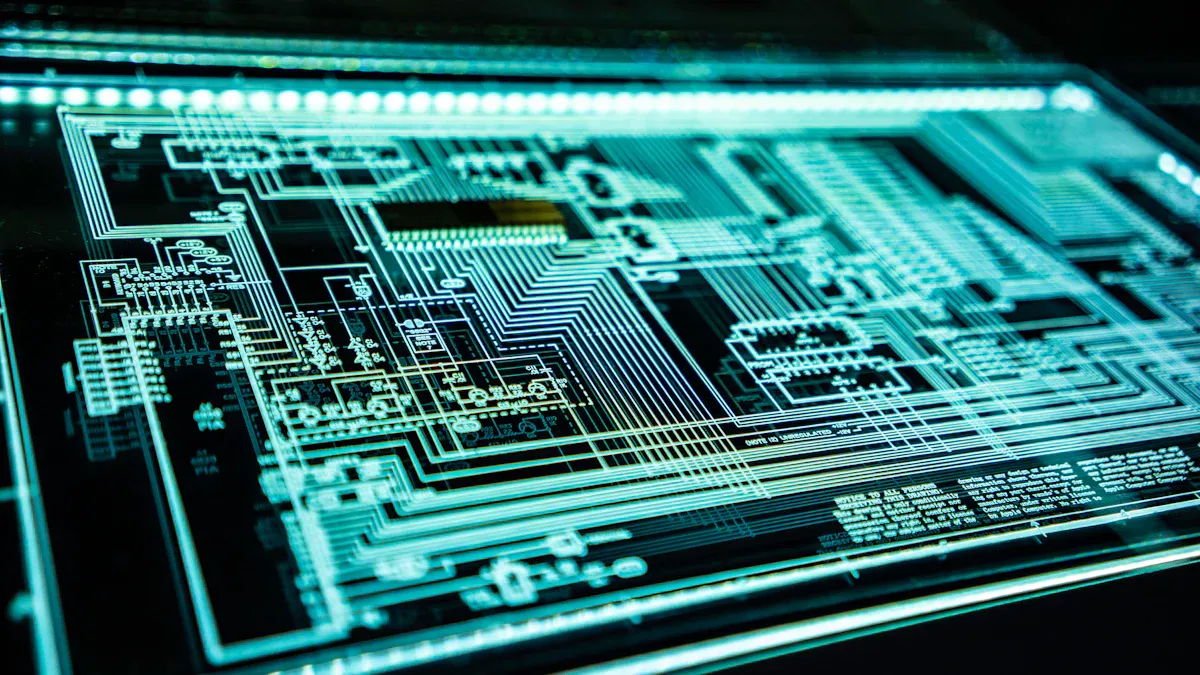

Selecting the right IoT edge device PCB assembly service in the USA is crucial for achieving high-quality, durable PCBs tailored to your needs. Partnering with companies experienced in IoT applications, such as wearables or smart home devices, ensures reliability. Look for providers with ISO 9001 or UL certifications to guarantee top-notch quality. Ensure they offer custom options like HDI or rigid-flex designs to meet specific requirements. Clear communication and excellent customer support are key to a seamless process.

Key Takeaways

Pick PCB services that know IoT devices well. Their skills help make boards work better and last longer.

Find makers with certifications like ISO 9001 and IPC-A-610. These prove they follow strict quality rules.

Choose companies that let you customize. Custom PCBs work better and match IoT needs.

Good communication and support are important. Helpful makers prevent delays and keep projects on track.

Spend on testing and prototypes. These find problems early, saving time, money, and improving results.

Key Factors for Picking a PCB Assembly Service for IoT Devices

Experience with IoT and Smart Home PCB Assembly

Choose companies that know IoT and smart home devices well. These experts understand small designs, saving energy, and wireless features. Their skills help avoid mistakes and make sure your boards work for busy IoT products.

Skilled manufacturers use smart tools to improve accuracy and speed. For example:

IoT tools track work in real-time, reducing errors.

Sensors find broken parts early, improving quality checks.

Predictive tools stop machine problems, avoiding delays.

