Choosing the right circuit board manufacturer is very important for your project. A good manufacturer provides reliable products that fit your needs. You should think about several things when you decide. Find manufacturers with modern technology to help your design. Great customer service is also very important. You want a partner who communicates well and solves your problems quickly. ocuFsing on these points will help you pick the best circuit board manufacturer for your project.

Key Takeaways

Picking the right circuit board maker is very important for your project. Think about how they communicate, their prices, and what they can do.

Find makers that use modern technology. New tools help make sure your circuit boards are accurate and reliable.

Quality checks are very important. Look for certifications like ISO 9001 to make sure the maker follows industry rules.

Quick turnaround times can help your project. Some makers can give you prototypes in just a few days, which helps you meet tight deadlines.

Check their customer support. A helpful maker can fix problems fast and keep your project on schedule.

Top PCB Manufacturers

Advanced Circuits Overview

Advanced Circuits is one of the top circuit board makers in the United States. They make high-quality printed circuit boards (PCBs) for many uses. Their focus on quality shows through their certifications. Advanced Circuits is UL certified in both the United States and Canada. This means their products meet strict safety rules.

Key Features and Capabilities

When you work with Advanced Circuits, you can expect some key features:

Quick Turnaround: They provide fast prototyping services. You can get your PCBs in just 24 hours.

Custom Solutions: Advanced Circuits offers solutions made just for your project needs.

Advanced Technology: They use the latest technology in PCB making. This ensures accuracy and dependability.

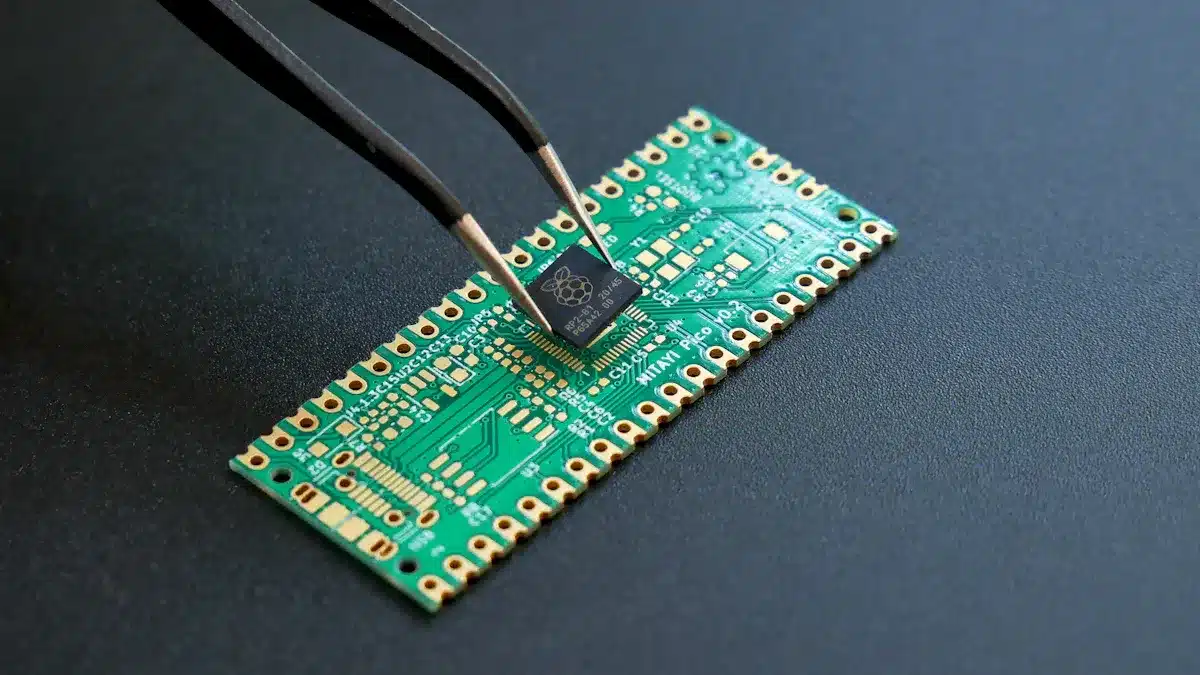

JLCPCB Overview

JLCPCB is another top company in the PCB field. They are known for their affordable solutions. Many hobbyists and professionals like them because of their low prices and quick service. JLCPCB aims to provide high-quality printed circuit boards quickly.

