Accurate fault finding helps keep your machines working well. Tools like the TD-30A PCB Short Circuit Finder and smart systems for bearing fault detection circuit boards are very precise. Using these tools can lower downtime and save money. For example, predicting problems early can cut downtime by 18.5% and reduce errors by 87.3%. These tools also make machines last 40% longer, saving money and avoiding delays.

Key Takeaways

Good diagnostic tools can cut machine downtime by 18.5% and mistakes by 87.3%, saving both time and money.

Pick tools that are very accurate, like the Enhanced Joint Model, to find problems exactly.

Use tools that are simple and easy to handle to save time and make repairs less stressful.

Choose strong and portable tools that work well in tough places and last a long time.

Buy affordable tools that give great value because they can stop expensive machine problems and delays.

Key Features to Look for in Diagnostic Tools

Accuracy and Sensitivity

Picking the right tool means focusing on accuracy and sensitivity. These features help find faults exactly, even in tricky systems. For example, the Enhanced Joint Model has 98.5% accuracy, making it great for fixing problems. The KIT2FCM model stays over 90% sensitive, even with noisy surroundings. This performance is key for real-world use where conditions can change results.

To check accuracy, use guides like the QUADAS-2 framework. It rates tools based on timing, flow, and how well they fit the task. For AI tools, the QUADAS-AI extension adds extra checks for reliability. Choosing tools that meet these standards reduces mistakes and boosts efficiency.

Diagnostic Tool | Accuracy/Sensitivity | Notes |

|---|---|---|

Enhanced Joint Model | 98.5% accuracy | Great for finding and fixing faults |

KIT2FCM | ≥90% sensitivity | Works well with up to 5% noise |

LSTM-based Method | High accuracy | Handles noisy and uncertain environments |

Ease of Use and Interface

Easy-to-use tools save time and lower stress. Tools with simple designs let you focus on fixing issues, not figuring out menus. Surveys show users like devices with clear layouts and simple controls. Tests prove people finish tasks faster with easy interfaces.

Studies also show fixing design flaws improves usability. Tools that follow user feedback often work better. When picking a tool, choose one that’s simple and meets safety rules.

Compatibility with Various Systems

Compatibility means your tool works with different systems. For circuit boards, deep learning models are great at spotting and sorting defects during PCB production. These models adjust to many uses, making them flexible.

Model | Application | Results |

|---|---|---|

PCB Manufacturing | Finds, locates, and sorts defects accurately |

Using a tool that works with many systems saves money and avoids buying extra devices.

Portability and Durability

When picking diagnostic tools, portability and durability are very important. A portable tool is easy to carry between places or to far-off sites. This is helpful for technicians who fix problems on location. Small and lightweight tools are easier to handle and use.

Durability means the tool can handle tough conditions. Many tools are used in hot, dusty, or shaky environments. Strong materials help tools last longer and work well in these settings. For example, tools with tough cases or shock-proof designs survive drops without breaking.

Battery life is also important for portable tools. A long-lasting battery lets you work longer without stopping. Some tools even have power-saving modes to make the battery last. Choosing a portable and durable tool makes work easier and reduces how often you need replacements.

Cost-Effectiveness

Cost-effectiveness is key when buying diagnostic tools. A good tool works well without costing too much. To decide, compare the costs and benefits of different tools.

Economic Evaluation Method | What It Does |

|---|---|

Cost-Minimization | Finds the cheapest option with the same results. |

Compares costs and results of different tools. | |

Cost-Utility | Adds quality of life to cost-effectiveness. |

Cost-Benefit Analysis (CBA) | Compares total costs to total benefits. |

Tools with high accuracy and sensitivity are worth higher prices. Better sensitivity can save money by avoiding machine problems and downtime. AI-powered tools are a great example. They may cost more upfront but save money by finding problems early. For instance, tools with 88% sensitivity and 80% specificity show this well.

Buying a cost-effective tool gives you better value and keeps your work running smoothly.

