectors come in different styles, including locking types for secure connections.

Voltage Ratings:

The maximum voltage rating shows the highest voltage a connector can handle to avoid problems.

The working voltage rating is a suggestion for the voltage of your system, often recommended to be one-third to half of the maximum rating.

You can find board-to-wire connectors in consumer electronics, car systems, and industrial machines. They are key for keeping stable connections in devices like smartphones and medical tools.

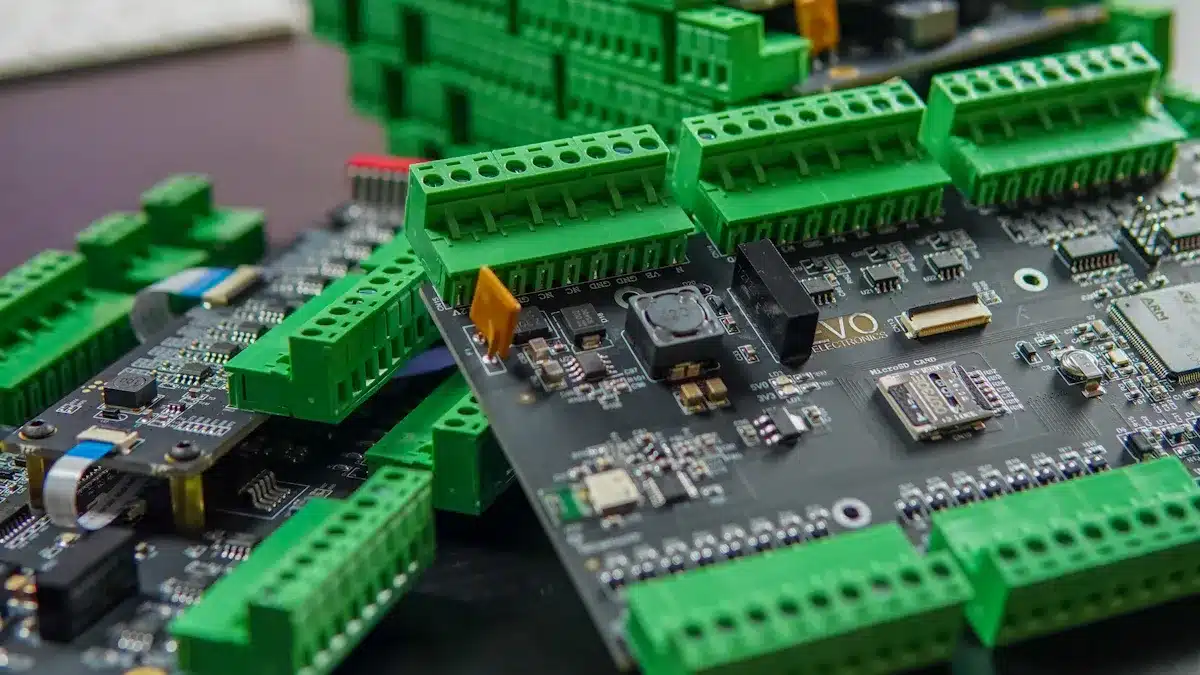

Board-to-Board Connectors

Board-to-board connectors link several PCBs together. They help with modular design, letting you stack or arrange boards in different ways. This makes it easier to set up electronic systems and supports fast data transfer.

Connector Type | Advantages |

|---|---|

Edge Connectors | Use sliding contacts; may wear out with many connections; not good for frequent disconnection. |

Fully-Shrouded or Coaxial Style | Allows high power transfer; provides shielding; good for RF systems; higher current ratings. |

Low-profile Horizontal Connector | Allows horizontal removal; great for low-profile uses; helps access add-in cards. |

Pin Header Blocks | Good for modularity; allows multiple levels; suitable for low current uses. |

