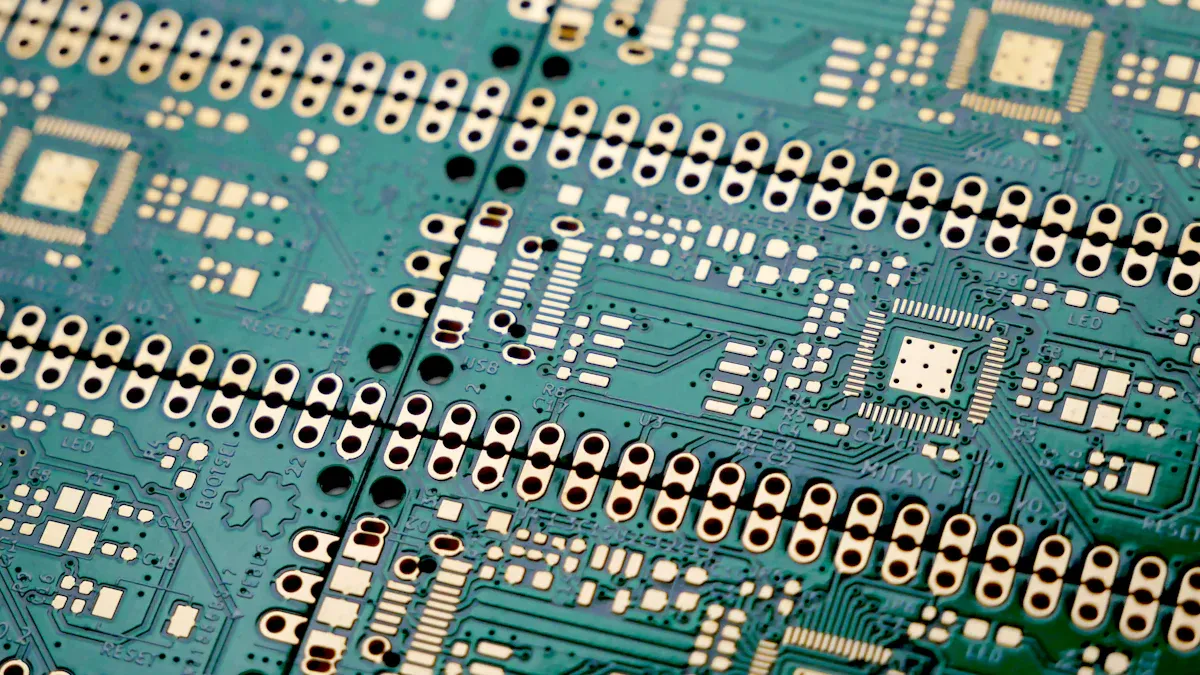

Choosing the right PCB fabrication company gives you a good board. A trusted PCB fabrication provider helps avoid delays and big mistakes. You need someone skilled in PCB fabrication and focused on quality. Whether for testing or large production, picking the best company is key. Look for good skills and service to build a strong partnership.

Key Takeaways

Pick the right PCB type for your project. Learn about rigid, flexible, and rigid-flex PCBs to match your needs.

Check the manufacturer’s skills and tools. Modern machines and good efficiency ensure better quality and accuracy.

Look for certifications like ISO and IPC. These show the manufacturer cares about quality and follows industry rules.

Talk clearly with your manufacturer. Regular updates and open talks prevent mistakes and keep your project moving.

Build a strong partnership with your PCB maker. A trusted partner can improve quality, save time, and adjust to future needs.

Understanding Your PCB Fabrication Needs

Picking the type of PCB (e.g., single-layer, multi-layer, rigid-flex)

Choosing the right PCB type is the first step. Each type works best for certain uses. For example:

Rigid PCB: These are made from strong materials like glass cloth. They are tough and hold components well.

Flexible PCB: These use bendable materials, fitting into small spaces. They work great for wearables and tight designs.

Rigid-Flex PCB: These combine rigid and flexible boards. They are used in tight spaces with complex designs.

If your project needs a multi-layer PCB, think about its complexity. These boards have many layers that need careful connections. Knowing these types helps you pick the right PCB fabrication process.

Deciding production size and deadline

Your project size and deadline affect your PCB manufacturer choice. For small projects or prototypes, focus on quick and cheap options. For big projects, pick a reliable maker with good tools and processes.

Think about how fast you need the boards. Some makers offer rush services for tight schedules. But rushing can lower quality. Balancing speed and care gives the best results.