Product Reviews

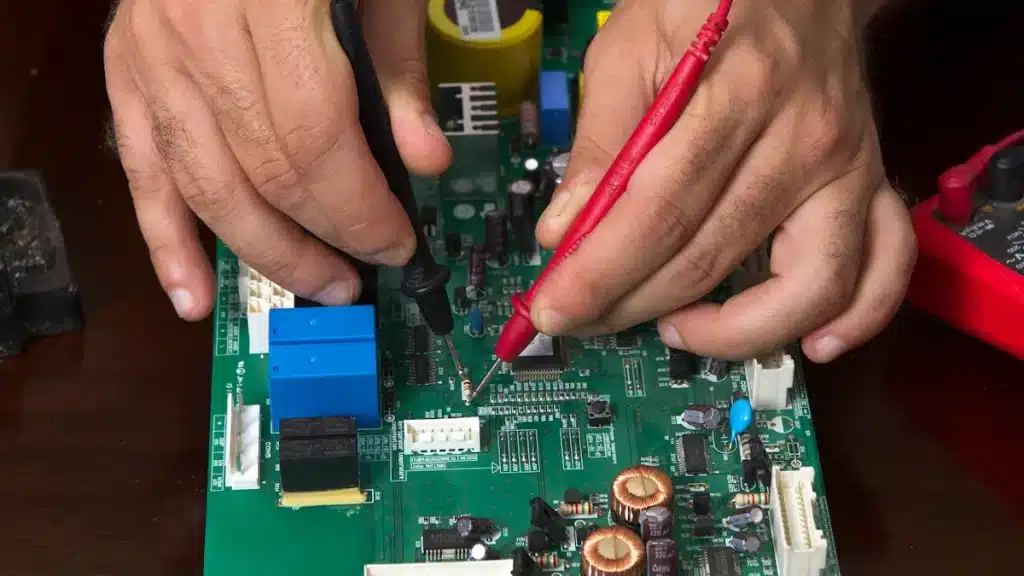

Circuit Board Diagnostic Tools

TD-30A PCB Short Circuit Fault Detector Box

The TD-30A PCB Short Circuit Fault Detector Box is a dependable tool for finding short circuits on PCBs. It uses smart technology to quickly locate problems, saving time during repairs. Its strong sensitivity helps it find faults accurately, even in tricky circuits. This tool is small and easy to carry, making it perfect for on-site checks. Plus, its simple controls mean you can use it without much training.

Main benefits:

High sensitivity for finding faults exactly.

Portable design for easy carrying.

Simple interface for quick and easy use.

If you often work with PCBs, this tool can make your work faster and more accurate.

High-Resolution Thermal Cameras with Calibrated Optics

Thermal cameras with calibrated optics are great for spotting overheating parts on circuit boards. These cameras give clear thermal pictures, helping you find hot spots that may cause problems. Using these cameras can stop damage from overheating and keep your circuits working well.

Important features:

High-resolution imaging for clear and detailed views.

Calibrated optics for correct temperature readings.

Non-invasive testing to avoid harming parts.

Thermal cameras are very helpful for stopping problems before they get worse.

Flying Probe Testing (FPT) Systems

Flying Probe Testing (FPT) systems are flexible tools for checking PCBs. They use moving probes to test connections and find problems without needing a fixed test setup. These systems work well for small batches and testing new designs.

Key advantages:

Fixture-less testing to save money.

Flexibility to test different PCB types.

High accuracy for finding problems.

FPT systems are a smart pick if you need a flexible way to check PCBs.

Bearing Fault Detection Tools

Deep Learning-Based Bearing Diagnostic Tools

Deep learning-based tools are changing how we find bearing problems. These tools study vibration signals to spot and sort faults with great accuracy. They use advanced algorithms to adjust to different bearings and conditions.

Main features:

Advanced algorithms for accurate fault finding.

Adaptability to many bearing types.

Real-time analysis for fast results.

Research shows these tools are excellent at finding faults in rolling bearings, even in tough places like fast trains. They are the future of bearing diagnostics.

Vibration Analysis Tools for Bearings

Vibration analysis tools are trusted for checking bearing health. They measure vibrations to find unusual patterns that show faults. These tools are widely used where reliable bearings are important.

Benefits include:

Non-invasive monitoring for easy setup.

Detailed analysis of vibration patterns.

Early fault detection to stop failures.

Studies prove vibration analysis works well for finding different fault types and sizes. These tools are vital for keeping machines running smoothly.

AI-Powered Bearing Fault Diagnosis Systems

AI-powered systems bring bearing fault detection to a higher level. They mix artificial intelligence with sensor data to give accurate and predictive insights. These systems can find fault locations and reasons, helping you act early.

Features include:

Predictive capabilities for better maintenance planning.

Integration with multiple sensors for full monitoring.

User-friendly interfaces for simple use.

These systems are especially useful for industries with fast machines, where early fault detection avoids costly delays.

