PCB connectors are very important in electronics. They connect different parts of printed circuit boards. There are three main ways to connect: board-to-board, wire-to-board, and wire-to-wire. Each way is good for certain types of connections. Knowing these types helps you pick the best one for your project. This makes sure your project works well. The most common pcb assembly methods are Surface Mount Technology (SMT), Through-Hole Technology (THT), mixed technology, and special assemblies.

Connection Method | Description | Soldering Technique(s) | Typical Applications/Advantages |

|---|---|---|---|

Surface Mount Technology (SMT) | Uses machines to place parts very carefully. It is great for small, crowded pcb. | Reflow soldering with solder paste and reflow ovens | Used in small, packed electronics. |

Through-Hole Technology (THT) | Parts go into holes in the pcb. This gives strong connections. | Wave soldering or manual soldering | Used for tough parts. |

Mixed Technology Assembly | Uses both SMT and THT. This gives more choices for parts. | Uses both reflow and wave soldering | Good for flexible designs. |

Specialized Assemblies | Has rigid, flex, and rigid-flex pcb. It can fit different board types. | Wave or reflow soldering, or both | Used for flexible or mixed uses. |

Lead-Free Soldering | Follows rules to protect the environment. Uses special solder. | Reflow soldering with lead-free paste | Better for the environment. |

Picking the right pcb on pcb connector type is important. It helps your project work well. This is true for usb, power, or signal connections.

Key Takeaways

PCB connectors have three main types: board-to-board, wire-to-board, and wire-to-wire. Each type is used for different connection jobs.

Picking the right connector helps your device work better. It also keeps it safe and helps it last longer. You must match the connector to power, size, and where it will be used.

Board-to-board connectors save space in devices. They also help stop signal loss. These connectors are good for small and tight electronics.

Wire-to-board connectors make strong and easy links for wires that are far from the PCB. You can pick from crimp, IDC, or terminal blocks.

Some connectors are special, like USB, RF, and waterproof types. They help send power, data, or signals safely in many devices and places.

PCB Connector Types

When you work with electronics, you see many pcb connector types. These connectors help link parts of your pcb or connect to other devices. The electronics industry sorts pcb connector types by how they connect and what they do. You can look at the main groups in the table below:

Category | Description | Examples / Notes |

|---|---|---|

Board-to-Board | Connects two PCBs without cables, suitable for close proximity boards. | Pins and receptacles connect PCBs; used in permanent or semi-permanent connections. |

Wire-to-Board | Provides electrical link from PCB to wire when boards or devices are farther apart. | IDC connectors for ribbon cables, crimp connectors, terminal blocks. |

Male/Female Connectors | Male connectors (pin headers) and female connectors (sockets) form basic PCB connector types. | Pin spacing varies; female connectors accommodate male pins for signal or power passage. |

Specialized Connectors | Designed for specific applications or signals. | Backplane connectors (high data rates), USB connectors (common in consumer devices), fiber optic, RF, industrial, automotive connectors. |

