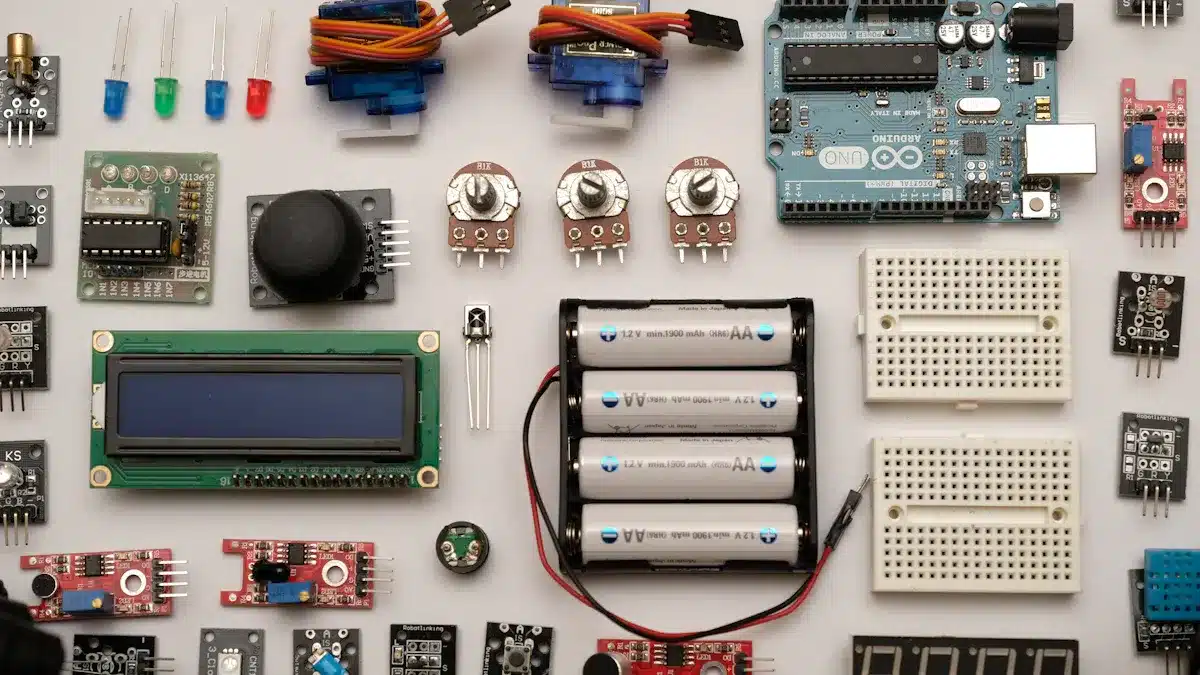

Circuit board components are the main parts of modern electronics. Each type, like passive, active, and power components, has its own job in circuit board design. The size, accuracy, and mounting style of a component change how well a device works. These choices also change how much it costs to make and how long it lasts. Smaller components help make devices smaller and signals clearer. But, they can make assembly harder. Good pcb design helps balance accuracy, fixing, and the effect on the environment. Picking the right parts makes devices work well, last long, and cost less.

Impact on Performance

Impact on Cost

Compact Design

Makes electronics small and easy to carry

Can make assembly harder and cost more

Precision

Makes devices work better and last longer

More accurate parts cost more

Key Takeaways

Circuit board parts can be passive, active, power, or electromechanical. Each type helps the device work well and last longer.

There are many circuit board types. These include single-sided, double-sided, multilayer, flexible, and rigid-flex boards. Each type is good for different things, from simple gadgets to high-tech devices.

Surface-mount technology lets devices be smaller and faster. It also lets them have more parts. Through-hole mounting gives stronger links for rough places.

Good electrical, mechanical, and thermal features help circuit boards work well. They also help control heat and make devices last longer.

Picking the right parts and board types is important. You should think about what the device needs, how much it costs, and how it is put together. This helps devices work better, cost less, and last longer.

