Top industrial PCB manufacturers in 2025 are special. They use new technology and follow strict quality rules. They deliver products fast and help customers well. These things are important to people who make decisions. They help make sure products work well and last long in industrial pcb manufacturing. Big companies like Jabil, TTM Technologies, and Zhen Ding lead the way. They focus on new ideas, being green, and making custom products. This helps them meet more needs in areas like cars, medicine, and factory machines.

Aspect | Details |

|---|---|

Market Size (2025) | |

CAGR (2025-2030) | 4.87% |

Key Growth Drivers | 5G, IoT, smart factories, and demand for high-performance PCBs |

Major Market Players | Jabil Inc., TTM Technologies, Wurth Elektronik Group, Zhen Ding, Unimicron |

Key Takeaways

Top industrial PCB manufacturers use new technology. This helps make better products. It also helps them work faster.

They follow strict quality rules and have certifications. This makes sure PCBs are safe and reliable. It also means they meet hard industry rules.

Customization lets manufacturers make PCBs for tough places. These PCBs can handle heat, shaking, and wet conditions.

Fast delivery and good customer support help companies. They get products to market quickly. This keeps customers happy.

Sustainability and new ideas help manufacturers. They try to make less waste and save energy. They also meet new market needs.

Key Differentiators

Technology

Top manufacturers spend money on new technology. They want to be leaders in industrial pcb manufacturing. They use automated optical inspection and X-ray analysis. In-circuit testing helps them find problems early. Real-time monitoring lets them watch the process as it happens. Workflow optimization helps them finish jobs faster. High machine use and quick prototyping speed up delivery. Digital platforms help teams work together on designs. This makes the process easier and more correct. Using these tools means they make more good products. It also helps them build complex, high-performance PCBs.

Quality Standards

Quality standards are very important in industrial pcb manufacturing. Top companies get ISO 9001 certification. This shows they care about customers and always want to get better. They follow RoHS rules to keep out dangerous materials. UL certification proves their products are safe and reliable. They use IPC standards and pick the right class for each job. IPC-A-600, IPC-6012, and IPC-A-610 help with design and assembly. Senior managers help run quality systems and focus on customers. These steps lower mistakes and make products work together. They also help meet tough international rules.

Note: Manufacturers use smart tests and green programs to lower defects and make products more reliable, especially for important uses.

Customization

Customization is a big reason top manufacturers stand out. They solve special problems like heat, shaking, and wet places. Regular PCBs may not work for these tough jobs. So, manufacturers make designs that fit the exact need. Clients and engineers work together and test ideas. This helps the PCB fit well and last longer. They must follow hard IPC rules and train workers well. Picking the right materials is also important. These steps make sure custom PCBs work well in hard places.

Common customization challenges:

Meeting special needs for each job

Testing if the PCB can handle tough places

Delivery Speed

Fast delivery is a big deal for top manufacturers. Best Technology delivers on time 97% of the time. This is better than most other companies. U.S. companies can ship faster because they have simple steps and short shipping times. Some prototypes come in just 48 hours. Big orders take 5 to 15 days, depending on how hard they are to make.

Manufacturer | Lead Time Range |

|---|---|

Wintech | |

Advanced Circuits | 5 – 10 days |

Sanmina Corporation | 10 – 15 days |

TTM Technologies | 7 – 12 days |

Sierra Circuits | 5 – 7 days |

Multek | 7 – 14 days |

Tip: Fast delivery makes customers happy and helps them sell products sooner.

Customer Support

Customer support is very important for industrial PCB makers. Top companies use Zendesk, HubSpot, and SuperOffice Service. These tools help them talk to customers in many ways. The systems do some jobs automatically and keep all customer info together. They let companies give personal help to each customer. Makers also have self-service sites with guides and answers. This means customers can fix some problems on their own. AI chatbots answer easy questions any time of day. Omnichannel routing sends questions to the right expert fast.

Feature Category | Description |

|---|---|

Handles lots of questions from different places and teams. | |

Security and Compliance | Keeps data safe with locks, codes, and records. |

Customizations | Lets companies change how things work to fit their needs. |

Real-time Reporting | Shows how support is working and how agents are doing. |

Unified Agent Workspace | Puts all messages from phone, email, chat, and more in one place. |

Automated Workflows | Sends tickets to the right person and helps agents work faster. |

Self-service Knowledge Base | Lets customers find answers by themselves and lowers support work. |

AI-powered Chatbots | Gives help any time and fills out tickets for easy questions. |

Omnichannel Routing | Sends questions to the best agent who is free and knows the answer. |

Robust Integrations | Connects with online stores and business tools to keep all info together. |

Manufacturers who care about customer support build better relationships and get higher customer happiness scores.