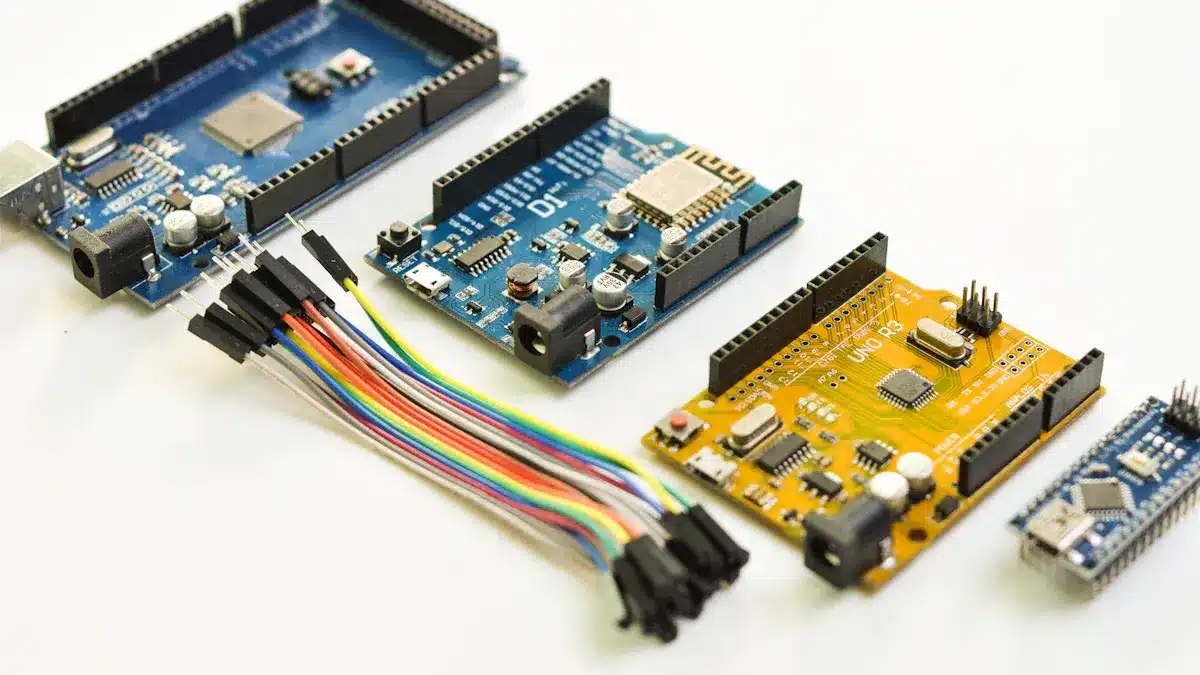

You will mostly use three main pcb connector types. These are board-to-board, wire-to-board, and wire-to-wire. Each type has its own uses and good points.

Board-to-Board Connectors

Board-to-board connectors join two pcbs right together. You do not need wires or cables for this. These connectors work best when boards are close. You can use them for permanent or semi-permanent links. Board-to-board connectors come in many shapes. Some are stacking, mezzanine, or right-angle types. You pick the right one based on how your boards fit.

Tip: Board-to-board connectors help make small devices. They save space and lower signal loss.

You see board-to-board connectors in many places. Here are some common uses:

Industry Sector | Typical Applications |

|---|---|

Home & Security | Smart home control panels, doorbells with cameras, thermostat control panels, monitoring equipment, robot vacuum cleaners |

Consumer Electronics | Smart health devices, wireless earbuds, tablets, VR glasses, wearables, drones, smartphones |

Vehicles | Navigation devices, car drive video recorders, autonomous vehicle systems |

Commercial | Point-of-sale terminals, self-checkout machines, security system panels |

Industrial | Rugged mobile devices, warehouse robots |

You can trust board-to-board connectors for strong, steady links in smart devices, cars, and machines. These pcb connector types carry fast signals and power. They are a top pick for new electronics.

Wire-to-Board Connectors

Wire-to-board connectors link wires to your pcb. You use these when boards or devices are far apart. This type lets you connect sensors, switches, or other parts to your pcb. There are many wire-to-board pcb connector types. Some are crimp connectors, IDC connectors, and terminal blocks.

Crimp connectors use metal ends you put on wires. Then you push them into a plastic case.

IDC connectors let you connect ribbon cables fast. You press the cable in, and sharp parts cut through the cover.

Terminal blocks use screws or springs to hold wires tight. You can use them for field wiring or quick changes.

Wire-to-board connectors have many good points:

They give you an easy, cheap way to send power and signals between pcbs.

New wire-to-board connectors are small and fit in tiny products.

These connectors keep signals safe, even if your device shakes or gets hot.

Gold-plated contacts and locks make the link strong and last long.

Crimped ends give you low resistance paths with no soldering.

Locks stop wires from coming loose.

Many wire-to-board connectors work with machines, which saves time.

Even small connectors can carry up to 2 A of current.

You can put in and take out wires easily, but the link stays tight.

Note: Wire-to-board connectors help you make strong products for cars, factories, lights, and telecom systems.

Wire-to-Wire Connectors

Wire-to-wire connectors join two wires together. You use these pcb connector types when you need to connect wires outside the pcb. These connectors help you make cables longer or link different parts of a system. You find wire-to-wire connectors in many forms, like cable assemblies and harnesses.

You can use wire-to-wire connectors for power, signals, or both. These connectors often have locks to keep the link safe. You see them in cars, home machines, and factory machines. Wire-to-wire connectors let you fix or change things without soldering. You just plug and unplug the wires as needed.

Remember: Picking the right pcb connector types helps you build strong, safe, and easy-to-fix systems.

PCB on PCB Connections

When you connect one pcb to another, you use pcb on pcb connectors. These connectors help you make small and strong devices. There are many types, and each has its own job. Using pcb on pcb connections gives you some good things:

Automated assembly lowers how much it costs to make.

You can test new ideas and designs more easily.

Good design helps stop electrical noise.

Repairs are easier because you can find problems fast.

Pin Header

Pin headers are a common pcb on pcb connector type. They look like rows of metal pins on a pcb. You use them to join two boards together. Pin headers can handle 1 A to 12 A of current. They also work with 50 V up to 630 V. You see them in home devices, machines, and medical tools. Pin headers are simple to use and fit many pcb types.

Socket

Sockets work with pin headers. You plug the pins into the socket for a strong link. Sockets let you remove or swap boards without soldering. You use sockets in test tools, computers, and other electronics. They come in many shapes and sizes for different pcb on pcb connector types.

Mezzanine

Mezzanine connectors let you stack one pcb above another. You can pick the height you need for your design. These connectors give you fast signals and strong links. Mezzanine types help you save space and add more features. They also support tight layouts and keep signals clear.

