Choosing the right materials for leiterplatten herstellen is very important for your electronic projects. You need to think about different factors that affect material choice. These include cost, electrical performance, and heat management. Good heat dissipation helps ensure reliability. Also, mechanical strength allows the PCB to handle physical stress. Plus, more people want eco-friendly materials now. This trend makes sustainable materials more important. Knowing these points will help you make smart choices when you create your leiterplatten.

Key Takeaways

Picking good materials helps your PCBs work better and last longer. Always look for material standards and certifications.

Think about the cost and how easy it is to find materials. Balance your budget with quality to make smart choices for your projects.

Good thermal management is very important. Use thermal vias and materials that conduct heat well to stop overheating.

Signal integrity is important for how well PCBs work. Keep controlled impedance and pick materials with the right dielectric properties.

Mechanical strength and chemical resistance are important. Choose materials that can handle physical stress and tough environments.

Quality of PCB Materials

When you pick materials for your PCB, quality is very important. Good materials make sure your PCB works well and lasts a long time. You should check material standards and certifications. They help you choose the right parts.

Material Standards

Material standards are important rules that help you check the quality of PCB materials. These standards make sure the materials meet certain performance needs. Here are some common international standards:

IEC 61188: Focuses on design rules.

IPC-2221: Gives layout guidelines for PCBs.

MIL-PRF-31032: Covers boards that need high reliability.

JPCA-BM02: Japan’s material rules.

BS 6221: UK’s tests for the environment.

These standards help you know what to expect from the materials you choose. They also make sure your PCB can handle different conditions and work reliably.

Testing and Certification

Testing and certification are key for making sure your PCB materials are reliable. Certifications like ISO 9001 require standard processes. This means manufacturers must follow strict rules for consistent performance. Here are some important points about how certifications help reliability:

Material certifications need careful testing and good material choices.

These certifications make sure only approved suppliers give materials, lowering the chance of problems.

Good materials improve assembly speed, electrical performance, and heat control.

For example, high-quality PCBs make assembly easier and improve production rates. This leads to a longer product life. Also, better heat flow stops overheating, which can harm parts.

Remember, the quality of your PCB materials affects how well your electronic devices work and how long they last. Spending money on good materials is worth it in the end.

Cost and Availability

When you choose materials for your PCB, cost and availability are very important. You need to balance your budget with the quality of materials. Knowing these factors helps you make smart choices that fit your project goals.

Budget Constraints

Budget limits often decide what materials you can use. You should look at the costs of different materials and see how they fit into your total budget. Here’s a list of average costs for different types of PCB materials:

Material Type | Cost Range (per square foot) |

|---|---|

FR-4 | $1 – $10 |

Rogers | $20 – $50 |

Aluminum | $10 – $20 |

Polyimide | $5 – $20 |

Ceramic | $50 – $200 |

As you can see, prices change a lot based on the material type. High-quality materials like Rogers and ceramic can cost more but may work better. You should think about how these costs affect your total manufacturing budget.

Changes in raw material prices can make budgeting harder. When prices go up, your production costs rise, which can lower profits. Unpredictable material costs make it tough to budget accurately. This can hurt competitive pricing and cash flow. So, you need to keep up with market trends and change your budget when needed.

Supply Chain Considerations

Supply chain issues are also important when picking PCB materials. Problems in the supply chain can cause delays and higher costs. Here are some common problems that can affect material availability:

Global Supply Chain Disruptions: Events like natural disasters, political issues, or pandemics can stop the flow of raw materials.

Fluctuating Demand: Sudden increases in demand, like for electric cars, can stress the supply of materials.

Supplier Reliability: Unsteady raw material amounts from suppliers can cause shortages.

Environmental Regulations: Rules can lower the output of important raw materials.

You should also know about other things that can affect availability:

Lack of availability: Shortages because of few source manufacturers.

Trade uncertainty: Tensions causing higher tariffs and limits on imports/exports.

Excess demand: Increased demand that exceeds manufacturing abilities.

High shipping prices: Rising costs that affect the supply chain.

Understanding these supply chain issues is key to reducing risks from material shortages. You can improve your PCB manufacturing by building strong relationships with reliable suppliers and using different material sources.

Thermal Factors

When you design PCBs, managing heat is very important. Good thermal management helps your electronic devices work well and last longer. If heat is not managed, parts can get too hot and fail. Here are some good ways to manage heat:

Use thermal vias to move heat away from important parts.

Add special thermal planes to help with heat sinking.

