PCBA manufacturing custom solutions play a crucial role in modern electronics. They offer tailored approaches to meet evolving demands, enabling the creation of compact, high-performance devices with intricate designs. These advancements are essential for technologies like 5G and IoT. Unlike traditional methods, PCBA manufacturing custom processes accelerate production, reducing timelines from weeks to mere days. As technology advances, the need for smaller, more efficient devices grows. PCBA manufacturing custom ensures devices are reliable, durable, and energy-efficient, empowering industries to innovate and adapt to rapid technological changes.

Key Takeaways

Custom PCBA manufacturing makes circuit boards for specific needs. This improves how electronics work and makes them more reliable.

It speeds up production, cutting time from weeks to days. This helps companies stay ahead in the market.

Custom PCBA allows flexible designs for quick testing and prototyping. This finds problems early and saves money.

Industries like healthcare and cars gain a lot from custom PCBA. It supports advanced tech and keeps quality high.

Using custom PCBA can save money over time. It uses better materials, avoids mistakes, and works more efficiently.

Understanding PCBA Manufacturing Custom Solutions

What Is Custom PCBA Manufacturing?

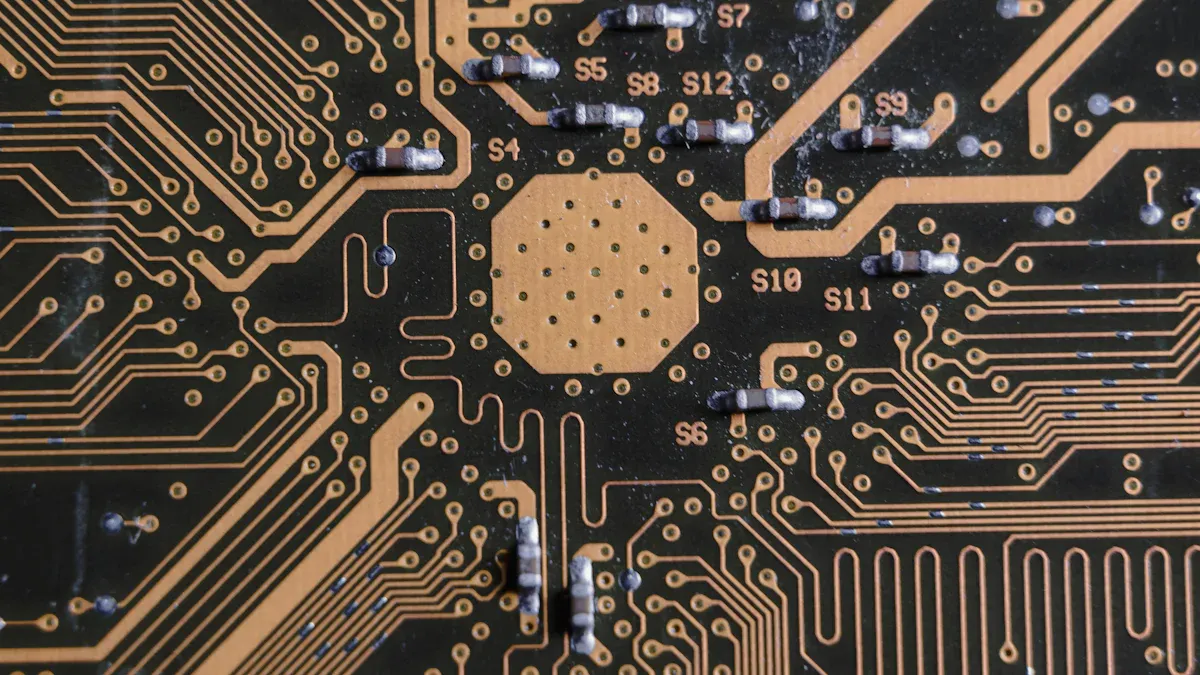

Custom PCBA manufacturing means making circuit boards for specific needs. Unlike old methods, it creates special solutions for complex electronics. It uses advanced tools to design and build boards that work perfectly. This is important for industries like electronics, cars, and automation, where new ideas need reliable boards.

Custom PCBA focuses on being flexible and accurate. It helps you test designs fast and fix problems before making many units. This way, your products are high-quality and have fewer mistakes.

