In today’s fast-moving electronics world, quick turn PCB assembly helps ideas come to life faster. It shortens the time needed to make prototypes and launch products. For example, a medical device company reduced their launch time by 40% while keeping high-quality standards. Similarly, aerospace companies had a 99.8% success rate on first prototype tests. Quick turn PCB assembly is also very fast, with average times of 1-5 days instead of the 2-6 weeks of older methods. These improvements help you meet market needs quickly and stay ahead in electronics.

Key Takeaways

Quick turn PCB assembly helps make prototypes in 1-5 days, not weeks.

It allows easy design changes and quicker market responses.

Using quick turn PCB assembly saves money by avoiding big mistakes.

Designers and manufacturers must work together for better designs and quality.

Fields like healthcare, aerospace, and electronics gain from its speed and efficiency.

What Is Quick Turn PCB Assembly?

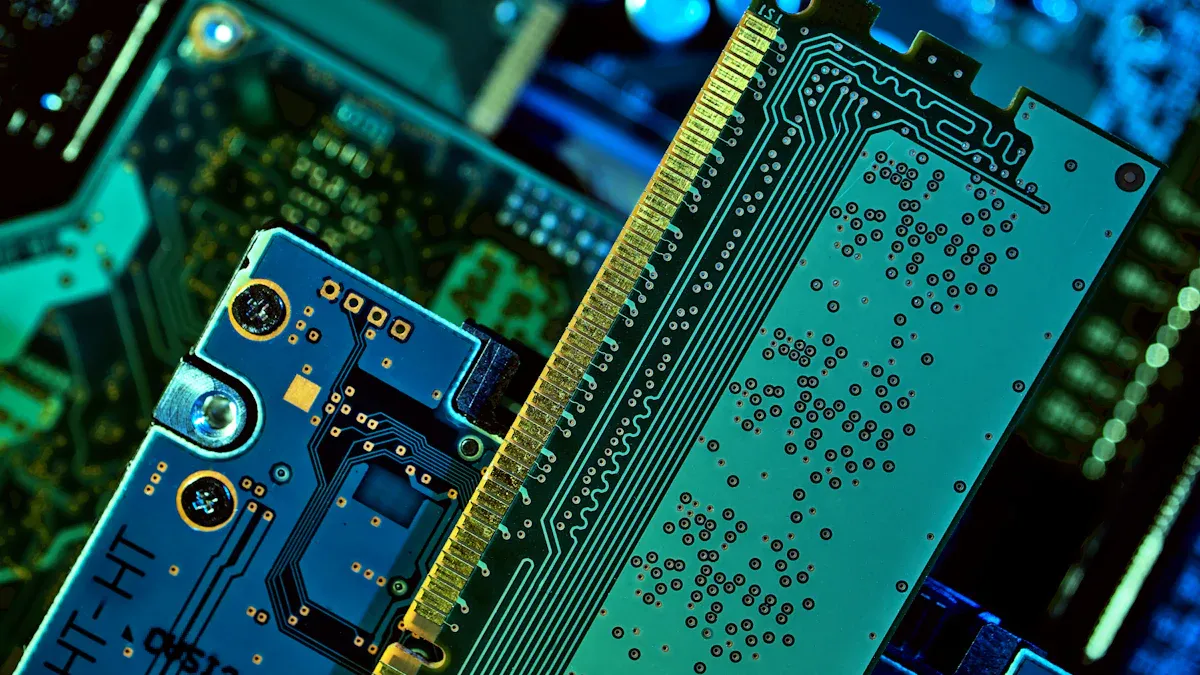

Definition and Key Features

Quick turn PCB assembly means making and assembling PCBs much faster than usual methods. It is made to match the fast needs of today’s electronics. Most quick turn PCB projects are done in under two weeks, and some are finished in just a few days.

Key features of quick turn PCB assembly include:

Rapid Prototyping: Helps test and improve designs quickly.

Component Procurement: Makes sure all parts are gathered fast.

Advanced Equipment: Uses modern machines for accuracy and speed.

RoHS Compliance: Follows eco-friendly rules for safe production.