Tip: Mezzanine connectors let you choose stack heights, keep signals strong, and work well at high speeds.

Backplane

A backplane connector links many pcbs in one system. You see these connectors in telecom, data centers, and aerospace. Backplane connectors help you build big, powerful systems. They let each pcb talk to others quickly and safely.

Examples / Notes | |

|---|---|

Telecommunications & Wireless | 5G and wireless equipment |

Aerospace | Defense, space, and military systems |

Data & Computing | Data centers, AI, and servers |

Automotive & Transport | Cars, trains, and industrial vehicles |

Industrial & Control Systems | Automation, machinery, and sensors |

Spring-Loaded (Pogo Pin)

Spring-loaded connectors, called pogo pins, use a spring to touch the pcb. You use them for testing, charging, or short-term links. Pogo pins last a long time—many can be used 50,000 to 200,000 times or more. Gold or nickel coating makes them even stronger. You find these connectors in phones and medical devices.

Typical lifespan: 50,000 to 200,000 cycles

Used in: testing, charging, and short pcb on pcb connections

SMT Board-to-Board

SMT board-to-board connectors use surface mount technology. You put them right on the pcb. These types save space and work well with machines. You use SMT connectors in small things like tablets, wearables, and smart home products. They help you make good pcb on pcb connections with less hand work.

Right-Angle

Right-angle connectors let you join two pcbs at a 90-degree angle. You use these when you want signals to go out the side. Right-angle connectors save space and fit in small places. You see them in electronics, cars, and machines. They work well in tough places and come in many sizes.

Used for board-to-board or cable-to-board links needing a 90-degree exit

Note: Picking the right pcb on pcb connector types helps you build strong, flexible, and easy-to-fix systems.

Wire-to-Board Connectors

When you need to join wires to a pcb, you use wire-to-board connectors. These connectors help you link things like sensors and switches to your pcb. There are different types, and each one is good for something special. The most used types are terminal block, crimp, and IDC connectors. The table below shows how these connectors are different:

Feature/Aspect | IDC Connectors | Crimp Connectors | Terminal Block Connectors |

|---|---|---|---|

Wire Preparation | No need to strip insulation; blades pierce insulation | Requires pre-stripped wires | Wires inserted and clamped or screwed |

Assembly Process | Quick, can terminate many wires at once | More time-consuming; needs a crimp tool | Simple, often tool-free or uses screwdriver |

Cable Type | Ribbon cable, stiff and flat | Discrete wires, flexible | Many wire types, flexible or solid |

Flexibility in Wiring | Limited bends | Allows many wire sizes and layouts | Very flexible, easy to change wiring |

Cost | Lower for mass production | Higher due to tools and labor | Moderate, easy for field work |

Ruggedness and Reliability | Gas-tight, vibration-proof | Rugged, many design options | Reliable if installed well |

Typical Applications | High volume, quick assembly | Complex wiring, mixed gauges | Field wiring, industrial controls |

Terminal Block

Terminal block connectors let you join wires to your pcb by clamping or screwing them in. You see these connectors in control panels and big machines. They make it simple to add or take out wires. You do not need to solder anything. You can use many wire sizes with them. You also do not need special tools.

⚠️ Some problems with terminal block connectors are bad contact, weak insulation, and loose wires. Sometimes wires fall out, short circuits happen, or the connector breaks. Good design and careful work help stop these problems. Checking them often also helps.

Crimp

Crimp connectors use metal ends that you press onto wires with a crimp tool. Then you put these ends into a case that connects to your pcb. Crimp connectors make strong and steady links. You use them where things shake or move a lot, like in trains or solar panels. These connectors keep out dust and water. They work in tough places. You can use them with many wire sizes and shapes.

Industrial Sector | Typical Applications and Use Cases |

|---|---|

Industrial Automation | Conveyor systems, machinery, sensors, actuators |

Transportation | Railways, signaling, power distribution |

Security and Defense | Military GPS, antennas, communications |

Energy and Renewables | Solar panels, wind turbines, energy storage |

Heavy Machinery | Construction, mining, generators |

Crimp connectors are great when you need a strong, long-lasting link in hard places.

IDC

IDC connectors let you join wires to your pcb fast. You do not have to strip the wire first. The connector has sharp blades that cut through the cover and touch the metal inside. This makes a tight and safe connection. IDC connectors work best with ribbon cables. They are good for quick and big jobs.

You save time because you can connect many wires at once.

You do not need to strip or solder wires.

The connection stays strong even if things shake or get rough.

You can use easy tools, and the steps are simple to learn.

IDC connectors help lower costs and make building faster.

💡 IDC connectors are smart to use when you need to join lots of wires to your pcb quickly and safely.