Choose materials that conduct heat well to improve heat transfer.

By using these methods, you can make PCBs that work well in different heat situations.

Heat Dissipation

Heat dissipation is key for keeping your PCB working well. As electronic parts create heat while they work, you need to manage this heat. If you ignore heat dissipation, you could damage your parts. For example, poor thermal management can cause delamination, which weakens the PCB.

Using a special thermal plane can help cool down heat-producing parts. This cooling area improves overall thermal management, helping your devices work better.

Thermal Conductivity

Thermal conductivity is very important in PCB design. It shows how well heat moves through the board. Materials with high thermal conductivity help get rid of heat made by parts, ensuring your electronics work reliably. Here are some key points about thermal conductivity:

Poor thermal management can cause delamination and device failure.

Good thermal conductivity helps parts last longer by stopping damage from too much heat.

Choosing the right substrate material can help keep temperatures down, reducing the need for extra cooling. As electronic parts get smaller, managing heat becomes harder. So, accurate predictions of thermal performance are important for keeping devices reliable and lasting longer.

Signal Integrity in PCBs

Signal integrity is very important for how well your PCBs work. It makes sure signals move through the board without getting messed up or lost. Two main things that affect signal integrity are impedance control and dielectric properties.

Impedance Control

Impedance control is key to keeping signal integrity. You need to make sure your PCB design has the same impedance everywhere. If there are differences, it can cause impedance problems that hurt signal performance. Here are some important points to think about:

Controlled impedance is needed for steady signal performance and less signal distortion.

It helps signals travel with little loss, interference, or reflections.

This is important in many fields like telecommunications, aerospace, automotive, and consumer electronics.

To get controlled impedance, do these steps:

Keep the trace width and spacing the same throughout the design.

Follow IPC standards or IPC-2141 for the best PCB trace impedance values.

By focusing on impedance control, you can make your PCB designs more reliable.

Dielectric Properties

The dielectric properties of PCB materials greatly affect how well signals travel. The dielectric constant (Dk) and dissipation factor (Df) are two key properties to think about. Here’s how they affect your designs:

Property | Impact on Signal Transmission |

|---|---|

Dielectric Constant (Dk) | Low Dk materials reduce signal loss and keep impedance stable, which is important for high-frequency uses. |

Dissipation Factor (Df) | Low Df materials lower energy absorption, stopping heat build-up and signal loss at high frequencies. |

Dielectric Thickness | Changes can cause impedance mismatches, leading to signal reflections and loss. |

Material Choice | Affects crosstalk and overall signal quality, especially in multilayer PCBs. |

For example, FR-4 has a Dk of about 4.3 to 4.5, which works well for lower frequencies but may cause losses above 1 GHz. On the other hand, special laminates with Dk values closer to 3.0 or lower are used in fast designs to reduce issues. Picking the right materials can greatly boost signal integrity and overall performance.

By understanding impedance control and dielectric properties, you can make PCBs that work well in many different uses.

Material Characteristics

When you choose materials for your PCB, think about mechanical strength and chemical resistance. These traits are very important for how long your boards last and how well they work.

Mechanical Strength

Mechanical strength is key to making sure your PCB can handle physical stress. You want your boards to survive vibrations, shocks, and other forces without breaking. Here are some important mechanical strength needs for PCBs used in cars:

Mechanical Strength Requirement | Description |

|---|---|

Durability | Must handle constant vibration and stress without cracking. |

Flexibility | Should be flexible enough to stay connected under stress. |

Resistance to Vibration | Materials must resist vibrations to avoid failure in cars. |

Choosing materials with good mechanical strength helps keep your PCB strong. Low moisture absorption is also important because it helps your board last in different environments. High thermal conductivity is needed for heat dissipation, especially where heat is a problem.

Chemical Resistance

Chemical resistance is another important factor when picking PCB materials. In factories, your boards might meet cleaning solvents, fluxes, and harmful substances. Good chemical resistance stops damage, like delamination and blistering, which can hurt device performance and reliability. Here are some reasons why chemical resistance is important:

It ensures materials can handle tough environments.

It helps keep the PCB strong over time.

It stops failures that could happen from chemical reactions.

By focusing on both mechanical strength and chemical resistance, you can make PCBs that work well in many situations. This careful choice of materials will improve the life and function of your electronic devices.

Copper Foil Considerations

When you make a PCB, copper foil is very important for how it works. The thickness and weight of the copper affect how well your board can manage electrical currents and heat.