Circuit Board Components

Passive Components

Passive components help control how electricity moves in a circuit. They do not need extra power to work. Some examples are resistors, capacitors, inductors, transformers, and fuses. Each one does something special. Resistors slow down the flow of current. Capacitors can store energy, filter out noise, and keep voltage steady. Inductors store energy using magnetic fields and help clean up signals. Transformers change how much voltage there is and keep parts separate. These circuit board components help decide how the whole system works.

Tip: Passive components keep circuits steady and help remove unwanted signals.

Common Examples | Description / Role | |

|---|---|---|

Passive Components | Resistors, Capacitors, Inductors, Transformers, Fuses | Shape signals, keep things steady, filter noise, store energy, and set how circuits work. |

Active Components

Active components need outside power to work. They can boost, control, or switch signals. The most common ones are transistors, diodes, and integrated circuits (ICs). Transistors make weak signals stronger and act like switches. Diodes let current go only one way, which helps shape signals and fix them. ICs have many active parts and do hard jobs, like handling data or making sound louder. These circuit board components help circuits do more than just sit still.

Active components make signals stronger for radios and TVs.

ICs help computers and smartphones work.

Power Components

Power components move and control electricity in a circuit. They include power MOSFETs, power management ICs, transformers, and big capacitors. These parts control voltage, change power, and stop circuits from getting too much power. Transformers can raise or lower voltage, and capacitors help keep power steady. Power components help devices work safely and well.

Typical Applications | |

|---|---|

Capacitors | Filtering, storing energy, timing circuits |

Inductors | Filtering, storing energy, making signals |

Diodes | Fixing current, controlling voltage, LEDs |

Transistors | Making signals bigger, switching, digital devices |

Transformers | Changing power, adjusting voltage |

Electromechanical Components

Electromechanical components link electrical and moving parts. Some examples are switches, relays, connectors, and motors. Switches let people turn circuits on or off. Relays use a small signal to control a bigger current, which keeps things safe. Connectors join different circuit board parts together. These circuit board components let people use devices and help control strong currents.

Note: Electromechanical components help make devices easy and safe to use.

The mix of active, passive, power, and electromechanical parts gives each device its special features.

Types of Circuit Boards

Single-Sided

A single-sided pcb has copper on just one side. This type uses a simple design and costs less to make. Many basic electronics, like calculators and LED displays, use single-sided pcb boards. Making these boards means etching copper, drilling holes, and adding a solder mask. Single-sided pcb boards are good for simple circuits but cannot handle lots of connections.

Single-sided pcb boards work best for cheap, mass-made products.

Double-Sided

A double-sided pcb has copper on both sides of the board. Vias are holes that connect the two layers together. This design lets circuits be more complex than single-sided boards. Double-sided pcb boards are in many devices that need more parts and wiring. Making these boards needs extra steps for vias and copper on both sides. Double-sided pcb boards give designers more ways to build circuits.

Multilayer

A multi-layer pcb has several copper layers with insulation between them. These layers are pressed together with heat and pressure. Multi-layer pcb boards let designers make small, complex circuits for powerful devices. Smartphones, laptops, and medical machines often use this type of board. Making these boards is harder and costs more because of the extra layers and careful lining up. Multi-layer pcb boards can hold lots of parts and manage heat better.

PCB Type | Layers | Applications | Manufacturing Notes |

|---|---|---|---|

Single-sided pcb | 1 | Simple electronics, LED displays | Easy, low-cost process |

Double-sided pcb | 2 | Consumer electronics, control panels | Needs vias, more complex |

Multi-layer pcb | 3 or more | Smartphones, laptops, medical devices | Advanced, costly, high precision |

Flexible

Flexible pcbs use a bendy polyimide base instead of a stiff one. These boards can twist and fold into many shapes. Flexible pcbs may have one or more copper layers. Devices like flexible screens, sensors, and solar panels use flexible pcbs because they fit in small spaces. Flexible pcbs are fast to make and cheap for big orders. But, flexible pcbs do not handle high heat as well as stiff boards. Flexible pcbs help make creative designs in new electronics.

