Ensuring good quality in custom PCBA manufacturing and testing is key for dependable electronics. Bad quality can cause expensive fixes and broken products. For example:

Prototypes (1-5 units) cost $50 to $200+ per PCB, so mistakes are pricey.

Small batches (10-50 units) cost $15 to $50 per PCB, showing why accuracy matters.

Large production (1000+ units) costs $1-$5 per PCB, but only if quality stays high.

In 2025, new automation and AI tools will change the quality rules in custom PCBA manufacturing and testing. Automated tools will make work faster, and AI machines will find problems instantly. Robots will work quickly and accurately, providing steady results. These tools will help you save money and maintain great quality in your work.

Key Takeaways

Good PCBA making saves money. Fixing prototype mistakes costs $50-$200, so being precise matters.

Better design tools help make products. Tools like Design for Manufacturability (DFM) lower mistakes and costs.

Picking the right materials is important. Correct materials make products work well in different situations.

Automated tests like AOI find problems early. This stops bad products from going to customers and saves money.

Use new tech. AI and machine learning improve quality checks and make production easier.

Design and Prototyping

Advanced design software for custom PCBA

In 2025, advanced design tools are very important for making high-quality custom PCBAs. These tools help improve designs for easier manufacturing (DFM), making production smoother and reducing mistakes. For example:

Feature | Benefit |

|---|---|

Optimizing PCB Design for DFM | Cuts costs and makes products more reliable by fixing issues early. |

Rapid Prototyping | Speeds up testing, so you can improve designs faster. |

Design Rule Checks (DRC) | Finds design mistakes early, avoiding fixes after production. |

Using these features makes designing faster and ensures your PCBA works well.

Prototyping techniques for quality validation

Prototyping is key to checking the quality of your custom PCBA. It helps find design problems early, saving money and avoiding issues in large production. Common methods include:

Breadboarding: Finds design problems at the start of the process.

Custom PCBs: Makes the manufacturing process better and more efficient.

Pilot Builds: Confirms the product works well and meets requirements.

Prototypes also allow detailed testing of how the product works. For example, tests like impedance analysis and automated optical inspection (AOI) check if designs meet standards. By using prototypes, you can avoid expensive fixes and product recalls.

Design optimization for manufacturability

Design optimization makes sure your PCBA is easy to produce without losing quality. Techniques like Design for Manufacturability (DFM) solve problems early to simplify production. Other helpful methods include:

Method | Description |

|---|---|

Poka Yoke Techniques | Stops assembly mistakes, improving overall product quality. |

Clear Labeling and Documentation | Helps place components correctly, reducing errors during assembly. |

Working with supply chain teams during design helps spot possible problems. Good documentation makes communication easier and reduces mistakes. By focusing on manufacturability, you can create reliable PCBAs that meet industry needs.

Material Selection and Preparation

High-quality materials for custom PCBA

Picking the right materials is key for strong PCBAs. The base of a PCB is made from prepreg, a glass fiber with resin. Copper foil covers this to create the conductive layer. This layer is crucial for the PCB to work. High-frequency uses, like 5G and car radar, need special materials. These materials must have low dielectric constants and handle heat well. This helps reduce signal loss and keeps performance steady.

Here’s a simple comparison of common materials:

Material | Features |

|---|---|

FR-4 | Strong, durable, and good at insulating electricity. |

Polyimide | Handles high heat, great for hot environments. |

CEM-1/CEM-3 | Cheaper options for less demanding uses. |

When choosing materials, check if they fit your design needs. This ensures your PCB works well in its environment.

Material compatibility and inspection

Matching materials correctly stops problems during production. You can check this by inspecting often and using key metrics. For example:

Metric | What It Does |

|---|---|

Manufacturing Defects Reduction | Finds issues like bad solder early, avoiding faulty boards. |

Waste Minimization | Catches defects early, saving materials and cutting costs. |

Yield Rates | Fewer mistakes mean more usable boards, boosting profits. |

By focusing on these checks, you ensure materials meet quality and production goals.

