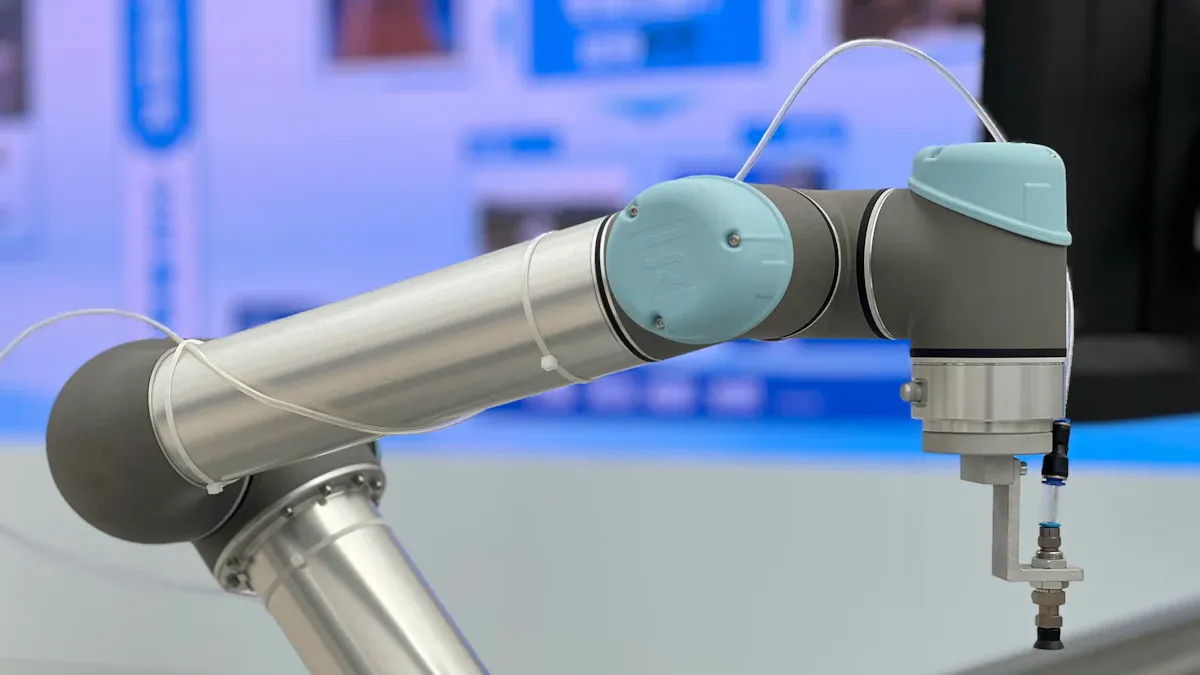

Custom PCBA for collaborative robots (cobots) is transforming the way robots operate in various industries. These specialized circuit boards enhance the performance of cobots, providing greater accuracy and reliability. With custom PCBA, cobots can effortlessly manage challenging tasks. By optimizing their design, custom PCBA enables cobots to deliver consistent results while consuming less energy. This innovation significantly boosts work speed and efficiency in modern workplaces.

Key Takeaways

Custom PCBA helps cobots work better, making them more accurate and dependable.

Safety parts like torque sensors and circuits keep cobots safe near people.

Energy-saving designs in custom PCBA let cobots run longer without charging often.

Modular designs make cobots easy to upgrade for new technology.

Fields like healthcare, factories, and shipping gain a lot from cobots with custom PCBA.

Understanding Custom PCBA for Collaborative Robots (Cobots)

