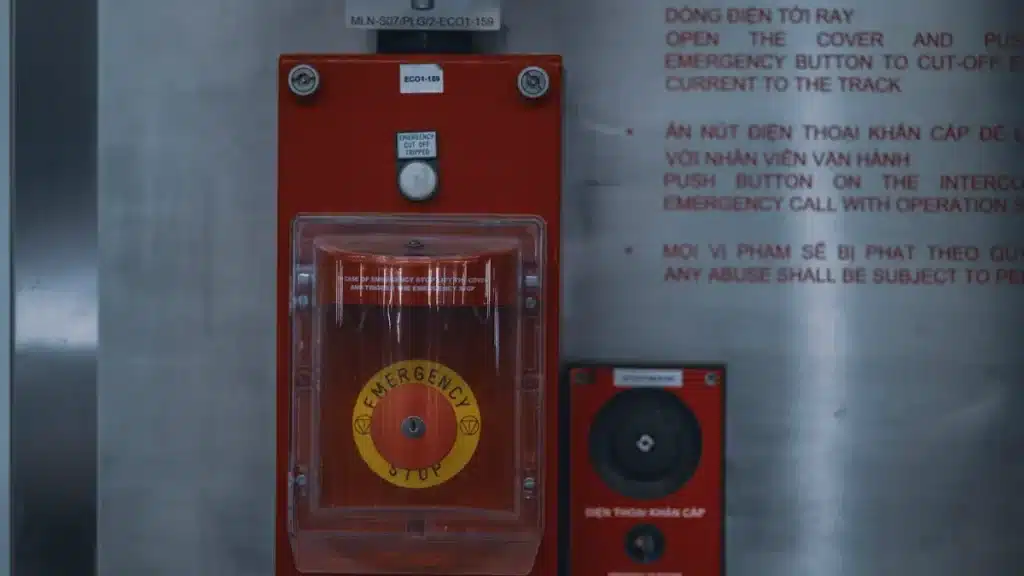

Consider the potential risks of a sudden power spike or overheating in PCBA work. Without an emergency shutdown system PCBA, this could lead to significant damage. An emergency shutdown system PCBA safeguards your machines and ensures the safety of workers. It swiftly responds to hazards, halting operations before any damage occurs. Additionally, it prevents downtime and costly repairs, maintaining a smooth production flow. This crucial safety measure should not be overlooked in the manufacturing process.

Key Takeaways

Emergency shutdown systems keep machines and workers safe from dangers.

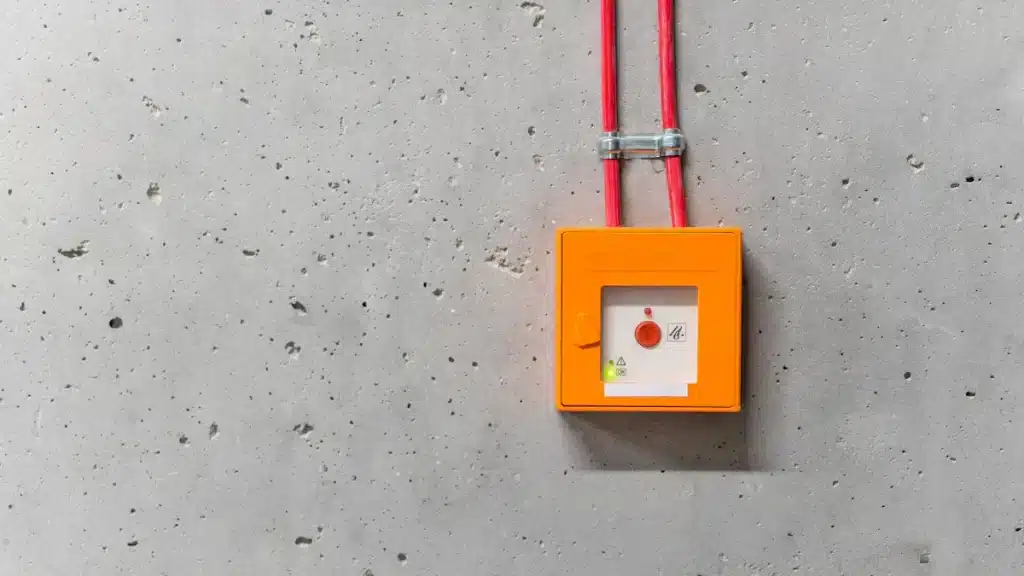

Pick systems with fast actions, like stop buttons, to stay safe.

Use systems that fit well with your current work process.

Look for systems you can adjust to match your setup needs.

Check if the company offers good help and regular fixes.

Key Features of an Effective Emergency Shutdown System for PCBA

Reliability and Response Time

A good emergency shutdown system PCBA must act fast in emergencies. Quick actions stop equipment damage and keep workers safe. Features like a 40mm red emergency stop button and twist-to-release safety make systems dependable. These tools help operators respond quickly when needed. Safety standards, like protective guards and yellow covers, also prevent accidental use.