Industrial PCB Manufacturing Trends

AI and Automation

Top manufacturers use AI and automation to make things better. They have machines that build and check PCBs by themselves. Companies like Samsung and Siemens use robots to save energy and cut waste. Samsung used automation and saved 40% energy. They also made 60% less PCB scrap. Apple used automated tests and got 20% more good products. These changes help factories work faster and meet quality rules. Automation means products are made quicker and with fewer mistakes. This makes customers happier.

5G and Miniaturization

5G and miniaturization have changed how PCBs are made. Companies use HDI boards and flexible PCBs to fit more parts in small spaces. This brings both problems and good things:

Small PCBs get hot, so makers use thermal vias and heat sinks.

Tiny parts need special tools like laser imaging and X-ray checks.

It is hard to keep signals clear, so ground planes and shields are used.

HDI tech lets makers build small, strong PCBs but makes things harder.

Working together early and using simulations helps make PCBs last longer.

Impact Area | Description | Effect on Performance and Reliability |

|---|---|---|

5G uses high frequencies and needs special materials. | Makes data fast but needs careful design for good signals. | |

Miniaturization & Density | HDI and flexible PCBs make small, packed layouts. | PCBs are smaller and stronger but harder to make. |

Thermal Management | More heat comes from higher power and speed. | Stops overheating and keeps PCBs working well. |

Advanced Materials | Makers use PTFE and ceramic-filled laminates. | Keeps signals strong at high speeds. |

Complex Testing | Special tools test heat and electricity. | Makes sure PCBs work in tough places. |

These new ideas help make faster and more reliable devices for smart factories, cars, and hospitals.

Sustainability

Sustainability is now important in making industrial PCBs. Big companies like Jabil want to cut waste and save energy. Jabil has more sites with Zero Waste to Landfill and wants 20% by 2026. PCBCart works with good suppliers and uses boxes that can be recycled. They watch how much energy they use and try to pollute less. Automation helps too. Samsung and Siemens use robots and smart tools to save energy and make less waste. New rules in Europe say PCBs must have recycling labels and digital product passports. This makes companies design PCBs that are easy to fix and recycle. These steps save money, help the planet, and make companies stronger.

Manufacturer Comparison

Global Leaders

Top global manufacturers are the best in industrial pcb manufacturing. They make the most money and use the newest technology. They work in tough areas like cars, planes, and medical electronics. These companies spend money on new ways to make PCBs. They use HDI, flexible PCBs, and miniaturization. They always try new ideas and care about the planet. This helps them stay ahead of others.

Nippon Mektron (Japan)

Unimicron Technology (Taiwan)

Zhen Ding Technology Holding Limited (Taiwan)

TTM Technologies (USA)

Ibiden Co., Ltd. (Japan)

These companies have big factories and use machines for accuracy. Japan, Taiwan, and South Korea focus on making things precise and new. China makes the most PCBs and has huge factories. North America is great at new ideas for defense and planes. Europe is good at making things exact and cares about the environment.

Market leaders use digital tools and machines to meet new needs and keep their supply chains strong.