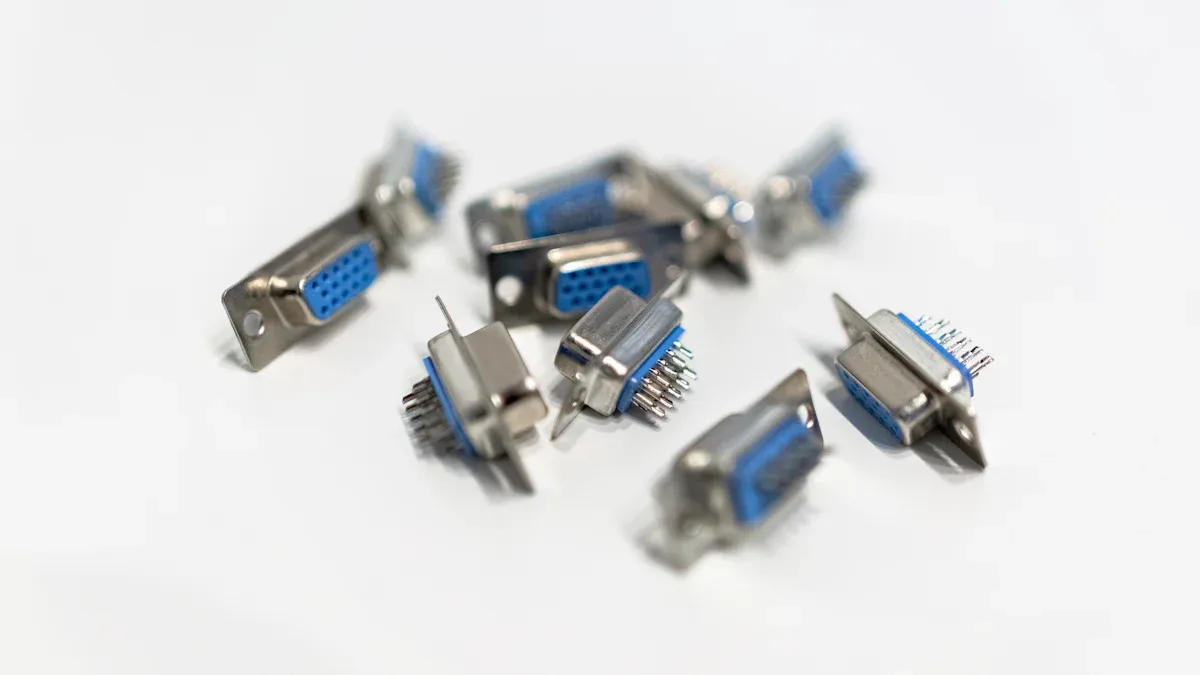

Input/Output Connectors

Input/output connectors give secure electrical contact for data sharing. They allow easy plugging and unplugging of cables. You often find these connectors in industrial communication systems and machines.

Characteristic | Description |

|---|---|

Functionality | Provides secure electrical contact and smooth cable plugging/unplugging for data sharing. |

Construction | Has terminal blocks with copper alloy contacts for better conductivity. |

Orientation Options | Offers different orientation choices for design flexibility. |

Installation Ease | Easy to install without needing wire termination or soldering. |

Durability | Good for tough environments due to its locking design. |

Space-saving | Made to save space, making them great for compact uses. |

FFC/FPC Connectors

FFC (Flat Flexible Cable) and FPC (Flexible Printed Circuit) connectors connect circuits in small devices. FFC connectors are simpler and cheaper, while FPC connectors allow more complex routing.

Feature | FFC (Flat Flexible Cable) | FPC (Flexible Printed Circuit) |

|---|---|---|

Structure & Function | Flat cable with simple 1:1 wiring | Flexible mini circuit board with complex routing |

Customization | Standardized, reusable | Custom-designed for specific tasks |

Design Complexity | Linear routing only | Supports multi-layer, angled paths |

Cost & Reusability | Lower cost, reusable | Higher cost, limited reusability |

Flexibility & Durability | Good for repeat-use connections | Better in tight spaces, harsh conditions |

You can find FFC connectors in devices like printers and laptops, while FPC connectors are common in smartphones and medical devices.

Crimp-Type Connectors

Crimp-type connectors provide a quick and reliable way to connect wires without soldering. They are very strong, making them great for industrial uses.

Advantages:

Faster installation than soldering, improving production speed.

Well-crimped connections resist shaking and stress, making them reliable in many uses.

But, be careful to avoid common problems, like uneven crimp quality and loose connections.

Pin Header and Socket Connectors

Pin header and socket connectors are important for testing and modularity in electronics. They allow removable connections, making it easy to change or replace parts without desoldering.