Checking technical needs (e.g., materials, tolerances, design complexity)

Technical needs are key in PCB fabrication. The materials you choose affect how the board works and lasts. For example:

Material Type | Tolerance Range | Uses | Challenges | |

|---|---|---|---|---|

FR4 | 4.5 – 5.0 | ±0.1mm to ±0.2mm | Electronics, cars | Shrinks with heat, not for high-frequency |

Teflon | 2.1 – 2.3 | ±0.05mm | High-frequency, 5G | Costly, hard to handle, shrinkage issues |

Flexible Substrates | 3.0 – 4.5 | ±0.1mm to ±0.2mm | Wearables, bendable boards | Flexing causes size changes |

You also need to check tolerances and design difficulty. Tools like AOI and X-ray inspection help find flaws. These tools catch problems like short circuits or bad soldering. By knowing your needs, you can talk clearly with your PCB manufacturer and get great results.

Evaluating the Best PCB Fabrication Manufacturer

Checking technical skills and tools

To pick a good PCB maker, check their tools and skills. Modern machines help make boards quickly and accurately. Companies with advanced tools can handle tricky designs like multi-layer, rigid, and flexible PCBs.

Look at how well they perform by checking these things:

KPI | What It Means |

|---|---|

Production Efficiency | Shows how well they make boards, aiming for high success rates (e.g., 96%). |

Quality Control Metrics | Tracks mistakes and ensures they follow industry rules. |

Cycle Time | Measures how fast they make a PCB. Shorter times mean better speed. |

Overall Equipment Efficiency (OEE) | Checks how well their machines work, including uptime and quality. |

Ask if they can handle both small and big orders. A good company will adjust to your needs, whether it’s a test board or a large batch.

Confirming certifications and standards (e.g., ISO, IPC rules)

Certifications show if a company is trustworthy and follows rules. These prove they care about quality and meet global standards. Look for these certifications:

Certification/Standard | What It Proves |

|---|---|

IPC Class 2 | Ensures good quality for regular electronics. |

IPC Class 3 | Guarantees top quality for important uses. |

Focuses on managing quality to meet customer needs. | |

IATF 16949 | Applies to car-related production and services. |

ISO 13485:2016 | Ensures quality for medical devices. |

RoHS | Limits harmful materials in electronics. |

UL | Confirms safety and material standards. |

For example, ISO 9001:2015 shows they have a system to keep quality high. IPC Class 3 is needed for very reliable boards. Always check these to ensure they meet your project’s needs.

Understanding quality checks and testing steps

Quality checks are very important in PCB making. A good company will have strong systems to keep quality steady. They might use tools like charts and Six Sigma to improve their work.

Tool | What It Does | Why It Matters |

|---|---|---|

Control Charts | Tracks changes over time. | Spots problems in production early. |

Process Capability Indices | Checks if processes meet goals. | Makes sure boards match what you need. |

Six Sigma Techniques | Reduces mistakes to very low levels. | Improves how well and consistently they work. |

Some companies also use lean methods like Kaizen to save time and cut waste. Regular checks and feedback help them stay reliable. By learning about their quality steps, you can trust they’ll make great PCBs for your project.

Understanding cost transparency and pricing structure

When picking a PCB maker, knowing their prices is important. Clear pricing helps you avoid surprises and stick to your budget. A trustworthy PCB manufacturer gives detailed quotes showing all costs upfront. These include materials, production, testing, and shipping fees.

Here are things to check for clear pricing:

Detailed Quotes: Find quotes that list costs by category. This shows exactly what you’re paying for.

Request for Quotation (RFQ): Use RFQ to get pricing info. It includes order size, board details, delivery time, and quote validity.

Total Cost of Ownership (TCO): Think about long-term costs, not just the first price. Spending more now can save money later by avoiding defects.

Hidden Fees: Make sure all extra fees are shared upfront. This avoids surprises during production.

For example, a company with low prices might charge more for fast delivery or extra tests. By checking quotes carefully, you can compare companies and pick one with fair prices and good quality.

Tip: If a quote is unclear, ask questions. A good company will explain their pricing clearly.

Evaluating customer support and communication responsiveness

Good customer support shows a PCB manufacturer is reliable. Clear communication helps your project go smoothly. When choosing a company, see how they answer your questions and solve problems.

Here’s what to look for in customer support:

Responsiveness: A good company answers quickly. Slow replies can delay your project.

Technical Expertise: The team should know your technical needs. They should give correct answers and useful advice.