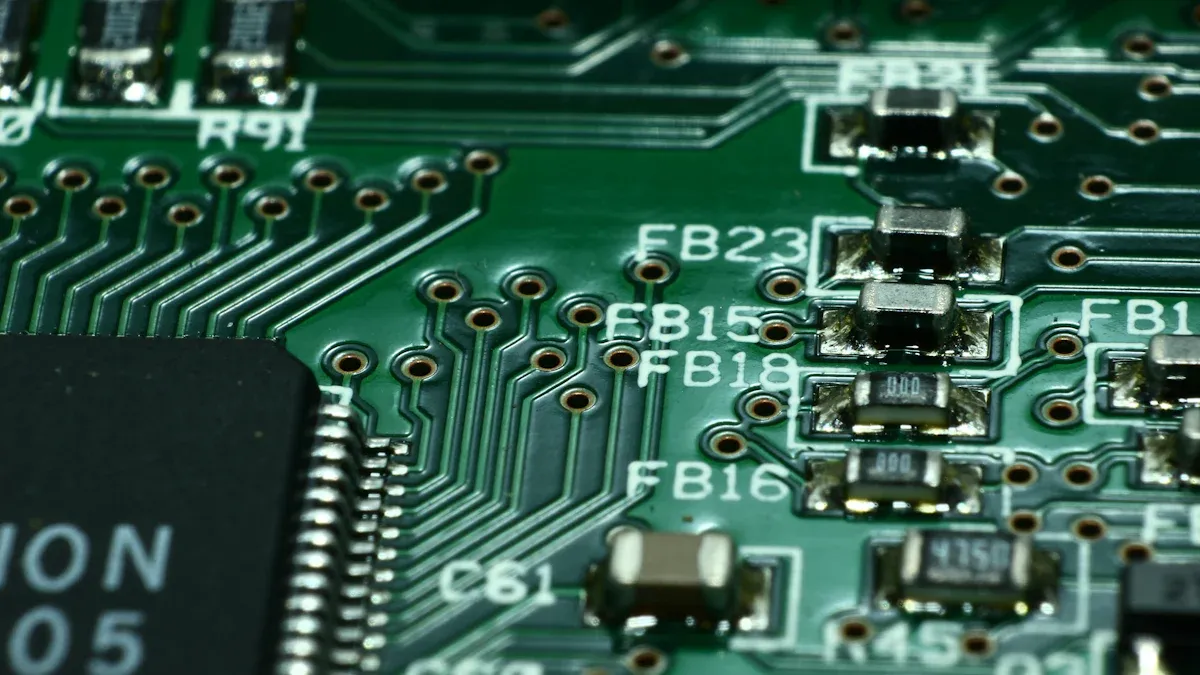

What Is Custom PCBA?

Custom PCBA, or printed circuit board assembly, means creating circuit boards for specific needs. In robotics, custom PCBA makes sure the parts fit cobots’ unique tasks. Unlike regular PCBs, custom PCBA improves how well cobots work and last. This helps robots handle hard jobs with accuracy and speed.

For cobots, custom PCBA includes features like small designs, heat control, and EMI shielding. These features help cobots work well in tough conditions. By solving specific problems, custom PCBA makes robotic systems work better overall.

Why Collaborative Robots Require Custom PCBA

Cobots need custom PCBA to do their jobs properly. They often work near people, so they need safety and precise control. Custom PCBA adds safety circuits, quick processing, and motion control for smooth, safe work.

Cobots are used in many fields, like healthcare and factories. Each job needs special features, like small designs for tight spaces or heat control for long use. Custom PCBA gives cobots the ability to meet these needs, making it vital for modern robots.

Key Features of Robotics PCBA in Cobots

Robotics PCBA in cobots has important features to improve performance:

Durability: Handles shocks and vibrations.

Compact design: Fits into small spaces.

EMI/EMC considerations: Blocks electromagnetic interference.

Thermal management: Controls heat effectively.

Flexibility: Works with different setups and upgrades.

To include these features, custom PCBA uses advanced methods, such as:

Placing parts for better signals.

Shorter traces to lower interference.

Good grounding and power flow.

Managing heat from hot parts.

Adjusting to the robot’s shape.

The table below shows how certain technologies improve robotics PCBA:

Evidence Type | Description |

|---|---|

Modular PDNs | Improve robot systems with better designs. |

High-density power modules | Solve power challenges and boost performance. |

Fixed-ratio converters | Adjust voltage and improve response speed. |

These features and methods help cobots work accurately, reliably, and efficiently.

How Custom PCBA Improves Collaborative Robot Abilities

Better Processing for Hard Tasks

Custom PCBA gives cobots strong processing power for tough jobs. They can process data quickly and make decisions right away. This helps cobots work well in busy places like factories or hospitals.

New PCBA designs use multi-core processors and smart signal paths. These features help sensors, motors, and controls talk to each other easily. For instance, special routing reduces signal problems, making cobot movements more accurate. Using 8+ layer boards improves signals, keeping cobots reliable even at high speeds.

Saving Energy for Longer Use

Cobots need to save energy, especially in places with little power. Custom PCBA uses smart cooling to lower energy use and extend battery life. Cooling tools like copper pillars and graphene pads keep parts cool and stop overheating.

Liquid cooling also helps remove heat, letting cobots work longer without problems. These designs save energy and make cobots last longer. With custom PCBA, cobots can run longer without needing frequent charging or repairs.