Standard Sizes:

2.54mm pitch spacing pin headers and sockets come in many styles.

They are available in straight, right angle, and U-shaped styles, offering various design choices.

These connectors are widely used in both consumer and industrial electronics, improving serviceability and design flexibility.

Applications of PCB Connectors

Consumer Electronics

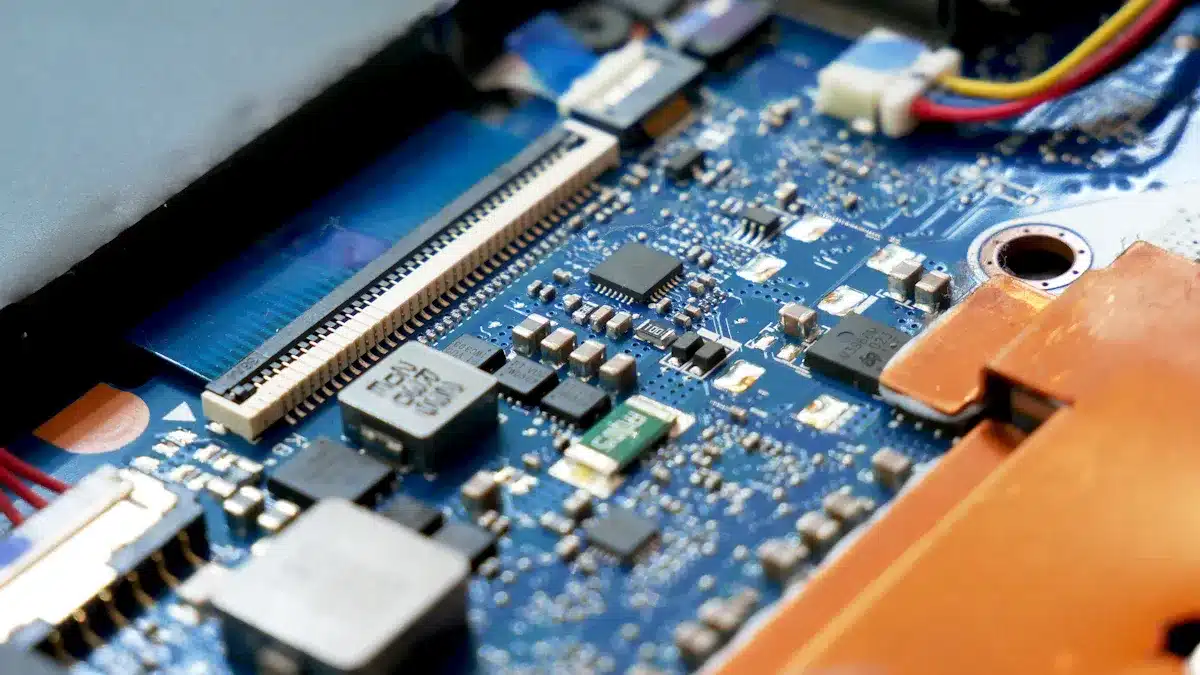

In consumer electronics, PCB connectors are very important. They help devices work well. You can find these connectors in smartphones, laptops, and gaming consoles. They connect different parts like displays, batteries, and audio/video connectors. These connectors need to be small and reliable. They must fit in tight spaces while still working well.

Industrial Equipment

Industrial equipment depends on strong PCB connectors. These connectors must handle tough conditions. They face extreme temperatures, vibrations, and exposure to dust and liquids. Important design features include strong locks and materials that resist corrosion. These features help ensure they work well in hard environments.

Application | Temperature | Shock/ Vibration | Pressure | Corrosion | Explosion | Liquids | Dust |

|---|---|---|---|---|---|---|---|

Industrial | X | X | X | X | X | X |

Automotive Systems

Automotive systems have special challenges. They deal with constant vibrations and changing temperatures. PCB connectors in cars must work between -55°C and 125°C. They also need to handle vibrations from engines and roads. Solutions like coatings and underfill materials make them last longer and reduce stress on solder joints.

Vibration problems cause about 25% of failures in automotive PCBs.

Changes in temperature and vibrations speed up solder joint wear.

