Printed circuit boards, or PCBs, which stands for “printed circuit boards,” are very important in electronics. They connect different parts in devices we use daily. Almost all modern devices need PCBs to work. This includes smartphones and home appliances. The global PCB market has grown a lot. This growth is due to the need for connected cars and IoT technology. As technology changes, PCBs stay key for new ideas and efficiency in many uses.

Key Takeaways

PCBs are important for linking electronic parts in devices like phones and computers.

There are three main types of PCBs: single-sided, double-sided, and multi-layer. Each type has different uses.

Picking the right materials for PCBs affects how well they work and how long they last.

PCBs are very important in industries like electronics, healthcare, cars, and airplanes.

Knowing about PCBs helps you see why they are important for modern technology to work well.

What is PCB?

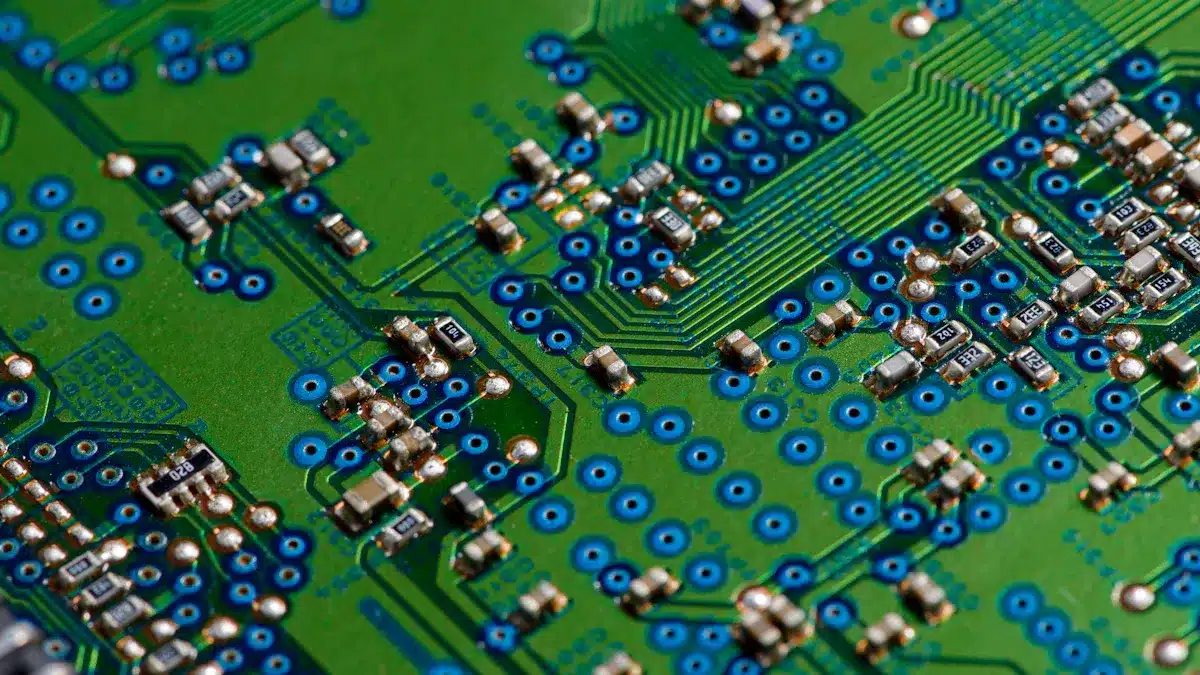

A printed circuit board (PCB) is very important in today’s electronics. It acts like a base for connecting different electronic parts. You can think of a PCB as the backbone of electronic devices. It holds and connects pieces like resistors, capacitors, and microchips. This helps them work together smoothly.

PCBs have several key jobs in electronic circuits:

Mechanical Support: They give a strong base for electronic parts. This keeps them secure.

Electrical Connections: Copper lines on the PCB create paths for electrical signals. These lines connect different parts, helping them talk to each other.

Space Efficiency: Using PCBs makes things simpler and saves space compared to old manual wiring. This compact design is important for modern devices, which often need to be smaller.

A typical PCB has many layers. These layers include a substrate, copper lines, a solder mask, and a silkscreen layer. Each layer helps the board work well and be reliable. The substrate gives support, while the copper lines carry electrical signals between parts. The solder mask protects the copper lines from harm, and the silkscreen layer helps with labeling.