Quality Management Systems (QMS): Checks for mistakes to ensure great quality.

Here’s a closer look at its meaning and abilities:

Definition/Capability | Description |

|---|---|

Quick Turn Definition | Means finishing in less than two weeks, sometimes faster. |

Capabilities | Includes fast prototypes, part sourcing, modern tools, and RoHS compliance. |

Benefits | Faster market time, quick testing, better flexibility, cost savings, and happy customers. |

Quality Management System | Strong QMS to catch and stop faulty parts. |

These features help quick turn PCB assembly bring ideas to life faster and more efficiently.

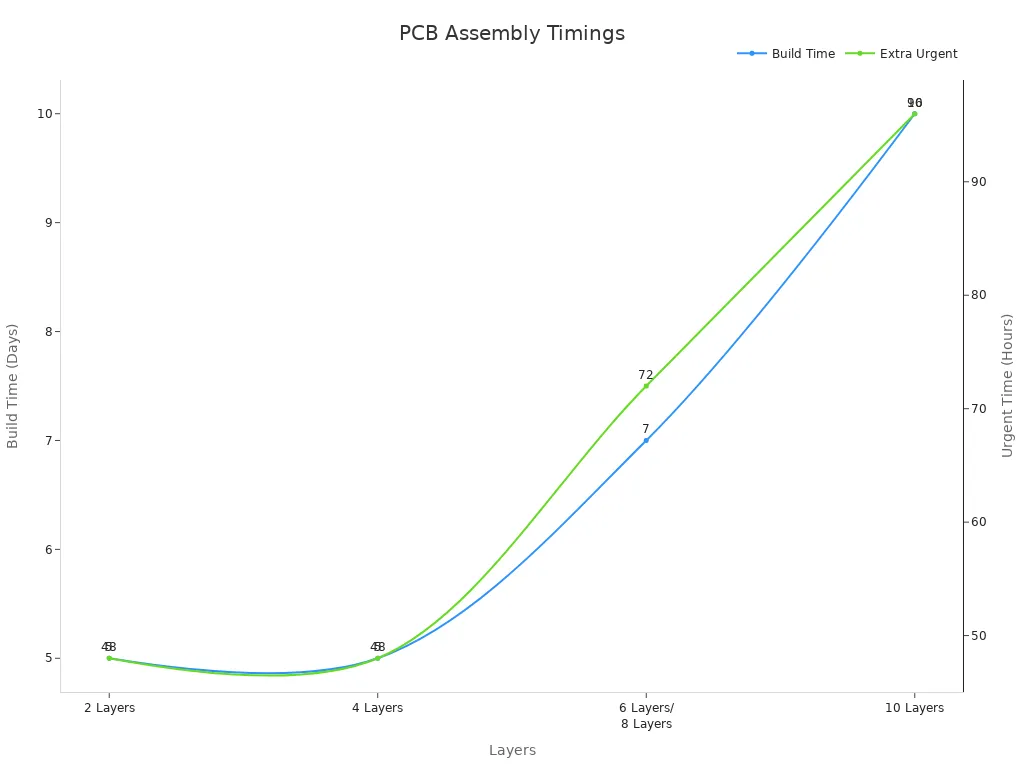

Differences Between Quick Turn and Traditional PCB Assembly

Quick turn PCB assembly is different from traditional methods in key ways. The biggest difference is speed. Traditional methods can take weeks, but quick turn PCB assembly can be done in just 24 hours. This makes it perfect for fast prototypes or urgent needs.

Here’s how they compare:

Factor | Quick Turn PCB | Traditional PCB |

|---|---|---|

Lead Time | 1 – 8 weeks | |

Cost | Higher per unit | Lower per unit in bulk |

Flexibility | Great for design changes | Less adaptable |

Best For | Prototypes, low-volume, urgent needs | Large-scale production |

Quick turn PCB assembly is more flexible, so it’s easier to make changes or meet market needs. While it costs more per unit, the faster delivery and shorter market time often make it worth it. Traditional PCB assembly works better for big projects where time isn’t as important.

