Printed Circuit Board Assembly (PCBA) is key to modern electronics, but what are PCBA exactly? They connect electronic parts on a circuit board to work well. This process improves performance by making connections accurate and reliable. For example, the global PCBA market was worth $68.4 billion in 2023. It is expected to grow to $105.8 billion by 2032, with a 4.9% yearly growth rate. This shows how important PCBA is for new ideas in many fields. It is used in things like gadgets and medical devices. PCBA turns ideas into working technology, making it essential today.

Key Takeaways

PCBA links electronic parts on a board, improving how devices work and last longer.

Knowing the difference between PCB and PCBA matters; PCB is just the board, but PCBA is ready to use and works.

PCBA is important in many fields like gadgets, medical tools, and cars, helping make things better and faster.

Green PCBA making is growing, using safe materials and ways to protect nature while staying good quality.

Spending on good PCBA means better working, lasting products, and happy customers, which is key for great electronics.

What Are PCBA and Its Components?

Definition of PCBA

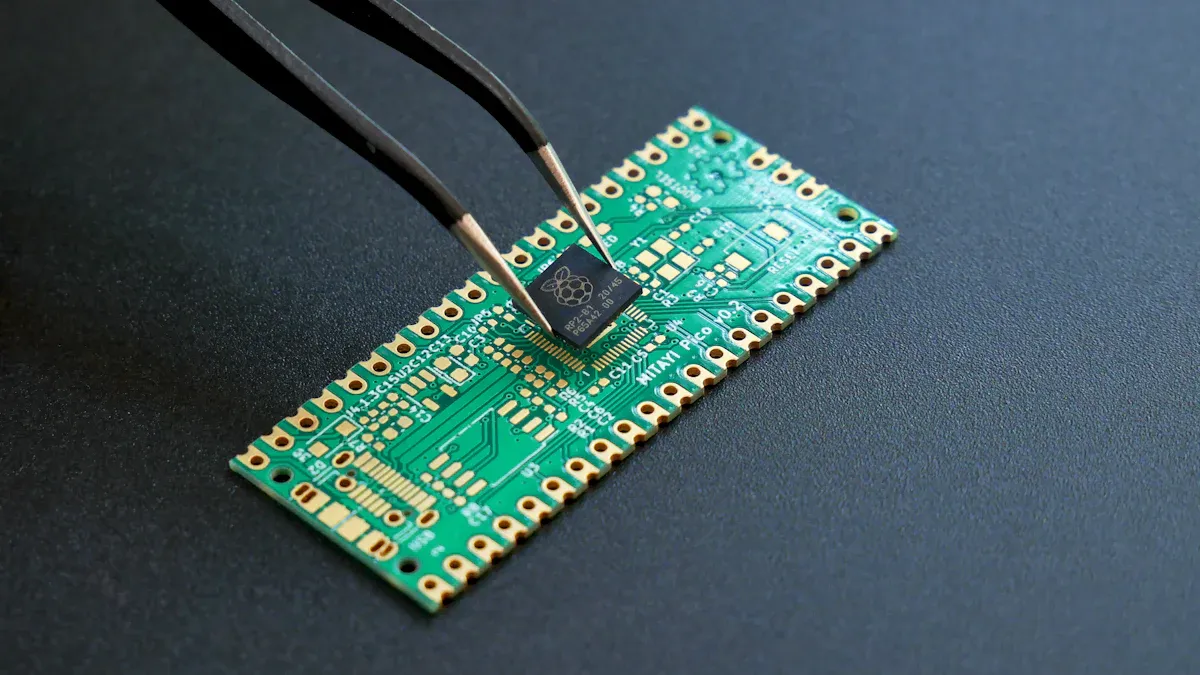

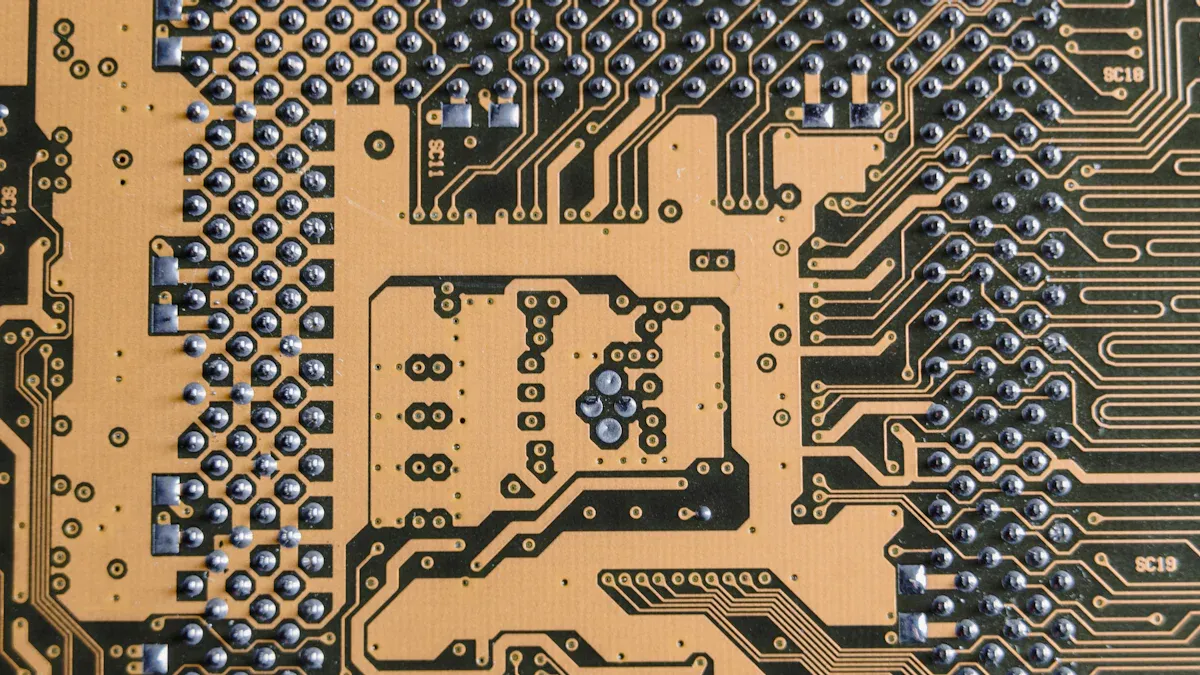

Printed Circuit Board Assembly (PCBA) means adding parts to a PCB to make it work. A PCB is just a base, but a PCBA adds parts like resistors and chips to make it useful. This process helps the board do tasks like powering devices or handling data. PCBA is very important in modern gadgets. It helps make small, fast, and dependable devices.

Key Components of PCBA

PCBA has many parts and steps that make it work. Here are the main ones:

Component/Process | Description |

|---|---|

Bill of materials (BOM) | A list of all parts needed, with amounts and details. |

GERBER files | Files showing designs like paths, pads, and part spots. |

Surface Mount Technology (SMT) | A way to attach parts directly on the PCB, great for small gadgets. |

Through-Hole Technology (THT) | Parts are put through holes in the PCB for strong links. |

Solder mask | A layer that stops short circuits and makes the board last longer. |

