Industrial power supply PCBA technologies are key for modern industries. They help change and share energy efficiently. These technologies make sure machines work well, even in tough places. New improvements in high-power electronics have changed energy use in industries. These updates bring smaller, quicker, and smarter solutions. Learning about these changes helps you use new tools to work better and faster.

Key Takeaways

Industrial power supply PCBA technologies help manage energy efficiently in industries.

Smaller designs and dense connections make devices cheaper and better.

Good heat control stops electronics from overheating and keeps them reliable.

Adding IoT features helps monitor systems, avoid delays, and work faster.

New materials and methods create stronger, greener PCBs for today’s needs.

Understanding Industrial Power Supply PCBA

Role of PCBA in Industrial Power Supplies

Industrial power supply PCBA is crucial for running powerful electronics. These assemblies help control and share electricity effectively, even in tough situations. They are the core of systems powering big machines, green energy setups, and modern gadgets.

Here are some main uses of industrial power supply PCBA:

Automotive Industry: Copper PCBs handle high currents in electric cars. They keep motors and batteries working well.

Industrial Machinery: These PCBs stop heavy machines from overheating. This keeps them running smoothly.

Renewable Energy: Copper PCBs manage electricity in solar panels and wind turbines.

Telecommunication: PCBs handle more power in base stations and routers.

Aerospace and Defense: They work in extreme conditions and manage high currents in complex systems.

Consumer Electronics: High-tech devices need these PCBs for better power use.

Using copper PCBs improves efficiency and makes systems last longer. This helps meet the needs of today’s industries.

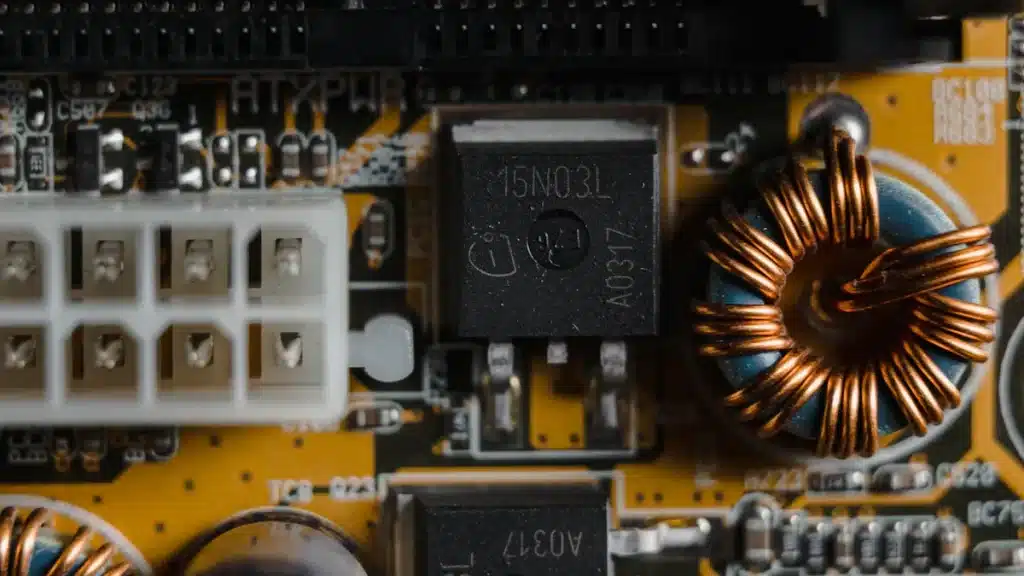

Key Components and Their Functions

The quality of an industrial power supply PCBA depends on its parts. Each part has a job to make the assembly work well. Below is a list of key parts and what they do:

Component | Function | Description |

|---|---|---|

Switch / Amplifier | Controls current and makes weak signals stronger. | |

Resistor | Limits current flow | Turns electrical energy into heat to control current. |

Capacitor | Stores and releases energy | Balances voltage by quickly storing and releasing energy. |

Diode | One-way current flow | Stops reverse current, important for converting electricity. |

Load | Converts electrical energy | Changes electricity into light, motion, or heat for use. |

Copper PCBs make these parts work better by conducting heat and electricity well. This helps the PCBA handle high power without losing quality or reliability.

Innovations in High Power Electronics

Miniaturization and High-Density Interconnects

Making things smaller has changed power supply designs. High-density interconnects (HDI) help fit more features in less space. Copper-based PCBs now handle complex circuits while staying reliable. Smaller parts let makers build compact devices without losing performance.

The demand for miniaturized and HDI solutions is growing fast. Experts predict a 6.1% yearly growth from 2025 to 2035. Revenue may rise from USD 5.47 billion in 2025 to USD 9.88 billion by 2035.

Metric | Value |

|---|---|

Yearly Growth Rate (2025-2035) | 6.1% |

Revenue in 2025 | USD 5.47 billion |

Revenue in 2035 | USD 9.88 billion |

This shows why copper-based PCBs are important for staying ahead. Smaller designs save space and cut material costs. This makes them a big step forward in high-power electronics.