A McKinsey study says automation can cut mistakes by 65%. This means fewer problems and better performance for your smart devices. Below is a table showing why experienced manufacturers are helpful:

Benefit | Description |

|---|---|

Precision | Machines place parts very accurately, lowering human mistakes. |

Speed | Automated systems work faster, making more products quickly. |

Cost Efficiency | Better processes save money, helping profits grow. |

Working with skilled PCB makers ensures your boards are strong and ready for tough conditions.

Certifications and Industry Standards

Certifications prove a company follows strict rules for quality. Certified makers stick to guidelines that ensure your boards are reliable. Look for certifications like IPC-A-610, ISO 9001:2015, or AS9100. These show the company cares about doing good work.

Here’s a table of important certifications:

Standard | Focus Area | Importance in Reliability |

|---|---|---|

IPC-A-610 | Rules for electronic assemblies | Ensures good quality during assembly |

IPC-A-600 | Rules for bare PCB fabrication | Ensures quality before assembly starts |

ISO 9001:2015 | Quality management system | Shows dedication to quality and reliability |

AS9100 | Aerospace quality management | Ensures high standards for aerospace products |

Certifications give you trust in the company’s ability to deliver great results. Always check their certifications before choosing them.

Advanced Manufacturing Capabilities

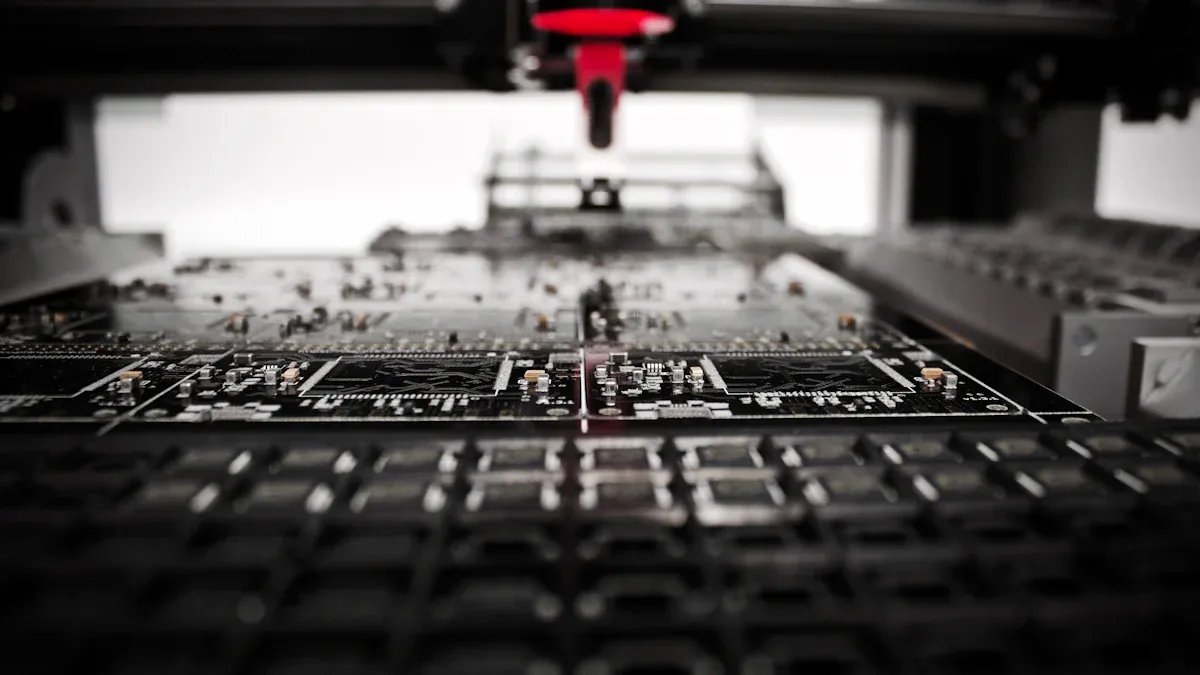

Modern tools are key for making top IoT devices. Advanced PCB makers use AI, robots, and smart analytics to improve production. These tools save time, cut costs, and make better boards.

For example:

AI finds ways to improve how things are made.

Smart analytics adjust processes in real-time for better quality.

Predictive tools stop defects and reduce waste.

A McKinsey report says IoT could add $4 trillion to manufacturing by 2030. This shows why advanced tools matter. Picking a company with modern tech ensures your boards meet today’s IoT needs.