Silkscreen | Labels on the PCB to help find and place parts. |

Soldering | Joining parts to the PCB using melted metal. |

Inspection and quality control | Checks like Automated Optical Inspection (AOI) to ensure everything works. |

These steps and parts make sure the PCBA works well and meets high standards. This makes it useful for many devices.

How PCBA Differs from PCB

People often mix up PCBA and PCB, but they are not the same. A PCB is just a plain board with no parts. A PCBA is a finished board with all the parts added, ready to do its job.

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Empty board with no parts | Finished board with all parts |

Function | Gives paths for electricity | Does specific tasks |

Components | None | Has resistors, chips, and more |

Stage | Starting point | Completed and working |

For example, in a phone, the PCB is the base. The PCBA makes features like touch and calls work.

Applications of PCBA in Electronics

Consumer Electronics (e.g., smartphones, laptops)

PCBA is very important for devices like phones and laptops. These gadgets use special PCBs to fit many features in small spaces. For example, phones use PCBA to connect processors, memory, and sensors. This helps them work fast and stay connected.

Smaller and better PCBs are needed as gadgets get smaller. New tech like 5G also needs strong and compact circuit boards. Experts say the PCB market for gadgets will grow to $123.5 billion by 2033. It will grow at a yearly rate of 5.2%. This shows how much PCBA helps modern devices improve.

Industrial Electronics (e.g., automation systems, robotics)

In factories, PCBA is key for robots and machines. It helps them work accurately in tough conditions. Robots use PCBA to move, control circuits, and manage power. Smart PCBs let robots talk to sensors and other devices, making them smarter.

Machines with PCBA save time and make more products faster. Robots with PCBA work better, make fewer mistakes, and give steady results. New materials like flexible boards make robots even better. PCBA is very important in industries like cars, factories, and shipping.

