Electronic manufacture services (EMS) are very important today. They include many outsourcing processes that help companies produce electronic products better and faster. When you choose electronic manufacture services, you can save money while also receiving expert assistance and improved product quality. The global electronic manufacture market is growing rapidly, with a value of USD 578.07 billion in 2024, and it is expected to reach USD 1,099.05 billion by 2033. This growth indicates a rising demand for these services across various sectors, including consumer electronics and healthcare. Outsourcing through electronic manufacture allows for greater flexibility and enables companies to concentrate on innovation and market responsiveness.

Key Takeaways

Electronic Manufacturing Services (EMS) help companies make electronic products quickly and cheaply.

Picking the right EMS provider can improve product quality. It also lets your business focus on new ideas.

Find EMS providers that are good at technology, have money stability, and hold quality assurance certifications.

Good communication and clear goals with your EMS partner lead to better teamwork and project success.

Check progress often using metrics and dashboards to keep your partnership on track.

Understanding Electronic Manufacturing Services

Definition and Scope

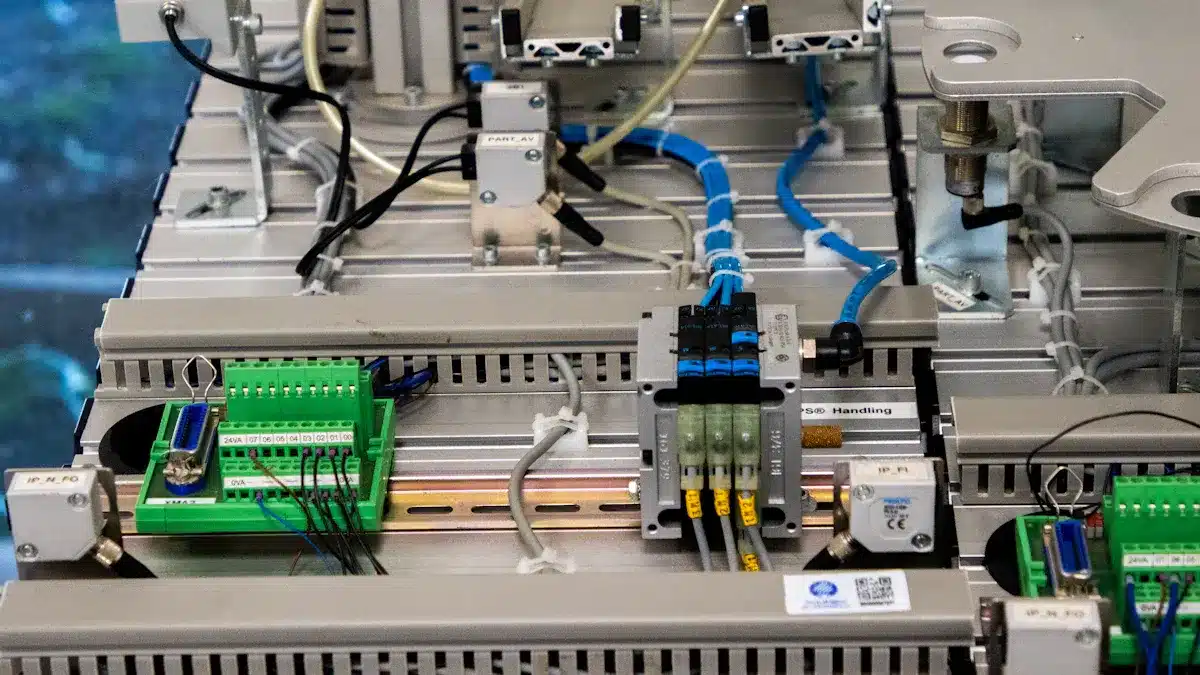

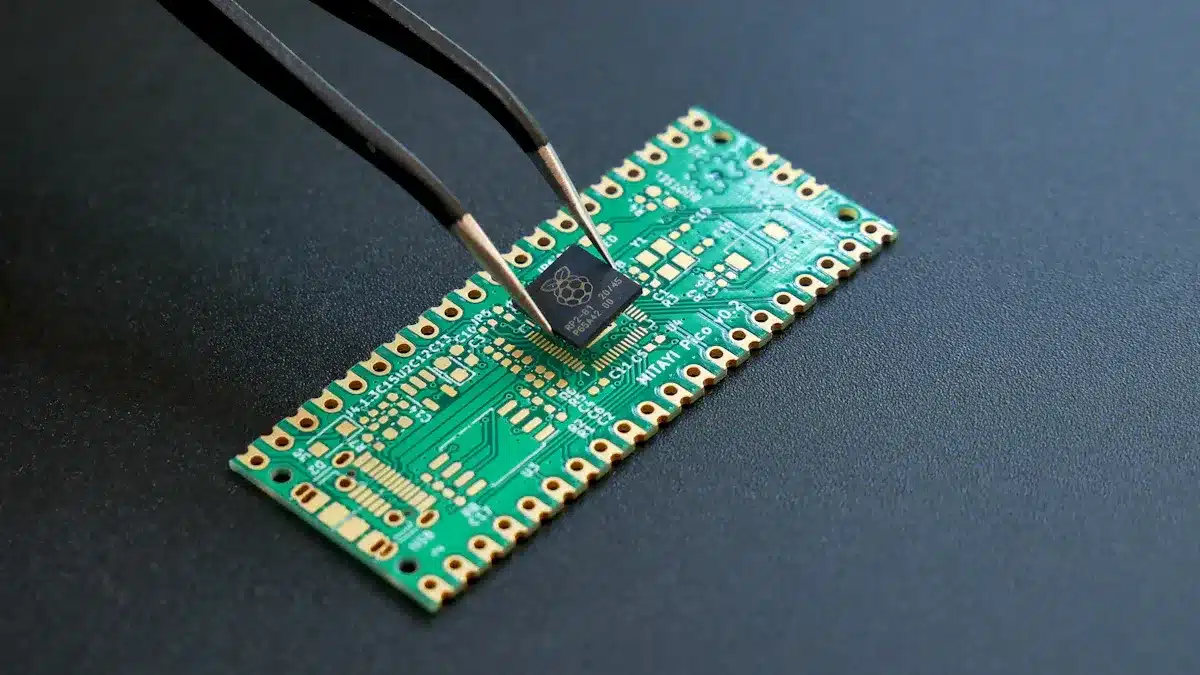

Electronic manufacturing services (EMS) are companies that design, make, test, ship, and fix electronic parts and assemblies. These services are very important in the electronics supply chain. They help original equipment manufacturers (OEMs) get their products to market quickly.

Here’s a breakdown of what EMS means and its main parts:

Main Components | |

|---|---|

Companies that design, make, test, ship, and fix electronic parts and assemblies for OEMs. | PCB Layout Design, Firmware Development, Conformal Coating, Warranty and Repairs |

EMS covers many steps, from the first design to the final assembly. This complete method lets OEMs focus on what they do best while EMS providers handle special tasks.

Importance in the Industry

EMS is very important in the electronics industry. When OEMs work with EMS providers, they can get many benefits:

Scalability: You can easily change production based on demand.

Cost Reduction: You can save a lot, with cuts of up to 35%.

Flexibility: EMS providers can adjust production amounts, so you can react fast to market changes.

Also, EMS providers have their own manufacturing setup. This means OEMs do not need to spend a lot on buildings and tools. You can focus on developing products and marketing while your EMS partner takes care of making them.

The effect of EMS goes beyond single companies. It makes the whole electronics supply chain work better. According to supply chain management studies, EMS companies see better profits and communication. But, there can be problems like automation and data transfer issues. To fix these problems, training employees and changing business processes are good ideas.