Flexible pcbs help make products light, thin, and tough.

Flexible pcbs mean fewer connectors and cables are needed.

Rigid-Flex

Rigid-flex pcbs mix rigid and flexible pcb types. These boards have both hard and bendy parts. Rigid-flex pcbs link sub-circuits in hard areas with bendy connectors. Many smartphones, cameras, and medical tools use rigid-flex pcbs for saving space and strong connections. Rigid-flex pcbs use many copper layers and special materials. Making rigid-flex pcbs is tricky and needs careful lining up. Rigid-flex pcbs are great for products that need to be strong and flexible.

Rigid-flex pcbs help make electronics lighter and more reliable.

Mounting Technologies

Through-Hole

Through-hole technology is one of the oldest ways to make pcb boards. Engineers put component leads through holes in the board. Then, they solder them on the other side. This makes a strong bond. It is good for devices that shake or get bumped, like machines or cars. Through-hole components can handle heat well. They are easy to use for testing and fixing by hand. Many designers pick through-hole for circuit boards that must be very reliable.

Tip: Through-hole mounting is best for big parts and tough places.

But, through-hole needs lots of holes drilled. This takes more time and costs more money. The big size of these parts means fewer fit on a board. This way also makes assembly lines slower.

Aspect | Through-Hole Technology (THT) Advantages | Through-Hole Technology (THT) Disadvantages |

|---|---|---|

Mechanical Strength | Strong connections, last under stress | Big parts, slower and more work to put together |

Heat Tolerance | Handles heat better | Long leads can mess up signals at high speeds |

Prototyping & Testing | Easier to test and change by hand | Needs holes drilled, takes longer to make |

Size & Density | Not as good at saving space | Big parts mean less room for more |

Cost & Production | Good for tough, reliable boards | More work, slower to build |

Surface-Mount

Surface-mount technology, or SMT, changed how pcb boards are made. Machines put parts right on top of the board. This lets more parts fit in a small space. SMT helps make small, light, and smart devices like phones and watches.

SMT uses short leads, so it works better for fast signals. Machines place parts quickly and make fewer mistakes. SMT lets designers use special packages, like Ball Grid Arrays, which help with heat and speed.

SMT lets boards have more connections and parts on both sides.

SMT uses less material and saves power in finished devices.

But, SMT parts do not stick as well as through-hole ones. They can break if the board gets hot or bent. It is harder to see and fix SMT parts by hand. Starting SMT can cost a lot, especially for small orders.

Note: SMT helps make new electronics smaller, faster, and more reliable.

Key Properties

Electrical

Electrical properties decide how a circuit board works. Copper thickness changes how much current can flow. Most boards use copper from 0.25 oz to 5 oz. Pure copper, about 99.7%, lets electricity move better. The copper surface is important too. A smooth copper-dielectric surface helps signals move fast. This is very helpful for high frequencies. Different copper foils, like electro-deposited or rolled, fit different boards.

Dielectric constant (Dk) changes how fast signals move and helps match impedance.

Dissipation factor (Df) shows how much signal energy is lost. Lower Df means less loss, which is good for fast circuits.

Impedance control keeps signals clear and stops reflections.

High surface and volume resistivity stop unwanted current leaks.

Breakdown voltage shows how much voltage the board can take before it fails.

Good electrical properties keep signals strong and devices working well.

Mechanical

Mechanical strength keeps a circuit board safe. Thin boards bend and fit in small spaces. But, they can break or warp. Thick boards are strong and work in cars or factories. Flexural and tensile strength show how much force a board can take. Toughness lets a board take shocks without cracking. Rigid boards use FR4 for strength. Flexible boards use polyimide so they can bend.

Flexibility or rigidity decides if a board can bend or must stay solid.

More layers and thicker boards make them stronger but heavier.

Good mechanical properties help boards last longer and work in tough places.