Proactive Communication: Choose companies that update you on your project. Regular updates help fix issues early.

Problem Resolution: Check how they handle problems. A reliable company fixes issues fast and takes responsibility.

For example, during prototyping, you might need design changes. A helpful company will guide you and make sure changes are done right. This support is important for both small and big projects.

Note: Building trust with your manufacturer can lead to better teamwork and results over time.

Researching and Shortlisting PCB Manufacturers

Checking testimonials and customer reviews

Reviews and testimonials show how good a PCB manufacturer is. They help you see if the company meets customer needs. By reading them, you can learn about past customers’ experiences and spot any problems.

Here’s why reviews are helpful:

They show what the company does well or poorly.

They share stories from customers with similar projects.

Case studies highlight the company’s skills in specific areas.

For instance, if you need rigid or flexible PCBs, find reviews from similar buyers. This ensures the company knows how to handle your project. Always choose a PCB manufacturer with mostly positive reviews.

Tip: Check reviews on different websites for a full picture. Look for common themes instead of focusing on one bad or good review.

Requesting samples or prototypes for evaluation

Asking for samples or prototypes is an important step. It lets you check the quality of the PCB and see if it meets your needs. You can also test how well the company handles changes.

Evidence Type | Description |

|---|---|

Sample Request | Ask for samples to check the quality of their work. |

Quality Evaluation | Look at the samples for precision and proper design. |

Manufacturer Assessment | See how fast they respond and handle changes during testing. |

When checking samples, look at things like solder mask and trace lines. These details show how careful the company is with their work. For prototypes, this step helps find problems before making a big order.

Note: A company that makes great prototypes is likely to do well with larger orders too.

Comparing quotes and assessing value for money

Comparing prices from different companies helps you get the best deal. A good quote should list all costs, like materials, production, and shipping. This helps you avoid surprise charges later.

Here’s how to compare value for money:

Get quotes from several companies to compare prices.

Use industry reports to understand fair pricing.

Check trade magazines for cost trends in your field.

Look closely at RFQ details to find the best deal.

Think about long-term costs, like fixing defects, when choosing.

For example, paying more for a prototype might save money later by avoiding mistakes. Always balance cost with quality to get the best results.

Tip: Don’t pick a company just because they’re cheap. Focus on quality, reliability, and support for the best value.

Evaluating responsiveness during initial inquiries

When picking a PCB manufacturer, how they reply to your first questions matters. A good manufacturer will answer clearly and quickly, showing they are reliable.

Here are things to check during your first talks:

Response Time

Notice how fast they reply to your questions. Quick replies mean they care about your time and want to help. Slow responses might cause problems later in the process.Clarity of Information

Check if their answers are clear and complete. For example, if you ask about PCB prototyping, they should explain their tools, steps, and timing. If answers are unclear, they might lack skill or honesty.Technical Knowledge

A skilled team knows your technical needs. Whether you need rigid or flexible PCBs, they should explain materials and designs well. Good advice now can stop mistakes later.Proactive Communication

Look for companies that ask about your project details. This shows they care about understanding your needs. For example, they might ask about your timeline or design challenges. This helps create better teamwork.Professionalism and Courtesy

How they treat you shows their customer service style. Polite and respectful replies build trust and help start a good partnership.

Tip: Ask detailed questions about their PCB fabrication process. This helps you see how skilled and helpful they are.

By checking these points, you can find a manufacturer who values your project and delivers great results. This is very important during PCB prototyping, where clear talks can save your project.

Working with Your Selected PCB Manufacturer

Getting design files and documents ready

Before production starts, prepare correct design files and documents. These files help the PCB prototyping process go smoothly and meet your needs. Begin by creating files like Gerber files, drill files, and assembly drawings. These are the base for PCB fabrication. Also, make a bill of materials (BOM) and pick-and-place files to help with assembly.

Do a Design for Manufacturing (DFM) check to find problems early. This check looks at trace spacing, drill sizes, and silkscreen clarity. It also checks edge clearance and layer alignment. A good BOM keeps costs low, ensures parts are available, and keeps quality high.

Here’s a simple checklist for your files:

Fabrication files: Gerber and NC drill files for making boards.

Assembly files: BOM and pick-and-place files for assembly work.

Prints and drawings: Detailed plans for the manufacturer.

Organizing these files helps you work well with your manufacturing partner.