Advanced tools also allow custom designs for smart devices. Whether you need a test board or many boards, skilled makers can meet your needs.

Customization and Tailored Solutions

Making PCBs fit IoT and smart home needs is important. A one-size-fits-all design often fails for these devices. You need a service that customizes PCBs for better performance in real-world use.

Custom services offer many benefits, such as:

Compact PCB Designs: Small designs, like Flipper Zero, combine communication tools. They use less power and stay durable, which is key for IoT devices.

Design for Manufacturability (DFM) Support: Companies like Highleap Electronics check your design for easy production. This lowers mistakes and speeds up manufacturing, saving time and money.

Rapid Prototyping: Testing prototypes helps improve designs before mass production. This ensures the final product works as planned.

Advanced Testing and Quality Control: Careful testing makes sure PCBs are reliable for large IoT projects.

Specialized PCB Options: Flexible or high-frequency PCBs meet different IoT needs.

Pick manufacturers skilled in customization. They adjust to your needs, making sure your IoT or smart home device works well. Custom solutions boost performance and reliability, making them worth the cost.

Communication and Customer Support

Good communication and support are key for successful PCB assembly. Complex IoT projects need clear teamwork between you and the manufacturer. Poor communication can cause delays, higher costs, and bad results.

Teams working together smoothly avoid confusion and keep production on track.

A great manufacturer keeps you updated during every step. They quickly solve problems and suggest fixes when needed. This builds trust and keeps your project moving forward.

Look for these customer support features:

Dedicated Support Teams: A team focused on your project gives you one contact for questions.

Proactive Communication: Manufacturers who share updates without being asked show they care.

Technical Expertise: Skilled support teams offer helpful advice for better decisions.

After-Sales Support: Good companies help with issues even after delivery.

Strong communication and support improve your experience and project success. Choosing a service that values these ensures smooth and efficient production.

Balancing Cost and Quality in PCB Assembly

Affordability vs. Reliability

Choosing between low cost and good quality is important. Saving money is nice, but cheap boards can fail. Bad boards hurt how your IoT edge devices or smart home gadgets work. A trusted PCB maker gives strong boards without charging too much.

For example:

A healthcare startup saved 20% and got 95% good boards.

An aerospace company got perfect boards for a satellite project.

These examples show skilled makers save money and give great results. Pick a service with good testing and prototype assembly. These steps make sure boards work well in real life. Reliable boards stop problems and save money later.

Identifying and Avoiding Hidden Costs

Hidden costs can ruin your budget if ignored. They come from tricky designs, bad communication, or extra features. Knowing all costs helps you plan better.

Hard | Soft |

* Board size/panelization * Layer count * Build complexity * Copper foil weights * Hole (size, quality, quantity) * Controlled impedance * Excessive tolerancing * Soldermask and silkscreen * Surface finishes | * Underspecification * Overspecification * Reliability * Communication |

For example:

A startup cut costs by 30% with better designs and parts.

Another company saved 15% by buying in bulk and tweaking designs.

These examples show planning and teamwork lower hidden costs. Talk clearly with your PCB maker to avoid surprises. Ask for quotes that list all costs, like materials and testing. This keeps your budget safe and ensures strong PCBs for your devices.

Ensuring High-Quality PCB Assembly for IoT Devices

Importance of Prototyping and Iteration

Prototyping helps make sure PCBs work well for IoT devices. It lets you check designs, find mistakes, and meet performance goals. Testing prototypes shows if the PCB works and fits with other parts. This lowers errors when making many boards. Prototyping also improves smart home PCB designs for real-world use.

Iteration means testing and improving designs again and again. Each test shows how the PCB handles power, wireless signals, and wear. These tests make PCBs stronger and save money by fixing problems early.

Prototyping and iteration help create strong PCBs for IoT devices.

Testing and Quality Assurance Processes

Testing ensures PCBs meet high standards and work well. Manufacturers use many tests to find and fix problems during production.