Quick Turn Prototypes

A great feature of JLCPCB is their quick turn prototypes. You can get your prototypes in just a few days. This is perfect for projects that need to be done fast. Their online platform makes ordering easy. You can upload your designs and get quotes right away.

Sierra Circuits Overview

Sierra Circuits is a well-known American maker of high-quality printed circuit boards. They focus on making American-made prototypes. These often have benefits over those made overseas.

American-Made Prototypes

Prototypes made in America by Sierra Circuits usually have better quality and faster lead times. Here’s a look at lead time options you might think about:

Lead Time Option | Description | Cost Implication |

|---|---|---|

Expedite | Fastest lead time with prioritization | Higher cost, no ground shipping |

Standard | Balance of cost and time | Significantly lower pricing than expedited |

Economy | Best for non-urgent projects | Reduces overall cost, may qualify for free shipping |

International Economy | Lowest pricing but longer delivery | Not available for ITAR restricted orders |

Choosing Sierra Circuits means you get their focus on quality and customer service. This makes them a trustworthy partner for your PCB needs.

Specialized Circuit Board Manufacturers

When you need special circuit boards, some manufacturers are better. They focus on certain industries and provide unique services.

Best Technology Overview

Best Technology makes high-frequency printed circuit boards. They offer advanced design and prototyping services to help your projects run smoothly. They work closely with firmware developers. This teamwork helps avoid delays during prototyping. They also use ready-made evaluation boards. This method uses vendor designs, which cuts down debugging time.

PCB Design and Prototyping

Best Technology uses automation for testing and documentation. They create scripts for Automated Test Equipment (ATE) systems. This process checks performance quickly and makes compliance reports. Their Design for Manufacturing (DFM) service shares designs with manufacturers early. This early sharing helps fix problems and avoids expensive re-spins. Also, their rapid prototyping service speeds up power supply development. This feature greatly shortens your time-to-market.

OSH Park Overview

OSH Park is another well-known manufacturer, especially for hobbyists and small projects. They focus on making low-volume PCBs. Their unique business model lets you order PCBs in small amounts without losing quality. OSH Park uses a purple solder mask, which is their signature look. This special color makes your boards stand out and ensures high visibility for your designs.

Hobby PCB Manufacturing

For hobbyists, OSH Park has an easy online platform. You can upload your designs and get instant quotes. This convenience makes starting your projects simple. Their focus on quality means even small orders meet high standards. Whether you are a beginner or an experienced maker, OSH Park gives you the tools to bring your ideas to life.

Global PCB Manufacturers

AT&S Overview

AT&S, which stands for Austria Technologie & Systemtechnik AG, is a top company in the global PCB market. They make high-quality printed circuit boards. Their products are used in many fields like cars, communication, and medical tech. AT&S cares about new ideas and being eco-friendly. They promise quality, so you get reliable products for your projects.

European Manufacturing Excellence

AT&S has many factories in Europe. These factories use advanced technology to create high-quality PCBs. Being in Europe helps them meet the growing need for PCBs worldwide. They focus on being friendly to the environment. Their production methods reduce waste and save energy. This commitment to being eco-friendly makes AT&S a popular choice for companies that want responsible partners.

Zhen Ding Technology Overview

Zhen Ding Technology is another important company in the PCB industry. Located in Taiwan, they are a leader in the Asian market. Zhen Ding makes many types of PCBs, including flexible and rigid-flex boards. Their creative designs and manufacturing skills help them meet different customer needs.