Wire-to-Wire Connectors

Wire-to-wire connectors let you join two wires together. You do not need a pcb for this. You use these connectors to link cables outside the pcb. They make it easy to build or fix your wiring. You can also change wires quickly. You see wire-to-wire connectors in cars and computers. They are also in home electronics. These connectors help send power and signals between parts. There are many types of wire-to-wire connectors. Each type is made for a special job in your pcb project.

Cable Assemblies

Cable assemblies are groups of wires bundled together. You use them to connect two places in your pcb system. Most cable assemblies have connectors at both ends. These connectors let you plug and unplug cables easily. There are many kinds of cable assemblies for pcb projects:

Point-to-point cable bundles are simple groups of wires. Tape or mesh holds them together. They connect one pcb to another.

Bifurcated cables split from one connector into two or more ends. You can link one pcb to several other pcbs.

Flex Printed Circuit (FPC) cables are flat and bendy. They work well in small or thin products. They connect many pcbs and use different connectors.

S-ATA data cables, flat cables, and USB cables move data between pcbs or devices.

FDD/HDD/Ultra ATA cables and 1394 data cables connect storage devices or other electronics.

Most cable assemblies use crimp connectors. These connectors hold wires tight and make strong links. You can use cable assemblies for testing. They are also good when you need to change connections often.

Harnesses

Harnesses help you manage lots of wires in your pcb system. You use harnesses when you have many wires and connectors to organize. A harness can hold 20 to 30 wires or even more. You can run harnesses through tight spaces in your device. This helps stop wires from getting tangled or connectors from breaking.

Key features of harnesses are:

They group many wires and connectors for big pcb systems.

You can run harnesses in special ways to fit your device.

Harnesses keep wires safe and help avoid problems.

You use both electrical and mechanical design to make a good harness.

Modern tools let you design harnesses in 3D and make flat drawings.

Automation helps you finish harness designs faster and with fewer mistakes.

You see harnesses in cars, robots, and smart devices. They keep your pcb connections neat and safe. Harnesses help you save time and make your connectors last longer.

Edge and Card Connectors

Edge and card connectors help you connect a pcb to another board or device. You often see these connectors in computers and other electronics. They make it easy to plug and unplug a pcb without soldering. These connectors use the edge of the pcb as the contact point. You can find them in many shapes and sizes.

Card Edge

Card edge connectors let you slide the edge of a pcb into a slot. The metal pads on the pcb touch the contacts inside the connector. You use these connectors when you want a quick and simple way to connect or remove a pcb. You see card edge connectors in old video game cartridges, RAM sticks, and expansion cards.

Key features of card edge connectors:

Easy to insert and remove a pcb

Good for high-speed signals

Support many pins for complex circuits

Tip: You should keep the edge of your pcb clean. Dirt or damage can cause bad connections.

You can use card edge connectors in arcade machines, computers, and test equipment. These connectors help you swap out parts fast.

PCI/PCIe

PCI and PCIe connectors are special types of card edge connectors. You find them on motherboards in most computers. These connectors let you add new features to your computer by plugging in cards. You can use PCI or PCIe connectors for graphics cards, network cards, and storage controllers.

Connector Type | Speed | Typical Use |

|---|---|---|

PCI | Up to 533 MB/s | Older expansion cards |

PCIe | Up to 32 GB/s | Modern graphics, SSDs |

PCIe connectors use multiple lanes to move data very fast. You can choose different sizes, like x1, x4, x8, or x16, based on your needs. These connectors help your pcb talk to the rest of the computer quickly.

Note: Always line up your pcb with the connector before you push it in. This keeps the contacts safe and working well.

Edge and card connectors give you a simple way to upgrade or repair your devices. You can trust these connectors for strong and fast connections in your pcb projects.

Power and Signal Connectors

You use power and signal connectors to send electricity and data. These connectors help your PCB talk to other devices. They give power to your project and move information. Each connector type has a special job. Some work better in certain places.

Barrel Power

Barrel power connectors are found in cheap electronics. You see them in things that plug into the wall. They come in different sizes and shapes. You can pick the right one for your device. Some barrel connectors have extra pins. These pins tell your device when you plug in power. This helps save battery by turning it off. You find barrel connectors in toys and small gadgets. They are easy to use and work well.