Telecommunications

In telecommunications, PCB connectors must keep signals clear. They also need to handle the right voltage and current levels. These connectors often connect and disconnect a lot, so high mating cycle ratings are very important. They must also resist tough environmental conditions like extreme temperatures, dust, moisture, vibrations, chemicals, and radiation.

Locking mechanisms are very important for connectors in moving devices.

Keeping signal quality is crucial based on the size and type of data sent.

Choosing the Right PCB Connector

Picking the right PCB connector is very important for your electronic project. You need to think about several things to make sure it works well and lasts long.

Factors to Consider

When you choose a PCB connector, pay attention to these factors:

Factor | Description |

|---|---|

Make sure the connector’s current and voltage ratings match your system’s needs for good power flow. | |

Environmental Conditions | Think about temperature, humidity, and dust or chemicals that can change how the connector works. |

Mechanical Durability | Check how many times you can connect and disconnect the connector without it breaking. |

Reliability Considerations | Pick connectors known for being reliable to avoid problems and make them last longer. |

Contact Resistance | Look for connectors with low contact resistance to reduce power loss and keep signals clear. |

Vibration and Shock Resistance | Choose connectors made to handle tough conditions, like in cars or planes. |

Installation Tips

Installing PCB connectors correctly can really help how they work. Follow these steps for strong connections:

Define Your Electrical Needs: Make sure the connector’s ratings are at least 25% higher than your system’s maximum values for safety.

Identify the Connection Type: Pick the connection type based on your design layout.

Consider Space Constraints: Choose a mounting option that fits your PCB layout and assembly process.

Evaluate Environmental Factors: Match the connector’s material and protection ratings to your device’s working conditions.

Prioritize Reliability: Go for connectors that are durable, have low contact resistance, and fit your application’s needs.

Tip: Always check your connections after installation. This helps avoid problems later.

Maintenance and Troubleshooting

Regular maintenance and troubleshooting can help your PCB connectors last longer. Here are some good techniques:

Finding Common Issues: Look for loose connections and rust or dirt on connector surfaces.

Fixing the Problems: Tighten loose connectors and clean rusty ones with the right tools.

Knowing When You Need Help: Spot tough problems that might need expert help.

To troubleshoot well, gather these tools:

Multimeter

Soldering Iron

Isopropyl Alcohol

Microscope or Magnifying Glass

Electrical Tape

Wipes

Quote: “Check the PCB visually, test power and connections, and find faulty parts to ensure good troubleshooting and repair.”

Looking at the visual parts and physical components of the PCB is very important. Check for burn marks, bulging parts, and test each part with a multimeter to find failures.

By thinking about these factors, following installation tips, and doing regular maintenance, you can make sure your PCB connectors work well and reliably in your electronic projects.

In this blog, you learned about different types of circuit board connectors. These include wire-to-wire, board-to-wire, and board-to-board connectors. Each type is used for specific jobs, from consumer electronics to industrial machines.

When picking connectors, remember these important points:

Make sure the connector can handle the voltage and current needed for your project. This helps avoid problems and safety risks.

Think about environmental factors like temperature, humidity, and chemicals that could change how well they work.

Choose connectors that fit in the space you have while still meeting performance needs.

By making smart choices, you can improve the reliability and efficiency of your electronic projects. 🌟

FAQ

What are circuit board connectors used for?

Circuit board connectors connect printed circuit boards (PCBs) to each other and to outside devices. They help move power and signals, making sure electronic devices work properly.

How do I choose the right connector for my project?

Think about things like current and voltage ratings, environmental conditions, and space limits. Make sure the connector fits your project’s needs for reliability and performance.

Can I reuse PCB connectors?

Some connectors, like crimp-type and pin headers, can be reused. But connectors that get worn out or damaged should be replaced to keep connections strong.

What maintenance do PCB connectors require?

Check connectors often for dirt, rust, or loose connections. Clean them with isopropyl alcohol and tighten any loose parts to keep them working well.

Are there different sizes of PCB connectors?

Yes, PCB connectors come in many sizes and pitches. Common sizes include 2.54mm and 1.27mm pitch connectors. Pick the size that fits your PCB layout and design needs.

See Also

Examining Key Differences Between PCBA And PCB Designs

Investigating Testing Methods for PCBA In Electronics Production

Benefits And Challenges Of Flex PCBA In Today’s Electronics