Asian Market Leader

Zhen Ding Technology’s earnings show their strong market position. In 2021, they made about $8.979 billion, making them one of the top PCB makers in Asia. By 2025, this number is expected to rise to $10.51 billion. The table below shows the earnings of different Asian PCB manufacturers:

Manufacturer | 2021 Revenue (Billion $) | 2025 Revenue (Billion $) |

|---|---|---|

China | 8.979 | 10.51 |

Japan | 7.022 | 8.182 |

India | 5.034 | 6.263 |

South Korea | 1.817 | 2.115 |

Australia | 0.886 | 1.018 |

Singapore | 0.937 | 1.161 |

South East Asia | 2.266 | 2.761 |

Taiwan | 0.524 | 0.606 |

Rest of APAC | 0.578 | 1.222 |

Zhen Ding’s ability to change with the market and invest in new tech makes them a leader in the Asian PCB market. Their focus on quality and new ideas ensures you get great products for your projects.

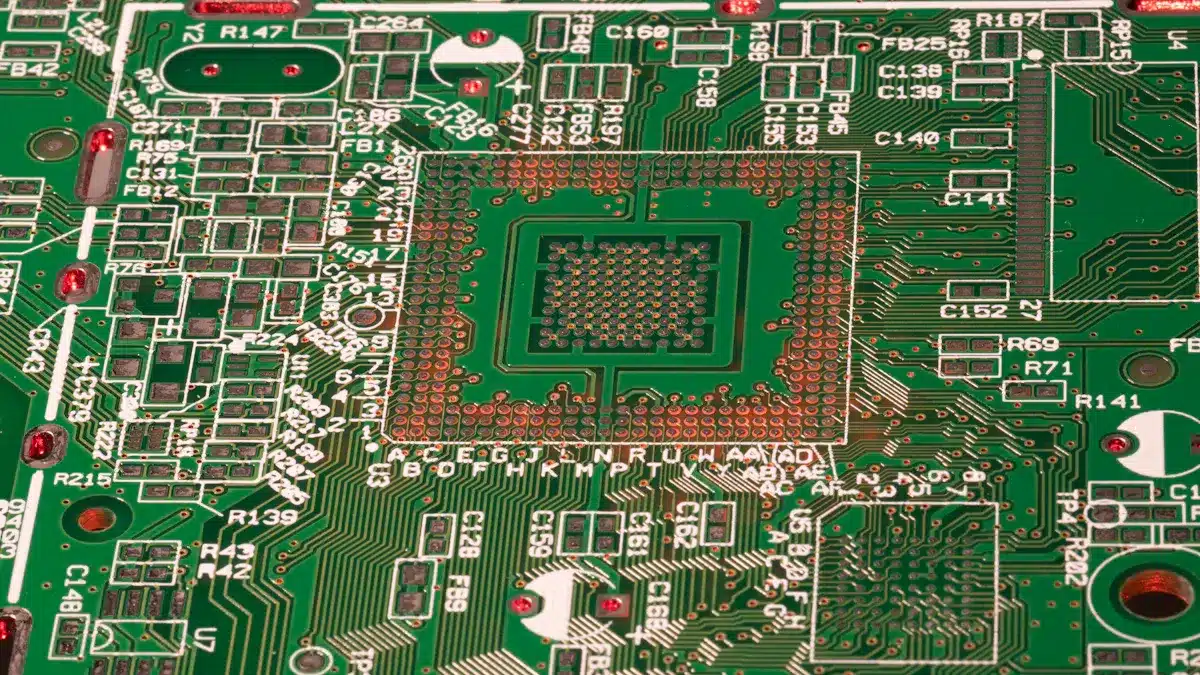

Factors to Consider in PCB Manufacturers

Choosing the right PCB manufacturer is very important. You need to think about several key factors. Look at quality assurance, technology, and customer support. Each of these parts helps you get reliable and effective PCB solutions.