Advanced Thermal Management Techniques

Managing heat is key for keeping copper PCBs working well. High-power parts create a lot of heat, causing hot spots. Without good heat control, parts may wear out faster or stop working.

New ways to manage heat focus on spreading it evenly. These include:

Using special materials to move heat better.

Designing PCBs to spread heat across copper layers.

Adding heat sinks and fans to cool down parts.

Knowing how materials act in heat is also important. For example, testing coatings can stop moisture that causes rust. These methods improve heat control and keep PCBs working in tough conditions.

Integration of IoT and Smart Features

Adding IoT and smart tools has improved power supply systems. Sensors and modules in copper PCBs allow real-time checks and fixes. This reduces downtime and boosts efficiency.

For example, IoT PCBs track voltage, current, and heat. This data finds problems early, avoiding bigger issues. Automated systems with sensors also make workplaces safer by reducing mistakes.

Benefits of IoT include:

Less downtime with early problem detection.

Safer workspaces with automated monitoring.

Using IoT and smart tools makes power systems better and more reliable. This meets the need for smarter and more efficient solutions.

Use of Advanced Materials and Manufacturing Processes

The materials and methods for making copper PCBs have greatly improved. These changes make PCBs better, stronger, and more eco-friendly. Now, manufacturers can meet the need for reliable and efficient designs.

New Materials Changing PCB Design

New materials have made copper PCBs more useful and greener. These materials are used in modern designs:

Halogen-Free Substrates: These remove harmful chemicals, helping the environment.

Biodegradable Substrates: Scientists are testing eco-friendly materials to replace old ones.

Flexible and Stretchable Materials: These allow bendable designs for wearable gadgets.

Ultra-Thin Laminates: Thin layers, just 50 µm, help make smaller devices.

Nanomaterials Integration: Graphene and nanotubes improve heat and electricity flow.

These materials make PCBs better and open new possibilities. For example, flexible materials are great for gadgets that bend or stretch, like smartwatches.

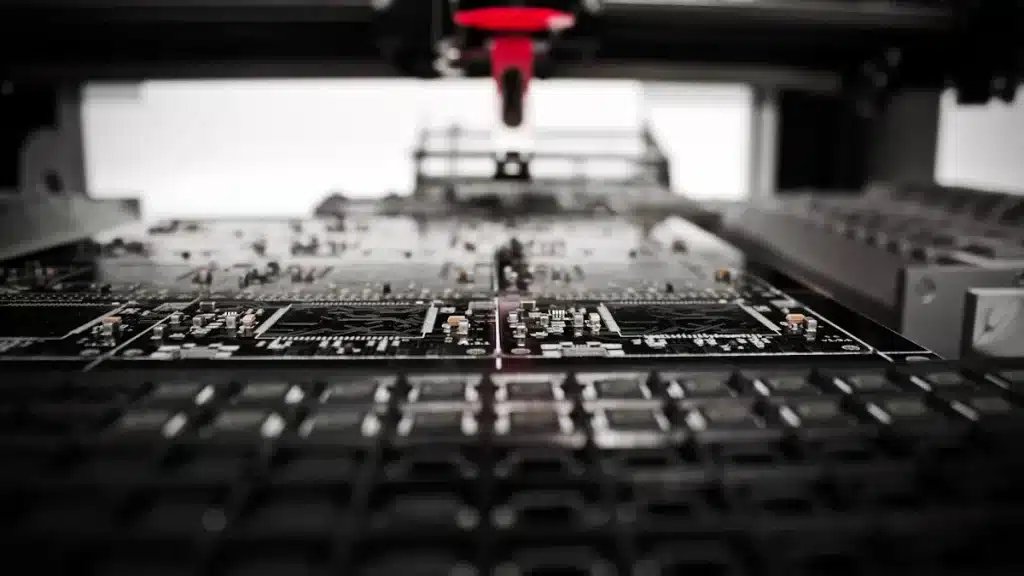

Better Manufacturing Methods

New ways to make PCBs help meet today’s needs. These methods improve accuracy, customization, and production:

Additive Manufacturing: This creates detailed designs that were hard to make before.

High-Temperature-Rated Components: These parts work well in very hot places.

Energy Storage Integration: Supercapacitors keep devices running during power loss.

Active Power Factor Correction (PFC): This reduces energy waste and boosts efficiency.

These methods let manufacturers make PCBs that fit different industries. For example, additive manufacturing helps create new designs faster.

Advantages of New Materials and Methods

Using advanced materials and processes gives many benefits:

Better Heat Control: Materials like graphene spread heat evenly, protecting parts.

Stronger PCBs: High-quality parts last longer, even in tough conditions.

Eco-Friendly Options: Halogen-free and biodegradable materials are better for nature.

Custom Designs: Additive manufacturing allows unique designs and easy scaling.

These improvements make copper PCBs perform better and meet the need for greener, smarter solutions. This helps industries stay ahead with advanced power systems.