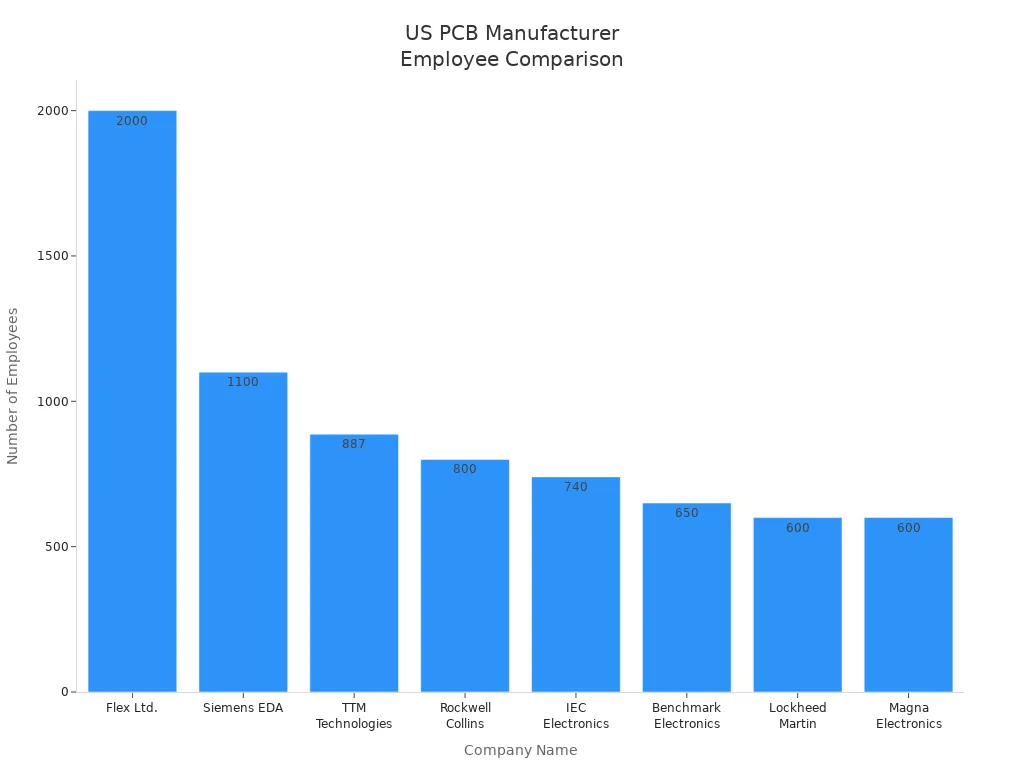

US Leaders

US manufacturers are known for new ideas, speed, and special solutions. They do everything from design to assembly in one place. Many US companies finish jobs fast, sometimes in just one day. They know a lot about flexible circuits, rigid-flex, microwave, RF, and high-density interconnect.

Company Name | Location | Employees | Specialization / Market Focus |

|---|---|---|---|

Flex Ltd. | Austin, TX | 2,000 | Automotive, cloud computing, medical, 5G |

Siemens EDA | Wilsonville, OR | 1,100 | Electronic design automation, integrated circuits |

TTM Technologies, Inc. | Chippewa Falls, WI | 887 | Fast production, high-volume, diverse industries |

Rockwell Collins, Inc. | Coralville, IA | 800 | Aerospace, defense, infrastructure |

IEC Electronics Corp. | Newark, NY | 740 | Complex electronics, full system assemblies |

Benchmark Electronics | Winona, MN | 650 | Defense, data centers, medical |

Lockheed Martin | Ocala, FL | 600 | Aircraft, maritime, defense |

Magna Electronics Tech. | Holly, MI | 600 | Automotive, vehicle design, power systems |

US companies make PCBs that work well for planes, defense, medicine, and cars. They follow strict rules and use advanced machines. They sell to other countries and work with global supply chains. TTM Technologies and Sanmina are great at making hard and high-quality PCBs.

US companies are the best at making quick samples and special, strong PCBs.

China and Asia

China and other Asian companies make more than half of all PCBs. They do this by having big factories, lower worker costs, and strong supply chains. Cities like Shenzhen, Guangzhou, and Suzhou help make lots of PCBs quickly. Chinese companies make their process better to save time and money.

Chinese companies make many types of PCBs. They make ones for phones, cars, medicine, and the military. They follow world rules and offer good prices. They can make samples fast and handle big or small orders.

Other Asian places like Taiwan and South Korea make fancy and HDI PCBs. Southeast Asia is good for cheaper options. Asian companies mix low prices with new technology and good customer service.

China is best for low prices and big factories. Taiwan and South Korea are best for new technology and smart ideas.

Comparison Table

Manufacturer | Region | Scale | Technology Focus | Quality Standards | Specialization | Strengths |

|---|---|---|---|---|---|---|

Zhen Ding | Taiwan | Very Large | HDI, Flex, Miniaturized | ISO, IPC, RoHS | Automotive, Telecom, Medical | High volume, advanced tech |

Unimicron | Taiwan | Very Large | HDI, Flex, Rigid-Flex | ISO, IPC, RoHS | Automotive, Consumer, Medical | Precision, innovation |

Viasion | China | Medium | Custom, Prototyping | ISO, IPC | Industrial, Medical, Automotive | Customization, fast prototyping |

Jabil | USA | Large | Automation, IoT, 5G | ISO, UL, RoHS | Industrial, Medical, Automotive | End-to-end solutions, automation |

