Industrial networks operate in challenging environments with significant EMI interference. This can disrupt communication. A noise-resistant industrial network PCBA is essential for maintaining functionality in these conditions. The demand for these solutions is rapidly increasing. For instance:

The noise control parts market is projected to grow from $16.02 billion in 2024 to $18.14 billion in 2025.

This indicates a 13.3% annual growth rate.

Stricter EMC regulations and the emergence of more advanced devices are driving this growth.

In 2025, three leading noise-resistant industrial network PCBAs are noteworthy:

ABC-5000: Excellent at mitigating EMI in high-noise environments.

Duraboard-XT: Designed for durability in extremely harsh conditions.

SignalPro-2025: Ensures strong signal integrity in complex networks.

These products address significant industrial challenges and ensure that networks operate efficiently.

Key Takeaways

PCBAs that resist noise are important for strong communication in factories. They lower EMI problems, helping machines work smoothly.

Good PCBAs have EMI shields, steady signal paths, and separated parts. These features make signals clear and parts last longer.

The ABC-5000 is great at blocking EMI, perfect for loud places. The Duraboard-XT handles tough conditions, while the SignalPro-2025 keeps signals strong.

Picking the right PCBA depends on what you need. Think about the environment and if it meets industry rules.

In the future, AI and robots will improve noise-resistant PCBAs. They will work better and be more dependable.

Criteria for Evaluating Noise-Resistant Industrial Network PCBAs

Why Noise Resistance Matters in Industrial Networks

Industrial networks often face EMI, which can cause communication problems. This interference may lead to downtime and lower productivity. Noise-resistant PCBAs are crucial for keeping systems working well in tough environments. They reduce the effects of EMI, keeping signals clear and preventing data errors.

Choosing a noise-resistant PCBA is important for reliable performance. It helps systems handle interference without losing functionality. Whether in a factory with loud machines or outdoors with environmental noise, these PCBAs ensure smooth operations by being durable and dependable.

Features to Focus On

When picking a noise-resistant PCBA, look for features that fight interference. Here are some key ones to check:

Controlled Impedance: Keeps signals clear by matching transmission line impedance.

EMI Shielding: Blocks interference, ensuring devices work in noisy areas.

Component Isolation: Separates parts to manage noise from digital circuits.

Short Return Paths: Reduces noise to improve mixed-signal board performance.

Ground Planes: Protects sensitive parts from nearby digital noise.

Faraday Cages: Covers circuits to block outside electromagnetic fields.

Guard Rings: Surrounds parts to cut interference and boost noise resistance.

These features help PCBAs handle industrial network demands. They keep signals strong and systems durable, reducing communication problems and improving performance.