Thickness and Weight

Copper thickness is key for high-current uses. You should think about using at least 2 oz (70μm) of copper for these cases. Here are some important points about copper thickness:

Higher Current Capacity: Thicker copper can carry about twice the current of thinner copper with the same trace width. For example, a 1mm trace width with 1 oz copper can handle 23A, while 2 oz copper can manage 46A or more.

Improved Thermal Performance: Thicker copper helps get rid of heat better. This is important for parts that create a lot of heat, like LED drivers and car electronics.

Increased Mechanical Strength: More copper makes the PCB stronger, helping it resist physical stress.

Choosing the right copper thickness makes sure your PCB works well in different situations.

Surface Finish Options

The surface finish of copper is also an important factor. It affects how well your PCB conducts electricity and how easy it is to solder. Here are some common surface finish options:

HASL (Hot Air Solder Leveling): This old method gives a good surface for soldering. It is cheap but may not work well for tiny components.

ENIG (Electroless Nickel Immersion Gold): This finish provides great flatness and resists rust. It is best for high-frequency uses because it has low contact resistance.

OSP (Organic Solderability Preservative): This eco-friendly choice protects copper from rust. It works well for boards that need a short shelf life.

Picking the right surface finish can improve how your PCB performs and lasts.

Reliability of PCB Materials

When you choose materials for your PCB, think about how reliable they will be over time. Reliability is very important for making sure your electronic devices work well for a long time. Two main things to focus on are environmental factors and long-term performance.

Environmental Factors

Environmental factors can greatly affect how reliable PCB materials are. Knowing these factors helps you make better choices. Here’s a table that shows the most common environmental factors that impact PCB reliability:

Environmental Factor | Description |

|---|---|

Temperature | High temperatures speed up chemical reactions and can damage materials. |

Moisture | Causes rust and movement of electricity, which can hurt performance. |

Vibration | Creates stress, leading to tiny cracks that can cause failures. |

Electromagnetic Interference (EMI) | Can create unwanted currents, messing up how things work, especially in fast circuits. |

Chemical Contaminants | Ionic materials can cause rust and short circuits. |

You need to think about these factors when designing your PCB. For example, if your device will be in hot places, pick materials that can handle heat. If it might get wet, choose materials that resist moisture well.

Long-term Performance

Long-term performance is another key part of PCB reliability. You want your PCBs to work well over time, even in different conditions. Here’s a table that lists common tests used to check long-term reliability:

Test Method | Purpose |

|---|---|

Thermal Cycling and Shock Testing | Tests how well materials handle temperature changes and stress. |

Humidity and Moisture Resistance | Checks how materials react to moisture, looking for rust or short circuits in wet areas. |

Mechanical Shock and Vibration | Finds problems under stress and movement to ensure reliability. |

Solderability Testing | Makes sure electrical connections are strong by checking solder pads and holes. |

Ionic Contamination Testing | Looks for ionic residues to avoid moisture-related problems and keep the board clean. |

Curing and Solder Mask Hardness | Tests how well coatings protect the PCB from environmental damage. |

By doing these tests, you can make sure your PCB materials will work reliably over time. For example, solderability testing checks that your connections stay strong, while humidity resistance testing ensures that moisture doesn’t harm your board.

Resin Systems in PCB Manufacturing

When you pick resin systems for making PCBs, you usually choose between epoxy and polyimide. Each type has good and bad points that can change how your PCB works.

Epoxy vs. Polyimide

Epoxy resins are popular because they have great electrical insulation and strong mechanical strength. They are also affordable, so many people use them for regular electronic projects. But, they can only handle moderate heat, up to 130°C.

On the other hand, polyimide resins work well in tough conditions. They can take heat up to 400°C, which makes them perfect for aerospace and car uses. Polyimide also has great chemical resistance and flexibility, but it costs more.

Here’s a comparison of the two resin types:

Property | FR4 Epoxy Sheet | Polyimide |

|---|---|---|

Electrical Insulation | Excellent | Good |

Mechanical Strength | High | Moderate |

Cost | Cost-effective | More expensive |

Thermal Stability | Moderate (up to 130°C) | Superior (up to 400°C) |

Chemical Resistance | Moderate | Excellent |

Flexibility | Limited | High |

Ideal Applications | Standard electronic applications | Extreme environments (aerospace, automotive) |

Curing Processes

Curing processes greatly affect how well PCB resins perform. The heat and time used for curing can change the resin’s strength and electrical properties. For example, curing at higher temperatures can make the material stronger and tougher.