Comparison Table

Circuit Board Diagnostic Tools Comparison

Picking a circuit board tool means checking accuracy, portability, and ease. Below is a table comparing three popular tools:

Tool | Accuracy | Portability | Ease of Use | Key Feature |

|---|---|---|---|---|

TD-30A PCB Short Circuit Detector | High | Excellent | Very Easy | |

High-Resolution Thermal Cameras | Moderate | Good | Easy | Non-invasive overheating checks |

Flying Probe Testing Systems | Very High | Limited | Moderate | Fixture-less testing |

The TD-30A is great for carrying and simple use. It’s perfect for finding problems on-site. Thermal cameras help spot overheating parts without touching them. Flying Probe Testing Systems are very accurate for tricky fault checks. Each tool has its own use, so pick one based on your needs.

Bearing Fault Detection Tools Comparison

Bearing tools study vibrations to find problems. The table below shows how different methods perform:

Method Type | Recognition Rate | Response Time | Computational Resources | Algorithm Complexity |

|---|---|---|---|---|

Time Domain Method 1 | High | Fast | Low | Simple |

Frequency Domain Method 1 | High | Fast | Medium | Moderate |

Time-Frequency Method 1 | High | Fast | Medium | Moderate |

Time-frequency methods are great for finding hard-to-spot faults. They check vibrations in both time and frequency for better results. Deep learning tools make this even better by adjusting to different fault types. Research shows these tools work faster and more accurately, making them very useful.

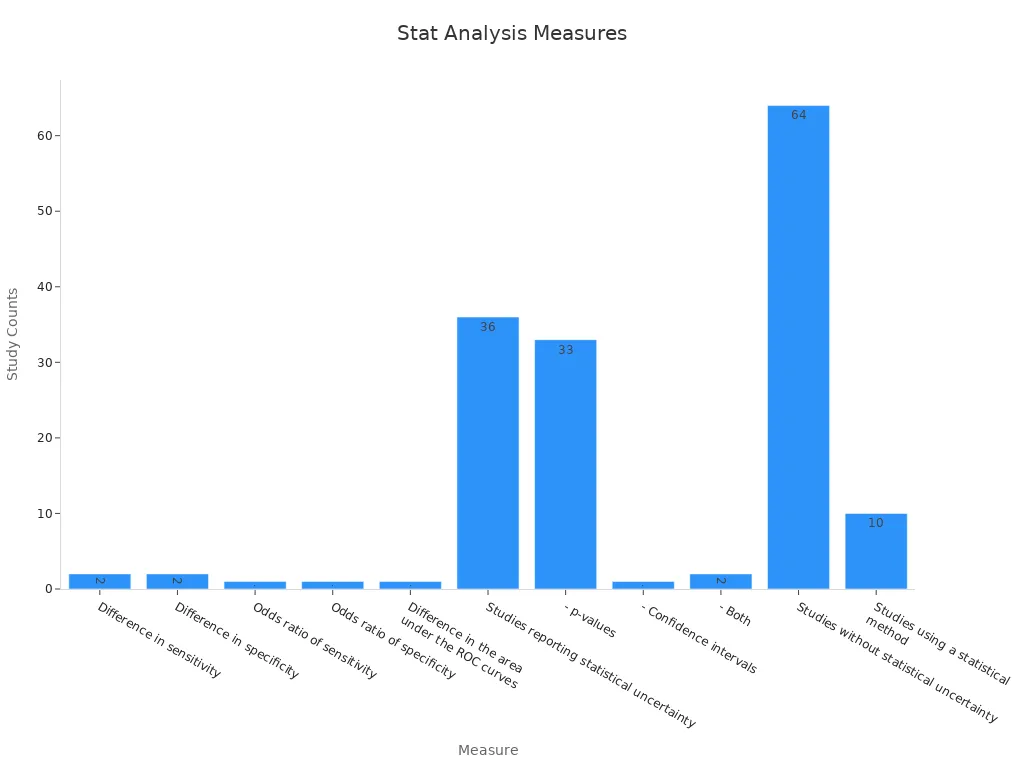

The chart above shows how sensitivity and specificity are used in fault studies. These measures help ensure tools give reliable results.

By mixing smart algorithms with real-world data, these tools find bearing problems quickly and correctly. Whether you need speed, accuracy, or flexibility, there’s a tool for you.

Final Recommendations

Best Overall Product

If you need a top-notch diagnostic tool, the TD-30A PCB Short Circuit Fault Detector Box is a great pick. It finds faults accurately, even in tricky circuits, thanks to its high sensitivity. Its small size makes it easy to carry, and the simple controls mean you don’t need much training to use it. This tool is perfect for professionals who need fast and accurate results during inspections.