Thermal

Heat control is important for circuit boards. Parts get hot when they work. Designers check datasheets for power loss and thermal resistance. This helps them know how hot parts will get. Boards with more copper or special materials move heat away faster. Thermal vias under hot parts help heat move to other layers. Heat sinks or fans can cool the board even more.

Boards attached to metal cases with thermal pads move heat better.

Picking the right package and layout helps keep temperatures safe.

Good thermal design stops overheating and helps devices last longer.

Cost

Cost depends on many things. Thicker copper makes boards cost 20-30% more. Fancy finishes like ENIG cost more than basic ones. Manual assembly costs more for each joint than machines. More layers make boards cost more, with each layer adding 20-40%. Special vias, tight traces, and fast circuits also raise prices. Bigger boards and more parts mean higher costs.

High-performance materials can cost up to 10 times more than normal ones.

Making more boards at once lowers the price for each one.

Sustainability

Sustainability is important for electronics today. Eco-friendly materials, like biodegradable substrates and lead-free solder, help the environment. Recycling old boards saves copper and other metals. Using less energy and safer chemicals helps the planet. Designers can make boards easy to take apart for recycling. Working with good suppliers and following rules keeps production safe.

Modular designs let people replace parts instead of throwing away the whole device.

Picking quality parts means fewer repairs and less waste.

Sustainable choices help the environment and make products last longer.

Printed Circuit Boards Comparison

Performance

Printed circuit boards work differently based on how they are made. Multilayer printed circuit boards are best for fast and complex devices. These boards have many layers that keep signals and power apart. This helps stop noise and keeps signals clear. High-frequency printed circuit boards use special materials like Rogers or PTFE. These materials help signals stay strong at very high speeds, over 1 GHz. Heavy copper printed circuit boards are good for devices that need lots of power. They can handle more heat and current.

Flexible pcbs and rigid-flex pcbs also work well in tough places. Flexible pcbs can bend and twist without breaking. This makes them fit in small or moving devices. Rigid-flex pcbs have both hard and bendy parts. This helps them last longer when things shake or move. These printed circuit boards keep wires safe and stop them from breaking.

Note: Picking the right printed circuit board makes devices faster, cooler, and last longer.

PCB Types and Their Performance for Special Applications:

PCB Type | High-Frequency Performance | High-Power Performance | EMI Shielding | Thermal Management |

|---|---|---|---|---|

Single-Sided | Low (simple circuits) | Low | Poor | Poor |

Moderate | Moderate | Fair | Fair | |

Multilayer | High | High | Good | Good |

Flexible PCBs | Moderate | Moderate | Fair | Fair |

Rigid-Flex PCBs | High | High | Good | Good |

Very High | High | Excellent | Good | |

Heavy Copper | Low | Very High | Fair | Excellent |

Application Suitability

Different printed circuit boards are used for different things. Single-sided printed circuit boards are best for simple and cheap products like toys or calculators. Double-sided printed circuit boards are used in things that need more parts, like power supplies or control panels. Multilayer printed circuit boards are found in smartphones, computers, and medical tools. These boards can handle lots of signals and keep devices small.

Flexible pcbs are used in wearables, cameras, and foldable phones. They can bend and twist, so they fit in tight spaces or moving devices. Rigid-flex pcbs are used in aerospace, military, and medical devices. These boards save space and weight by not needing extra cables. Rigid-flex pcbs also work well in rough places because they can take shocks and shaking.

High-frequency printed circuit boards use special materials for fast signals. Devices like radar, satellites, and 5G equipment need these boards. Heavy copper printed circuit boards are used in power supplies, electric cars, and big machines. These boards can handle lots of current and heat.

Best PCB Types for Different Applications:

Single-sided: Toys, LED lights, calculators

Double-sided: Power supplies, audio gear, industrial controls

Multilayer: Smartphones, laptops, routers, medical devices

Flexible pcbs: Wearables, cameras, foldable screens, sensors

Rigid-flex pcbs: Aerospace, military, medical implants, small electronics

High-frequency: 5G, radar, RF modules, satellites

Heavy copper: Power converters, electric cars, big machines

Pros and Cons

Every printed circuit board type has good and bad points. Designers must think about these before picking a board.

