Electronic waste, called e-waste, is growing very fast. This creates big problems for the environment. In 2022, the world made 62 billion kilograms of e-waste. This is 82% more than what was made in 2010. Sadly, only 22.3% of this waste was recycled the right way. This shows we need better ideas, like recyclable PCB assembly processes. These processes help reuse important materials like copper and gold. These materials come from printed circuit boards, which are 25–30% of PCBs. Using these methods saves natural resources and lowers harm to the planet. This change is very important for making the world more sustainable.

Key Takeaways

Recyclable PCB processes cut down e-waste by reusing materials like copper and gold from old devices.

Using green materials and methods in PCB making reduces pollution and saves resources, helping the planet.

Recyclable PCB tech can save companies money over time by cutting waste and following eco-rules.

People can help by picking products with recyclable PCBs and recycling old gadgets the right way.

Teamwork between makers, recyclers, and governments is key to improving recyclable PCB tech and supporting eco-friendly habits.

Understanding Recyclable PCB Assembly Processes

What Are Recyclable PCB Assembly Processes

Recyclable PCB assembly processes make printed circuit boards (PCBs) reusable or recyclable. These methods recover valuable materials like copper, gold, and ICs from old electronics. Unlike older methods, which create waste that can’t be reused, these focus on being eco-friendly. Using recyclable PCB processes saves resources and protects the environment.

Key Materials and Techniques Involved

Recyclable PCB assembly uses new materials and methods to make recycling easier. Some recent improvements include:

Key Materials and Techniques | Description |

|---|---|

Materials that break down naturally, helping the environment. | |

Conductive Inks | Special inks for circuits without needing copper etching. |

Nanomaterials | Tiny materials that improve performance and use fewer resources. |

Additive Manufacturing | 3D printing that cuts waste and speeds up production. |

Automation | Machines that make production faster and more reliable. |

Lean Manufacturing | Ways to reduce waste and use resources wisely. |

Component Harvesting | Taking useful parts from old electronics for reuse. |

Material Recovery | Collecting valuable materials from e-waste to avoid mining new ones. |

Refurbishment | Fixing and reusing PCBs and parts to make them last longer. |

These materials and methods make PCBs easier to recycle and better for the planet. They also help create greener electronic designs with less harm to nature.

How They Differ From Traditional PCB Manufacturing

Recyclable PCB processes are very different from older manufacturing ways. Traditional methods use harmful chemicals and create waste that can’t be reused. Recyclable processes focus on being eco-friendly by:

Reusing ICs, which lowers the environmental damage of electronics.

Using materials like smart labels and conductive inks to cut waste.

Removing ICs with heat, which is cheaper and works better than old methods.

These changes show why recycling in electronics is so important. Choosing sustainable PCB designs helps technology and the planet work together.

Environmental Benefits of Recyclable PCB Assembly Processes

Cutting Down on Electronic Waste

E-waste is growing fast and harming the planet. Using recyclable PCB processes can help reduce this problem. These methods recover useful materials like copper, gold, and ICs from old PCBs. Without recycling, these materials would end up in landfills.

Recycling saves materials that would otherwise go to waste.

Biodegradable options, like JIVA’s Soluboard®, make recycling easier.

These ideas fight rising e-waste while protecting the environment.

Choosing recyclable PCBs helps reuse materials instead of throwing them away. This reduces waste and helps solve the e-waste problem.

Saving Natural Resources

Recyclable PCB processes help save important natural resources. Making traditional PCBs uses mined materials like copper and gold. Mining harms the earth and uses up limited resources. Recycling materials from old PCBs helps save these resources for the future.

For example, taking parts from old PCBs allows reuse of valuable materials. This reduces the need for mining and lowers harm to nature. Using biodegradable materials and special inks also cuts down resource use.

Supporting these methods helps protect resources and the environment.

Reducing Carbon Emissions in Manufacturing

Making regular PCBs creates a lot of carbon pollution. This happens because the process uses a lot of energy and non-recyclable materials. Recyclable PCB processes are better for the planet. For example, Jiva Materials’ RPCBs cut carbon emissions by 67% compared to regular boards.

These methods lower emissions by:

Using eco-friendly materials like biodegradable substrates.

Using 3D printing to save energy and reduce waste.

Improving efficiency with automation and smart manufacturing.

By using these processes, you help lower the environmental damage from electronics. Cutting carbon emissions is key to a sustainable future.

Challenges in Using Recyclable PCB Assembly Processes

Technical and Material Problems

Recyclable PCB processes face many technical and material problems. For example, making PCBs can create a lot of waste. This includes harmful chemicals, which go against eco-friendly goals. Old PCBs are also hard to throw away safely. They release dangerous pollutants and don’t break down over time. This causes long-term harm to the planet.