Knowing these differences helps you pick the best option. If you need speed and flexibility, quick turn PCB assembly is the best choice.

How Quick Turn PCB Assembly Works

Step-by-Step Process

Quick turn PCB assembly uses a clear process for speed and accuracy. Each step is important to turn your design into a working circuit board. Here’s how it’s done:

Stencil Preparation: A stencil is made to match the PCB size. Solder paste is added for placing parts correctly.

SMT Assembly: Machines place small parts on the PCB with precision.

Reflow Soldering: Heat melts the solder paste, securing the parts in place.

Inspections after Reflow: Machines like AOI and X-ray check for any mistakes.

THT Assembly: Larger parts are added by hand to the PCB.

Wave Soldering: Hot liquid solder attaches the larger parts firmly.

Visual/AOI Inspections: More checks ensure the PCB is built correctly.

Conformal Coating: A protective layer is added to keep the PCB safe.

ICT Test and Function Test: Tests confirm the board works and connections are solid.

Clean and Drying: The PCB is cleaned and dried, ready for delivery.

This process ensures your PCB is made quickly and works perfectly.

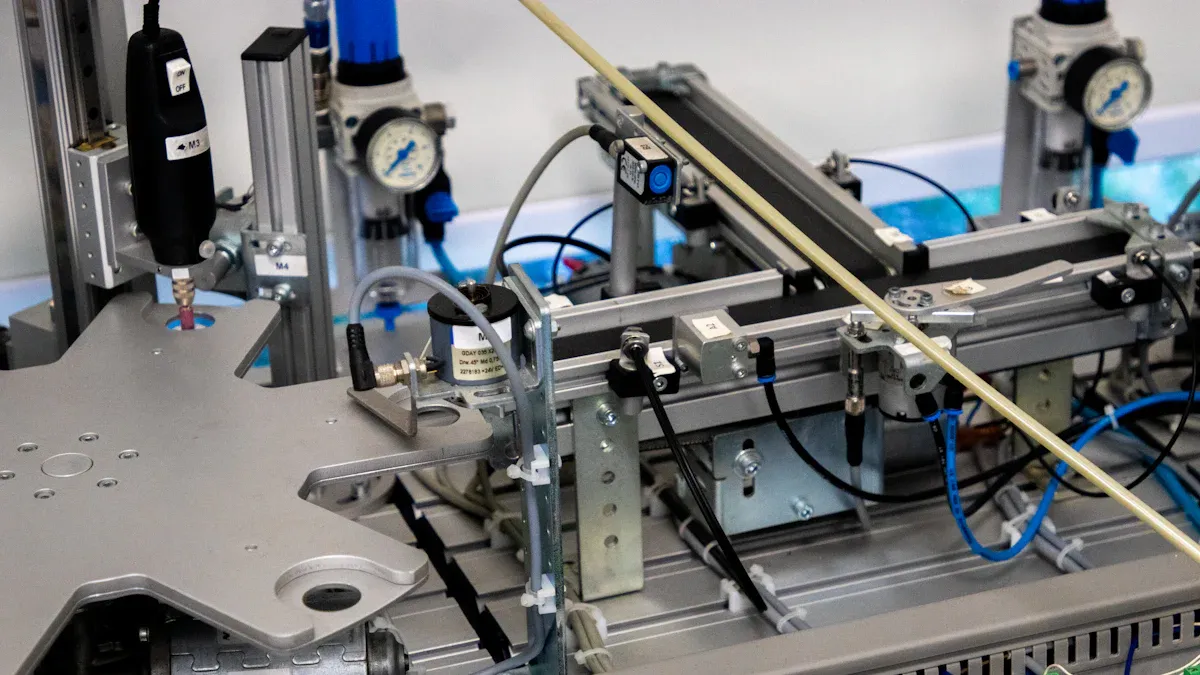

Role of Advanced Manufacturing Techniques

Modern tools are key to quick turn PCB assembly. These tools make the process faster, more accurate, and better. For example:

Laser imaging creates patterns quickly without old photo tools.

Automated drilling makes precise holes, avoiding mistakes.