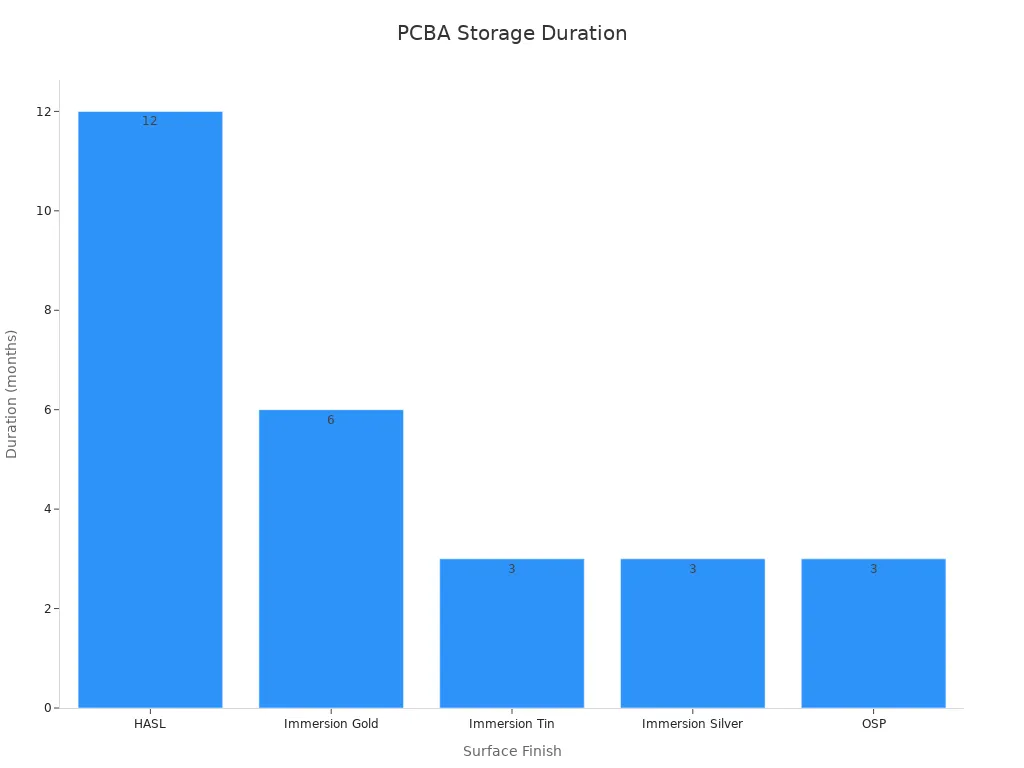

Proper storage and handling practices

Storing and handling materials right keeps them safe and high-quality. Use anti-static and moisture-proof packs to avoid damage. For instance, vacuum bags or bubble wrap can protect PCBAs. Keep storage areas dry, airy, and out of sunlight.

Here’s a guide for storing surface finishes:

Surface Finish | Best Temperature | Best Humidity | Storage Time |

|---|---|---|---|

HASL | 22±4℃ | 30%-60%RH | 12 months |

Immersion Gold | 22±4℃ | 30%-60%RH | 6 months |

Immersion Tin | 22±4℃ | 30%-60%RH | 3 months |

Immersion Silver | 22±4℃ | 30%-60%RH | 3 months |

OSP | 22±4℃ | 30%-60%RH | 3 months |

Following these steps helps materials last longer and keeps PCBAs high-quality.

Manufacturing Processes

Precision in PCB fabrication

Making precise PCBs is important for reliable and strong boards. Use advanced tools and follow strict rules to ensure quality. Modern tools like laser drills and AOI catch mistakes early. These tools help keep the process accurate.