Here’s a summary of what we found about EMS in the supply chain:

Findings | Description |

|---|---|

E-supply chain management systems boost profits and improve communication in EMS companies. | |

Challenges | Problems like automation and data transfer can happen. |

Recommendations | Training employees and changing business processes can help solve these issues. |

Choosing an EMS Provider

Picking the right electronic manufacturing services (EMS) provider is very important for your business. You should think about several things to find a company that fits your needs. Here are some main areas to check:

Company Capabilities

When looking at an EMS provider, check what they can do. Find companies that show strong creativity and technology. They should spend money on research and development to help you. It’s also important that they are financially stable. Look at their financial reports and credit scores to see if they can handle supply chain risks well.

Think about location advantages too. A provider with good logistics can make operations run smoother. Also, how they manage their workers is important. If they focus on keeping employees and training them, it shows they care about quality.

Here’s a summary of key capabilities to look for:

Capability Type | Description |

|---|---|

Innovation and Technology | Importance of R&D investments and support capabilities for OEM enterprise customers. |

Financial Viability | Assessment of corporate financial statements, credit ratings, and ability to manage supply chain risks. |

Geographic Advantages | Evaluation of logistical strengths and weaknesses, impacting operational efficiency. |

Human Capital Management | Focus on employee retention, training programs, and access to skilled labor pools. |

Quality Assurance | Ensuring high standards in production processes to maintain product integrity and reliability. |

Quality Assurance

Quality assurance is very important in electronics manufacturing services. You want to make sure the provider keeps high standards during production. Look for certifications that show they care about quality. Common certifications include:

Certification | Description |

|---|---|

IPC Standards | Standards for electronic assemblies, globally recognized for quality. |

ISO 13485 | Management standard for medical devices ensuring product safety and reliability. |

ISO 9001 | Standard for quality management systems, demonstrating consistent product quality. |

AS9100 | Management system standard for aerospace, ensuring safety and reliability in products. |

To make sure products are reliable, good quality control processes are key. Here are some important practices:

Incoming Material Inspection: Check that raw materials meet the right standards.