Fast lamination speeds up bonding layers together.

Surface finishes are applied quickly while keeping quality high.

Automated tests like AOI find problems early, saving time and materials.

These methods save time, cut costs, and improve how well your PCB works.

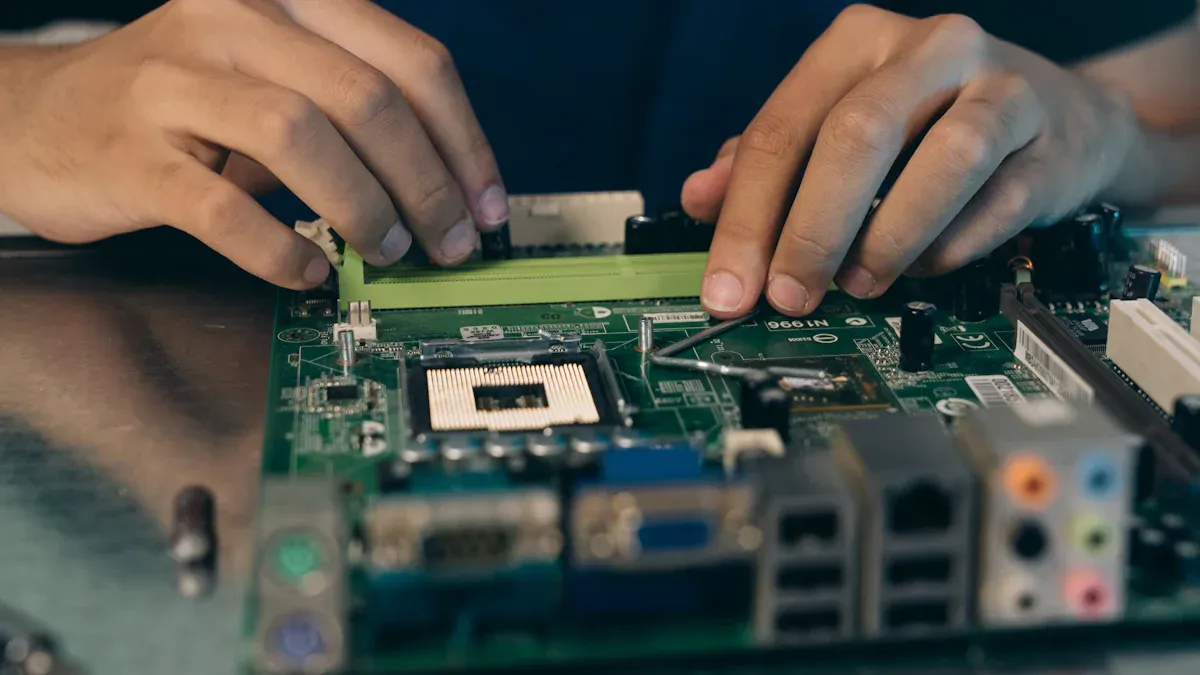

Collaboration Between Designers and Manufacturers

Teamwork between designers and manufacturers is very important for success. Working together helps improve designs for easier building. This lowers mistakes and speeds up production.

For instance, Company D worked with manufacturers to fix designs, reducing errors and improving quality. Company E used data to work faster and lower defect rates. These partnerships help make better PCBs and get them to market faster.

By teaming up, you can create great results and stay ahead in the fast-changing electronics world.

Benefits of Quick Turn PCB Assembly

Faster Prototyping and Innovation

Quick turn PCB assembly helps you create products faster. It lets you test ideas quickly without waiting too long. This process helps improve your product by fixing problems early. For example, finding mistakes early saves time and money later. You can avoid expensive fixes or recalls.

With faster development, you can try new features easily. This speeds up testing and ensures your product works well. Companies using quick-turn prototyping can adjust to market changes faster. This gives them an advantage in making better electronics.

Tip: Use quick-turn prototyping to get feedback fast. It helps you improve designs and make better PCBs for real-world use.

Reduced Time-to-Market

In electronics, launching products quickly is very important. Quick turn PCB assembly cuts down the time needed to finish projects. Traditional methods take weeks, but quick-turn methods deliver results in days. This helps you stay ahead of competitors and meet customer needs faster.