How Custom PCBA Differs from Traditional Methods

Custom PCBA is different from older ways in many ways. Old methods use standard designs that may not fit modern products. Custom PCBA changes to meet unique needs with better designs and tools.

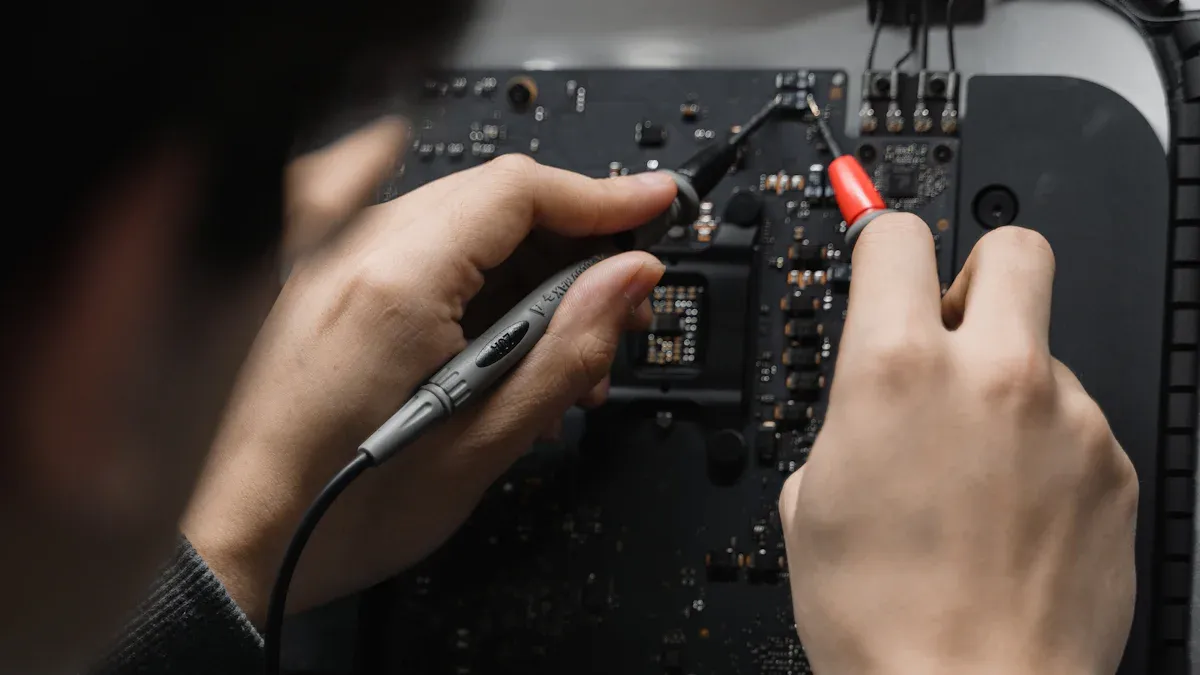

Automated systems now replace manual checks in PCB making. This change improves accuracy and keeps up with faster production. Automated Optical Inspection (AOI) finds problems quickly, helping industries aim for perfect products and smarter systems.

Custom PCBA also includes strict testing and checks. Each board is carefully inspected to ensure it works well. Traditional methods often skip these detailed tests, focusing on simpler designs.

Unique Features of Custom PCBA Manufacturing

Custom PCBA has special features that make it stand out. These include advanced tools, special machines, and a focus on quality. The table below shows how prototyping and mass production differ in custom PCBA:

Aspect | Prototyping | Mass Production |

|---|---|---|

Focus | Quick changes and testing | Cost-saving and consistent production |

Assembly Techniques | More hands-on work | Mostly automated processes |

Equipment | Basic tools | High-speed, special machines |

Cost per Unit | Higher cost per piece | Lower cost per piece |

Design Goal | Testing ideas and functions | Finalized designs for production |

Volume | Small numbers (1-100 units) | Large numbers (thousands to millions) |

Quality Checks | Fewer checks | Very strict checks and controls |

These features make custom PCBA great for unique electronics. Whether you need a few samples or many units, this process ensures top-quality boards.

Challenges in Traditional PCBA Manufacturing

Limited Design Flexibility

Old PCBA methods use standard designs that limit creativity. These designs make it hard to create new, unique products. For example, if you need a special circuit board, old methods might not work. This lack of flexibility slows down product development and limits ideas.

