Printed circuit board repair services are very important. They help your electronic devices last longer. When you choose to repair instead of replace, you help cut down on electronic waste. PCB repair supports sustainability in a few important ways:

It focuses on fixing instead of replacing.

New technologies make repairs faster and reduce waste.

It follows circular economy ideas, which help products last longer.

These actions help the environment. They also help create a better future for the electronics industry.

Key Takeaways

PCB repair makes electronic devices last longer. This means you won’t need to replace them as often. It also helps reduce electronic waste.

Choosing to repair instead of replace can save you up to 70% in costs. This is a smart way to save money.

Professional repair services use special tools and techniques. They make sure repairs are high-quality and improve how well your device works.

Repairing PCBs helps the environment. It saves resources and uses less energy, which is good for our planet.

If you notice signs of PCB damage early, you can stop bigger problems. Watch for signs like overheating or losing power.

Significance of PCB Repair

Printed circuit board repair is very important in the electronics world. You need PCBs for many devices, like smartphones and machines. When these boards break, it can cause big problems. Repair services not only fix the boards but also make your electronic systems more reliable.

Here are some benefits of PCB repair:

Minimized Downtime: Fast repairs keep your equipment working, so you stay efficient.

Extended Lifespan: Fixing parts helps devices last longer, so you don’t need replacements soon.

Cost Savings: Choosing repair can save you up to 70% compared to buying new ones, making it cheaper.

The money-saving benefits of PCB repair help more than just individual users. Businesses gain a lot from these services too. By repairing instead of replacing, you can avoid extra costs. This choice saves money and helps the environment by cutting down waste.

Fixing PCBs is a key step for helping the environment. Making new circuit boards needs raw materials, like precious metals such as gold, silver, and palladium, plus harmful chemicals. By choosing to repair, you lower the need for these resources and the damage from getting them. Also, PCB repair usually uses less energy than making new boards. This lower energy use helps cut greenhouse gas emissions and makes the electronics industry’s carbon footprint smaller. A study by the Fraunhofer Institute for Reliability and Microintegration shows that fixing electronic products can lower environmental harm by up to 50% compared to making new ones.

As the PCB repair market grows, new technology will make these services even better. The industry is expected to recover well, with global output value likely reaching $73 billion in 2024 and $90.4 billion by 2028. This growth shows the rising need for reliable and eco-friendly electronic solutions in many areas.

Common PCB Issues

Printed circuit boards (PCBs) can have many problems that hurt how they work. Knowing these common issues helps you see when your devices need help.

Types of Damage

PCBs can get different kinds of damage, each with its own reasons. Here’s a list of the most common types:

Type of Damage | Description |

|---|---|

Environmental failure | Happens because of dirt, moisture, dust, power surges, and heat. |

Electrical stress failure | Comes from electrostatic discharge (ESD), surface breakdown, dielectric failure, and too much voltage. |

Mechanical failure | Often caused by vibrations and physical hits on the PCB. |

Thermal failure | Happens when too much heat damages the materials. |

Aging failure | Occurs when parts go past their working life, causing wear and tear. |

Knowing these types of damage helps you take steps to keep your devices in good shape.

Symptoms of Repair Needs

You should look for certain signs that show your printed circuit board needs fixing. Here are the main symptoms to notice:

Intermittent or total loss of power

Overheating or burn marks on the PCB

Malfunctioning or non-responsive components

Visible physical damage or corrosion

Frequent circuit shortages or open circuits

If you see any of these signs, it’s important to get professional printed circuit board repair services. Fixing these problems quickly can stop more damage and help your electronic devices last longer.