Medical Devices (e.g., diagnostic equipment)

PCBA is very important in medical tools where accuracy matters. Machines like MRI scanners and blood testers use PCBs for correct results. These PCBs are safe for healthcare use and meet strict rules.

Medical robots also use PCBA to process data and control tools during surgery. Smart PCBs help these robots connect with other systems easily. As healthcare gets better, PCBA will play a bigger role. It will help create new tools and improve patient care.

Automotive and Aerospace Applications

PCBA is very important in cars and airplanes. In cars, it powers systems like engines, safety features, and brakes. These PCBs are made to handle tough conditions like heat, shaking, and wetness. This makes them work well even in hard situations.

In airplanes, PCBA helps with navigation, communication, and flight controls. Planes use these boards to process data fast and stay safe. PCBA can fit many parts into small spaces, making it perfect for modern airplanes.

Important Facts About Automotive PCBs:

The car PCB market was worth $8.87 billion in 2023.

It may grow to $13.58 billion by 2031, with 5.48% yearly growth.

This shows more people need strong and good PCBA for cars and planes. As technology in vehicles and planes improves, the need for better PCBA will grow.

Telecommunications Equipment (e.g., routers, network devices)

Telecom devices depend on PCBA for faster and better data sharing. Routers and modems use special PCBs to keep signals strong, especially with 5G. These boards combine processors, memory, and other parts into small, smart designs.

The global PCB router market is growing fast with new tech. Automation helps make better PCBA faster and with more accuracy. The need for high-frequency PCBs shows how important special designs are in telecom.

As networks grow, PCBA will stay key for faster communication. Whether at home, work, or big data centers, these boards help devices work well and reliably.

Benefits of PCBA in Electronics

Better Functionality and Performance

PCBA improves how electronic devices work by assembling parts correctly. It tests designs to find errors and checks programming for accuracy. Important checks include signal flow, wave quality, and communication rules. These tests, done by hand or machines, ensure devices are reliable and consistent.

Here are the main performance benefits of PCBA:

Benefit | Description |

|---|---|

Quality Assurance | Finds problems early, cutting down on repairs and returns. |

Reliability | Makes sure products meet plans and work as expected. |

Cost Reduction | Boosts production success, saving money. |

Customer Satisfaction | Creates great products, improving brand trust. |

By focusing on these points, PCBA ensures top-quality boards for modern electronics.

Smaller and Compact Designs

PCBA helps make smaller and smarter devices. Methods like Surface Mount Technology (SMT) and High-Density Interconnects (HDI) allow more parts on smaller boards. Microvias help connect layers, adding complex features to tiny designs.

Technology | How It Helps Make Smaller Devices |

|---|---|

Surface Mount Technology (SMT) | Fits more parts on smaller boards. |

High-Density Interconnects (HDI) | Adds more wiring and reduces signal issues. |

Microvias | Helps connect layers for advanced designs. |

These PCBA methods make small, powerful devices without losing quality.

Affordable PCBA Manufacturing

Smart processes make PCBA a cheaper way to build electronics. By reducing mistakes and improving success rates, it lowers costs. Automated assembly keeps quality steady and cuts labor costs. This helps both makers and buyers, making advanced gadgets more affordable.

Reliability and Durability

Reliability and durability are very important in electronics. PCBA helps devices work well, even in tough conditions. This happens through careful testing during the making of PCBA. These tests check if the assembly can handle different situations, ensuring top quality.

Here are some common tests for PCBA reliability:

Test Type | Purpose |

|---|---|

Temperature Cycle Test | Checks if it works in very hot or cold places. |

Heat and Humidity Cycle Test | Tests if it stays strong in wet and humid areas. |

Vibration Test | Makes sure it doesn’t break during shaking or moving. |

Impact Test | Confirms it stays safe when hit or dropped. |

Electrical Test | Ensures it works well with electricity, like voltage and current. |

These tests prove PCBA can handle heat, moisture, and stress. For example, the vibration test checks if it stays together during shipping or use. The electrical test ensures the PCB works without problems. By passing these tests, PCBA provides strong and reliable solutions for today’s electronics.

Faster Prototyping and Reduced Time-to-Market

Speed is key in making new electronics. PCBA speeds up creating prototypes, helping launch products faster. Advanced methods like automated assembly and surface mount technology make production quicker. These techniques lower mistakes and improve quality in less time.

Prototyping with PCBA has many benefits:

Quick Changes: Test and fix designs fast to avoid delays.

Save Money: Spot problems early to cut development costs.

Teamwork: Engineers and designers can work better together.