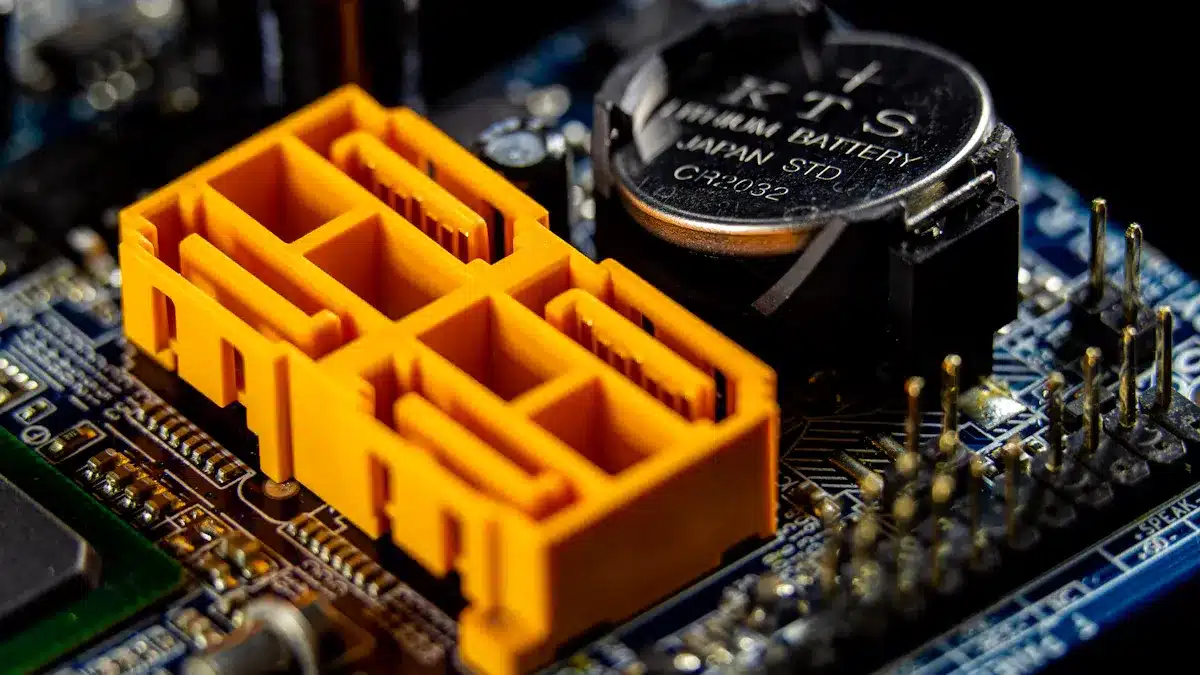

Molex

Molex connectors give strong and flexible links for power and data. You can use them for board-to-board or wire-to-board jobs. They also work with flexible cables. Molex connectors are used in cars, factories, and computers. They handle fast data, lots of power, and tough places.

Molex Connector Type | Common Applications in PCB Assemblies |

|---|---|

Board-to-Board Connectors | High-speed, high-density PCB connections |

Wire-to-Board Connectors | Rugged, sealed, reliable PCB connections |

Flexible flat cable connections | |

Automotive Connectivity | Vibration and temperature resistance |

Industrial Connectors | Power distribution, harsh environments |

High-Speed Internal I/O Connectors | High-frequency data transmission |

Memory/SIM Card Connectors | Compact, reliable memory/SIM card connections |

Modular Jacks and Plugs | Communication devices, PoE support |

Specialty Power Connectors | Power in commercial vehicles, harsh environments |

I/O Connectors | USB and other I/O interfaces |

Screw Terminal

Screw terminal connectors help you attach wires to your PCB. They are good for high current uses. These connectors have low resistance, so more current flows. Tin plating on screws helps carry more current. Many pins keep the connector safe and steady. Even if you pull the wires, it stays strong. You use screw terminals in power supplies and machines.