Types of PCBs

When you look at printed circuit boards, you will see three main types: single-sided, double-sided, and multi-layer PCBs. Each type has its own structure and works for different uses in electronic devices.

Single-Sided PCB

A single-sided PCB has one layer of substrate with a conductive layer on one side. All components are placed on this one side. This design is simple and cheap, making it great for basic devices like LED drivers.

Advantages of Single-Sided PCBs:

Easier to test and fix because traces and components are visible.

Repairs are simpler since there are no hidden layers.

However, single-sided PCBs might not work well for complex projects. They have lower capacity and are larger than other types.

Double-Sided PCB

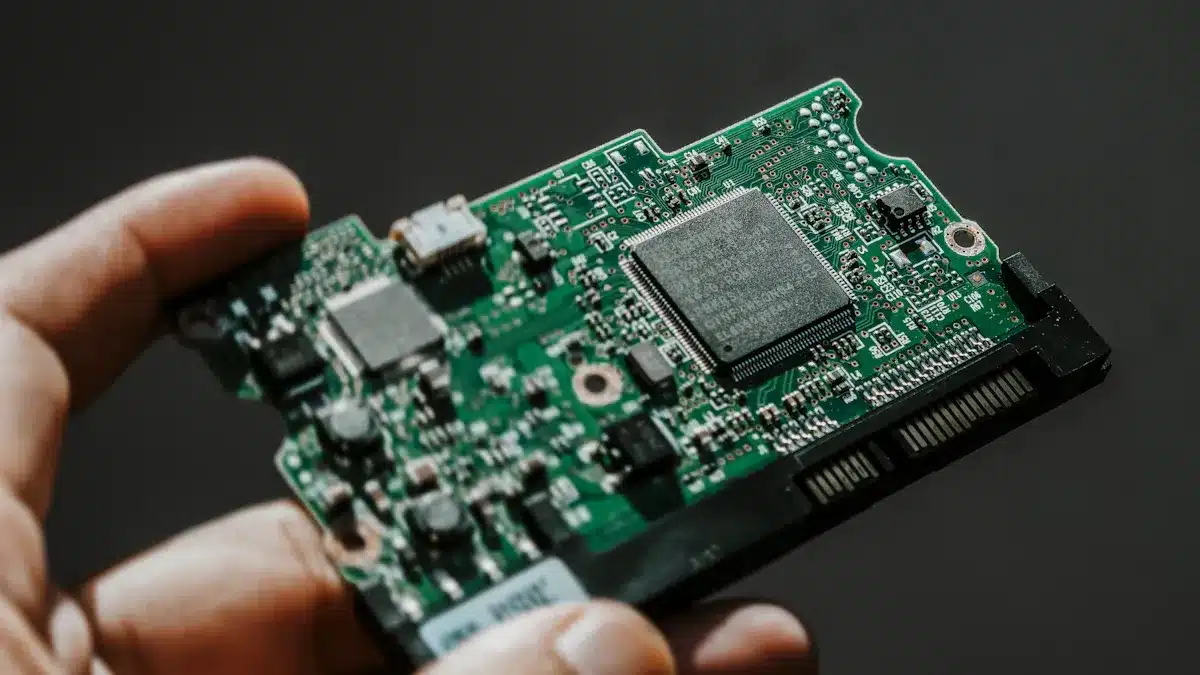

Double-sided PCBs have conductive layers on both sides of the substrate. These layers connect through vias, allowing for more complex designs. You will often find double-sided PCBs in smartphones, computers, and industrial control systems.

Key Features of Double-Sided PCBs:

More components can fit on the board.

Compact designs that boost performance.

This type of PCB is great for applications needing higher circuit complexity. It supports advanced communications and is widely used in cars.