New materials like Soluboard are better for nature but have issues. Many factories can’t use these materials easily. Another problem is scaling up production. Water-soluble materials seem helpful but aren’t ready for large-scale use yet. The table below explains these problems:

Problem Type | Description |

|---|---|

Waste Creation | Making PCBs creates waste, including harmful chemicals. |

Hard Disposal | Old PCBs release pollutants and are tough to dispose of. |

Not Biodegradable | Traditional PCBs don’t break down, causing lasting damage. |

Factory Compatibility | New materials like Soluboard don’t work well in current factories. |

Scaling Issues | Water-soluble materials aren’t proven for big production yet. |

Fixing these problems is key to making recyclable PCB processes work better.

Money Problems in Adoption

Cost is a big issue for using recyclable PCB methods. Making eco-friendly materials costs more money. For example, biodegradable boards and special inks are pricier than regular ones. Small companies may not afford these higher costs.

Switching to recyclable PCBs also needs new machines and staff training. These changes cost a lot upfront. Companies may not want to spend this money without quick benefits. But in the long run, they can save money by cutting waste and following green rules. Businesses need to think carefully about these costs and benefits.

Rules and Industry Problems

Rules and industry habits also slow down recyclable PCB progress. Old PCBs have toxic stuff like heavy metals and BFRs. If not recycled properly, they harm the environment. Sadly, good recycling methods are still not widely available due to cost and technical limits.

The electronics industry also lacks clear rules for making recyclable PCBs. This causes confusion in how they are made and recycled. Creating shared rules and encouraging companies to follow them can help. Fixing these rule gaps can lead to a greener future for PCB production.

Current Advancements and Uses in Recyclable PCB Technologies

New Eco-Friendly PCB Materials

The electronics world is using greener materials for PCBs. Companies now use biodegradable boards like Jiva Materials’ Soluboard. These boards break down naturally and create less waste. Conductive inks are another new idea. They replace copper etching, making recycling easier and cutting pollution.

Many businesses also use lead-free solder and recyclable parts. These steps help meet global green goals by lowering waste and saving energy. As more people want electronics, these ideas reduce harm to the planet. Using recyclable materials makes production better and builds a green reputation.

Companies Leading in Green PCB Production

Some companies are leading the way in eco-friendly PCB making. Jiva Materials uses Soluboard to cut carbon emissions. Apple uses recycled tin and rare earth metals in its products. These actions show how businesses can be green without losing quality.

Dell and HP also stand out with their recycling systems. They reuse parts from old electronics to make new ones. This reduces waste and gives them an edge in the market. These examples can inspire others to choose sustainable methods.

Uses in Different Industries

Recyclable PCB technologies are helping many industries go green. The table below shows some key uses:

Industry Sector | Uses of Recyclable PCB Assembly |

|---|---|

Healthcare | Medical tools and devices |

Manufacturing | Home electronics and appliances |

Retail | Checkout systems |

Aerospace | Aircraft electronics |

Automotive | Electric cars and parts |

Telecommunications | Phones and network systems |

These uses show how recyclable PCBs help many fields. For example, they support electric cars, which lower pollution. In healthcare, they help make strong and eco-friendly medical devices. Using recyclable PCBs boosts innovation and protects nature.

The Future of Recyclable PCB Assembly Processes and Sustainability

New Trends and Research

Recyclable PCB processes are improving quickly with new ideas and studies. These changes aim to make recycling faster, greener, and easier to expand. Below is a table showing exciting trends shaping the future of PCB recycling:

Trend | Description |

|---|---|

AI and Automation | Makes recycling faster and better at sorting materials. |

Uses safer methods to cut down harmful chemicals. | |

Better Material Recovery | New ways, like bioleaching, help get rare metals sustainably. |

Stricter Rules | Tougher laws push companies to use advanced green technologies. |

Circular Economy Growth | Encourages reusing materials to meet sustainability goals. |

These trends show how technology and rules are changing PCB recycling. For example, AI speeds up recycling and recovers more valuable materials like copper. Bioleaching, which uses tiny organisms to get metals, is a cleaner option than old chemical methods.

Helping Global Sustainability Efforts

Recyclable PCB processes can greatly improve global sustainability. They reduce e-waste and save natural resources, solving big environmental problems. Studies show e-waste can be turned into building materials. This reduces landfill waste and replaces natural resources in construction. It also saves money and lowers harm to the planet.

Recycling old PCBs helps protect nature and boosts the economy. Taking apart electronics allows valuable materials to be reused. This supports better e-waste management and matches global green goals. The electronics industry can lead the way in fighting environmental damage.