Process | Description |

|---|---|

Lamination | Checks heat and copper sticking for durability. |

Drilling | Tests hole smoothness and drill accuracy. |

Copper Plating | Measures copper thickness with light tests. |

Electroplating | Uses tools to make copper layers even. |

Developing and Etching | Checks line width and spacing for design accuracy. |

AOI (Automated Optical Inspection) | Finds PCB defects using cameras. |

Soldermask and Silkscreen | Spot checks ensure proper coating and labels. |

Electrical Testing | Confirms circuits work with flying probe tests. |

Routing | Cuts boards to exact sizes. |

V-CUT | Checks accuracy after cutting grooves. |

FQC (Final Quality Control) | Final checks ensure boards are ready to use. |

Physical Lab | Extra tests for quality using special tools. |

These tests make sure PCBs work well in tough conditions. For example, electrical tests check if smart home PCBs handle power safely. Picking a service with strong testing ensures reliable boards.

Design for Manufacturing (DFM) Analysis

DFM analysis improves PCB designs and saves money. About 70% of costs come from design choices, so DFM is important. It simplifies designs, lowers costs, and makes production faster.

DFM helps by:

Finding problems early to avoid delays.

Making production smoother and quicker.

Matching PCBs to factory tools to stop mistakes.

For IoT PCBs, DFM can shrink board size without losing quality. Smaller designs are great for IoT devices, which need compact parts.

DFM makes production better and ensures PCBs fit IoT needs. Working with experts in DFM gives you strong and efficient boards.

Top PCB Assembly Manufacturers for IoT Edge Devices in the USA

Overview of Leading Companies

Picking the right PCB assembly service is important for IoT devices. Knowing the best companies helps you choose wisely. These manufacturers are known for making high-quality PCBs designed for IoT needs. Here are some top names:

DSBJ: With 35+ years of experience, they offer many PCB services for IoT and smart devices.

UETPCB: For 15 years, they’ve made reliable, custom PCBs for specific needs.

Kinwong: They create thin, light boards, perfect for small IoT devices.

Shennan Circuits: Based in China but now in North America, they’ve made Triplex boards for 30+ years.

Epec Engineered Technologies: One of North America’s biggest PCB makers, they offer great service at fair prices for IoT projects.

These companies are experts in making PCBs that meet IoT device demands.

Key Strengths of Each Manufacturer

Each company has special strengths to fit your IoT project needs. Here’s what makes them unique:

DSBJ: Their long experience helps them handle tricky PCB designs well. They meet many industry needs, including IoT.

UETPCB: They focus on custom designs, giving you PCBs that match your IoT device perfectly.

Kinwong: They make flexible, lightweight PCBs, which are great for IoT designs.

Shennan Circuits: Their Triplex boards are strong and efficient, ideal for IoT projects.

Epec Engineered Technologies: They mix quality and fair pricing, offering great value for IoT projects.

Your choice depends on your project’s needs. Whether you want custom designs, low costs, or new technology, these companies have solutions for you.

Picking the best PCB assembly service is very important. A good service makes sure your IoT devices work well. Choose companies with experience in making IoT products. Look for certifications like ISO 9001 and IPC-A-610 to ensure quality. Testing and prototyping improve designs and prevent expensive mistakes. By focusing on these points, you can build strong and reliable IoT devices that achieve your goals.

FAQ

What matters most when picking a PCB assembly service for IoT?

Choose a service with IoT design experience. These experts know how to make small, energy-saving boards with wireless features. This ensures your boards work well for IoT devices.

How does prototyping help improve IoT PCBs?

Prototyping lets you test and fix your PCB design early. It finds problems, checks if parts fit, and boosts performance. This step saves time and money by avoiding big mistakes later.

Why are certifications important for PCB assembly companies?

Certifications like ISO 9001 and IPC-A-610 show the company follows strict quality rules. They ensure your PCBs are strong, reliable, and meet industry standards. Always check for these before choosing a manufacturer.

How do advanced tools help in making IoT PCBs?

Modern tools like AI and robots make production faster and more accurate. They reduce mistakes, improve quality, and allow custom designs. These tools ensure your PCBs are ready for real-world use.

Can custom designs make IoT PCBs better?

Yes, custom designs match PCBs to your device’s needs. They improve size, performance, and durability. Flexible or high-frequency PCBs help devices work better in their environments.

See Also

Essential Guidelines for Choosing Top PCB Assembly Services

Tips for Choosing the Ideal PCB Prototype Manufacturer

Finding the Right RF PCBA Company for Your Requirements