Safety Features for Working with People

Safety is very important when cobots work near humans. Custom PCBA adds safety circuits to make cobots safer. Torque sensors let cobots feel forces and stop quickly if they bump into something. This makes cobots more accurate and safe.

Custom PCBA follows global safety rules like ISO 10218-1:2011 and IEC 62061:2005. These rules need strong safety systems with multiple channels and checks. The table below shows key safety rules:

Standard | Requirement | Description |

|---|---|---|

ISO 10218-1:2011 | Control system must meet PL = D Category 3 | Needs 2 safety channels with at least 60% checks for each. |

IEC 62061:2005 | Safety Integrity Level (SIL) 2 with HFT of 1 | Ensures safe control systems for cobots in industries. |

Special coatings protect PCBA parts from water and dust, keeping safety features working well. These custom PCBA designs make cobots safer and workplaces better for everyone.

Real-Time Obstacle Detection and Adaptive Motion Control

Real-time obstacle detection helps cobots work safely and efficiently. With custom PCBA, cobots quickly process data to spot obstacles. This lets them avoid collisions and work smoothly, even in busy areas.

Custom PCBA uses advanced sensors and processors for better movement control. Cobots use cameras, LiDAR, and ultrasonic sensors to scan their surroundings. They map the area and find dangers. For example, if a cobot sees an object in its way, it changes direction fast. This prevents crashes and keeps work moving without delays.

Tip: Adaptive motion control helps cobots work safely with people nearby.

Real-time obstacle detection does more than improve safety. Cobots with this tech plan better routes, saving energy and time. In warehouses, cobots using overhead sensors finish tasks faster and more efficiently. The table below shows real-world examples:

Case Study | Findings | Metrics Improved |

|---|---|---|

Warehouse Operations | Overhead sensors detect obstacles in real time | |

Household Cleaning | Better awareness of surroundings | Higher productivity and better task results |

These examples show how real-time systems make cobots better at their jobs. By adjusting to their environment, custom PCBA keeps cobots reliable and effective.

Key features of this technology include:

Better obstacle detection and response.

Faster task completion times.

Lower energy use, saving money.

Improved teamwork among robot groups.

Custom PCBA also uses special designs like differential routing to keep signals clear. This helps cobots process data quickly and avoid delays. With these upgrades, cobots can handle tough jobs with speed and accuracy.

Applications of Robotics PCBA in Collaborative Robots

Manufacturing and Assembly Automation

Robotics PCBA helps robots improve factory and assembly work. Custom PCBA makes cobots more accurate and efficient for tasks like welding and assembling. These robots speed up production lines and reduce downtime, increasing productivity.

Custom PCBA combines many functions into one module. This lowers the number of parts needed, saving money and reducing mistakes. Flexible PCBA designs also let robots upgrade easily for future technology, making them a smart investment.

A study showed some industries still use regular robots for heavy lifting. But cobots with custom PCBA are becoming popular because they work well with people. In electronics factories, cobots handle jobs like picking and inspecting with great accuracy.

Healthcare and Medical Robotics

In healthcare, robotics PCBA helps cobots do careful and exact tasks. These robots assist with lab work, drug making, and medical packaging, ensuring safety and quality. Custom PCBA allows small designs and good heat control, perfect for clean environments.

For example, cobots with custom PCBA sort and label items in pharmacies. They do this with consistent accuracy, reducing human mistakes and improving efficiency. Safety circuits in PCBA make sure cobots work safely near doctors and patients.

Hospitals and labs want more automation to save money and time. Custom PCBA helps robots handle hard jobs reliably, meeting these growing needs.

Logistics and Warehouse Management

Robotics PCBA improves logistics and warehouse tasks. Cobots with custom PCBA manage inventory, pick orders, and track shipments in real time. These features make operations faster and cheaper.

Custom PCBA helps cobots keep stock levels correct, avoiding too much or too little inventory. Advanced tracking systems powered by PCBA monitor shipments accurately, reducing delays and pleasing customers.

In warehouses, cobots sort and pack items quickly and correctly using robotics PCBA. They avoid mistakes and increase productivity. Adaptive motion control and obstacle detection help cobots move safely in busy areas.

As labor costs rise, businesses need cobots to stay efficient. Custom PCBA makes cobots reliable and competitive for logistics tasks.

Precision Agriculture and Inspection

Custom PCBA is important for improving farming and inspection tools. It helps drones and machines work better, making farming easier and crops healthier. These systems use custom PCBAs to do their jobs faster and smarter.

