In the fast-changing world of electronics, the need for PCB prototyping services has grown a lot. The global market size is about USD 4.8 billion in 2024. This shows how important these services are for new ideas. Fast changes in technology have made product lifecycles shorter. This pushes companies to find better prototyping solutions. As you learn about this area, knowing the details of different PCB prototypes will help you make smart choices in your projects.

Key Takeaways

PCB prototyping helps find design problems early. This saves time and money in product development.

There are four main types of prototypes: visual models, proof of concept, working, and functional prototypes. Each type has a special purpose.

Good communication and clear instructions with your prototyping service help avoid delays and expensive mistakes.

Choosing the right provider means looking at their experience, quality, speed, and customer support.

Regular design testing and changes improve product quality. They also lower risks before mass production.

What are PCB Prototyping Services?

PCB prototyping services are very important for making electronic devices. These services help you create a first version of a printed circuit board (PCB). You can test and check your design before making many copies. Using these services helps you find problems early. This saves time and money later on.

The prototyping process usually has several main steps:

Design Preparation: First, choose the right schematic design software. Create your schematic and make sure all parts connect correctly. Test the circuit to find any problems early.

PCB Layout Design: Place parts in a logical way on the board. Connect electrical parts while following the manufacturer’s rules.

Gerber File Generation: Save and check Gerber files. These files have all the information needed for manufacturing.

Prototyping and Assembly: Send your Gerber files to a manufacturer. When you get the prototype, check it for problems. Put together parts using soldering methods and test the prototype to see if it works.

Iteration and Finalization: After testing, make changes to the design and repeat the prototyping steps if needed. Write down changes and get ready for full production with quality checks.

This step-by-step method helps you improve your design. It makes sure it meets your needs and works well. PCB prototyping services not only improve the quality of your final product but also cut down development time. By allowing quick design changes, these services help you check and improve your designs easily.

PCB Prototype Types

When you start working on PCB development, knowing the different types of prototypes is very important. Each type has its own purpose and helps in the design process. Let’s look at the four main types of PCB prototypes:

Visual Model

A visual model prototype shows the physical parts of the PCB design. It helps you see the size, shape, and where the components go without working. This type is great for the early stages of development. You can use it for design reviews and to check if the layout is what you want.

Tip: Use visual models to find design problems before making more complex prototypes. This early check can save you time and money later.

Proof of Concept

The proof of concept (POC) prototype shows if your design can work. It has some working parts but is not the final product. This type is best when you want to test your design ideas without making a full product.

Here are some common uses for POC prototypes:

Breaking down complex designs into smaller parts.

Finding design problems early to avoid expensive fixes later.

Discovering ways to save money by trying different materials.

POC prototypes are very helpful for startups or projects with tight budgets. They let you improve product details before making a custom PCB design.

Working Prototype

A working prototype is a PCB that works as it should. This prototype lets you test the whole design and find any mistakes before making many copies. By using a working prototype, you can:

Find and fix design mistakes early, avoiding costly errors.

Save time by allowing thorough testing, cutting down on big changes.

Provide a real model that helps others understand the design and how it works.

Working prototypes are key to making sure your PCB meets all needs and works well in real life.

Functional Prototype

The functional prototype is the closest to your final product. It has all features and functions, letting you do complete testing. This prototype checks that your design, assembly, software, and production steps are ready for mass production.

Note: The functional prototype is very important for checking how well your PCB works. It helps you make sure everything functions correctly before you start production.

Benefits of PCB Prototypes

Knowing the benefits of PCB prototypes can really help your product development. Each type of prototype has special advantages. These can make your design work easier and improve results.

Visual Model Advantages

Visual models are very useful in the early stages of PCB development. They let you see the layout and where parts go without needing a working board. This early look helps you:

Find design problems before making more complex prototypes.

Talk with others, leading to better feedback and teamwork.

Save time and money by fixing issues early in the design stage.

A study showed that showing physical prototypes made stakeholders more involved. This led to better feedback than just talking about ideas.

Proof of Concept Advantages

Proof of concept (POC) prototypes are important for checking if your design can work. They help you:

Quickly spot possible problems, saving time and resources.

Improve designs with expert help, reducing risks later on.

Test key features without spending too much on full prototypes.

By checking if parts fit together and meeting rules early, you can avoid expensive changes during production.