Here are key points for precise PCB fabrication:

Benchmark Type | Description |

|---|---|

Advanced Technologies | New tools make sure PCBs are made with great precision. |

Quality Control Standards | Following rules ensures PCBs are consistent and work well. |

IPC, IEEE, and ISO Standards | These rules guarantee quality and help compete globally. |

Testing under stress checks how well boards handle tough conditions. This includes high heat or physical pressure. By focusing on precision, you can make PCBAs that meet industry needs.

Component mounting for accuracy

Placing components correctly is vital for a working PCB. It starts with applying solder paste carefully for strong connections. Machines can place parts quickly and correctly, reducing mistakes.

Steps for accurate component mounting:

Solder Paste Application: Put solder paste exactly where needed for good connections.

Component Placement: Use SMT or THT to place parts in the right spots.

Reflow Soldering: Heat carefully to attach parts without damage.

Inspection: Check for mistakes using visual checks or AOI.

Wave and selective soldering are also useful for mixed boards. These methods help ensure your PCB is accurate and reliable.

Reliable soldering methods

Soldering is key in making PCBs, and good methods avoid problems like weak joints or bridges. Low-heat soldering is becoming popular as it reduces stress on parts and improves quality.

Tips to avoid soldering problems:

Failure Mode | Best Practices |

|---|---|

Cold soldering | Add thermal relief features for better soldering. |

Head-in-pillow | Match solder paste and flux settings properly. |

Bridging | Check for warping in large BGA parts before soldering. |

Non-wetting | Keep materials clean and stored correctly to avoid oxidation. |

Choosing the right solder and process is crucial for reliable PCBs. Fixing these issues ensures your PCBAs work well for a long time.

Quality Assurance and Testing

Automated optical inspection (AOI)

Automated optical inspection (AOI) is very important for checking PCBA quality. It uses fast cameras and smart programs to find problems. These problems include bad soldering, missing parts, or parts in the wrong place. AOI catches mistakes early, stopping bad boards from moving forward.

In 2025, AOI systems use two main types of smart programs:

Algorithm Type | What It Does |

|---|---|

Feature-based Algorithms | Spots edges, colors, or textures to find problems. |

Machine Learning Algorithms | Learns from many images to find tricky and hidden defects. |

These tools make AOI great at finding even tiny issues. It works fast and saves money by avoiding costly mistakes.

Tip: Use AOI in your checks to find problems early and work faster.

Functional and circuit-level testing

Functional and circuit-level testing makes sure your PCBA works correctly. These tests check if the board’s circuits and parts are working as they should.

Here are common testing methods and what they do:

Testing Method | Problems Found | Why It’s Important |

|---|---|---|

Visual Examination | Finds misplaced or broken parts | Ensures all parts are in the right spots. |

In-Circuit Testing | Checks for open or short circuits | Confirms the board’s electrical connections are correct. |

Automated Optical Inspection | Finds soldering problems | Makes sure solder joints are strong and neat. |

Flying Probe Testing | Spots holes, shorts, and other flaws | Acts as a backup check for simpler problems. |

Functional Tests | Checks if the board works when powered on | Makes sure the board performs as expected. |

Electrical Performance Tests | Measures current and voltage levels | Ensures the board meets electrical standards. |

These tests confirm your PCBA is built right and works well. Combining these methods gives you strong quality checks.

Note: Functional testing is key to making sure your PCBA works and avoids costly problems later.

Environmental and stress testing

Environmental and stress testing checks if PCBAs can handle tough conditions. These tests copy real-world challenges to see if the boards stay reliable.

Here are common stress tests:

Electrical overstress tests: Check if the board can handle extra voltage or current.

Electrostatic discharge tests: Test how well the board resists static electricity.

Environmental stress screening tests: Expose the board to changing heat and moisture to find weak spots.

Accelerated life tests:

Burn-in testing: Find early failures by running the board for a long time.

Highly accelerated life testing (HALT): Push the board to its limits to find breaking points.

Highly accelerated stress testing (HAST): Test for total failure under controlled stress.

Highly accelerated stress screening (HASS): Use lighter stress after HALT to ensure reliability.