The table below shows common problems with traditional PCBA designs:

Challenge | Description |

|---|---|

Standard designs block innovation and customization. | |

More heat needs better cooling, which old methods can’t handle. |

Traditional PCBA also struggles with precision. High-tech boards need exact placement of parts. Older methods often fail, causing mistakes and wasted time.

Inefficiencies in Specialized Production

Old PCBA methods are not good for small or custom projects. If you need small batches or quick changes, it takes longer and costs more. Adjusting machines can take 7 to 10 days, adding 20% to 30% more time. These delays can waste 10% to 15% of your yearly budget.

Statistic Description | Value |

|---|---|

Extra time for product development | |

Yearly losses from inefficiencies | 10%–15% |

Time for machine adjustments | 7–10 days |

More customer complaints due to quality issues | 40% higher than modern services |

These problems make it harder to compete in fast-changing markets.

Difficulty Adapting to Emerging Technologies

New tech like IoT and AI needs advanced PCBA solutions. Old methods can’t keep up with these demands. For example, traditional soldering can’t handle the heat of modern parts. Assembly lines are also slow, delaying product launches.

Common problems include:

Heat damage and part misplacement

Slow assembly processes

Trouble handling high-power devices

Using old PCBA methods makes it hard to meet modern needs. This can stop you from creating new products and staying ahead in the market.

Key Benefits of Custom PCBA Manufacturing

Improved Performance and Dependability

Custom PCBA manufacturing helps electronics work better and last longer. Unlike older methods, it uses advanced tools to make PCBs for specific needs. This makes devices stronger and more useful, even in tough conditions.

To ensure great performance, manufacturers run many tests during assembly:

Thermal Cycling: Checks if PCBs handle temperature changes without breaking.

Electrical Testing: Makes sure circuits work properly in real-life situations.

Mechanical Stress Tests: Tests if PCBs can handle shaking and physical hits.

Metric | Description |

|---|---|

Custom PCBA allows for designs that fit exact needs. | |

Design for Manufacturing (DFM) | Ensures designs follow rules for smooth production. |

Prototyping | Tests designs before making large amounts. |

By focusing on these areas, custom PCBA creates reliable electronics. This is very important for devices like medical tools or car systems, where failure is not an option.

Tip: Checking quality during design and assembly lowers defects. This ensures your products meet top standards.

Affordable Solutions for Complex Electronics

Custom PCBA manufacturing offers smart ways to save money on complex devices. It may cost more at first, but it prevents errors and delays later. Picking a good PCB maker ensures your products work well, avoiding expensive fixes or redesigns.

Here are ways to save money:

Material Optimization: Uses materials wisely to avoid waste.

Efficient Equipment: Machines lower labor costs and make more products.

Process Improvement: Better processes reduce mistakes and save time.

Supplier Negotiation: Buying in bulk lowers material costs.

Sustainable Practices: Recycling and saving energy cut waste costs.

Strategy | Description | Cost Reduction Impact |

|---|---|---|

Material Optimization | Smart layouts and inventory control | Cuts down on wasted materials. |

Efficient Equipment | Fast machines for big production | Lowers labor costs, boosts output. |

Process Improvement | Fewer mistakes, faster production | Saves time and reduces errors. |

Supplier Negotiation | Bulk buying and contracts | Lowers material prices. |

Sustainable Practices | Recycling and energy-saving methods | Reduces waste and energy costs. |

Using these methods balances cost and quality. Custom PCBA is a great choice for making high-quality electronics without overspending.

Flexible for Advanced and Special Designs

Custom PCBA manufacturing works well for advanced and unique designs. Whether for new technology or special uses, it ensures your PCB fits your needs. It supports tiny parts, complex designs, and modern assembly methods.

Examples show how custom PCBA adapts:

Case Study | Application | Description |

|---|---|---|

Healthcare | Shows custom PCBA in cleaning devices for hospitals. | |

Non-Surgical Medical Device | Healthcare | Highlights PCBA in non-invasive medical tools. |

Hospital Room Illumination | Healthcare | Features PCBA improving patient recovery spaces. |

5G Automotive Gateway | Automotive | Shows strong PCBA for self-driving cars. |

Dental Chair Control Board | Healthcare | Adds IoT features to modern dental chairs. |

These examples prove custom PCBA helps many industries, like healthcare and cars. Its flexibility lets you create new products for today’s technology.