Working Prototype Advantages

Working prototypes let you test your PCB in real-life situations. They offer several benefits, such as:

Finding design mistakes early, which stops costly errors in mass production.

A real model that helps explain your design to team members and stakeholders.

The chance to improve your design based on thorough testing, making sure it meets all needs.

This step-by-step process boosts product quality and reliability, leading to a better launch.

Functional Prototype Advantages

Functional prototypes are the closest to your final product. They let you:

Do complete testing of all features and functions.

Make sure your design, assembly, and software are ready for mass production.

Spot any last-minute changes needed before full manufacturing.

By testing your functional prototype well, you can improve reliability and performance. This ensures a smoother move to production.

Common Pitfalls in PCB Prototyping

In PCB prototyping, there are some common mistakes that can mess up your project. Spotting these problems early can help you save time and money.

Miscommunication Issues

Miscommunication can cause big delays and higher costs in PCB projects. Here are some common miscommunication problems you might face:

Not clearly telling apart standard and critical-to-quality (CTQ) items.

Forgetting to talk early about CTQ items like stackup design and material choice.

Not agreeing on panelization and plating/finish details.

Not discussing tolerances and drill sizes enough, which can cause manufacturing issues.

Having different expectations about delivery and lead times.

To reduce these risks, keep communication open from the beginning. Give clear specifications and ask for pre-production reviews. One case showed that an engineer did not specify fiducial needs, causing a one-week delay in production. Such mistakes can lead to defects and expensive rework.

Underestimating Costs

Many teams do not estimate the costs of PCB prototyping correctly. This mistake can happen because they do not understand the whole process. You need to think about all parts, like materials, labor, and possible rework. Not considering these things can lead to going over budget.

To avoid this mistake, make a detailed budget that includes all possible costs. Check and update your budget regularly. This careful planning helps you stay on track with money and makes sure you have enough resources for each step of the prototyping process.

Ignoring Design Iterations

Ignoring design iterations can hurt the quality of your final PCB prototype. Skipping these important steps can leave design errors and lower functionality. The iterative design process helps you improve component placement, signal integrity, and manufacturability through several prototype cycles.

By using feedback from testing, you can boost product quality and reliability. Ignoring this process raises the chance of failure and can lead to higher costs from rework or scrapping during mass production. Always focus on refining your design to ensure good quality and customer satisfaction.

By knowing these common pitfalls, you can handle the PCB prototyping process better and get better results in your projects.

Choosing PCB Prototyping Services

Picking the right PCB prototyping service is very important for your project’s success. Here are some key things to think about to help you choose wisely.

Assessing Your Needs

Before you start searching for a provider, think about what you need. Consider these factors:

Project-specific needs: Figure out if you need high-frequency, multilayer, or flexible boards.

Manufacturer certifications: Look for certifications like ISO 9001, which show quality management.

Production capabilities: Make sure the provider can handle complex designs and quick turnarounds.

Scalability: Check if they can grow production from small runs to mass manufacturing.

Client reviews: Look for positive feedback and case studies that show reliability and quality.

By checking these points, you can match your project needs with the right service provider.

Evaluating Providers

After you know what you need, look at possible providers. Here are some important factors to think about:

Experience and reputation: Pick providers with a good track record and happy customers.

Quality assurance: Make sure they follow industry standards and have strong quality control.

