In today’s fast-paced electronics world, one-stop PCBA manufacturing services have transformed the way products are created. By consolidating all processes in one location, you save time, reduce costs, and achieve superior results. The Electronics Manufacturing Services market is projected to reach $614.77 billion by 2025, continuing to grow at a rate of 5.9% annually. Many small and medium businesses are now outsourcing their production to save money. One-stop PCBA manufacturing services provide straightforward solutions to help companies stay competitive in a rapidly evolving market.

Key Takeaways

One-stop PCBA services handle all steps in one place. This saves time and cuts costs for businesses.

Fast prototyping gives quicker feedback and fixes. It helps companies release products faster.

Easy communication in one-stop services lowers mistakes. It also makes managing projects simpler and improves quality.

Buying parts in bulk through one-stop providers saves 15%-20%. This lowers the total cost of making products.

Careful testing and following rules ensure products are high-quality and dependable.

Efficiency and Time-to-Market with One-Stop PCBA Services

Faster processes for quicker delivery

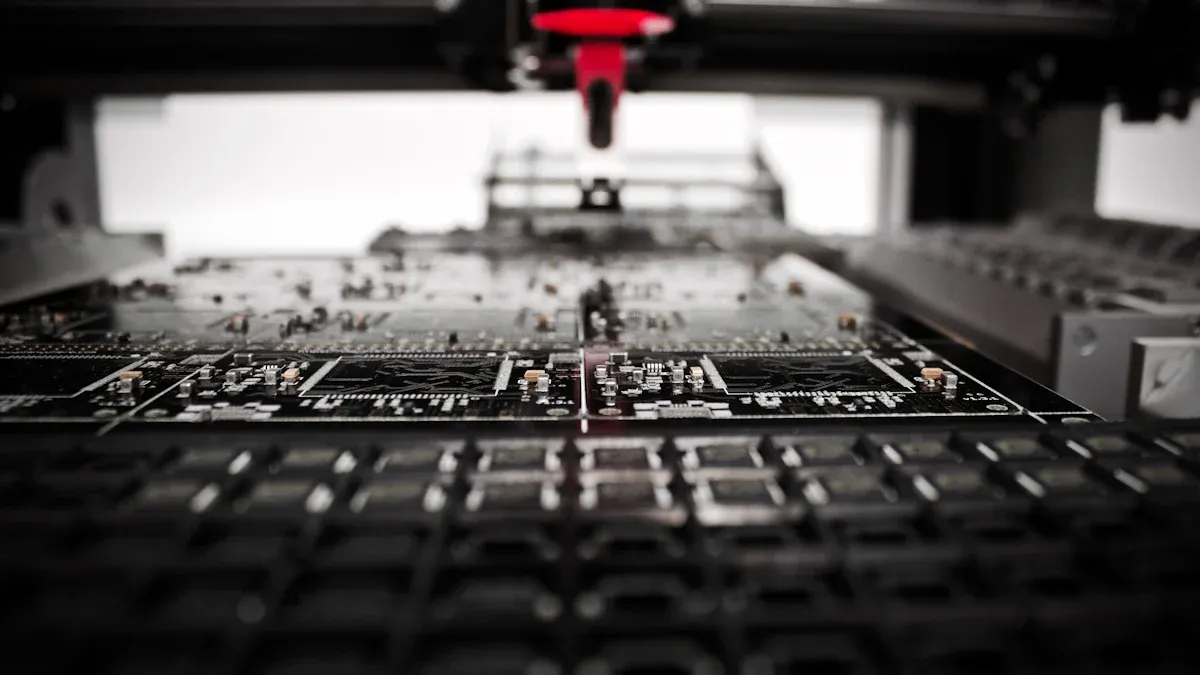

One-stop PCBA services make manufacturing easier by combining all steps in one place. This removes the need to work with many vendors, cutting delays and keeping things simple. With tasks like sourcing parts and assembly done together, your electronic products can be ready faster.

Top companies like Tempo Automation show how this works. Their smart software helps deliver prototypes in just three days. This is useful for industries like medical devices that need quick results. Using automation and scanning, they avoid mistakes and stay efficient.

Speeding up prototyping and production

Quick prototyping is a key part of one-stop PCBA services. Engineers can make prototypes in hours or days instead of weeks. This speed helps them get feedback and fix issues before full production starts. Faster prototyping means you can meet market needs and launch new products sooner.

For instance, rapid prototyping solves problems like long wait times and high costs. It offers faster results and saves money. This process improves accuracy and avoids delays. Making prototypes quickly helps deliver quality products to customers faster.