Setting up clear communication

Talking clearly with your PCB manufacturer avoids mistakes and delays. Use fab notes to explain board details, making sure everyone understands the project. These notes include fabrication needs and special instructions.

Stay in touch with regular updates and meetings. Plan calls to check progress and solve problems. Quarterly reviews can track things like defect rates and delivery times. Share your needs clearly and tell them about changes early to avoid confusion.

Good communication builds trust and keeps your PCB prototyping on schedule, even with tight deadlines.

Using feedback to improve designs

Your manufacturer’s feedback can make your PCB designs better. Working together during prototyping helps fix problems before big production starts. For example, DFM analysis from manufacturers can simplify production and cut costs.

Here’s how feedback has helped others:

Company | What They Did | Results |

|---|---|---|

Company D | Worked with manufacturers on DFM | Faster production, lower costs, better quality, quicker time-to-market |

Company E | Used data to improve processes | Better efficiency, fewer defects, faster cycles, happier customers |

Using feedback improves designs for both rigid and flexible PCBs. It boosts quality and strengthens your bond with reliable manufacturers.

Tip: Think of your manufacturer as a partner, not just a supplier. Their knowledge can help you succeed and improve results over time.

Building a long-term partnership for future projects

Working closely with your PCB manufacturer for a long time can help your projects and business. A dependable partner keeps quality steady, makes processes easier, and adjusts to your changing needs. Instead of seeing it as a one-time deal, aim to build a team-focused and growth-driven relationship.

Long-term teamwork makes managing supplies easier. Sticking with the same company saves time and speeds up production. This reduces delays and helps your products get to market faster. A trusted maker also ensures high-quality boards, cutting down on defects and making your devices more reliable.

Here are some benefits of long-term partnerships:

Better product quality and fewer warranty issues.

Strong quality checks that lower mistakes and failures.

Easier supply management for smoother production.

Room for new ideas and changes as your needs grow.

Companies like Highleap Electronic show how valuable long-term partnerships can be. They focus on new technology and top-notch quality, helping clients succeed with their products and businesses. By teaming up with such companies, you can focus on creating new ideas while they handle the hard parts of PCB fabrication.

To keep a strong partnership, talk openly and give clear feedback. Check performance often, like defect rates and delivery times. Celebrate wins and solve problems together. This teamwork builds trust and keeps your manufacturer committed to your success.

Tip: Think of your manufacturer as a teammate, not just a supplier. Their skills can help you improve and grow, ensuring your projects succeed in the long run.

Picking the right PCB manufacturer is very important for your projects. Companies with strong skills and certifications, like ISO 9001 and IPC, show they care about quality. These certifications help keep products reliable and meet industry rules.

Doing good research and working well with others is key. Talk to experts, study market trends, and check details carefully to make smart choices. Sticking with a trusted manufacturer ensures steady quality and helps create new ideas for future projects.

Tip: Focus on quality and trust instead of just low prices for long-term success in PCB fabrication.

FAQ

What matters most when picking a PCB manufacturer?

The top priority is quality. A good manufacturer makes sure your PCBs work well and meet industry rules. Check for certifications like ISO 9001 and IPC to see their focus on quality.

Tip: Ask for samples to check their work yourself.

How do I make sure my design files are ready?

Get key files like Gerber, drill files, and a BOM ready. Use a Design for Manufacturing (DFM) check to find mistakes. This helps avoid errors and keeps production smooth.

Note: Clear files make manufacturing faster and easier.

Why are certifications like IPC and ISO needed?

Certifications show the manufacturer follows strict rules for safety and quality. For example, IPC Class 3 means high reliability, and ISO 9001 ensures steady quality management.

Emoji Reminder: ✅ Certified makers = Trustworthy results!

How can I check a manufacturer’s customer support?

See how they reply to your first questions. Fast answers, clear info, and helpful communication mean they care about your project. Good support helps solve problems quickly.

Pro Tip: Ask specific questions to test their knowledge and willingness to assist.

Should I focus on cost or quality when choosing?

Quality is more important than cost. Cheap options can lead to bad boards and higher costs later. Spending a bit more upfront gives you strong, reliable PCBs that save money over time.

Reminder: Quality boards = Fewer problems and happy customers.

See Also

Choosing The Ideal PCBA Manufacturer For Your Business

Selecting The Right PCBA Factory For Your Custom Needs

Essential Advice For Selecting A PCBA Contract Manufacturer

Important Considerations For Choosing A Custom PCBA Maker

Finding The Perfect Fusion PCBA Service For Your Requirements