Low resistance lets more current flow

Strong hold keeps wires safe

Good for tough and high-current jobs

USB

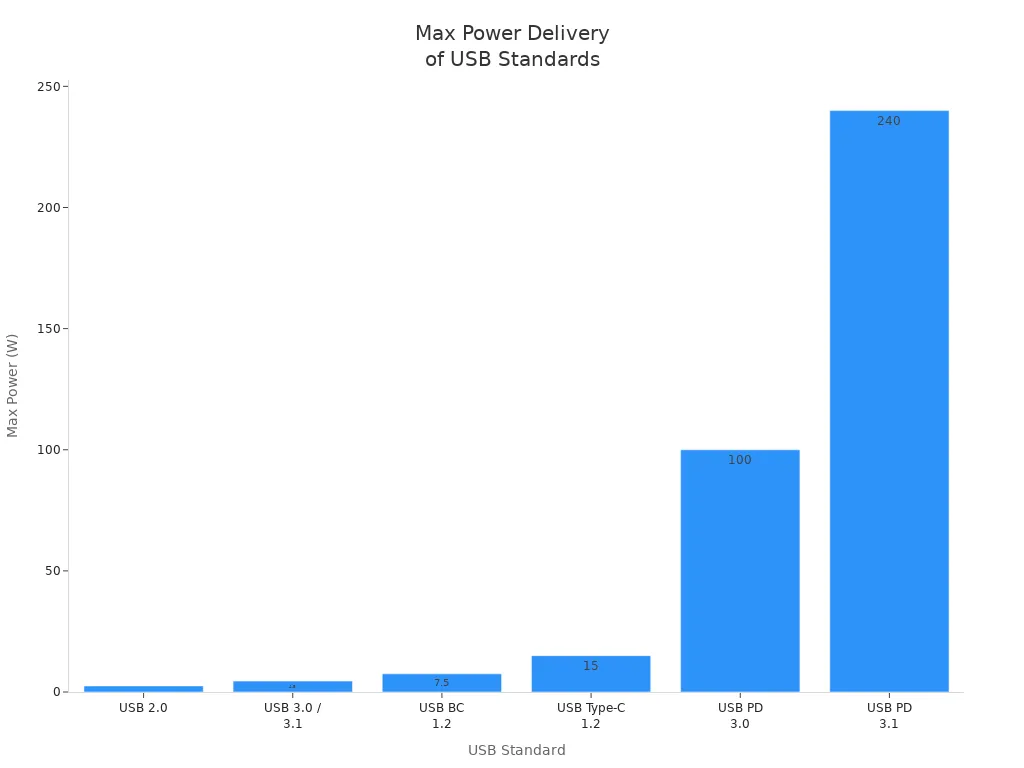

USB connectors are used everywhere. You use them to send data and power. USB connectors come in many types. Some are USB 2.0, USB 3.0, and USB Type-C. Each type gives different speeds and power. USB Type-C can give up to 240 W. It can also move data very fast. USB connectors are great for charging and moving files.

USB Standard | Max Power | Max Voltage (V) | Max Current (A) |

|---|---|---|---|

USB 2.0 | 2.5 W | 5 | 0.5 |

USB 3.0 / 3.1 | 4.5 W | 5 | 0.9 |

USB BC 1.2 | 7.5 W | 5 | 1.5 |

USB Type-C 1.2 | 15 W | 5 | 3 |

USB PD 3.0 | 100 W | 5 / 9 / 15 / 20 | 5 |

USB PD 3.1 | 240 W | 28 / 36 / 48 | 5 |

Tip: USB connectors are not just for data. You can use a usb pcb connector for charging and fast data.

HDMI

HDMI connectors send video and sound signals. You use them in TVs and game consoles. HDMI connectors keep signals clear with shielded contacts. This helps you get sharp pictures and sound. Some HDMI connectors work in tough places like military gear.

SATA

SATA connectors move data between your PCB and storage. They keep data safe and fast. Shielded contacts help stop signal loss. You find SATA connectors in computers and servers.

FFC/FPC

FFC/FPC connectors let you use flat, bendy cables in small spaces. You see them in phones, tablets, and cars. They help save space and move data fast. FFC/FPC connectors are great for small devices that need good data links.

Note: You can use FFC/FPC connectors in many small things, like audio and gaming gear.

RF and Coaxial Connectors

RF and coaxial connectors help you send signals and data with very little loss. You use these connectors when you need to move radio frequency signals or high-speed data between devices. These connectors keep your signals safe from outside noise. You often see them in wireless systems, antennas, and test equipment.

SMA

SMA connectors are small and strong. You use them for high-frequency signals and data. These connectors work well up to 18 GHz. You find SMA connectors in Wi-Fi routers, GPS modules, and radio boards. They have a screw-type design that gives you a tight and stable connection. This design helps keep your data clear and safe from interference.

Key features of SMA connectors:

Good for high-frequency data and signals

Secure screw-on connection

Used in wireless, test, and measurement devices

Tip: Always tighten SMA connectors by hand. This keeps the connector and your data safe.

BNC

BNC connectors are easy to use and quick to connect. You twist and lock them in place. You use BNC connectors for video, test equipment, and radio signals. These connectors can handle data up to 4 GHz. You often see them in labs and on oscilloscopes. BNC connectors give you a strong link for both analog and digital data.

Simple twist-lock design

Used for video, radio, and test data

Reliable for fast and clear signals

U.FL

U.FL connectors are very small. You use them when you need to save space on your PCB. These connectors work well for high-frequency data and signals. You find U.FL connectors in laptops, tablets, and IoT devices. They connect antennas to your board without taking up much room. U.FL connectors are not as strong as SMA or BNC, but they are perfect for tiny devices.

Connector Type | Size | Max Frequency | Typical Use |

|---|---|---|---|

SMA | Medium | 18 GHz | Wi-Fi, GPS, test boards |

BNC | Medium | 4 GHz | Video, lab equipment |

U.FL | Very Small | 6 GHz | Laptops, IoT, small PCBs |

Note: Pick the right RF and coaxial connectors to keep your data safe and your signals strong.

Testing and Temporary Connectors

Testing and temporary connectors help you check your PCB or make quick changes. You use these connectors when you want to test, measure, or fix something without making a permanent connection. These tools make your work easier and safer.

Test Points

Test points are small metal pads or pins on your PCB. You use them to measure voltage, current, or signals. You can touch them with a probe or clip to check if your circuit works.