These tests help find problems before the boards are sold, ensuring they last a long time.

Reminder: Add stress testing to your process to make sure your PCBAs are durable and reliable.

Future Trends in 2025

New ideas in custom PCBA manufacturing

The custom PCBA industry is changing fast with new ideas. In 2025, tools like HDI, flexible PCBs, and smart machines are improving how things are made. These tools help create smaller and better designs for industries like cars and phones. Flexible PCBs make lightweight devices, while HDI helps with high-speed tasks.

The market for multilayer PCBs is growing quickly. People want smaller and stronger electronics, so more layers and better materials are used. Companies are also using eco-friendly methods to keep customers happy. By following these trends, you can stay ahead in the market.

Here’s a quick look at some new techniques shaping the industry:

Technique/Advancement | What It Does |

|---|---|

Faster Testing Methods | Finds and fixes problems quickly without slowing production. |

In-Circuit Testing (ICT) | Checks circuits for problems like shorts or broken connections. |

Functional Testing | Tests if the PCB works well in real-life conditions. |

Better Materials | New materials handle heat better and improve performance. |

Makes production smarter by predicting problems and improving designs. |

Using these ideas can make your PCBs better and meet modern needs.

Keeping quality high

As technology grows, keeping PCBA quality high gets harder. Modern PCBs have more layers and complex designs, so stricter checks are needed. Numbers like First Pass Yield (FPY) and Defects Per Million Opportunities (DPMO) show how important accuracy is.

Metric | Typical Range |

|---|---|

First Pass Yield (FPY) | 95% to 98% |

Defects Per Million Opportunities (DPMO) | 500 to 1000 |

Customer Return Rate | Less than 1% |

To solve these problems, focus on strong testing and better inspections. Regular checks and improving processes help keep quality high. Working with suppliers to get good materials is also important.

Tip: Train your team to handle modern PCBs and learn new quality methods.

AI and machine learning for better quality

Smart tools like AI and machine learning are changing how quality is checked in PCBA. These tools help find and fix problems before they happen. For example, smart programs like deep learning can spot tiny mistakes better.

Here’s how AI and machine learning improve quality:

Predictive tools warn about problems early, saving time and materials.

Smart cameras and programs find bad parts more easily.

AI in design makes production faster and reduces mistakes.

Using these tools makes your PCBs better and your work smoother.

Reminder: Adding AI tools improves quality and shows your business is innovative.

Ensuring quality in custom PCBA needs a complete process. Combining design, production, and testing in one place makes work easier. This one-stop service keeps quality steady and lowers costs. Tests like heat cycling, electrical checks, and stress tests ensure PCBs are strong and reliable.

Improving constantly is very important. Using new tools and better methods helps you stay ahead. Focusing on quality meets industry needs and earns customer trust. This keeps your business strong in the changing 2025 market.

FAQ

What is PCB testing, and why is it important?

PCB testing checks if circuit boards work correctly. It finds problems like broken parts or bad connections. Testing saves money and ensures products meet quality rules.

How does automated optical inspection (AOI) improve quality?

AOI uses cameras and smart tools to spot mistakes. It finds missing parts or bad soldering quickly and accurately during production.

What are the benefits of environmental stress testing?

Environmental stress testing checks if PCBAs survive tough conditions. It tests heat, moisture, and static electricity to ensure they last and work well.

How can you optimize PCBA design for manufacturability?

Use DFM techniques to make production easier. Clear labels, good instructions, and teamwork with suppliers help avoid mistakes and save time.

What role does material selection play in PCBA quality?

Picking the right materials makes PCBAs work better. Good materials reduce signal problems, handle heat, and make boards more reliable.

See Also

Best Practices for Achieving Quality and Efficiency in PCBA

Improving Quality Control Measures in the PCBA Workflow

The Significance of Custom PCBA Manufacturing in Today’s Electronics

Ensuring Quality and Reliability Through PCBA Functional Testing

Key Role of PCBA Manufacturing in Electronics Design Process