Modern farm drones with custom PCBAs offer many advantages:

Precision spraying: Drones spray chemicals only where needed. This saves money and helps the environment.

Autonomous flight control: PCBAs let drones fly on their own. They can cover big fields accurately.

Real-time data processing: PCBAs quickly study sensor data. This helps farmers make smart choices fast.

Tip: Drones with custom PCBAs save money and help the planet.

Custom PCBA also helps with farm inspections. Drones with special sensors check crops, find pests, and study soil. They take clear pictures and give detailed reports. This helps farmers fix problems early.

The table below shows how drones with custom PCBAs help farming:

Feature | Benefit | Impact on Farming |

|---|---|---|

Precision spraying | Uses fewer chemicals | Saves money and protects nature |

Autonomous flight control | Covers fields quickly | Saves time and effort |

Real-time data processing | Gives useful information | Helps farmers decide better |

Custom PCBA keeps drones working well in tough conditions. Heat control and EMI shielding protect the parts, ensuring steady performance. Using these tools can make farming easier, smarter, and better for the environment.

Benefits of Custom PCBA in Collaborative Robots

Better Precision and Accuracy

Custom PCBA helps cobots work with more precision and accuracy. It uses advanced sensors and cameras to improve performance. For example, sensors measure force carefully to meet exact needs. Cameras help cobots sort items by quality, reducing mistakes. These tools keep cobots working well, even in tough jobs.

Cobots can also save image data to improve their work. They track trends and find problems early, avoiding big errors. In car factories, cobots with smart PCBs save time and work more precisely. In healthcare, robots with IoT PCBs check vital signs and warn about issues. These examples show how custom PCBA helps cobots do reliable and accurate work.

PCBasic, a top PCBA maker, tests every unit carefully. This ensures all parts meet high standards for robotic tasks. With custom PCBA, cobots can handle jobs with great accuracy.

Stronger and More Reliable

Cobots need to be tough and dependable for hard jobs. Custom PCBA makes them stronger with better materials and designs. For instance, ceramic parts like aluminum nitride handle heat and last longer. These materials protect cobots from extreme heat and shaking.

Custom PCBA also uses special adhesives and flexible solder. These protect delicate parts from breaking under stress. Cobots with these features pass strict vibration tests, like IEC 60068-2-6. This makes them perfect for rough environments.

Protective coatings, like parylene, add extra safety. These coatings keep out water and stop rust while managing heat. Cobots with these upgrades work well in factories or outdoor farms. Custom PCBA ensures cobots stay reliable and last a long time.

Saves Money with Smart Design

Custom PCBA helps businesses save money by improving cobot designs. Automated assembly lowers costs by up to 30% and boosts output by 50%. Fewer parts are needed, which reduces mistakes and repair costs.

The PCB market is growing fast, from $68.4 billion in 2023 to $105.8 billion by 2032. This shows how useful custom PCBA is as more businesses use cobots to compete.

Custom PCBA also allows cobots to upgrade easily for future needs. Flexible designs make sure cobots stay useful as technology changes. Choosing custom PCBA improves cobot performance and saves money over time.

Scalability for Future Technological Needs

Custom PCBA helps cobots get ready for future changes. As industries grow, cobots face more challenges. They need systems that adjust to new tech without full replacements. Custom PCBA keeps cobots flexible and useful, making them a smart long-term choice.

Modular Designs for Easy Upgrades

Custom PCBA often uses modular designs for simple upgrades. These designs let you change parts without replacing the whole system. For example, if a better sensor is made, you can add it by swapping the module. This saves time and money.

Tip: Modular PCBA designs help keep cobots updated with less downtime.

Support for Emerging Technologies

New tech like AI, ML, and 5G needs adaptable hardware. Custom PCBA gives cobots the power and speed to use these tools. For example, cobots with AI-ready PCBAs can process data fast, improving tasks and decisions.

A report says the AI in robotics market will grow from $6.9 billion in 2023 to $15.7 billion by 2028. This shows why scalable PCBA designs are key for future tech.

Future-Proofing Through Customization

Custom PCBA helps cobots stay ready for future needs. Examples include:

Expandable Memory: Add storage as data grows.

Enhanced Connectivity: Upgrade to faster networks like Wi-Fi 6 or 5G.

Advanced Power Management: Use new energy-saving tools to cut costs.

These features keep cobots competitive as technology changes.