Clear communication with one-stop services

One-stop PCBA services remove communication problems caused by using many vendors. You don’t have to talk to designers, manufacturers, and suppliers separately. Instead, everyone works together in one system, making things clear and reducing mistakes.

This setup makes managing projects easier and ensures every step, from design to delivery, runs smoothly. One-stop electronic manufacturing services lower costs, improve quality, and avoid delays. They help you finish projects faster while keeping high standards.

Saving Money with One-Stop PCBA Services

Lower costs and simpler operations

One-stop PCBA services bring all steps into one place. This removes the need for middlemen, saving time and keeping results consistent. By letting experts handle tasks like part sourcing, assembly, and testing, you can focus on creating new products and growing your business.

Small businesses and start-ups save the most money this way. They avoid high costs and risks of working with many vendors. Full PCBA services help cut extra expenses, simplify work, and get better results.

Buying parts in bulk saves money

One-stop PCBA providers buy parts in large amounts to save money. They get discounts of 15%-20% compared to regular buying methods. These savings help your business spend less.

Benefit Type | Details |

|---|---|

Cost Savings | Providers save 15%-20% by buying in bulk. |

Better Resource Use | Businesses improve resource use by 30%-40% with faster capital turnover. |

Buying in bulk also helps businesses use their money more wisely. By working with a one-stop PCBA provider, you enjoy these benefits without managing many suppliers.

Fewer mistakes and lower repair costs

Mistakes in making products can cost a lot to fix. One-stop PCBA services reduce these problems by checking quality at every step. With smart tools and machines, they make sure assembly and testing are done right. This lowers the chance of errors and saves money.

For example, automated systems catch problems early before they grow bigger. Careful testing ensures your products meet high standards. By avoiding mistakes, you save money and give customers reliable products.

Expertise and Innovation in Electronic Manufacturing Services

Skilled experts and advanced knowledge

One-stop electronic manufacturing services connect you with skilled experts. These professionals know how to handle modern electronics. Their expertise ensures your products work well and meet standards.

The rise of consumer electronics and IoT devices shows why expertise matters. By 2024, the electronic manufacturing market will grow to $626.8 billion. It is expected to grow 5.1% yearly until 2034. This growth comes from the need for better technology and new ideas.

Advanced tools and technology working together

Innovation happens when great tools meet advanced technology. One-stop PCBA providers use modern machines to make production faster and better. For example, automated machines reduce mistakes and improve quality checks.

Studies show technology has changed manufacturing. Research from Germany shows digital tools help skilled workers and change old jobs. Using these tools ensures products are made accurately and consistently.

Study | Findings |

|---|---|

Technology increases non-routine jobs in manufacturing. | |

Brynjolfsson et al. (2018) | Machine learning affects jobs differently by type. |

Harrigan et al. (2021) | Tech-related jobs push manufacturing forward. |

Strong testing and quality checks

Good quality makes electronics reliable. One-stop PCBA services use strong testing at every step. These include tests like in-circuit testing, functional testing, and stress screening. Each test ensures products work well in real-life situations.

Testing Method | Purpose |

|---|---|

Checks parts placement and finds shorts or open circuits. | |

Functional Testing | Tests if products work correctly in real conditions. |

Environmental Stress Screening | Finds weak spots by testing in extreme environments. |

These tests lower mistakes and make products more reliable. Continuous improvements also boost quality, making sure products impress customers.

Ensuring Quality and Reliability with One-Stop PCBA Services

Following important standards like ISO 9001 and IPC-A-610

One-stop PCBA services focus on meeting key industry standards. These rules, like ISO 9001 and IPC-A-610, ensure products are high-quality and reliable. By following these standards, your products meet customer needs and legal rules.

For example, ISO 9001 ensures strong quality systems for consistent results. IPC-A-610 sets rules for how electronic assemblies should look and work. These guidelines help make sure your products meet strict quality levels.

Here’s a simple table of important standards one-stop PCBA services follow:

Compliance Standard | What It Does |

|---|---|

ITAR | Manages defense-related exports and imports. |

EPA Regulations | Ensures safe waste disposal and environmental care. |

OSHA | Keeps workers safe during manufacturing. |

RoHS | Limits harmful materials in electronics. |

ISO 9001 | Focuses on quality systems to meet rules and customer needs. |

IPC Standards | Ensures reliable and quality electronics. |

By choosing a one-stop service that follows these rules, you get reliable products with consistent quality.

Better tracking and fewer mistakes

Tracking parts and processes is key to making good products. One-stop PCBA services use advanced systems to track every step. This helps find and fix problems early.