Shorter production times also let you respond to trends quickly. If you need to change your design, quick turn PCB assembly makes it easy. You can make updates without slowing down your project. This flexibility is key to staying competitive in the fast-changing electronics world.

Cost-Efficiency and Flexibility

Quick turn PCB assembly may cost more per unit, but it saves money overall. Fixing design problems early avoids costly changes during mass production. Faster production also reduces costs from delays, like missed sales or longer development times.

Quick-turn prototyping is very flexible. You can change designs or test ideas without stopping production. This is helpful for small projects or innovative electronics needing updates. Quick turn PCB assembly balances speed, quality, and cost, keeping your project on track.

Note: Quick turn PCB assembly’s flexibility helps you handle challenges. It ensures your product meets both quality and market needs.

Staying Ahead in Electronics Development

Quick turn PCB assembly helps you stay ahead in electronics. It lets you make products faster, improve quality, and save money. These benefits make it a smart choice for leading businesses.

Faster Time-to-Market

Speed is very important in electronics. Quick turn PCB assembly helps you finish projects faster. Old methods take weeks, but quick turn methods take just days. This speed helps you follow trends and meet customer needs quickly. Some companies finish complex projects in seven days or urgent ones in one day. By being faster, you can launch products before others and grab market chances.

Cheaper Prototyping

Prototyping helps improve your designs. Quick turn PCB assembly makes it quicker and cheaper. You can test many versions without wasting time or money. Early testing finds problems before big production, saving you from costly mistakes. Advanced tools help make prototypes fast without losing quality. This method supports new ideas while keeping costs low.

Better Product Quality

Quick turn PCB assembly also makes your products better. Faster steps allow more testing to ensure high standards. Automated tools and strict checks find problems early, avoiding bad products. Some companies promise UL-approved prototypes with detailed inspections. This focus on quality ensures your electronics work well in real life.

Flexibility and Customer Care

Quick turn PCB assembly is flexible for changing needs. You can update designs or meet tight deadlines easily. Many companies focus on customer satisfaction by matching their services to your goals. This teamwork keeps your project on track. Choosing quick turn PCB assembly gives you a partner who cares about your success.

Today, quick turn PCB assembly is more than just making PCBs. It’s a smart way to create faster, save money, and make great products. Using it helps you stay strong in the electronics business.

Challenges and Solutions in Quick Turn PCB Assembly

Common Challenges in Quick Turn PCB

Quick turn PCB assembly has its own set of problems. Knowing these issues helps you avoid delays. Here are some common ones:

Communication Issues: Poor communication between teams can cause mistakes in the product.

DFM/DFT Optimization: Skipping design for manufacturability (DFM) or testability (DFT) slows production and raises costs.

Testing Challenges: Bad test points and weak signals make finding faults harder, increasing costs.

Tight Deadlines: Fast deadlines can lead to errors or lower quality.

Higher Costs: Quick turn processes often cost more per unit due to speed.

Suraj said, “Time is our biggest challenge. Boards must arrive on time.”

Best Practices to Overcome Challenges

You can solve these problems by using smart strategies. These tips help make the process smoother:

Optimize Designs: Work with manufacturers to improve DFM and DFT. This reduces mistakes and speeds up work.

Choose the Right Supplier: Pick suppliers with good tools and fast delivery to avoid delays.

Focus on Quality: Make sure your supplier uses strict quality checks to reduce defects.

Plan for Testing: Add enough test points to your design to find faults easily.

Communicate Effectively: Keep clear communication with your supplier to avoid confusion.

Using these tips helps you create prototypes faster while keeping quality high.

Selecting the Right Quick Turn PCB Partner

Picking the right partner is key for quick turn PCB success. Look for these traits in a supplier:

Experience: Skilled suppliers handle tough designs and tight schedules well.

Quality Assurance: Strong quality checks ensure your PCBs meet standards and have fewer defects.

Cost vs. Value: Look at the overall value, not just the price. Higher costs often mean better quality and fewer future problems.