PCB Type | Pros | Cons |

|---|---|---|

Single-Sided | Simple, cheap, easy to make and fix | Not much space, not for fast or complex circuits |

Double-Sided | More parts, better work, not too costly | Harder to make, costs more than single-sided |

Multilayer | Fits more parts, good for small and fast devices | Expensive, hard to design and fix, tricky to test |

Flexible PCBs | Bendable, light, fits small spaces, needs fewer connectors | Not as good with heat, can cost more for small orders |

Rigid-Flex PCBs | Strong and bendy, saves space, very reliable | Costs a lot, hard to design and build, takes longer to make |

Heavy Copper | Handles lots of current, great with heat | Thick, heavy, costs more, not for small or light devices |

High-Frequency | Keeps signals strong at high speeds, low loss, steady | Expensive materials, needs special making, harder to get |

Tip: Flexible pcbs and rigid-flex pcbs help make new shapes and lighter devices, but they cost more and need special skills.

Summary Table: Pros and Cons of PCB Types

Aspect | Pros | Cons |

|---|---|---|

Component Density | More parts fit on multilayer and double-sided boards | Layout and wiring are harder |

Electrical Performance | Shorter paths and better wiring make signals faster and clearer | More layers and holes can cause more problems |

Miniaturization | Smaller devices are possible with multilayer and flexible pcbs | Making them is harder and costs more |

Reliability | Rigid-flex pcbs give strong, steady connections in tough places | Higher cost and takes longer to make |

Manufacturing | Flexible pcbs and rigid-flex pcbs need fewer connectors and cables | Need special ways to make and test them |

Printed circuit boards come in many types. Each one is good for certain jobs, from toys to medical tools. Designers must think about performance, price, and how long it will last when picking the best printed circuit board for their project.

Selection Guide

Application Needs

Picking the right circuit board parts starts with knowing what the device needs. Every device is different. These needs help decide which parts and board type to use.

Functionality: What the device does tells you which parts to pick. A simple timer only needs basic passive and active parts. A fancy sensor needs special ICs and connectors.

Size and Power: Small gadgets need tiny parts and good power use. Big power devices need parts that can handle more heat and current.

Reliability: Devices in cars or hospitals must work for a long time. Using strong parts from trusted brands helps with this.

Cost: The budget limits which parts and materials you can use. Designers must find a balance between price, how well it works, and how long it lasts.

Availability: Parts should be easy to buy and swap out. Using common parts helps stop delays when making the pcb.

Assembly Method: You can pick surface-mount or through-hole assembly. This depends on how big the device is, how strong it needs to be, and how many you will make.

Layout and Accessibility: Good design puts active parts in the middle to stop signal problems. Connectors should be easy to reach.

Tip: Always pick the part that fits the job. This helps the device work better and last longer.

Trends in Modern Electronics

Modern electronics change fast. New trends affect how engineers pick parts and design boards.

Trend | Impact on Component Selection and PCB Design |

|---|---|

Very small parts and tight layouts. SMT and HDI PCBs let more parts fit in less space. | |

Need materials that lose less signal and control impedance well. | |

IoT and Connectivity | More sensors, wireless parts, and safe chips for smart gadgets. |

Flexible and Wearable Tech | Use of flexible PCBs and tough parts for bending and moving. |

Thermal Management | Use of heat spreaders, thermal vias, and special stuff to control heat. |

Environmental Sustainability | Pick halogen-free, bio-based, and recyclable materials. |

Advanced Manufacturing | Use 3D printing, lasers, and AI to make boards faster and better. |

Flexible PCBs help make gadgets lighter and tougher, especially in wearables and phones.

IoT gadgets need parts for wireless, low power, and strong security.

Miniaturization means using tiny SMT and chip-scale parts. These need careful placement and checking during pcb making.

HDI tech and microvias let more complex circuits fit in small spaces.