Benefits of Modern Industrial Power Supply PCBA

Enhanced Efficiency and Reliability

Modern industrial power supply PCBA designs aim to work better and last longer. They help systems use less energy and stay reliable in tough conditions. Accelerated Life Testing (ALT) checks how well copper-based PCBs handle stress. This testing shows they can manage high currents and last longer. Functional testing finds problems early, making sure PCBs work perfectly in their jobs.

Copper-based PCBs are great for efficiency. They stop parts from overheating with good heat control. Smart heat management methods, like better heat paths and temperature checks, keep systems cool. These ideas cut downtime and repair costs, making operations smoother and easier to plan.

Tip: Pick PCBs with parts that handle high heat, like capacitors rated for 150°C. They work well in very cold or very hot places.

Cost-Effectiveness and Scalability

Modern industrial power supply PCBA designs save money and grow with your needs. Automated assembly costs more at first but saves money over time. These systems let you add more production easily with modular designs and software updates. This helps you adjust to changes without spending too much.

Multi-layer PCBs are a smart way to save money. They fit more circuits and work better, perfect for complex designs. Double-sided PCBs balance cost and function, working well for many uses. Rigid PCBs last longer, cutting replacement costs.

Better quality also saves money. Automated assembly lowers warranty claims, returns, and repair costs. It also stops production delays caused by quality problems. These savings help you spend money on other important things.

Note: Multi-layer PCBs are popular because they adapt well and perform great. They help make smaller designs and fit more circuits, which is key for saving money in advanced industries.

Applications of Industrial Power Supply PCBA

Industries Using High Power Electronics

Industrial power supply PCBA is important for many industries. These assemblies help systems work efficiently and reliably. High power electronics are growing fast because they save energy and cut costs. For example, devices like UPS systems and motor drives use these technologies to stay consistent.

Here’s how different industries use high power electronics:

Sector | Details |

|---|---|

Automotive & Transportation | Electric vehicles need power electronics for better energy use. |

This sector grows quickly, showing the need for reliable PCBs. | |

Renewable Energy | Solar panels and wind turbines use copper PCBs to convert energy. |

Aerospace & Defense | Military systems need strong PCBs for tough conditions and high currents. |

Rigid-flex circuit boards are also popular in medical tools. They are strong and flexible, perfect for wearable devices and diagnostic machines.

Tip: Choose copper-based PCBs for industries needing reliable heat control. These PCBs last longer in tough environments.

Real-Life Examples and Success Stories

Real-life cases show how industrial power supply PCBA works well. In consumer electronics, a top smartphone maker cut prototype failures by 50%. They did this by testing and improving designs. This shows why reliable PCBs are important.

In cars, an ECU maker improved heat control by changing PCB layouts and materials. This saved 20% on prototype costs, proving copper PCBs boost efficiency.

Industry | Example Details | Success Result |

|---|---|---|

Consumer Electronics | Fewer prototype failures after better design testing. | 50% fewer prototype failures |

Automotive Industry | Better heat control with improved PCB layout and materials. | 20% lower prototype costs |

Aerospace and Defense | Stronger military systems after strict testing. | 30% better prototype reliability |

Military systems also gain from copper PCBs. A communication system became 30% more reliable after better testing. These examples show how advanced PCBs help industries succeed.

Note: Using copper-based PCBs with good heat control can improve reliability and lower costs in high power electronics.

Industrial power supply PCBA technologies have changed how industries work. New ideas like smaller designs, smart tools, and better heat control make systems work better. These updates also save money and help create smaller, smarter gadgets.

Improvement/Benefit | Details |

|---|---|

Robots and machines speed up work and cut labor costs. | |

Improved Accuracy | New soldering methods make parts fit better and last longer. |

Smaller Designs | Tiny PCBAs help make smaller devices like smartwatches. |

Lower Costs | Smarter ways to build PCBAs make products cheaper to make. |

New Ideas | Fresh updates lead to cool gadgets with better features. |

Using these new technologies can make your business stronger. Try them to find new ways to grow and succeed in your field.

FAQ

1. What is PCBA, and why is it important in industrial power supplies?

PCBA means Printed Circuit Board Assembly. It links and powers electronic parts in machines. PCBA helps machines work well, even in tough conditions. It is key for managing energy and keeping systems reliable.

2. How does miniaturization impact industrial power supply PCBA?

Miniaturization makes it possible to add more features in less space. High-density interconnects (HDI) allow smaller designs without losing performance. This helps industries make smarter devices, save materials, and use energy better.

3. What materials improve the performance of industrial PCBA?

New materials like graphene and halogen-free substrates improve heat control. Ultra-thin laminates also help with better electricity flow. These materials make PCBA stronger, eco-friendly, and fit for modern needs.

4. How does IoT integration enhance industrial power supply systems?

IoT adds real-time monitoring and automatic fixes. Sensors check voltage, current, and heat to find problems early. This lowers downtime, improves safety, and makes systems more efficient.

5. Can modern PCBA designs save costs for industries?

Yes, modern PCBA designs like multi-layer boards save space and work better. Automated assembly reduces mistakes and repair costs. Modular designs make it easy to grow production and save money over time.