Location: Local suppliers can deliver faster and communicate better.

Customer Service: Good support and custom solutions show the supplier cares about your success.

Choosing the right partner ensures your quick turn needs are met with great quality and efficiency.

Is Quick Turn PCB Assembly Right for Your Project?

Key Factors to Consider

To decide if quick turn PCB assembly suits your project, think about a few things. First, check how fast you need the boards. Quick turn PCB assembly is great for prototypes or small orders in just days. Next, look at quality checks. Good manufacturers have strict inspections to keep quality high, even with tight deadlines.

Flexibility is also important. Quick turn PCB assembly is ideal for projects with frequent design changes or smaller production needs. Finally, think about costs. While each unit might cost more, faster delivery and fewer mistakes can save money overall.

Description | |

|---|---|

Lead Time Speed | Check how quickly manufacturers can deliver your boards. |

Quality Control Rigor | Make sure quality stays high even with fast production. |

Flexible & Adaptive Processes | See if the manufacturer can handle changes or small orders. |

Cost Effectiveness | Compare higher unit costs with savings from faster delivery. |

Industries That Benefit from Quick Turn PCB

Many industries need quick turn PCB assembly for speed and accuracy. Consumer electronics use it for fast prototypes and short production times to follow trends. Healthcare depends on it for quick design updates and testing, especially for medical devices.

Consumer electronics: Needs fast prototypes and short production cycles.

Healthcare: Requires quick design updates and testing for devices.

Aerospace and defense: Demands precision and reliability for critical tasks.

Automotive: Helps with new ideas for electric and self-driving cars.

IT and telecommunications: Speeds up making networking tools and hardware.

Smaller, lighter designs are becoming popular, making quick turn PCB assembly useful, especially for rigid-flex PCBs.

Questions to Ask Before Starting

Before starting your quick turn PCB project, ask some key questions. Does the manufacturer offer the services you need, like advanced PCB assembly? Do they use modern tools to ensure good quality? Can they work with materials your design needs, like FR4 or flexible PCBs?

Also, think about technical needs like signal strength and easy manufacturing for prototypes. Adjusting designs for fast production is important too. These questions help you plan and make sure your project goes well.

Aspect | Description |

|---|---|

Check if the manufacturer offers PCB assembly and other services. | |

Technology and Equipment | Look for modern tools that ensure high-quality boards. |

Material Options | Confirm they can work with materials like FR4 or flexible PCBs. |

Tip: Talk clearly with your manufacturer to meet both quality and time goals.

Quick turn PCB assembly changes how modern electronics are made. It speeds up creating and testing new ideas quickly. This helps you launch products faster, beating competitors to customers. It also adjusts to changes, letting you improve designs or follow trends.

By solving problems and picking a good partner, you get the most from quick turn PCB assembly. A trusted supplier delivers quality PCBs on time. This keeps you ahead and ready for changing market demands.

FAQ

What is the main benefit of quick turn PCB assembly?

Quick turn PCB assembly helps make prototypes and products faster. This speed lets you test ideas and launch products quickly. It gives you an advantage over competitors.

Can quick turn PCB assembly work with complex designs?

Yes, it can handle complex designs easily. Modern tools and advanced methods ensure accuracy and high quality, even for detailed layouts.

Is quick turn PCB assembly worth the cost?

It may cost more per unit, but it saves money overall. Faster production and early testing prevent delays and expensive mistakes during large-scale production.

How do I pick the best quick turn PCB partner?

Choose a partner with experience and good quality checks. Make sure they have modern tools, flexible services, and great customer support to fit your project needs.

Which industries use quick turn PCB assembly the most?

Industries like electronics, healthcare, aerospace, and cars benefit a lot. They use it for fast prototypes and to keep up with market changes.

See Also

The Importance of Custom PCBA Production in Today’s Electronics

Understanding Turnkey PCB Assembly and Its Significance

Benefits and Drawbacks of Flex PCBA in Electronics

The Role of PCBA in Advancing Modern Electronics

Essential Strategies for Enhancing PCB Assembly Productivity