Detailed Review of Top Noise-Resistant Industrial Network PCBAs

ABC-5000

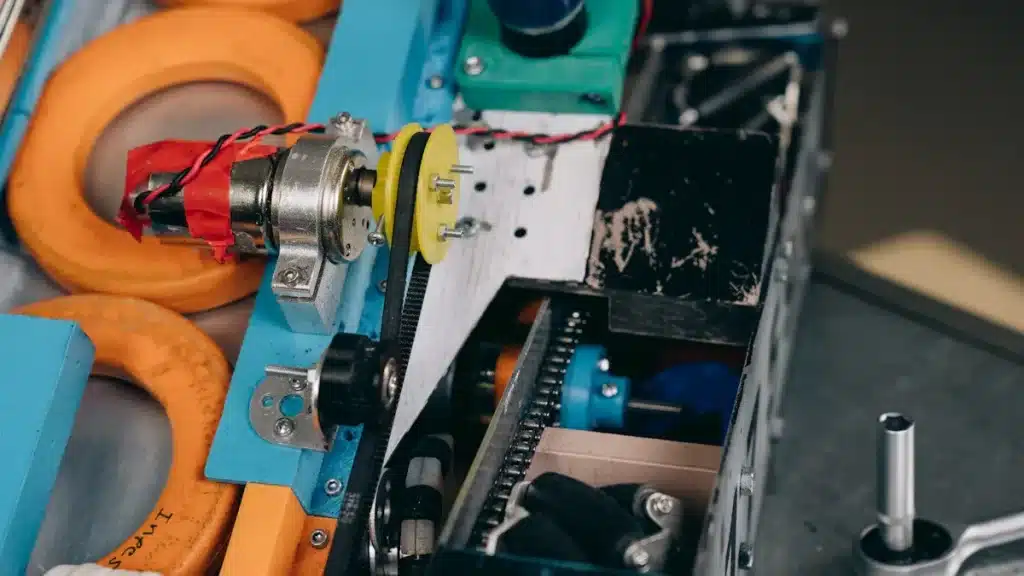

The ABC-5000 is a top noise-resistant PCBA. It uses advanced EMI shielding to block interference. This keeps it working well in noisy places. Its modular design supports different communication types like CAN, Ethernet, and RS-485. This makes it great for tasks needing clear signals.

The PCBA has programmable controllers for easy updates. These updates let it work with new protocols, making it ready for the future. It’s tested to work with many industrial devices, so setup is easier. Strong grounding, shielding, and filtering improve its noise resistance. Features like differential signaling and opto-isolation keep signals clear.

For large-scale production, the ABC-5000 is a good choice. It’s built for efficient manufacturing without losing quality. Whether in tough conditions or complex networks, it stays reliable and strong.

Duraboard-XT

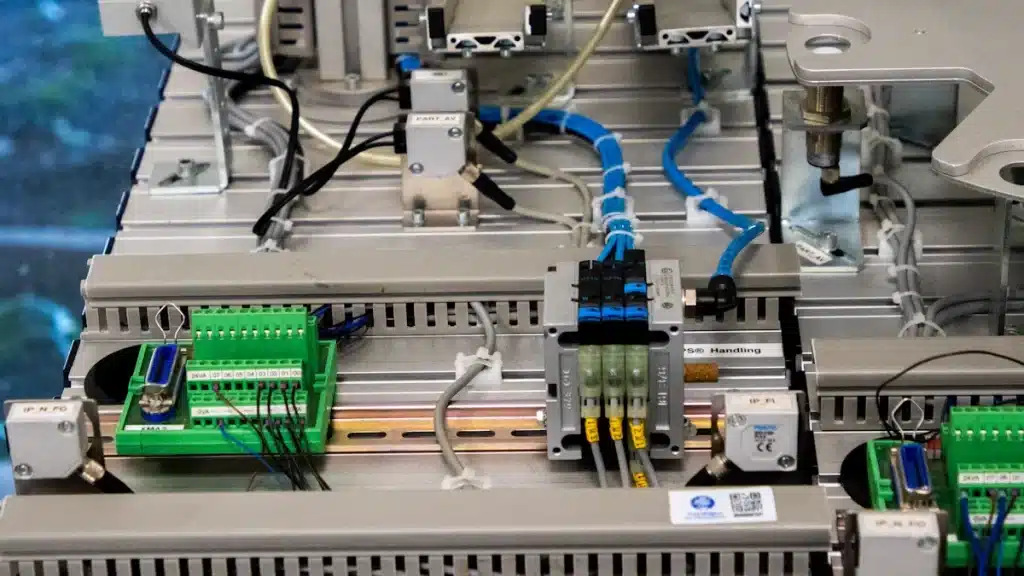

Duraboard-XT is made for tough environments. Its strong design and connectors handle heat, humidity, and vibration. It works well in industries needing durable solutions and high production.

Its EMI/EMC design is very effective. Grounding, shielding, and filtering stop interference early. Signal testing ensures communication stays clear. Short return paths and guard rings reduce noise and improve performance.

This PCBA connects old and new systems easily. Its protocol conversion helps devices work together smoothly. If you need reliable parts for tough jobs, Duraboard-XT is a great pick.

SignalPro-2025

SignalPro-2025 is for networks needing precise signals. It focuses on keeping signals clear. A Faraday cage blocks outside interference. Component isolation cuts noise for accurate data.

It supports modular interfaces for switching between protocols. Programmable controllers make it ready for future needs. It’s tested in harsh conditions to ensure it works well.