Multi-Layer PCB

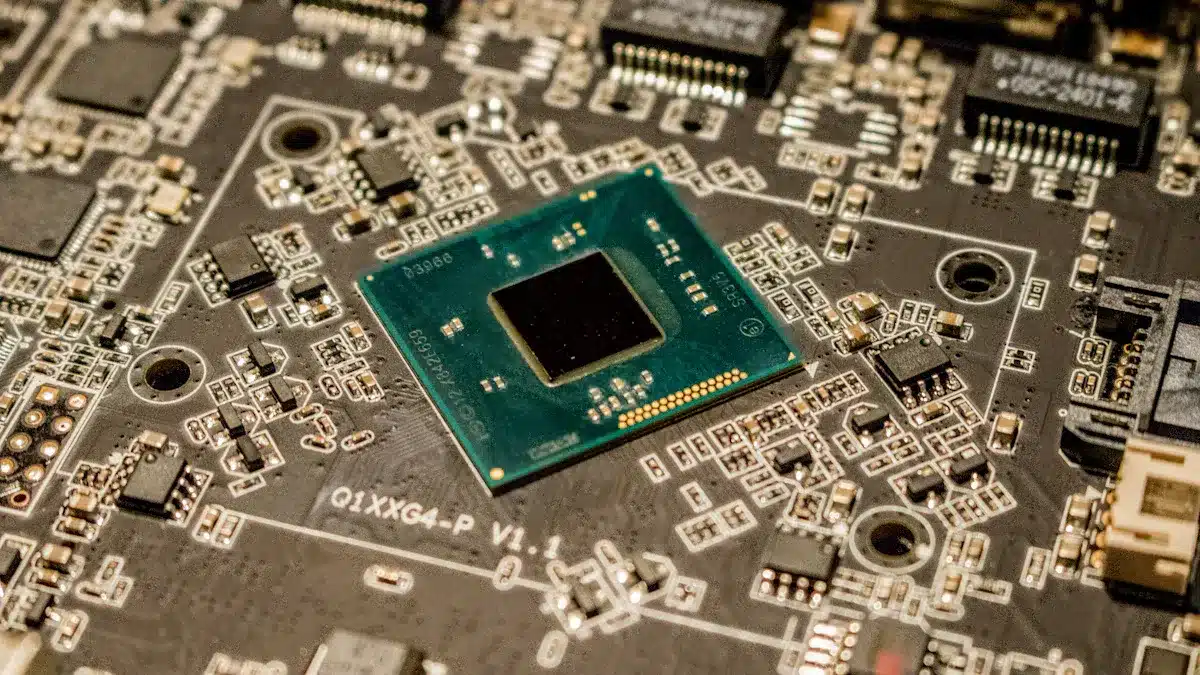

Multi-layer PCBs have three or more conductive layers connected with different types of vias. This design allows for high-density circuits, making them important for advanced devices.

Benefits of Multi-Layer PCBs:

Improved signal quality and reliability.

You will find multi-layer PCBs in IoT devices, advanced sensors, and medical devices. Their ability to support smaller designs makes them vital for modern technology.

Type of PCB | Structure Description | Complexity Level |

|---|---|---|

Single-Sided PCB | One layer of substrate with a conductive layer on one side. Components are on one side. | Simple, used in basic devices. |

Double-Sided PCB | Two conductive layers on both sides of the substrate, interconnected through vias. | Moderate, allows for more complex designs. |

Multi-Layer PCB | More than three conductive layers, interconnected with various types of vias. | High, used in sophisticated devices requiring many connections. |

Knowing these types of circuit boards helps you see their roles in different uses. Each type has a special purpose, making sure electronic devices work well.

Construction of Printed Circuit Boards

Making printed circuit boards needs careful choice of materials and a detailed process. Knowing these parts helps you see how PCBs work in electronic devices.

Materials Used

Many materials are used to build PCBs. These materials form the base of the board. They provide support, connect electricity, and insulate. Here are some important materials:

FR-4: This is a fiberglass-reinforced epoxy resin. It is the most common substrate material. It gives great electrical insulation and strength.

Polyimide: This material is good for high temperatures. It is known for its thermal stability.

Rogers: These are polymer-ceramic composites. They work well in high-frequency uses.

Aluminum: This is often used for LED boards. Aluminum helps with heat dissipation.

Choosing the right substrate material affects how long the PCB lasts and its cost. Good quality substrates ensure the best electrical insulation and reliable performance in different conditions.

Manufacturing Process

The process of making PCBs has several important steps. Each step is key to making sure the final product is good quality. Here’s a simple overview of the process:

The Design

Printing the Design

Creating the Substrate

Printing the Inner Layers

Ultraviolet Light Exposure

Removing Unwanted Copper

Inspection

Laminating the Layers

Pressing the Layers

Drilling

Plating

Outer Layer Imaging

Final Quality Check

In this process, design is very important for good electrical connections. Things like trace width and impedance can change how well the PCB works. For example, wider traces lower resistance. This improves efficiency and stops overheating in high-current uses. Good design helps keep signals clear and reduces noise in the circuit.

By learning about the materials and steps in PCB construction, you understand how these important parts help modern electronic devices work.