Quality Assurance Processes

Quality assurance is very important in making PCBs. It makes sure the products meet the right standards. Here are some key quality assurance processes to check for:

Design for Manufacturing (DFM) Reviews: This process finds possible problems early in design. It helps avoid production issues that could slow down your project.

Material Selection and Sourcing: Good materials improve how well your PCBs work. Make sure the manufacturer uses strong and reliable materials.

Manufacturing Process Control: Using standard procedures and machines helps reduce mistakes. This control makes the final product more consistent and reliable.

Final Inspection and Testing: Testing methods check functionality and find defects before shipping. This step is very important for high-reliability circuit boards.

Technology and Equipment

The technology and equipment a PCB manufacturer uses affect the final product’s quality. You should think about these aspects:

Advanced Manufacturing Strategies: Look for manufacturers that use the latest technology. This includes automated assembly lines and advanced testing tools. These strategies can improve efficiency and lower errors.

Manufacturing Capacity: Make sure the manufacturer can handle your project size. Some focus on large production, while others make custom PCBs. Choose one that fits your needs.

Customer Support and Communication

Good customer support and communication are key for a successful partnership. You want a manufacturer that is quick to respond and easy to work with. Here are some things to think about:

Experience and Market Reputation: Check the manufacturer’s history and reputation in the U.S. PCB industry. A well-known company usually has proven reliability.

Delivery Time and Customer Support: Timely delivery is important for your project. Make sure the manufacturer meets deadlines and offers great customer service.

Certificates: Look for certifications that show the manufacturer’s commitment to quality and following industry standards.

By thinking about these factors, you can make a smart choice when picking a PCB manufacturer. This careful evaluation will help you get high-quality products that fit your project needs.

Choosing the right circuit board maker is very important for your project’s success. You need to think about several things to make a good choice. Look at how well they communicate, their prices, what they can make, their quality, where they are located, and their customer service.

Here’s a quick look at these factors:

Factor | Description |

|---|---|

Communication | Find makers who talk openly about problems and help your project succeed. |

Pricing Structure | Know the different parts of pricing, like board size, number of layers, and special needs. |

Manufacturing Capabilities | Check if the maker can meet your project needs and how many they can produce. |

Quality Standards | Look for important industry certifications like ISO 9001, AS9100, or TS 16949 to ensure quality. |

Geographic Considerations | Think about how the maker’s location affects cost, delivery times, and communication. |

Customer Service | Look at how quickly and well the maker’s sales and engineering teams respond to you. |

By carefully checking your options, you can find a maker that fits your needs and helps make your project happen.

FAQ

What is a PCB?

A PCB, or printed circuit board, connects electronic parts. It gives a solid base for parts and electrical links. You can find PCBs in nearly all electronic gadgets.

How do I choose the right PCB manufacturer?

To pick the right PCB maker, think about quality, technology, prices, and support. Look into what they can do and check reviews. This helps you find a maker that fits your project needs.

What is the typical lead time for PCBs?

Lead times for PCBs depend on the maker and how complex the project is. Usually, you can expect a few days for prototypes and several weeks for bigger orders. Always check lead times before you order.

Can I get custom PCBs?

Yes, many makers provide custom PCBs made to your needs. You can ask for specific sizes, materials, and designs. Make sure to explain your needs clearly to get what you want.

What certifications should I look for in a PCB manufacturer?

Look for certifications like ISO 9001, IPC-A-600, or UL certification. These show that the maker follows industry rules for quality and safety. They help make sure you get reliable and safe products.

See Also

Choosing The Ideal PCB Prototype Manufacturer For Your Project

Selecting The Right PCBA Manufacturer For Your Business

Finding The Perfect PCBA Manufacturer For Business Success

Streamlined PCBA Solutions For Quick Electronics Projects

Selecting The Top PCB Fabrication Manufacturer For Your Needs