For industries needing large-scale production, SignalPro-2025 is efficient. It balances precision and strength, making it good for hard tasks. Whether indoors or outdoors, it stays reliable and lasts long.

Comparison of the Top Products

Feature Comparison Table

Here’s a simple table to help you pick the right PCBA:

Feature | ABC-5000 | Duraboard-XT | SignalPro-2025 |

|---|---|---|---|

Noise Resistance | Great EMI shielding | Strong EMI/EMC design | Faraday cage for top shielding |

Durability | Medium | Very high | Very high |

Signal Integrity | Excellent | Good | Outstanding |

Protocol Support | CAN, Ethernet, RS-485 | Protocol conversion | Modular interfaces |

Best Use Case | Large production | Tough environments | Precise applications |

This table shows what each PCBA does best. It helps you compare their features easily.

Best Product for Specific Scenarios

Each PCBA works best in different situations. If you need something for noisy places and large production, go with the ABC-5000. Its strong EMI shielding keeps it working well in hard conditions.

For jobs needing tough parts, like mining or heavy work, choose the Duraboard-XT. It handles heat, moisture, and shaking, making it great for rough environments.

If you need clear signals for precise tasks, pick the SignalPro-2025. Its Faraday cage and part isolation keep signals clean and data accurate in tricky networks.

By knowing what you need, you can pick the PCBA that fits your job perfectly.

Future Trends in Noise-Resistant Industrial Network PCBAs

Emerging Technologies

The future of noise-resistant PCBAs is changing with new ideas. These updates will make industrial networks work better and last longer. One example is AI-powered systems that watch for noise. They adjust automatically to keep networks running smoothly in noisy places.

Another big change is using advanced automation to make PCBAs. Automation speeds up production and reduces mistakes. Factories now use systems to check quality in real-time. This helps industries needing fast and accurate parts for their work.

Transportation is also pushing new designs. Stricter rules about noise pollution mean companies are creating smarter solutions. These systems adapt to noise changes quickly. As cities grow, these technologies will become even more important for PCBA designs.

Predictions for 2025 and Beyond

By 2025, noise-resistant PCBAs will grow in popularity. Better automation and improved electronic parts are key reasons for this. For instance, ceramic PCBAs are expected to grow by 8.2% yearly from 2024 to 2032. This shows the need for materials that handle heat and work fast.

More industries will want PCBAs made for large-scale production. They need parts that are both affordable and high-performing. AI systems and real-time monitoring will become common features. These tools will improve production and keep networks reliable.

PCBAs for precise tasks will also improve. They will have better signal clarity and noise control. These upgrades will help industrial networks manage modern systems while working efficiently.

Noise-resistant PCBAs are key for keeping industrial networks working well. Each one—ABC-5000, Duraboard-XT, and SignalPro-2025—has special benefits. The ABC-5000 is great at blocking EMI, Duraboard-XT handles tough environments, and SignalPro-2025 keeps signals super clear.

To pick the right PCBA, think about what you need. For example:

Standards Compliance: Look for products that follow IEC and EN rules. These ensure they resist surges, handle static, and work fast.

Environment: Strong and noise-resistant designs work better in hard conditions.

Match these features to your needs to find the best PCBA for your network.

FAQ

What is a PCB, and why is it important in industrial networks?

A PCB is a printed circuit board. It links electronic parts and helps them work together. In noisy places, good PCBs keep systems reliable and running smoothly.

How does conformal coating improve PCB performance?

Conformal coating shields PCBs from water, dust, and chemicals. It makes them last longer and work better in tough places. This coating also keeps signals clear by cutting interference.

What features should you prioritize when selecting a PCB?

Look for noise resistance, conformal coating, and controlled impedance. These features make PCBs work well and stay reliable. Strong materials and EMI shielding also boost performance.

How do you maintain the quality of PCBs in tough environments?

Choose PCBs with protective coatings and strong designs. Check them often and install them properly. These steps help them last longer and work better in hard conditions.

Why is efficiency critical in PCB design?

Efficiency helps PCBs work well in tough situations. It saves energy and keeps signals clear. Good efficiency also makes your network parts last longer.