Process Monitoring and Control: Use Statistical Process Control (SPC) to keep tolerances acceptable.

In-Process Inspections: Inspect at different assembly stages to find defects early.

Functional Testing: Test products to ensure they work as they should.

Environmental and Reliability Testing: Simulate real-world conditions to check durability.

Defect Tracking and Analysis: Record and study defects to find root causes.

Final Quality Assurance (QA): Do a thorough check of the finished product.

Compliance with Standards: Make sure to follow industry standards like ISO 9001 and IPC-A-610.

Contract Manufacturing Services

Knowing the types of contract manufacturing services an EMS provider offers is very important. Here are some common services you should expect:

PCB Layout

PCB Fabrication

Surface Mount and Printed Circuit Board Assembly (PCBA)

New Product Introduction (NPI)

Box/System Assembly

Cable Assembly

BGA Rework

Inspection and Testing

Engineering Support

Contract terms and service level agreements (SLAs) are also very important in your relationship with the EMS provider. They explain roles, responsibilities, and expectations. A good contract can reduce risks and align goals, which is key for a successful partnership.

By focusing on these areas, you can make a smart choice when picking an EMS provider that matches your business goals.

Working Together in Electronics Manufacturing Services

Working well with your electronic manufacturing services (EMS) provider is very important for success. Good communication can make your partnership stronger and lead to better results.

Communication Methods

To help work together, you should use good communication methods. Here are some important ways to do this:

Start by sharing small bits of important information to build trust.

Treat EMS as partners to improve teamwork.

Focus on being open and honest to make professional relationships stronger.

Also, think about these steps to make communication better:

Set clear goals for what needs to be done and when.

Be open by sharing plans and problems.

Involve EMS providers in design talks to empower them.

Build relationships by visiting regularly.

Regular updates and clear processes are very important. They help everyone stay informed about production progress and any issues. This kind of communication builds trust and helps with planning and decision-making.

Setting Goals

Setting clear goals is key for a successful partnership. If expectations are not aligned, it can cause big problems. For example, unclear technical needs can lead to confusion and wasted work. To prevent this, follow these best practices:

Choose outside partners that fit your teamwork.

Define how you will work together based on your goals.

Make formal documents to set up structure and protections.

Set clear goals and success measures from the start.

Clearly explain roles and responsibilities.

By defining roles, you encourage team members to take responsibility and ownership.

Checking Progress

Checking progress is important to keep your teamwork on track. Use tools and measures to watch performance. Here are some good options:

Tool/Metric | Description |

|---|---|

Gives live data for quicker decisions, reducing urgent issues and boosting audit confidence. | |

Manufacturing Dashboards | Combines key KPIs into one display for real-time tracking of production data. |

Real-time Monitoring Systems | Gathers information from machines and IoT devices, putting data into customizable reports. |

By focusing on these areas, you can improve teamwork with your EMS provider and get better results.

In short, knowing about electronic manufacturing services (EMS) is very important for your business. You can make your manufacturing better by choosing the right EMS provider. Here are some main points to remember:

Process Optimization: Make operations smoother with lean manufacturing ideas.

Adopting New Technologies: Use automation and AI to boost efficiency and product quality.

Fostering Constant Improvement: Build a culture of innovation to stay ahead.

By using these tips, you can improve product development and cut costs. Keep in mind, a strong partnership with your EMS provider can help you get products to market faster and improve quality.

FAQ

What are Electronic Manufacturing Services (EMS)?

Electronic Manufacturing Services (EMS) are companies that make electronic products. They take care of design, production, testing, and shipping. This lets original equipment manufacturers (OEMs) focus on what they do best.

Why should I choose an EMS provider?

Choosing an EMS provider can save you time and money. They have skills, can grow with your needs, and are flexible. This helps you get products to market faster while keeping high quality.

How do I evaluate an EMS provider?

To evaluate an EMS provider, check their skills, quality control methods, and financial health. Look for certifications and read customer reviews to make sure they meet your needs.

What types of services do EMS providers offer?

EMS providers offer many services, like PCB design, assembly, testing, and product support. They can also help with new product launches and managing the supply chain.

How can I improve collaboration with my EMS partner?

To improve teamwork, keep communication open, set clear goals, and check progress often. Building a strong relationship creates trust and helps the project succeed.

See Also

Exploring EMS And PCBA Services In Today’s Electronics

Defining PCBA Services And Their Importance In Manufacturing

The Significance Of Custom PCBA Manufacturing In Electronics

Key Role Of PCBA Manufacturing In Electronics Design

Choosing PCBA Manufacturing Services With Superior Capabilities