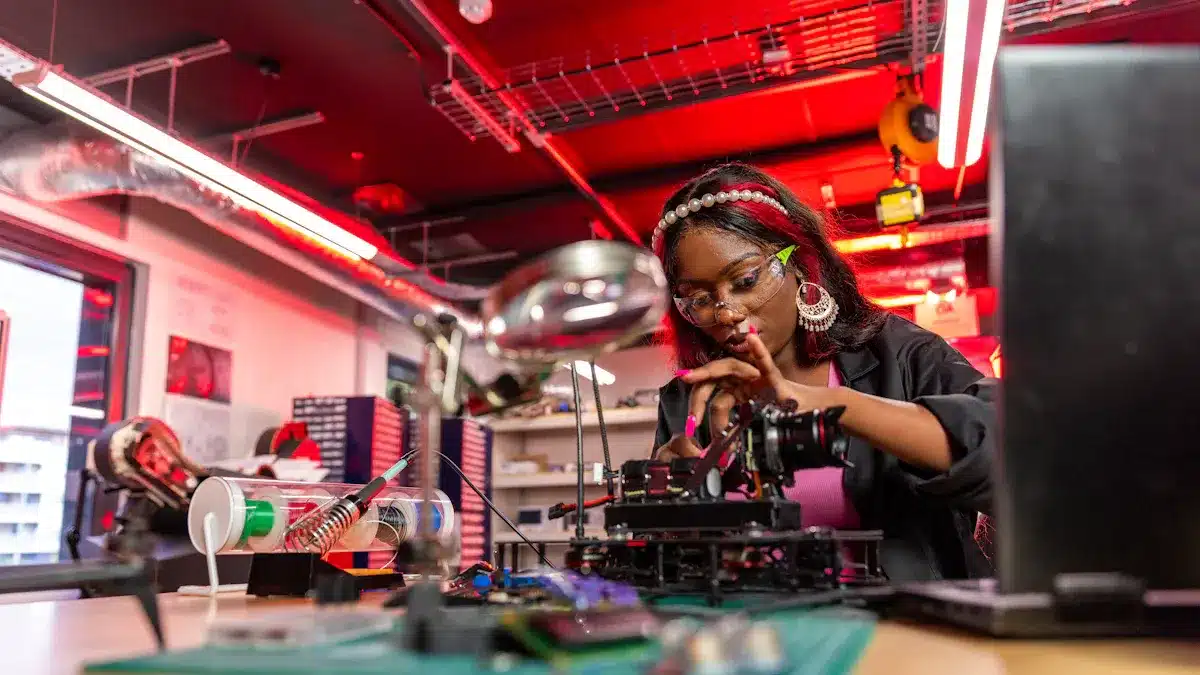

Repair Techniques

When fixing printed circuit boards, many techniques are important. They help make your devices work again and last longer. Knowing these methods shows how skilled PCB repairs can be.

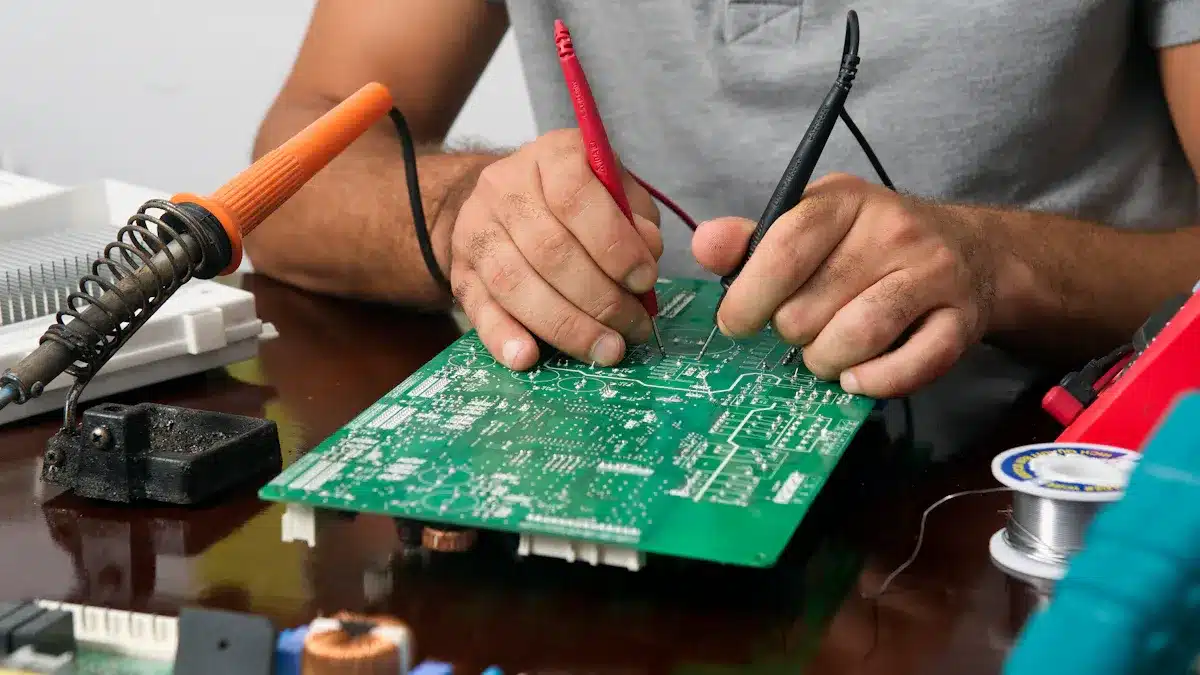

Soldering and Desoldering

Soldering and desoldering are basic skills in PCB repair. They mean adding or taking away parts from the circuit board. Here are some common methods:

Technique | Description | Common Use |

|---|---|---|

Soft Soldering | Attaching small parts to a PCB using a low-temperature alloy. | Most common for small components. |

Hard Soldering | Makes a stronger bond using solid solder, like silver soldering and brazing. | Used for maintenance and making things. |

Desoldering Braid | A tool that removes solder without hurting the PCB. | Commonly used for PCB repair. |

To solder well, remember to:

Use desoldering braid to take off solder easily.