You find test points in almost every electronic device.

Test points help you find problems fast.

You can use them during design, repair, or quality checks.

💡 Tip: Mark your test points with bright colors or labels. This helps you find them quickly when you need to test your board.

Alligator Clips

Alligator clips are spring-loaded metal clips with teeth. You use them to grab onto wires, pins, or test points. Alligator clips make temporary connections for testing or troubleshooting.

Common uses for alligator clips:

Connect a multimeter to a test point.

Hold wires together during a quick test.

Link power or ground to a circuit.

Feature | Benefit |

|---|---|

Spring-loaded | Easy to attach and remove |

Insulated grips | Safe to handle |

Wide jaws | Grab many wire sizes |

⚠️ Note: Alligator clips can slip or short out if you bump them. Always check your connections before turning on power.

IC Clips

IC clips, also called chip clips, let you connect to the pins of an integrated circuit (IC) without soldering. You use IC clips to test or program chips on your PCB.

IC clips fit over the legs of a chip.

You can measure signals or inject data.

These clips help you avoid damaging the chip or board.

🛠️ Pro Tip: Use IC clips when you need to debug or update firmware on a chip. This saves time and keeps your board safe.

Specialty PCB Connectors

Battery

Battery connectors link batteries to your PCB. They help power your device safely and easily. Battery connectors come in many shapes and sizes. Some types are snap, blade, and spring contacts. Each type fits a different battery style, like coin cells or cylindrical batteries.

Why choose battery connectors?

You can change batteries without soldering.

You get a safe and steady power link.

You protect your PCB when you swap batteries.

💡 Tip: Always use the right connector for your battery. This stops loose connections and keeps your device working well.

Magnetic

Magnetic connectors use magnets for quick connections. You see these in charging cables, medical devices, and wearables. The magnets pull the connector into place. You do not need to line up pins or push hard.

Benefits of magnetic connectors:

You can connect and disconnect with one hand.

You lower wear and tear on your PCB.

You help stop damage if someone pulls the cable.

Feature | Benefit |

|---|---|

Self-aligning | Easy to connect |

Safe release | Stops damage |

Sealed design | Blocks dust and moisture |

Magnetic connectors are good when you need fast and safe connections.

Waterproof

Waterproof connectors keep water and dust away from your PCB. You use them in outdoor gear, marine devices, and factory equipment. These connectors have seals or gaskets to block moisture.

Key features:

You keep your electronics safe from rain and dust.

You can use your device in rough places.

You keep your connections strong, even when it is wet.

🛡️ Note: Pick connectors with an IP67 or higher rating for strong water safety.

Choosing PCB Connectors

Picking the right PCB connector helps your project work well. It also helps your project last longer and stay safe. You need to think about a few important things before you choose.

Electrical Needs

You should check the voltage and current for each connector. Make sure the connector can handle the power your circuit uses. Look at the highest current it can take. Hotter temperatures can lower how much current is safe. The metal coating and how thick it is can change how well it carries electricity. If your project sends fast data, pick connectors that keep signals clear and block outside noise.

⚡ Always use connectors that match your circuit’s needs. This stops your device from getting too hot and keeps it safe.

Mechanical Fit

The connector must fit your board and device the right way. Think about the size, shape, and how it mounts. Some connectors use surface mount technology. Others use through-hole or panel mount. Check if the connector has locks, keys, or covers. These parts help keep the connector in place. They also stop it from coming loose. A good fit makes it easier to put together and stops damage.

Mechanical Feature | Why It Matters |

|---|---|

Helps keep the connector steady | |

Locking mechanism | Stops it from coming apart |

Keying/Retention | Makes sure it goes in the right way |

Environment

Think about where your device will be used. If your project faces water, dust, or chemicals, pick connectors that block these things. Look for waterproof connectors with IP67 or IP68 ratings. Gaskets and O-rings help keep water out. For tough places, use connectors made from strong materials. Make sure the connector can handle shaking, bumps, and big changes in temperature.

Handles heat and does not rust

Stays strong with shaking and bumps

Application

What you use the connector for changes what you need. For outdoor or factory use, pick connectors that last a long time. They should work even if you plug and unplug them a lot. For computers or home devices, you may want small connectors to save space. Always think about cost, how well it works, and if it will last. Pick connectors from brands you trust and with good instructions.

🛠️ The right connector for your job helps your project work better and last longer.

PCB Connector Types Summary

You have seen many pcb connector types in this guide. Each type helps you fix different problems in electronics. Board-to-board connectors join two circuit boards without using wires. Wire-to-board connectors let you attach wires to your board for things like sensors or switches. Wire-to-wire connectors connect cables outside the board. Edge and card connectors make it simple to plug in or take out boards, like in computers or game consoles.