Note: Custom PCBA keeps your designs ready for the future. It helps you adjust to new trends and tech quickly.

Faster Prototyping and Getting Products Ready

Custom PCBA manufacturing changes how products are made and sold. It helps turn ideas into prototypes much quicker than before. This speed is very important because being first in the market often leads to success. Using advanced tools, custom PCBA manufacturing tests and improves designs fast, making them ready for production.

Why Quick Prototyping is Important

Fast prototyping gives businesses a big advantage. It shortens the time to test ideas and fix problems. This saves time and money while encouraging new ideas. For example, if you’re making a new IoT gadget, custom PCBA manufacturing lets you try different designs until you find the best one.

Here’s how quick prototyping helps businesses:

Speeds up turning ideas into prototypes to meet deadlines.

Saves money by fixing design mistakes early.

Makes sure complex designs are accurate, reducing errors.

Encourages trying new ideas and materials for better products.

Allows early testing to catch problems before mass production.

Benefits of Faster Market Launch

Custom PCBA manufacturing not only speeds up prototyping but also helps products get to market faster. Early testing ensures designs are reliable and meet standards. This lowers the chance of costly mistakes later. Plus, custom PCBA manufacturing adapts to market changes, keeping products competitive.

The table below shows the benefits of quick prototyping and faster launches:

Benefit | Description |

|---|---|

Shortens the time from idea to prototype, helping stay competitive. | |

Cost Savings | Fixes design issues quickly without spending too much. |

Better Design Accuracy | Ensures designs are correct, reducing mistakes in production. |

More Innovation | Lets you try new materials and ideas for better products. |

Early Testing | Finds and fixes problems early, saving money before production. |

Tip: Working with a trusted custom PCBA manufacturer ensures prototypes are fast and accurate. This reduces risks and boosts success in the market.

Real-Life Example

Think about launching a wearable health gadget. Traditional methods might take weeks to make a prototype, delaying your launch. Custom PCBA manufacturing can create and test prototypes in just days. This speed helps you beat competitors and sell your product sooner. Testing and improving the design also ensures it meets customer needs, increasing its chances of success.

By using custom PCBA manufacturing, you can improve how you develop products. Faster prototyping and quicker launches help you stay creative, flexible, and successful in today’s fast-moving world.

Custom PCBA Manufacturing in Emerging Technologies

Helping IoT and Consumer Electronics Grow

Custom PCBA manufacturing is key for IoT and electronics progress. As gadgets get smaller and smarter, better PCB designs are needed. Multi-board PCBs combine many features into tiny spaces. These are used in smartwatches, home devices, and health trackers.

Consumer electronics lead the market with high demand for gadgets. Devices like smartphones and laptops need custom PCBs with many layers and detailed designs. This keeps IoT devices working well, lasting long, and saving energy.

Key Insights | Description |

|---|---|

Dominant Application Segment | Consumer electronics lead due to high demand for gadgets like smartphones and laptops, boosting multi-board PCB needs. |

Demand Drivers | New tech and more features in devices increase demand for custom PCBs. |

Growth Indicators | More high-layer PCBs show the need for compact, complex designs for IoT. |

Market Growth | Multi-board PCBs will grow as small, powerful electronics are needed in cars, 5G, and more. |

Custom PCBA manufacturing helps IoT devices meet modern needs. With advanced designs, you can make products that shine in a tough market.

Boosting AI and Machine Learning Systems

AI and machine learning need super-fast PCBs. Custom PCBA manufacturing makes this possible with smart designs and strong materials. For example, split planes and blind vias improve signals and reduce noise. These are vital for AI servers and fast computers.

Materials like FR-4 and polyimide are also important. They help signals move quickly and keep systems cool. Custom PCBA manufacturing meets AI needs like 10 Gbps speeds and multi-core processing.

AI system needs include:

At least 10 Gbps for fast communication.

4 to 32 cores for heavy tasks.

1 GPU for normal tasks; more GPUs for big projects.

Custom PCBA manufacturing makes AI systems faster and stronger. This keeps your tech ahead in a fast-changing world.

Improving Renewable Energy and Green Tech

Green tech depends on custom PCBA manufacturing for better efficiency. Solar panels, wind turbines, and batteries need PCBs that handle high power and tough conditions. Custom designs make these systems last longer and work better.