Studies show that good diagnostic tools go through strict testing. Many consumer apps don’t check safety or effectiveness well. But tools like the TD-30A are tested carefully, proving they work reliably in real-world situations. This makes it a smart choice for both beginners and experts.

Best Budget Option

If you’re on a budget, vibration analysis tools for bearings are a solid choice. These tools measure vibrations to find problems early. They are easy to set up and don’t damage parts. While they don’t have fancy AI features, they still give clear and reliable results at a lower cost.

Buying a cheaper tool doesn’t mean giving up quality. Vibration analysis tools focus on key features like finding faults and lasting durability. They are great for small businesses or anyone wanting to save money while keeping machines running smoothly.

Best for Specific Needs

Some industries need special tools for unique problems. Deep learning-based bearing diagnostic tools are perfect for jobs needing precision and flexibility. These tools study vibration signals to find and sort faults with high accuracy. They work well in industries like manufacturing and telecom, where predicting problems is very important.

Industry | Example Use Case | Result |

|---|---|---|

Manufacturing | A factory used IoT sensors with supply chain systems. | |

Telecommunications | A telecom company combined network and customer data. | Boosted customer satisfaction by 30%. |

Deep learning tools adjust to different conditions, making them very useful. They combine fault detection with predictions, helping industries stay efficient and reliable over time.

Future Trends in Diagnostic Tools

AI and Machine Learning Integration

AI and machine learning are changing how diagnostic tools work. These technologies study data faster and more accurately than older methods. For example, AI systems for chest X-rays now match the skills of expert doctors. Automated tools for diseases like malaria and tuberculosis are already helping in places like Uganda and Brazil. These advancements also improve bearing fault checks by spotting vibration patterns and predicting issues early.

The move toward digital tools and AI is driving new ideas. Companies are spending a lot on research to stay ahead. This focus on smarter tools and less invasive methods helps both patients and industries. AI-powered tools also make real-time maintenance easier, cutting downtime and boosting productivity.

Enhanced Portability and Miniaturization

Portable diagnostic tools are becoming very important for today’s industries. Devices like small ultrasound machines and compact MRI scanners give clear images in far-off places. For example, the Swoop portable MRI system found brain problems in 97% of patients in intensive care units. These tools are light, strong, and simple to use, making them great for on-site bearing checks.

Magnetic nanoparticles are another exciting development. They improve image quality, helping find problems early. Portable tools also allow technicians to check bearings in tough environments. This trend toward smaller devices ensures they stay useful and easy to use in many situations.

Real-Time Monitoring and Cloud Connectivity

Real-time monitoring and cloud technology are changing how faults are found and fixed. Systems that monitor continuously can catch problems right away, stopping bigger failures. For example, IBM’s CloudHeatMap shows live data, helping people make quick decisions. These systems can also send alerts and fix issues automatically, keeping operations smooth.

Cloud-connected tools let technicians check data from anywhere. This is especially helpful for bearing fault checks, where quick maintenance can stop expensive breakdowns. By mixing cloud systems with smart algorithms, these tools offer top-notch accuracy and performance.

Picking the right tools helps machines work better and last longer. The TD-30A PCB Short Circuit Detector makes checking circuit boards easier. AI-powered tools are great for finding bearing problems quickly. These tools save time, cut downtime, and reduce costs.

New trends like AI and live monitoring will improve tools even more. Knowing about these changes helps you choose tools that fit your needs. Smarter tools keep your work running smoothly and ready for the future.

FAQ

What matters most in a diagnostic tool?

Accuracy is the key feature to look for. It helps find problems exactly, saving time and avoiding damage. Tools with good sensitivity and dependability work best for circuit boards and bearings.

How do deep learning tools help find bearing problems?

Deep learning tools study vibrations to spot faults very accurately. They adjust to different conditions and bearing types, giving quick results. This makes them perfect for jobs needing precise and early maintenance.

Can circuit boards be checked with automated visual inspection?

Yes, automated visual inspection works well for circuit boards. It finds problems like bad soldering or misplaced parts without needing manual checks. This method speeds up work and lowers mistakes during production.

Are portable tools good for on-site checks?

Portable tools are built to work well on-site. They are tough and have advanced features to find problems in hard places. Their light weight and long battery life make them easy to use in the field.

How do vibration tools help with bearing care?

Vibration tools check bearings by spotting strange patterns. They warn you early about possible problems, helping you avoid big repairs. These tools are simple to use and don’t harm the equipment, making them a favorite for maintenance.