Real-World Example: Automotive Industry

In car factories, cobots do jobs like welding and painting. With more electric cars, new tools and methods are needed. Custom PCBA lets cobots adapt by adding sensors, controllers, and software. This keeps cobots useful as standards change.

Feature | Benefit | Example in Automotive Industry |

|---|---|---|

Modular PCBA Design | Easy tool upgrades | Adding EV-specific welding tools |

AI-Ready Hardware | Smarter decisions | Real-time quality checks during assembly |

Advanced Connectivity | Faster system communication | Working with automated conveyors |

Why Scalability Matters to You

Scalable cobots with custom PCBA help you stay ahead. You won’t need to replace systems when new tech arrives. Instead, upgrade parts to save time and money. Scalable designs also make it easy to grow your business by adding or improving cobots.

Note: Scalability isn’t just about tech. It’s about growing with your business needs.

Custom PCBA builds cobots that adapt and improve over time. Choosing scalable solutions protects your investment and helps your business succeed in the future.

The Future of Collaborative Robots with Custom PCBA

AI and Machine Learning in Robotics PCBA

AI and machine learning are changing how robots work. Custom PCBA helps robots think faster and make better choices. For example, machine learning studies PCB layouts to improve signals and designs. This makes robots more accurate and dependable.

Here are some real-world examples of AI with custom PCBA:

A robot learns tasks by watching and listening to people. It has two moving arms, a camera for vision, and custom tools on wheels.

Smart algorithms like neural networks and genetic methods improve PCB designs. This boosts signal quality and robot performance.

By mixing AI with custom PCBA, robots can handle tough jobs and work smarter.

New Trends in Custom PCBA Technology

Custom PCBA is improving quickly with exciting new ideas. High-power PCBs now handle over 48V, adding more features. Tiny PCBs are lightweight and great for small robots. Flexible PCBs are strong and work well in rough conditions.

Innovation Type | What It Does |

|---|---|

High-Power PCBs | Handles higher voltages for more features. |

Miniature PCBs | Small and light for portable robots. |

Flexible PCBs | Tough and good for harsh environments. |

Sustainable Designs | Uses eco-friendly materials to cut waste. |

Automation in Manufacturing | Robots make PCBs faster and more accurately. |

These trends, along with AI and IoT, help robots stay useful and ready for future challenges.

Growing Uses for Cobots in Industries

Custom PCBA helps cobots succeed in many fields. In factories, cobots place parts on PCBs with great care, improving assembly lines. In warehouses, they manage stock and pick orders, saving time and reducing mistakes.

Application Area | What Cobots Do |

|---|---|

PCB Assembly | Place parts carefully to improve production. |

Material Handling | Boost speed and accuracy in factories. |

Versatility in Industries | Do jobs like checking quality, running machines, and organizing goods. |

More industries like healthcare and logistics want flexible robots. Better safety and AI make cobots safer and easier to work with. Custom PCBA helps cobots do more and meet the needs of growing industries.

Custom PCBA helps collaborative robots (cobots) work better and smarter. It solves specific problems, making cobots accurate and dependable. Improved PCBA designs save money and fit different industries’ needs. As PCBA technology improves, cobots can do more jobs in new ways. With more industries using cobots, custom PCBA is key for growth and staying flexible.

FAQ

What is the main benefit of custom PCBA in cobots?

Custom PCBA makes cobots work better by matching circuits to tasks. It improves accuracy, dependability, and energy use, helping cobots perform well in many industries.

How does custom PCBA keep cobots safe?

Custom PCBA adds smart safety circuits and sensors. These help cobots spot obstacles, change movements, and follow safety rules like ISO 10218-1:2011.

Can custom PCBA adapt to future technologies?

Yes, modular custom PCBA designs allow simple upgrades. You can add better sensors, processors, or connections without changing the whole system.

Which industries gain the most from cobots with custom PCBA?

Industries like factories, healthcare, warehouses, and farming benefit a lot. Cobots do jobs like building, packing, tracking, and spraying with more efficiency.

Is custom PCBA a good value for businesses?

Custom PCBA saves money by improving designs and reducing mistakes. It also makes cobots last longer and ready for upgrades, cutting costs over time.

See Also

Enhancing Workflow Productivity in PCBA Manufacturing Processes

Why PCBA Manufacturing Skills Are Crucial for Electronics Design

Ten Pro Tips for Cost-Effective and Efficient PCBA Assembly

The Significance of Custom PCBA Manufacturing in Today’s Electronics

Best Practices for Guaranteeing Quality and Efficiency in PCBA Production