Keep the soldering iron tip clean for better heat flow.

Follow good practices to avoid hurting the PCB when desoldering.

Component Replacement

Changing broken parts is key to fixing the PCB’s electrical system. This helps the board work like it should. Here are some benefits of replacing parts:

It fixes the electrical system of the PCB, so it works right.

Good repairs can stop more damage, making the board last longer.

Repairing instead of replacing can save money and reduce electronic waste, helping the environment.

Advanced Techniques in Printed Circuit Board Repair

Today’s PCB repair often uses advanced tools. These tools help workers find problems quickly and accurately. Some common tools are:

Multimeter: Measures voltage, current, and resistance to find shorts and open circuits.

Oscilloscope: Looks at signal behavior and finds issues in active circuits.

Soldering Iron and Desoldering Tools: Needed for changing broken parts or fixing damaged traces.

Magnifying Glass or Microscope: Checks tiny parts and solder joints.

Schematic Diagrams: Helps understand the PCB layout and connections.

Thermal Camera (Optional): Finds overheating parts due to shorts or failures.

These techniques and tools make sure PCB repair services are effective and trustworthy. They change how you take care of your electronic devices.

Benefits of Professional Services

When you pick professional printed circuit board repair services, you get many benefits. These benefits help your electronic devices work better and last longer. Here are some important advantages:

Expertise of Certified Technicians

Certified technicians are very important for successful PCB repairs. Their training gives them the skills to do precise and effective repairs. Here are some reasons why their skills are important:

Certified technicians follow industry standards. This makes sure repaired PCBs are reliable.

Their training, like IPC-7711/7721, helps them find and fix problems well.

A good provider with certified technicians has a history of successful repairs. This improves how long your devices work without issues.

Description | |

|---|---|

IPC-A-610 | A common inspection standard for accepting printed circuit assemblies. |

IPC-A-600 | Sets the standard for quality in PCB workmanship for bare printed boards. |

IPC/WHMA-A-620 | An important standard for cable and wire harness assemblies, focusing on requirements. |

IPC-7711/7721 | Focuses on reworking, modifying, and repairing electronic assemblies and printed circuit boards. |

Having skilled technicians is very important. They not only change broken parts but also follow a careful process that needs precision. This affects how successful the repairs are.

Quality Assurance and Cost-Effectiveness

Quality assurance steps taken by professional PCB repair services make sure your devices are safe and work well. Here are some common practices:

Automated Optical Inspection (AOI): Finds surface problems early on.

X-ray Inspection: Spots hidden issues in multilayer PCBs.

In-Circuit Testing (ICT): Checks electrical performance and design compliance.

Functional Testing: Simulates real-life conditions to check performance.

Environmental Stress Testing: Tests durability under tough conditions.

These quality assurance steps help keep PCB repair services reliable. They also save money. Repairing parts is usually cheaper than replacing the whole device. For example:

Cost-Effectiveness | |

|---|---|

Component-Level Repair | Usually cheaper than full replacement, especially for valuable or out-of-warranty devices. |

Full Device Replacement | Often more expensive, so repair saves a lot of money. |

Personalized Customer Support

Personalized customer support makes your experience with PCB repair services better. Here’s how it helps:

Custom solutions can set a company apart in a crowded market, making customers happier.

Building strong relationships through good communication leads to higher satisfaction and repeat business.

When you get personalized support, you feel appreciated as a customer. This attention to detail can really improve your overall experience with the repair process.