For example, automated testing during assembly checks if parts work correctly. This reduces the need for manual checks, saving time and effort. Using PCBA, you can meet deadlines while keeping quality high. This gives your products an advantage in the market.

Future Trends and Innovations in PCBA

New Materials and Better Manufacturing

PCBA is changing with new materials and methods. For example, eco-friendly materials for electric cars are being developed. These materials aim to protect the environment while working well. Flexible and multilayer PCBs are also becoming common. They help fit complex electronics into small devices like wearables and EVs.

Manufacturing is improving too. By 2025, AI will change how PCBs are made. AI can design better layouts, fix mistakes, and speed up production. High-frequency materials are another big step forward. They support advanced tech like mmWave and beyond-5G. These changes help PCBA meet the needs of modern electronics.

PCBA in IoT and AI Devices

PCBA is key for IoT and AI-powered devices. These devices need precise assembly to work smoothly. For example, smart home gadgets like cameras and thermostats use PCBs. These boards connect sensors, processors, and communication parts. This helps them collect and share data easily.

AI devices, like robots, also need advanced PCBA. Robots use PCBs to process data and make quick decisions. As IoT and AI grow, PCBA will help create smarter devices. This shows how important quality and new ideas are in PCBA.

High-Frequency and Filtering Devices

High-frequency devices like 5G stations need special PCBs. Engineers use multilayer PCBs to handle complex circuits. Shielding and grounding reduce interference for stable performance.

New materials like high-speed laminates are important for these devices. They manage high frequencies and stay strong. Testing is also crucial. For instance, impedance tests check if PCBs meet strict rules. These advancements make PCBA vital for modern technologies.

Sustainability and Eco-Friendly PCBA Manufacturing

Making PCBA in a green way is now very important. Companies want to lower harm to the environment. But how do they do this? They use eco-friendly materials and methods to make circuit boards. These ways cut down on waste and energy use. For example, using low heat saves power and lowers pollution. Recycling old electronics helps get back useful parts.

Laws like the Ecodesign for Sustainable Products Regulation support green ideas. These rules push companies to use better, eco-friendly ways to make PCBA. Big companies like Samsung and Intel are leading the way. They create new methods that are good for the planet but still make great products.

Testing is key to making eco-friendly PCBA. Advanced tests find problems early, cutting waste. This ensures only good products are sold. For example, machines like Automated Optical Inspection (AOI) check for mistakes in soldering. This makes sure the final product is high quality and reliable.

You also gain from these green methods. Devices made with eco-friendly PCBA last longer and are safer for nature. Flexible and recyclable materials make it easy to recycle old gadgets. By choosing these products, you help keep the planet clean.

Here are some main points about green PCBA:

New methods like low-heat processing and recycling cut waste.

Rules encourage eco-friendly practices in electronics.

Testing ensures reliable products with less harm to the environment.

By supporting green PCBA, you help make electronics better for the earth. This helps both the planet and the devices you use.

PCBA is important for making electronics work better. It turns simple boards into systems that do useful tasks. You can find PCBA in many areas, like gadgets, medical tools, and airplanes. It helps devices perform well, stay small, and cost less to make.

New inspection tools, like automated optical inspection (AOI), check for mistakes. These tools make sure PCBA is strong and lasts a long time. As technology grows, PCBA will help improve smart devices, AI, and eco-friendly production. Learning about PCBA and its uses shows how it shapes the future of electronics.

FAQ

1. What is the difference between PCBA and PCB?

A PCB is an empty board with no parts. A PCBA has all the parts added and is ready to work. PCBA performs tasks, while PCB is just the base for circuits.

2. Why is PCBA important in modern electronics?

PCBA helps devices work well by connecting parts correctly. It makes gadgets smaller, faster, and more reliable. This is why it’s vital for industries like healthcare, cars, and telecom.

3. How does PCBA improve device performance?

PCBA improves performance by assembling and testing parts carefully. It reduces mistakes, increases reliability, and supports features like fast data and small designs.

4. Can PCBA be eco-friendly?

Yes! Companies now use green materials and energy-saving methods. Recycling old devices and using eco-friendly ways cut waste and help the planet.

5. What industries benefit most from PCBA?

Industries like electronics, healthcare, cars, planes, and telecom need PCBA. It powers things like phones, medical tools, cars, and network devices, helping them improve.

💡 Tip: Pick PCBA from trusted makers to get strong and lasting devices.

See Also

The Role of PCBA in Elevating Modern Electronics

Exploring PCBA Uses and Advantages in Today’s Electronics

The Importance of PCBA Prototyping for Electronic Advancements

Understanding PCBA Services and Their Importance in Manufacturing