In industries like medical devices, tracking materials is very important. Rules like IPC-1752A require detailed records of materials used. Batch records are also needed for FDA checks and safety reviews.

Here’s how one-stop PCBA services improve tracking and reduce mistakes:

Keep detailed batch records for audits.

Work with experts who find and fix problems.

Use smart tracking tools to monitor parts in real time.

These steps make production clear and help deliver error-free products to customers.

Strong testing at every step

Testing is a big part of one-stop PCBA services. It ensures your products are reliable and high-quality. Tests are done at every stage to catch and fix problems.

For example, heat tests check if devices can handle extreme temperatures. Vibration tests check if products stay stable. Statistical methods measure reliability over time. These tests make sure products last and work well.

Common testing methods include:

In-Circuit Testing (ICT): Checks connections between parts using special tools.

Functional Testing (FCT): Tests if the whole PCBA works as it should.

While some tests cost more, they are important for quality control. By working with a one-stop PCBA provider, you can use these tests to create reliable products.

Scalability and Flexibility for Modern Electronic Manufacturing Needs

Adjusting to different production sizes and needs

One-stop PCBA services handle both small and large orders. Whether you need a few items or many, they adjust easily. This helps you grow without delays or extra costs. Custom manufacturing lets you make products that fit customer needs. It also cuts waste and speeds up inventory turnover.

For example, companies can start small to test the market. As demand grows, they can increase production. This lowers risks and ensures you have enough products. With this flexibility, you can quickly adapt to market changes and customer preferences.

Company | Proof of Scalability |

|---|---|

Boeing | Automation cut assembly time by 25%, saving resources and ensuring safety. |

Intel | New methods made stronger, energy-saving microprocessors. |

Samsung | Smart factories improved production and quality checks. |

General Electric | 3D printing reduced part weight by 80% and production time by 50%. |

Helping with fast innovation and market shifts

Electronics manufacturing depends on new ideas. One-stop PCBA services help you stay ahead. They offer expert support to solve problems like part shortages or changing customer needs.

In 2024, the electronics market was worth $569.03 billion. By 2032, it may grow to $968.41 billion. This shows the need for new ideas in electronics and IT. Using smart manufacturing improves efficiency and keeps you competitive.

Quick prototyping speeds up product creation.

Automated assembly lowers mistakes and boosts quality.

Digital tools help you adjust to market changes faster.

Options for unique product designs

One-stop PCBA services let you customize your products. They handle everything from finding parts to assembly. This allows you to focus on making better products. For example, PCBWay works with tech companies to create custom items like smart meters.

Customizing makes your products stand out in the market. It also helps reduce waste and use resources wisely. By choosing providers with tailored solutions, you can design products that meet customer needs.

Custom manufacturing fits special product needs.

Unique designs make your products more appealing.

Full services simplify work and improve results.

One-stop PCBA services change how electronics are made. They combine all steps to save time and money. This process improves quality and makes production easier. Using one provider gives access to better tools and expert help. You don’t need to spend extra on new technology. These services include strong testing and follow strict quality rules. This ensures your products meet market needs. For companies, choosing one-stop PCBA services helps them stay ahead in the fast-changing electronics world.

FAQ

What are one-stop PCBA services?

One-stop PCBA services combine all steps of making PCBs. These include design, getting parts, assembly, and testing. Everything is done in one place to save time and money. This process also helps keep quality high.

How do one-stop PCBA services improve product quality?

These services use smart tests like in-circuit and functional testing. Testing happens at every step to catch problems early. They follow strict rules like ISO 9001 and IPC-A-610 to make products reliable.

Are one-stop PCBA services suitable for small businesses?

Yes, they work well for small businesses. Combining steps saves money and avoids dealing with many vendors. This lets small companies focus on creating new ideas and growing.

Tip: Small businesses can save money by buying parts in bulk. One-stop providers offer discounts that lower costs.

Can one-stop PCBA services handle custom designs?

Yes, they can make custom designs for special products. Providers work closely with you to meet your needs. This helps your product stand out and attract customers.

How do these services help with scalability?

One-stop PCBA providers adjust to your production size easily. They handle small or big orders without delays. This flexibility helps you grow as demand increases.

See Also

Understanding PCBA Services And Their Significance In Electronics

Enhancing Electronics Performance Through Innovative PCBA Solutions

Why PCBA Manufacturing Skills Are Crucial For Electronics Design

The Role Of Custom PCBA Manufacturing In Today’s Electronics

Defining PCBA Manufacturing And Its Importance In Electronics