Here is a quick table to help you remember the main groups:

Connector Category | Best Use Case |

|---|---|

Board-to-Board | Stacking or joining PCBs directly |

Wire-to-Board | Connecting wires to a PCB |

Wire-to-Wire | Linking cables outside the PCB |

Edge/Card | Removable boards or upgrades |

Power/Signal | Sending power or data |

RF/Coaxial | High-frequency signals |

Specialty | Unique needs (waterproof, battery) |

Tip: Always pick the connector type that fits your project. This helps your device work better and last longer.

You should think about where your device will be used, how big it is, and how much power or data you need to send. Choosing the right pcb connector types keeps your project safe and easy to fix. You can stop problems like loose wires or weak signals. When you choose well, your electronics stay strong and work for a long time.

You have learned about the main types of PCB connectors and how you can use them in your projects. Each connector type fits a different job, from sending power to moving data. Picking the right connector helps your device work well and last longer.

Always check datasheets before you choose.

Ask experts if you have questions.

Think about what your project needs now and in the future.

Choosing wisely gives your electronics the best chance for success.

FAQ

What is the main job of a PCB connector?

You use a PCB connector to join different parts of your circuit. It helps you send power or signals between boards, wires, or devices. You can also use connectors to make repairs or upgrades easier.

How do I choose the right PCB connector for my project?

You should check the voltage, current, and size you need. Think about where you will use your device. Pick a connector that fits your board and can handle the environment, like heat or water.

Can I reuse PCB connectors after removing them?

You can reuse some PCB connectors if you remove them carefully. Check for damage before using them again. Some connectors, like IDC or crimp types, may not work well after removal.

Why do some connectors have gold plating?

Gold plating helps stop rust and keeps the connection strong. You get better signal quality and longer life with gold-plated contacts. This is important for high-speed or sensitive circuits.

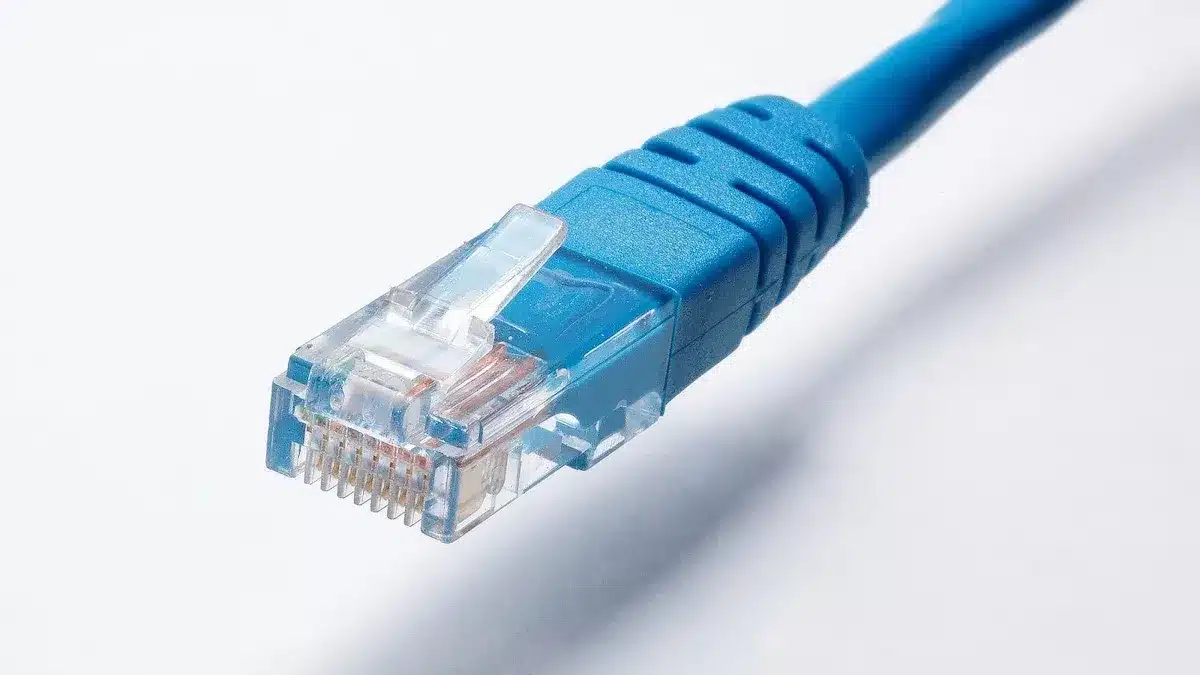

What are modular/ethernet connectors used for?

You use modular/ethernet connectors to connect network cables to your PCB. These connectors help you send data between computers, routers, or other devices. They are common in networking and communication equipment.

See Also

Essential PCBA Parts And Their Primary Roles Explained

A Comprehensive Overview Of PCBA Coating Types And Basics

Exploring How PCBA Is Applied In Consumer Electronic Devices