Flex | USA | Large | Flex, Rigid-Flex, IoT | ISO, UL, RoHS | Automotive, Medical, 5G | Flexibility, global reach |

Sanmina | USA | Large | High-Reliability, HDI | ISO, IPC, UL | Aerospace, Defense, Medical | Quality, reliability |

TTM Technologies | USA | Large | HDI, Rigid, Flex | ISO, IPC, UL | Aerospace, Defense, Automotive | Speed, high-reliability |

Benchmark | USA | Medium | Complex Electronics | ISO, IPC | Defense, Data Centers, Medical | System integration |

JLCPCB | China | Very Large | Mass Production, HDI | ISO, IPC | Consumer, Industrial, Automotive | Affordability, fast prototyping |

China | Large | Prototyping, Custom | ISO, IPC | Consumer, Industrial, Medical | Rapid prototyping, customization | |

SeeedStudio | China | Medium | IoT, Prototyping | ISO, IPC | IoT, Consumer, Industrial | Fast prototyping, maker support |

Who Excels Where?

Industrial Automation: Jabil, Flex, and Siemens EDA are best at using machines and digital tools.

Rapid Prototyping: JLCPCB, PCBWay, SeeedStudio, and Viasion are great for making samples fast.

Affordability: JLCPCB and PCBWay have the lowest prices, especially for big orders.

High-Reliability Applications: Sanmina, TTM Technologies, and Benchmark make PCBs for jobs that need to be very strong and safe.

Top companies keep their supply chains strong by using many suppliers, smart computer tools, and making products close to customers. These steps help them keep making PCBs and meet what customers want.

Applications

Industrial Automation

Industrial automation uses PCBs to control machines and send data. These boards help run things like welding machines and battery chargers. PCBs also work with motion controllers and sensors. They must handle heat, shaking, water, and strong signals. Pro-Active Engineering makes reliable boards in the US. Victory PCB ships edge-plated boards fast with no minimum order. They have ISO 9001, IATF 16949, and UL certifications. Tests like AOI, X-Ray, and aging check if boards last long.

Important features of industrial automation PCBs:

Strong design for tough places

Long life and steady supply

Custom options for smart tech

Makers focus on reliability and rules so factories run smoothly.

Automotive

Cars use PCBs for engines, transmissions, screens, safety, lights, batteries, and sensors. Boards must work in hot and cold, from -40°C to +150°C. They also face shaking, wetness, and chemicals. Polyimide and high-Tg FR-4 help boards handle heat. Rigid-flex PCBs and good mounting help with shaking. Special coatings and ENIG finishes protect from water and rust. Shielding and routing help with EMI/EMC rules. Car PCBs need to last 10–20 years and follow ISO 26262, IPC-6012DA, and AEC-Q100/Q200. Tests like heating, shaking, and burn-in check if they work well.

Main needs:

Controlled impedance for fast signals

Heat control with vias and sinks

Extra safety for important systems

Medical Devices

Medical devices use PCBs for signals, power, and real-time data. Boards must meet FDA 21 CFR Part 820, ISO 13485, ISO 14971, IEC 60601, and UL 94 rules. High-density interconnects, EMI/EMC control, and backup help make them reliable. Polyimide and parylene coatings keep boards safe for the body and strong, even inside people. Tests for the environment and body safety, like cytotoxicity and sensitization, are needed for patients.

Role/Aspect | Description |

|---|---|

Signal Processing | Boards work well in medical devices for tests and treatments |

Regulatory Compliance | Boards follow FDA, ISO, IEC, RoHS, REACH, EU MDR, IPC Class III, UL 94 |

Design Features | Boards have dense connections, EMI/EMC control, backup, and easy testing |

Material Selection | Safe and strong materials for devices inside the body |

Testing | Boards get tested for safety in the body and environment |

Medical PCBs must pass hard checks to keep patients safe and devices working.

Aerospace

Aerospace PCBs need to be strong, resist rust, handle heat, and work well. Makers use ceramic and thick film parts for heat and shaking. Heavy copper layers help boards carry more power and last longer. Boards can handle up to 2000 heat cycles from -40°C to 145°C with thermal vias and high Tg materials. Finishes like HASL, Gold, and ENIG help soldering and stop gas leaks. Coatings and sprays protect boards from heat, wetness, and shaking. Designs use big ground areas and shields to lower EMI and crosstalk. Filling vias makes boards stronger and helps them conduct better. Boards follow AS9100D, MIL-STD-202G, MIL-STD-810G, and IPC Class 3 rules for quality.