Strong materials are important for reliability too. Systems rated NEMA 4 and IP65 resist water, dust, and impacts. This makes them work well indoors or outdoors. They stay reliable in tough conditions.

Tip: Pick systems with pre-wired parts for easy setup and less downtime.

Seamless Integration with PCBA Processes

Your emergency shutdown system PCBA should fit easily into current workflows. Systems that work with automated processes reduce interruptions during use. For example, pre-wired contact blocks and cable glands make installation simple. This lowers mistakes and keeps production smooth.

Advanced systems can also connect with other machines for group shutdowns. This is helpful in busy PCBA areas with many machines running. Smooth integration keeps work moving while staying safe.

Scalability and Customization for Diverse Needs

Scalability and customization help meet different PCBA needs. Modern systems adjust to small or large production setups. For example, automated product validation systems show how shutdowns adapt to testing needs.

Custom options let you design systems for specific tasks. You can add automatic shutdowns for key parts or extra safety for complex setups. These features protect equipment and improve workflows.

Case Study | Description |

|---|---|

Automated Product Validation Systems | Flexible shutdowns for different testing setups. |

Product Validation using LabVIEW RT & FPGA | Saves operator time and boosts production, showing scalability. |

Endurance Tester for Mission-Critical Components | Customizable for automatic shutdowns, showing flexibility. |

Investing in scalable and customizable systems keeps your operations ready for the future. It also ensures long-term success.

Top Emergency Shutdown Systems for PCBA in 2025

System A: Features, Pros, and Cons

Features:

System A has advanced safety tools for modern PCBA setups. It includes safety modules that meet strict rules like IEC 61508 SIL3. The system works well with automated machines, causing little disruption. Its smart design separates emergency shutdowns from other system parts for safety.

Pros:

Certified modules make approval easier.

Smart monitoring keeps performance steady.

High fault coverage (>99%) ensures it works reliably.

Cons:

Setup might need expert help.

Advanced features can cost more upfront.

Note: System A is best for big operations needing top safety and compliance.

System B: Features, Pros, and Cons

Features:

System B is great for growth and flexibility. It offers reusable safety designs, so you can adjust it to your needs. Certified patterns, like dual-core lockstep MCUs, improve fault handling. Its modular setup makes upgrades simple as production expands.

Pros:

Fits many PCBA setups.

Grows with your production needs.

Proven parts help with certifications.

Cons:

Customizing takes extra time.

Not ideal for small operations due to cost.

Tip: Pick System B if you need a flexible system for changing demands.

System C: Features, Pros, and Cons

Features:

System C is affordable and safe. It uses smart safety circuits to cut costs while staying reliable. Advanced checks, like online RAM/ROM testing, keep it working well without being too complex.

Pros:

Budget-friendly for small to medium setups.

Simple design lowers maintenance work.

Reliable checks ensure it runs smoothly.

Cons:

Not ideal for large setups.

Fewer options for customization.

Recommendation: System C is perfect for businesses wanting a low-cost, safe emergency shutdown system PCBA.

Emerging Trends in Emergency Shutdown Systems for PCBA

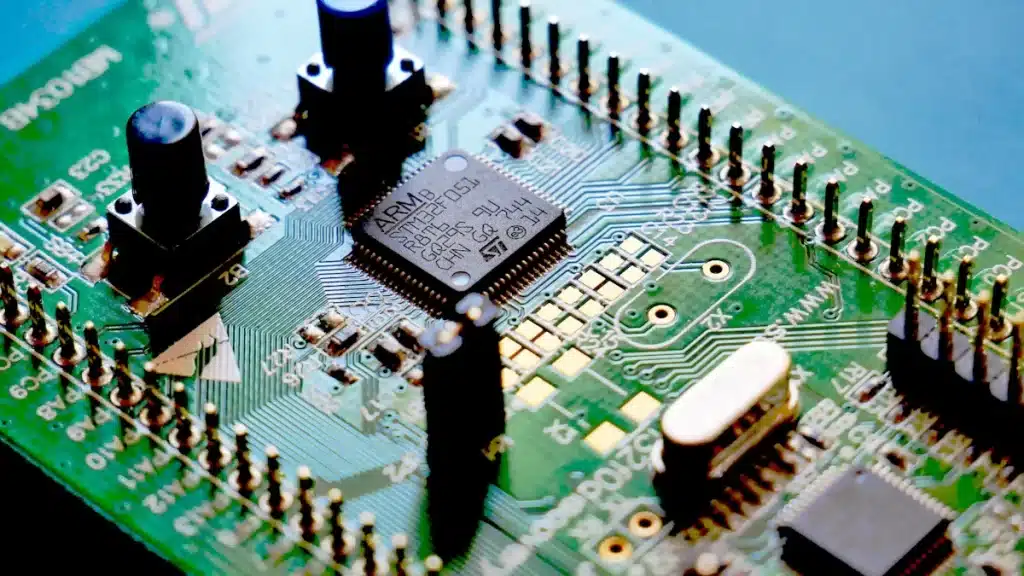

Influence of Smart PCBs and High-Density Interconnect Designs

Smart PCBs and HDI designs are changing shutdown systems. These technologies make systems quicker and more dependable. For example:

A car company used HDI PCBs in safety systems. This made emergency features respond faster.