For example, energy storage systems use PCBs with good heat control. This stops overheating and extends their life. Solar inverters use custom PCBs to save energy and cut power loss.

Electric vehicles (EVs) also need custom PCBs. These manage complex systems while staying safe and reliable. Eco-friendly manufacturing, like recycling and saving energy, supports green goals. This helps you make innovative and eco-friendly products.

Tip: Work with a custom PCBA manufacturer that values sustainability. This can boost your brand and attract eco-friendly buyers.

Applications in Medical and Automotive Sectors

Custom PCBA manufacturing is important for medical and car industries. These fields need special and reliable electronics for their unique needs. Custom PCBs help make devices safer, better, and more advanced.

Transforming Medical Devices

Medical devices must be precise and dependable. Custom PCBA manufacturing helps create circuit boards that meet strict medical standards. Whether for diagnostic tools or health trackers, custom PCBs ensure devices work well and consistently.

For instance, patient monitors use PCBs to track heart rate and oxygen levels. Custom PCBs add features like wireless connections and small designs, making these systems easier to use. Health trackers also benefit from lightweight PCBs that save energy and improve comfort.

Sector | Application Examples |

|---|---|

Medical Devices | Diagnostic tools, patient monitors, wearable health trackers, medical equipment |

Tip: Use strong materials and smart layouts for durable medical PCBs that follow rules.

Improving Automotive Technology

Cars are getting smarter and more connected. Custom PCBA manufacturing helps design PCBs for advanced car systems. These boards are flexible and fit complex needs.

Driver-assistance systems (ADAS) use custom PCBs to process data from cameras and sensors. These boards handle fast data and work in tough conditions. In-car entertainment systems (IVI) also use custom PCBs for touchscreens, navigation, and voice control.

Engine control units (ECUs) and car sensors need custom PCBs too. These boards improve fuel use and lower emissions. Custom PCBA manufacturing creates strong systems that make cars safer and better.

Sector | Application Examples |

|---|---|

Automotive Industry | Driver-assistance systems, in-car entertainment, engine control units, car sensors |

Note: Car PCBs must handle heat and shaking. Pick the right materials for lasting performance.

Why Custom PCBA Is Key for These Fields

Medical and car industries need electronics that are reliable and high-quality. Custom PCBA manufacturing offers solutions for these needs. It helps make life-saving medical tools and advanced car systems.

Using custom PCBA manufacturing keeps you ahead in these industries. It ensures your products meet top standards, giving you an edge in the market.

Custom PCBA manufacturing is very important for today’s electronics. It fixes problems with old methods and meets modern tech needs. This process creates special designs for small and complex devices. Industries like cars, healthcare, and gadgets use it to stay ahead and improve.

Segment | Reasons for Growth | |

|---|---|---|

Consumer Electronics | Big Increase | Used in phones, tablets, wearables, and laptops for smaller designs. |

Automotive Electronics | High Demand | Needed for strong and light parts in new cars. |

Healthcare Applications | Fast Growth | More use in medical tools needing flexibility and strength. |

Multilayer Flexible PCBs | Key Market Role | Fits complex designs into small spaces. |

As technology changes, custom PCBA manufacturing will lead progress. It helps industries create better and smarter products.

FAQ

What is the difference between a PCB and PCBA?

A PCB is just the board without parts. A PCBA has all the parts added, so it works in devices.

Why is custom PCBA manufacturing important?

Custom PCBA makes sure your board fits your needs. It adds special features, improves reliability, and speeds up testing for modern gadgets.

How does custom PCBA manufacturing improve product quality?

Custom PCBA uses smart tools and careful testing. This makes sure your board works well, has fewer mistakes, and meets high standards.

Can custom PCBA manufacturing handle small production runs?

Yes, custom PCBA is great for small batches. It’s flexible, quick to change, and saves money, perfect for testing or unique products.

What industries benefit most from custom PCBA manufacturing?

Healthcare, cars, and electronics benefit a lot. Custom PCBA helps make strong, energy-saving, and advanced designs for these fields.

See Also

Why PCBA Manufacturing Skills Are Crucial for Electronics Design

Understanding PCBA Services and Their Significance in Manufacturing

Defining PCBA Manufacturing and Its Importance in Electronics

The Role of PCBA in Advancing Today’s Electronics Industry

Essential Considerations for Selecting a Custom PCBA Provider