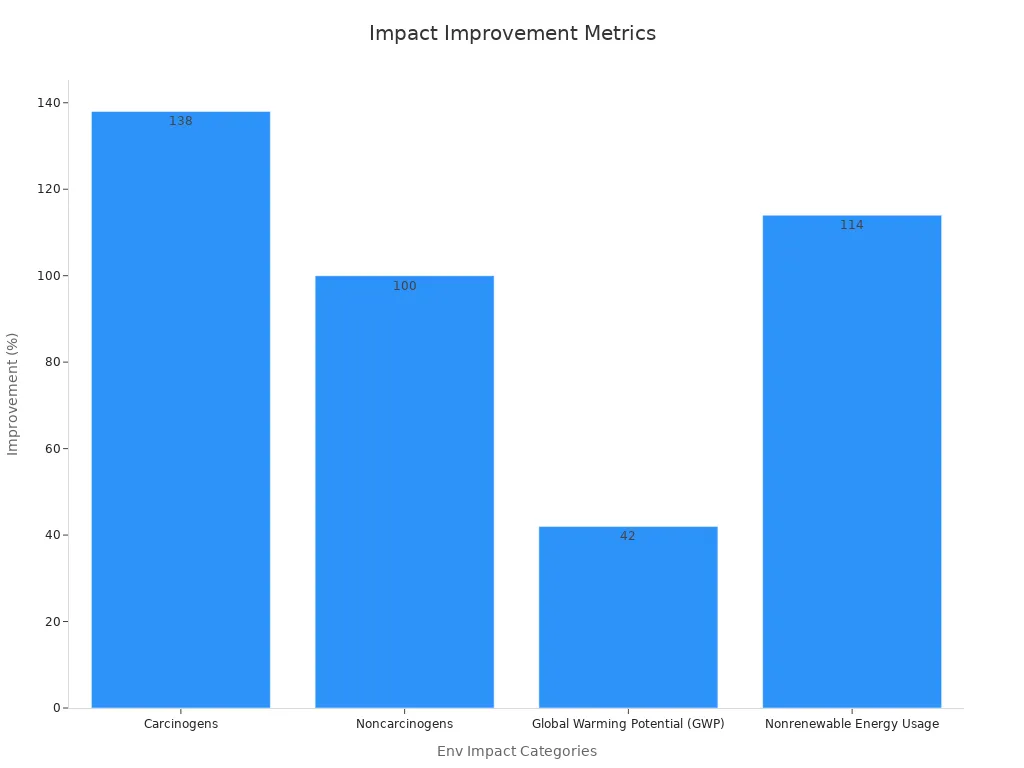

The benefits of these processes can be measured. For example, recyclable PCB technologies improve these environmental areas:

Environmental Impact Category | Improvement (%) |

|---|---|

Carcinogens | 138% |

Noncarcinogens | 100% |

Global Warming Potential (GWP) | 42% |

Nonrenewable Energy Usage | 114% |

These numbers show how recyclable PCB processes can make a big difference. They are key to helping the planet and reaching sustainability goals.

Ways to Speed Up Adoption

To enjoy the full benefits of recyclable PCB processes, we need plans to make them more common. Here are some ideas:

Support Research: Invest in new materials and recycling methods to lower costs and make them easier to use. For example, water-soluble boards and special inks help recycling.

Work Together: Manufacturers, recyclers, and governments should team up to share ideas and resources for greener practices.

Offer Incentives: Governments can give tax breaks or grants to companies using recyclable PCB technologies. This helps cover high starting costs.

Teach Consumers: Inform people about the harm of regular PCBs and the benefits of recyclable ones. Choosing green electronics helps the planet.

The electronics industry has huge chances for green changes. For example, integrated circuits are the third most traded product worldwide. This shows how recyclable PCB technologies can make a big impact. But the industry must also handle rising energy and water use. Reports say energy use in semiconductors will grow 12% yearly from 2025 to 2035, and water use will grow 8%. Using recyclable PCB processes can help reduce these problems.

By following these steps, we can push the electronics industry toward greener practices. This will help protect the planet for future generations.

Recyclable PCB processes help cut down e-waste and save resources. They recover materials like copper and gold from old electronics. Without recycling, these valuable materials would be wasted. These methods also reduce harm to the environment, making them key for a greener future.

The electronics industry can lead in protecting the planet. Recyclable PCB technologies lower waste and carbon pollution during production. Supporting these ideas as a consumer or business makes a big difference. Choosing recyclable PCBs helps create a cleaner world for the future.

FAQ

What makes recyclable PCB assembly processes eco-friendly?

Recyclable PCB methods use materials that break down naturally. They recover metals like copper and gold from old electronics. These processes avoid harmful chemicals and reuse parts to save resources. This helps protect the planet.

Are recyclable PCBs as durable as traditional ones?

Yes, they are just as strong as regular PCBs. Makers use new materials like biodegradable boards and nanomaterials. These keep the boards tough while being better for the environment.

How can you identify products with recyclable PCBs?

Check for eco-friendly labels or certifications on products. Many companies mention recyclable PCBs in their product details. You can also look up brands that focus on green practices.

Do recyclable PCB processes cost more?

At first, they might be more expensive due to new materials. Over time, they save money by cutting waste and using fewer resources. They also help companies follow green rules.

How can you support recyclable PCB technologies?

Buy electronics from brands that care about the environment. Recycle old devices the right way and support green ideas in the industry. This helps recyclable PCB methods grow.

See Also

A Comprehensive Guide To PCBA Manufacturing And Assembly

Essential Strategies For Enhancing PCB Assembly Productivity

Emerging Innovations In PCB And PCBA Design And Manufacturing

The Importance Of Custom PCBA Manufacturing In Today’s Electronics