The company earned better safety ratings, gaining customer trust and sales.

These improvements make shutdown systems work better. They allow smaller designs and faster part communication. This is helpful in modern setups where space and speed matter most.

Advancements in Safety Integrity Levels (SIL) and Automation

SIL ratings are improving safety system reliability. Higher SIL levels mean fewer failures and better protection. New shutdown systems now include automated features that meet strict SIL rules.

Automation is very important. It lowers human mistakes and keeps performance steady. For example, automated checks find problems early. This keeps operations safe and running smoothly.

Market Growth and Key Players in 2025

The shutdown systems market is growing fast. By 2025, experts expect big improvements in design and technology. Companies are creating smarter systems to meet industry needs.

Top companies like Siemens, Honeywell, and Schneider Electric lead this growth. They focus on new ideas and customer needs. Soon, you’ll see safer and cheaper systems available.

Tip: Follow market trends to pick the best system for your PCBA needs.

Choosing the Right Emergency Shutdown System for Your PCBA Needs

Assessing Production Scale and Specific Requirements

The size of your production decides the emergency shutdown system PCBA you need. Small setups often use simple systems with basic safety tools. Bigger operations need advanced systems with better fault coverage and scalability.

Think about how complex your processes are. If your PCBA has detailed designs or high-density interconnects, pick systems that work well with automated workflows. Systems with pre-approved safety modules, like IEC 61508 SIL2/3, make certifications easier and ensure safety rules are met.

Tip: Write down your production needs, like machine types, safety rules, and automation levels. This helps you find the best system for your setup.

Balancing Budget, Performance, and Long-Term Goals

It’s important to balance cost and performance when choosing an emergency shutdown system PCBA. Affordable systems like System C are great for small to medium setups. They provide good safety features without costing too much. For bigger setups, advanced systems like System A offer top performance and meet strict safety rules.

Think ahead about your future plans. If you want to grow your production, choose systems that can expand with your needs. Modular designs and reusable safety tools save time and lower costs later.

Budget | Performance | Long-Term Goals |

|---|---|---|

Low-cost systems | Basic safety tools | Good for small setups |

Mid-range systems | Better fault coverage | Great for medium-scale operations |

High-end systems | Advanced safety checks | Best for large-scale growth |

Note: Pick systems that fit your budget now but also support future growth.

Evaluating Vendor Support and Maintenance Services

Vendor help is very important for your emergency shutdown system PCBA. Good vendors offer approved safety solutions, expert advice, and regular maintenance. These services make safety rules easier to follow and keep your system working well.

Find vendors that give full safety documentation. Records for design, testing, and checks make audits and certifications simpler. Also, choose vendors with proven safety designs, like dual-core lockstep MCUs, for better reliability.

Recommendation: Work with vendors who provide flexible systems and quick customer support. This keeps your system ready for changes and reduces downtime.

An emergency shutdown system PCBA helps keep equipment safe. It protects workers and keeps production running without problems. This system stops risks before they cause damage or delays. Picking the right system for your needs is very important. It ensures safety rules are followed and helps your business succeed long-term. Think about your production size, future plans, and vendor help. Choose a system that matches your goals to make work safer and smoother.

FAQ

What is an emergency shutdown system for PCBA?

An emergency shutdown system is a safety tool for PCBA. It stops machines during dangers like overheating or power spikes. This keeps equipment safe, protects workers, and avoids delays.

How do I choose the right system for my PCBA setup?

First, think about your production size and safety needs. Pick systems that fit your budget and future plans. Choose vendors with good support and maintenance services.

Are emergency shutdown systems customizable?

Yes, many systems can be adjusted. You can add features like automatic stops for certain parts or extra safety for tricky setups. Customization helps meet your specific needs.

Do emergency shutdown systems require regular maintenance?

Yes, regular checks keep the system working well. Plan inspections to find problems early. Work with vendors offering maintenance help and safety records.

Can small-scale PCBA operations benefit from these systems?

Yes, even small setups need protection from risks like damage or injuries. Budget-friendly systems, like System C, offer key safety features without high costs.

Tip: Safety should always come first. A good emergency shutdown system protects your workers and equipment.