Here’s how different curing temperatures affect resin properties:

Curing Profile (°C) | Ultimate Tensile Strength (MPa) | Young’s Modulus (GPa) | Toughness | Microstructural Observations |

|---|---|---|---|---|

170 | 71.5 | 5.53 | N/A | Most even polymer network |

150 | N/A | N/A | Highest | Even filler distribution |

190 | N/A | N/A | N/A | Thermal damage seen |

110 | N/A | N/A | N/A | SiO2 filler settling seen |

By knowing these differences, you can make smart choices about which resin system and curing process fit your PCB manufacturing needs best.

Glass Types for Printed Circuit Boards

When you pick materials for your PCB, the kind of glass is very important. One common choice is FR-4, but there are other options too. Knowing the differences can help you make better choices for your projects.

FR-4 vs. Other Materials

FR-4 is a popular pick for PCBs because it has many benefits. Here’s how FR-4 compares to other glass types:

Advantage | Description |

|---|---|

FR-4 is made a lot and is easy to find, which keeps costs low without losing quality. | |

Compatibility with processes | FR-4 works well with standard PCB making methods, making production easier and reducing mistakes. |

Electrical insulating properties | FR-4 has strong dielectric strength, stopping electrical leaks and keeping performance steady in different conditions. |

While FR-4 is good, other materials like quartz and borosilicate glass have special benefits. For example, quartz glass has a lower dielectric constant, which makes it great for high-frequency uses. On the other hand, borosilicate glass is more flexible and cheaper for low-frequency applications.

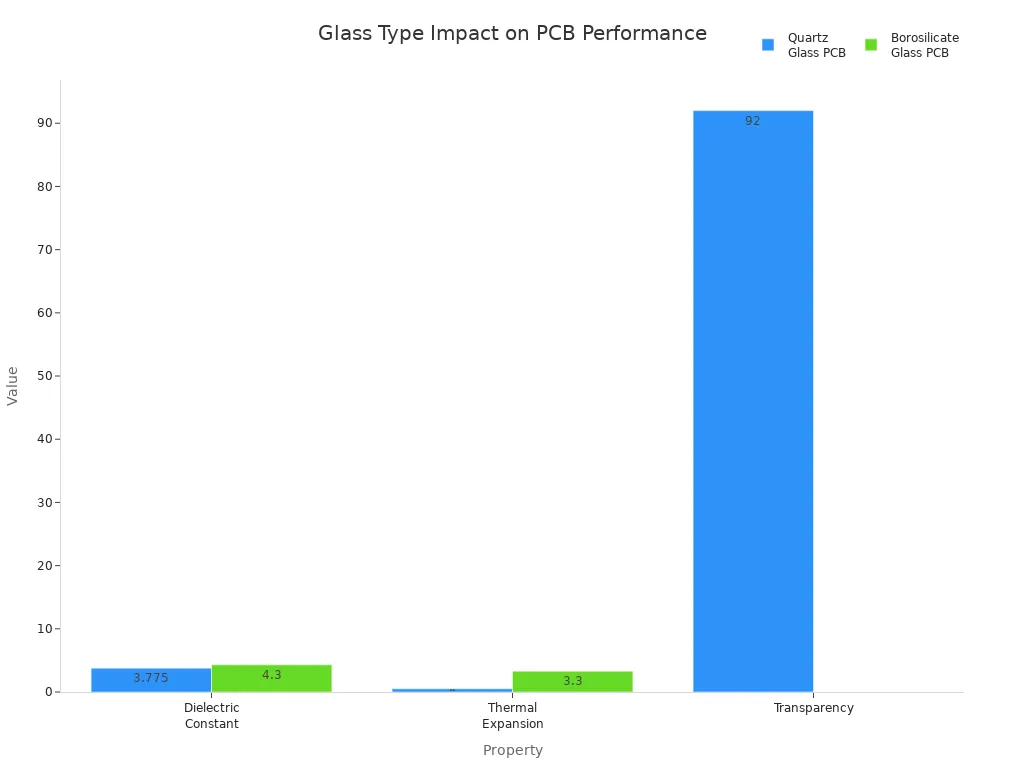

Impact on Performance

The kind of glass you choose affects both thermal and electrical performance. Here’s how quartz and borosilicate glass compare:

Property | Quartz Glass PCB | Borosilicate Glass PCB |

|---|---|---|

Dielectric Constant | ~3.75–3.8 at 10 GHz | ~4.0–4.6 |

Thermal Expansion Coefficient | ~0.5 ppm/°C | ~3.3 ppm/°C |

Mechanical Flexibility | Low | Higher |

Cost | Higher | Lower |

Application Suitability | High-frequency signals | Low-frequency optoelectronics |

Dielectric Loss | Ultra-low | Moderate |

Transparency | Up to 92% | Lower |

Choosing the right type of glass can improve your PCB’s performance. For high-frequency uses, quartz glass might be the best choice. For more general purposes, FR-4 is still a reliable and cost-effective option.