Applications of PCBs

Printed circuit boards (PCBs) are very important in many industries. They help many electronic devices work properly. PCBs are used in everything from everyday gadgets to important systems in healthcare and aerospace. Let’s look at some key uses of PCBs.

Consumer Electronics

PCBs are found in many consumer electronics. You use them in devices like:

Smartphones

Tablets

Smartwatches

Radios

Computers

Televisions

Stereos

Video game consoles

Refrigerators

Microwaves

Coffee makers

More and more consumer products have advanced electronics. This trend helps grow the Internet of Things (IoT). High-Density Interconnect (HDI) technology creates small paths for electricity. This is important for adding more features to one PCB. It helps make devices like smartphones and tablets smaller and lighter while improving performance. Surface Mount Technology (SMT) also helps create smaller devices without losing functionality.

Medical Devices

PCBs are very important for medical devices. They make complex circuits easier, ensuring they work well. The design of PCBs follows strict medical rules for safety. Here are some medical devices that use PCBs:

Cochlear implants

Implanted defibrillators

Responsive Neurostimulator (RNS)

MRIs (Magnetic Resonance Imaging)

CT (Computerized Axial Tomography) scans

Ultrasound equipment

Blood glucose monitors

Heart pacemakers

Medical PCBs must meet high safety and reliability standards. Technologies like rigid-flex boards and Lab-on-PCB improve their functions. This makes PCBs important for smart healthcare. Good thermal management is key since many devices work in tough conditions. Techniques like thermal vias and heat sinks help keep temperatures right, preventing damage and ensuring reliability.

Automotive Applications

In cars, PCBs are crucial for safety and performance. They support many systems, including:

Safety systems like airbag deployment and tire pressure monitoring.

Engine control units that manage how the vehicle runs.

Infotainment systems for entertainment and navigation.

PCBs in safety-critical areas must be very reliable. They need to respond quickly and have backups to avoid failures. Making them smaller is also important because space is limited. Rigid-flex PCBs mix rigid and flexible parts for better placement. Many car systems need energy-efficient PCBs to save battery life, using low-power parts and power management circuits.

Aerospace Components

PCBs are essential in aerospace, supporting communication systems and avionics. They help with data and voice communication needed for safe flights. Here are some key points about PCBs in aerospace:

Choosing components focuses on durability in tough conditions.

Quality control includes strict inspection and testing to ensure they work.

Aerospace PCBs must handle harsh conditions like radiation and temperature changes. Manufacturers use special components and coatings to protect against these factors. This ensures the reliability and long life of important systems. Following standards like IPC-A-610 and IPC-6012DS guarantees high-quality production and performance.

In conclusion, printed circuit boards (PCBs) are very important in today’s technology. They connect electronic parts, improve reliability, and help many industries. You can find PCBs in things like consumer electronics, medical devices, car systems, and aerospace parts.

Here are some important changes that are shaping the future of PCBs:

Miniaturization and HDI: More parts can fit on smaller boards.

Flexible and Rigid-Flex PCBs: These designs allow for new uses.

Embedded Components: They make devices work better and more reliably.

As you use your devices every day, think about how important PCBs are for technology to work well and dependably. Their ongoing changes keep pushing new ideas in the electronics world. 🌟

FAQ

What is PCB design?

PCB design is the process of making the layout for printed circuit boards. You place components and connections to make sure everything works well. Good PCB design is very important for how well electronic devices perform and how reliable they are.

What are the types of PCB assembly?

There are different types of PCB assembly, like surface mount technology (SMT) and through-hole technology. Each type has its own benefits and works best for different uses, based on how complex and big the components are.

How are PCBs used in medical imaging systems?

PCBs are very important in medical imaging systems. They connect different electronic parts, making sure data is processed correctly and images are clear. Reliable PCBs are key for the safety and effectiveness of these important devices.

Can PCBs be used in military and defense applications?

Yes, PCBs are commonly used in military and defense applications. They help with communication systems, navigation, and control systems. Their reliability and strength are very important for good performance in tough situations.

What is a LED PCB?

A LED PCB is a printed circuit board made just for LED uses. It provides electrical connections and helps manage heat for LEDs, making sure they work well and last a long time in lighting solutions.

See Also

Exploring PCBA: Definition and Its Essential Uses in Electronics

Defining PCBA in Electronics and Its Significance Explained

The Advantages and Uses of PCBA in Today’s Electronics