Aerospace PCBs get tested for how they work, stress, and boundaries.

Reliability checks include heat and shaking cycles, ESD resistance, and working right.

Boards must meet strict rules for defects and assembly.

Aerospace makers build PCBs to work well in tough places and help important systems.

Pros and Cons

Advantages

Top industrial PCB manufacturers give many good things. They help teams talk and work together well. This makes design and building easier for everyone. Companies do not worry about language or time zones. They get answers faster and solve problems quickly. Many manufacturers check quality very carefully. They follow strict rules and make audits simple. Their products last longer and work better.

Supply chain stability is a big plus. Recent studies show more CEOs want to move work back home. They do this because of world problems and to lower risks. Local manufacturers help companies avoid slowdowns and problems. This makes it easier to keep track of parts and products.

Manufacturers also help get products to market faster. They cut down on shipping delays and change quickly for customers. They use smart ways to build and test, which saves money. This also stops recalls from happening. Local manufacturers care about the environment and follow tough rules. Prices are better when hidden costs from delays and bad quality are gone.

Key advantages include:

Careful quality checks and rules

Quick delivery and changes

Strong supply chain

Smart building skills

Following green rules

Good prices

Drawbacks

Even with many good points, top industrial PCB manufacturers have some problems. Cost can be high for some buyers, especially compared to overseas choices. Wait times can get longer if lots of people order or if there are supply chain problems. Manufacturers fix these by working with suppliers early. They plan how much they can make and split big orders to stop slowdowns.

Companies use smart machines and clear tests to keep quality high. This helps them stay reliable and not slow down making products.

Manufacturers handle design changes with clear steps and good talking. They use computers and regular updates to work together better. Following rules takes work, so they plan early for certifications. They make shipping better to stop delays, especially when making things close by.

Common drawbacks and ways to fix them:

Higher starting costs – fixed by saving on hidden costs.

Wait time risks – fixed by planning and flexible schedules.

Supply chain problems – fixed by using more suppliers and keeping extra parts.

Hard rules – fixed by planning ahead for rule checks.

Design changes – fixed by using clear steps for changes.

Top manufacturers always try to get better and work together. This helps them find and fix problems before they reach customers.

Top industrial PCB manufacturers are different because they are great at technology, quality, speed, and special skills.

They use advanced machines like SMT machines and AOI systems to make sure products work well.

They follow strict rules and deliver products quickly, which sets a high standard.

They can make special boards like HDI and multilayer boards for different needs in industrial pcb manufacturing.

People who make choices often:

Want new technology and good quality.

Look for partners who care about the environment and handle risks well.

Picking the best partner means checking these things for long-term success.

FAQ

What certifications do top industrial PCB manufacturers hold?

Most top manufacturers have ISO 9001, UL, and RoHS certifications. These rules help keep products safe and reliable. They also show companies care about the environment. Manufacturers use IPC standards for good design and assembly.

Tip: Always look for certifications before picking a PCB company.

How fast can manufacturers deliver industrial PCBs?

Delivery times can be as quick as 48 hours for prototypes. Big orders may take up to 15 days. U.S. companies ship faster because they make products close by. Asian companies are good at making lots of PCBs quickly.

Order Type | Typical Lead Time |

|---|---|

Prototype | 2–5 days |

Mass Production | 7–15 days |

What industries use industrial PCBs the most?

Industrial PCBs are used in automation, cars, medical devices, and planes. Manufacturers build boards to meet tough rules for each job. These boards help machines, vehicles, and devices work safely.

How do manufacturers ensure product quality?

Manufacturers use automated optical inspection, X-ray checks, and in-circuit tests. Senior managers watch over quality systems. Companies follow IPC and ISO rules to lower mistakes and make products better.

Note: Regular checks and smart tests help keep products high quality.

Can manufacturers customize PCBs for unique environments?

Yes, top manufacturers make special boards for heat, shaking, and wet places. Engineers work with clients to design boards for each need. Picking the right materials and testing helps boards last longer in hard places.

Common custom features:

Thermal management

Shock resistance

Waterproof coatings

See Also

Comparing PCBWay With Other Leading PCB Manufacturers

Choosing The Ideal PCBA Manufacturer For Your Business

Finding The Right PCB Prototype Manufacturer For Projects