Manufacturability of PCB Designs

When you create PCBs, manufacturability is very important for your project’s success. You should think about how easy it is to make your designs. Knowing about fabrication methods and using design for manufacturability (DFM) ideas can really improve your PCB production process.

Fabrication Techniques

Different fabrication methods can affect the quality and speed of making your PCBs. Here are some common ways used for multilayer PCB designs:

Stacking Single-layer Boards: This method layers several single-layer PCBs and sticks them together with glue. It works well for prototypes and small batches.

Using Thin Blanks and Adhesives: This technique uses thin copper-clad blanks glued together. It needs precision but gives good results for less critical uses.

Creative Lamination Techniques: Some hobbyists use vacuum bags and homemade presses for lamination. This method works well for small circuits and can be a fun DIY project.

These methods let you pick the best way based on your project needs. However, you should also know about the problems that can happen during fabrication. For example, using the wrong materials can cause electrical issues. Also, unreliable suppliers may weaken your boards. Clear communication about material needs is key to avoiding production delays.

Design for Manufacturability (DFM)

Design for manufacturability (DFM) greatly improves production efficiency by matching your designs with manufacturing abilities. This match reduces delays, speeds up production times, and increases output. Here are some important DFM principles to think about:

Maximize Resource Allocation: Make sure to use manufacturing tools and workers effectively. This cuts downtime and raises productivity.

Limit Errors and Rework: By designing for manufacturability, you can cut down on material waste and save money.

Optimal Component Placement: Focus on good soldering and connections to lower assembly mistakes.

Address Signal Integrity Early: Dealing with signal integrity issues in the design stage reduces the chance of signal loss during production.

By using these DFM principles, you can improve PCB making and assembly processes. This leads to better yields and shorter manufacturing times. In the end, DFM helps you create designs that are both useful and cost-effective.

Choosing the right materials for printed circuit boards is very important for making sure they work well and last a long time. You need to think about different things, like how strong the materials are, how well they resist moisture, and how they handle chemicals. Here’s a quick look at how picking the right materials affects your PCBs:

Mechanical Property | Impact on Reliability and Performance |

|---|---|

Flexibility and Rigidity | Shows if the material can bend or needs to be solid. |

Tensile Strength | Strong materials are needed for parts that face physical stress. |

Layer Count and Thickness | More layers and thickness make the board stronger but can add weight and cost. |

Also, keep these important points in mind when choosing materials:

Materials like FR-4 and PTFE help keep performance good in wet conditions.

Polyimide works well in places with chemicals or harmful substances.

Pick materials that are easy to use to make manufacturing faster.

By choosing materials carefully, you can improve how well your printed circuit boards work and make sure they fit your project needs.

FAQ

What materials are commonly used for PCBs?

You usually use materials like FR-4, polyimide, and aluminum for PCBs. FR-4 is popular because it balances cost and performance well. Polyimide is good for high-temperature uses, while aluminum helps manage heat effectively.

How do I choose the right PCB material?

Think about things like what you need the PCB to do, how it will handle heat, and your budget. Check the environment where the PCB will be used. This helps you pick materials that are reliable and work well.

What is the role of copper thickness in PCBs?

Copper thickness is important for how much current it can carry and how well it manages heat. Thicker copper can handle more current and get rid of heat better. For high-current uses, you should use at least 2 oz of copper.

Why is signal integrity important in PCBs?

Signal integrity makes sure signals move through the PCB without getting messed up or lost. It affects how well everything works, especially in high-frequency uses. Good impedance control and dielectric properties help keep signal integrity strong.

How do environmental factors impact PCB reliability?

Environmental factors like temperature, moisture, and vibration can change how reliable a PCB is. High temperatures can speed up material damage, while moisture can cause rust. Choose materials that can resist these environmental issues for longer life.

See Also

Essential Factors To Evaluate When Selecting PCB Or PCBA

Important Aspects To Assess When Picking A Custom PCBA Maker

Guidelines For Selecting The Ideal PCB Fabrication Provider

Effective Strategies For Choosing Top PCB Assembly Solutions