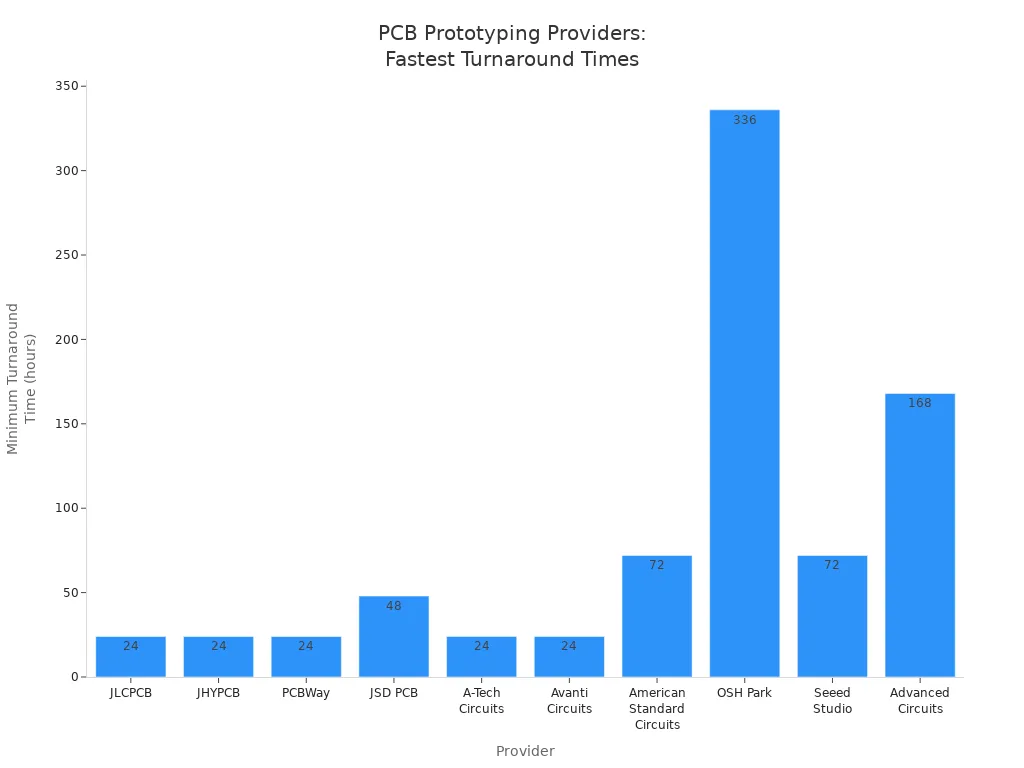

Turnaround time: Check if they can meet your deadlines without lowering quality.

Customer service: Choose providers with helpful support teams that can assist you during the project.

Factor | Description |

|---|---|

Balance pricing with quality; watch out for hidden fees. | |

Delivery and Lead-times | Check the supplier’s ability to meet deadlines and manage logistics well. |

Technical Know-How | Confirm their skills with complex designs and teamwork in solving problems. |

Customer Service | Look for quick responses and clear communication. |

Communication Tips

Good communication is key for working well with your PCB prototyping service. Here are some tips to improve your talks:

Early consultation: Talk to fabricators early to make sure everything can be made.

Regular design reviews: Have frequent reviews to spot issues early.

Clear communication channels: Keep open lines for feedback and updates during the project.

Collaborative design software: Use tools that let you work together on designs in real-time.

By using these communication tips, you can build a strong relationship with your PCB prototyping provider, leading to better results for your project.

In conclusion, PCB prototyping services are very important in making electronics. They help you find design problems early, which saves time and money. Here are some main points:

Good prototyping lowers long-term costs by avoiding costly recalls and redesigns.

Fixing the Bill of Materials (BOM) early can help find cheaper parts without losing quality.

Working prototypes are key for getting investment and support from stakeholders.

By picking the right prototyping partner and using new technologies, you can improve your product development process and encourage new ideas in your projects. Use these services to make sure your designs meet market needs quickly. 🚀

FAQ

What is the typical turnaround time for PCB prototypes?

The time it takes to get PCB prototypes back can change based on the provider and how complex the design is. Usually, you can expect it to take 1 to 2 weeks for standard prototypes. If you need it faster, rush services can cut this down to a few days, but they usually cost more.

How do I choose the right PCB prototyping service?

First, think about what your project needs, like how complex it is and how many you need. Then, look into the providers’ experience, quality checks, and customer reviews. This will help you find a service that fits your needs.

Can I make changes to my PCB design after prototyping?

Yes, you can change your design after prototyping. Use the feedback from testing to improve your design. Making changes helps make sure it works well and is reliable before you start making a lot of them.

What materials are commonly used in PCB prototyping?

Common materials used are FR-4, which is a fiberglass epoxy laminate, and polyimide for flexible circuits. Your choice will depend on what you need it for, how well it should perform, and your budget.

Are there any hidden costs in PCB prototyping?

Yes, there can be hidden costs from design changes, faster shipping, or extra testing. Always ask for a detailed quote and check for any extra charges before starting the project.

See Also

Essential Insights Into PCBA Prototypes And Their Applications

The Importance Of PCBA Prototyping In Electronics Innovation

Key Distinctions Between PCB And PCBA In Manufacturing Electronics

Comparing PCBWay With Other PCB Manufacturers In Depth

Choosing The Ideal PCB Prototype Manufacturer For Your Project