Case Studies of PCB Repair

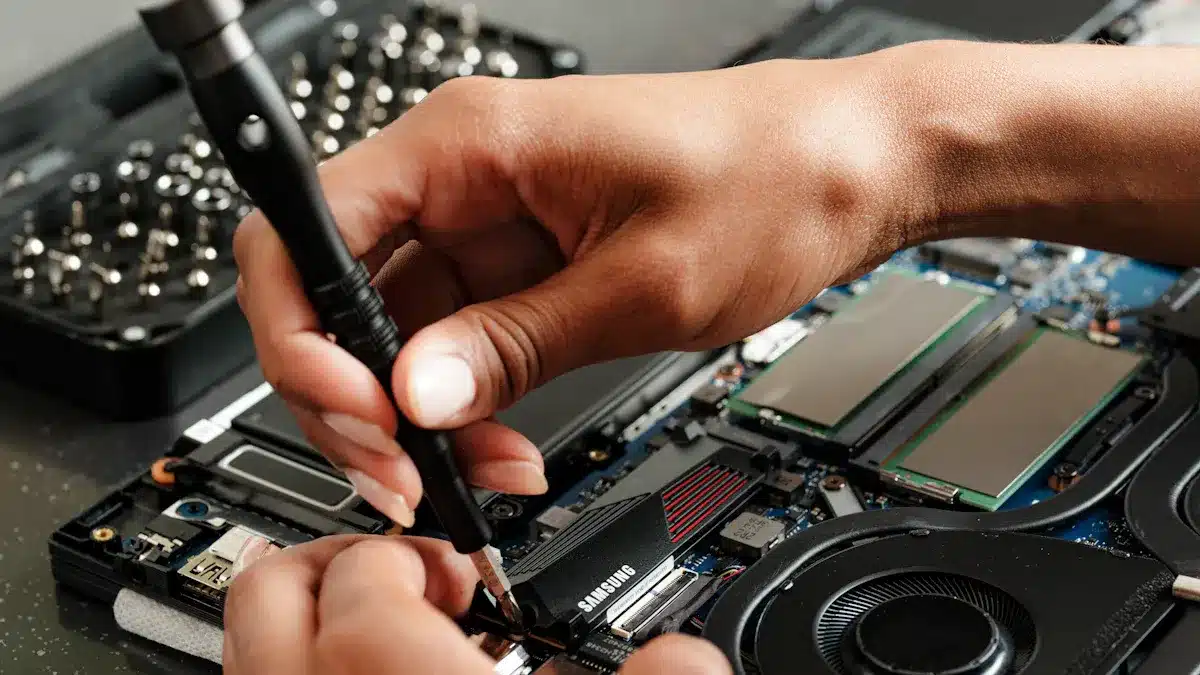

Success in Consumer Electronics

In the consumer electronics world, printed circuit board repair services are very helpful. Many devices, like smartphones and laptops, often have problems such as overheating or physical damage. When you fix instead of replace, you save money and cut down on waste. Here are some great examples:

Smartphone Repairs: Many people have saved hundreds by choosing PCB repairs instead of buying new phones.

Laptop Longevity: Repair services can fix common problems like broken traces or burnt parts, making laptops last much longer.

These repairs not only save you money but also help create a more sustainable way to use electronics.

Applications in Automotive and Industrial Sectors

The automotive and industrial fields depend a lot on printed circuit boards. These boards face special challenges that can cause failures. Common reasons for PCB failure in cars include:

Vibration and mechanical stress

Electrical overstress (EOS)

Corrosion and environmental damage

Manufacturing defects

Repair services handle these problems well. They use advanced diagnostic tools to find issues and replace broken parts with high-quality ones. This way, your devices work at their best.

In industrial electronics, common failures include:

Burnt parts from overheating

Corrosion from moisture exposure

Repair services focus on these problems by doing careful inspections and replacing damaged parts. This attention to detail helps keep things running smoothly and lowers costs from mistakes. Investing in quality control with advanced inspection methods can catch problems early, leading to better production processes.

By choosing professional PCB repair services, you make your devices more reliable while supporting sustainability in both consumer and industrial electronics.

Printed circuit board repair services change the electronics industry a lot. When you choose to repair instead of replace, you help cut down on electronic waste. You also save important resources. Here are some main benefits of PCB repair:

It keeps devices working longer, which reduces waste.

It saves materials needed to make new devices.

It uses less energy needed for making new electronics.

Fixing devices helps support eco-friendly practices and a circular economy. You can save up to 50% on costs over time by choosing PCB repair services. This choice not only makes your products last longer but also helps create a better future. Think about using professional repair services for your electronic devices.

FAQ

What is PCB repair?

PCB repair means fixing broken printed circuit boards. This helps them work again. The process can include soldering, changing parts, and using special tools to find problems.

How long does a PCB repair take?

The time it takes to repair a PCB depends on how bad the damage is. Simple fixes might only take a few hours. More serious problems could take several days to fix.

Can all PCBs be repaired?

Most PCBs can be fixed, but some may be too damaged. A skilled technician can check the board and suggest the best way to handle it.

How much does PCB repair cost?

The cost of repairs depends on how bad the damage is and what parts need fixing. Usually, repairs can save you up to 70% compared to buying a new board.

Why should I choose professional PCB repair services?

Choosing professional services means you get high-quality repairs done by certified experts. They bring knowledge, quality checks, and personal help, which makes your device last longer and work better.

See Also

Exploring EMS and PCBA Solutions in Today’s Electronics

The Importance of PCBA Services in Electronics Production

The Role of PCBA in Advancing Today’s Electronics