Eco rules push for safer materials and designs that are easy to recycle.

Note: Trends like miniaturization and IoT mean we need smarter, smaller, and better parts.

Practical Tips

Engineers can follow some easy steps to pick the best parts.

Check power needs. Make sure the power supply can handle all parts, even if voltage drops or changes.

Look at tolerance and temperature ratings. Pick parts that stay steady when it gets hot or cold.

Match footprints. Make sure each part fits the board, including pins and pads.

Pick the right assembly method. Use through-hole for strength and surface-mount to save space.

Check electrical compatibility. Make sure pinouts match and use decoupling capacitors to keep signals clean.

Place parts smartly. Keep paths short, group similar parts, and keep noisy parts away from sensitive ones.

Work with skilled pcb makers. They can help check designs, signals, and heat plans.

Know failure risks. Learn about ESD, moisture, and heat, and use parts that protect against these.

Use test tools. Multimeters, oscilloscopes, and X-rays help find and fix problems early.

Test with prototypes before making lots. Testing helps catch mistakes and makes things more reliable.

⚡ Avoid common mistakes: Do not use the wrong PCB material for fast circuits. Always check trace width, spacing, and heat control. Keep designs simple and run checks before making boards.

Common Mistake | How to Avoid |

|---|---|

Wrong PCB material | Use high-frequency materials for fast circuits |

Poor power/ground planes | Use solid planes and keep them close together |

Inadequate trace width/spacing | Follow design rules and use calculators |

Ignoring signal integrity | Match impedance and use proper termination |

Bad via placement | Use microvias for tight layouts, avoid on fast paths |

Poor heat dissipation | Add thermal vias, copper pours, and heat sinks |

Overcomplicating design | Keep it simple and ask manufacturers for help |

Skipping prototyping | Always test before making lots of boards |

When thinking about pcb design, engineers must balance price, performance, and how long it lasts. They often use a mix of high-end and cheaper layers. Testing early helps make sure the final product works well. Working with suppliers and makers helps get better results and fewer surprises when making pcbs.

Remember: Good planning and picking the right parts make devices work better and last longer.

Circuit board components have passive parts like resistors and capacitors. They also have active parts such as ICs and diodes. Each part does a special job and uses certain mounting ways. Board types, like motherboards and daughterboards, are not the same. They have different uses and can be simple or complex. Picking the right part and board type helps the device work well. It makes sure parts fit, signals stay clear, and heat is managed.

To get the best results, designers should check ratings, layout, and how to put parts on the board.

Read beginner guides, technical articles, and join forums to keep learning as technology changes.

FAQ

What is the difference between passive and active components?

Passive components, like resistors and capacitors, work without extra power. Active components, such as transistors and ICs, need power to work. Active parts can make signals stronger or control them.

Tip: Passive parts help shape signals. Active parts can boost or control signals.

Why do engineers use multilayer PCBs?

Engineers use multilayer PCBs to fit more circuits in less space. These boards help keep signals fast and cut down on noise. Devices like smartphones and laptops need multilayer PCBs to work better.

PCB Type | Use Case |

|---|---|

Multilayer | Smartphones |

Single-sided | Simple gadgets |

Which mounting technology is better: through-hole or surface-mount?

Surface-mount technology (SMT) is best for small, modern gadgets. Through-hole mounting makes stronger connections for big or heavy parts. Engineers pick the type based on what the device needs.

SMT: Small, quick, fits many parts

Through-hole: Strong, simple to fix

How does PCB material affect device performance?

PCB material changes how signals move and how much heat the board can take. Good materials keep signals clear and help with heat. Fast or hot devices need better materials to work well.

Note: Good materials help devices run faster, last longer, and stay safe.

See Also

Benefits And Obstacles Of Flex PCBA In Electronics

Understanding Functional And Structural Variations Between PCBA And PCB

Advanced Electronics Manufacturing: PCBA Testing Methods Explored

Unveiling The Key Differences Between PCBA And PCB

The Importance Of Custom PCBA Manufacturing In Electronics Today