Flexible 3D printed electronics are bringing new ideas to industries. These devices are bendable and work really well, making new things possible. For example, the global market for 3D printed electronics was worth $1.2 billion in 2023. It is expected to grow to $5.8 billion by 2032, increasing by 19.5% each year. This shows how they are changing how products are made and customized. Their ability to fit easily into different designs is changing industries like healthcare, cars, and airplanes.

Key Takeaways

Flexible 3D printed electronics are changing industries with lightweight, custom designs.

These designs improve how products work and make them better.

Healthcare uses these technologies for wearable devices and smart implants.

These tools help doctors monitor patients and give better care.

In cars, flexible electronics make parts lighter and safer.

This makes vehicles more efficient and easier to use.

Eco-friendly materials are being made for flexible electronics.

These materials help the environment while still working well.

Teamwork between industries and research is important for new ideas.

This helps solve problems and improve flexible electronics production.

The Rise of Flexible 3D Printed Electronics

The Evolution of Flexible Electronics

Flexible electronics have improved a lot over the years. At first, the goal was to replace hard materials with bendable ones. This made it possible to create stretchable and flexible devices. Later, better materials like conductive polymers and nanocomposites boosted their performance. New methods, such as additive manufacturing and inkjet printing, sped up progress even more.

Important moments in this journey show how fast things changed. For example:

Year | Milestone Description |

|---|---|

Quantum dots and perovskite nanocrystals improve displays and sensors. | |

2025 | Gallium-based liquid metals allow self-healing circuits under stress. |

N/A | Roll-to-roll (R2R) processing makes large-scale production faster. |

These advancements made flexible electronics more useful and efficient. They are now used in many industries for new purposes.

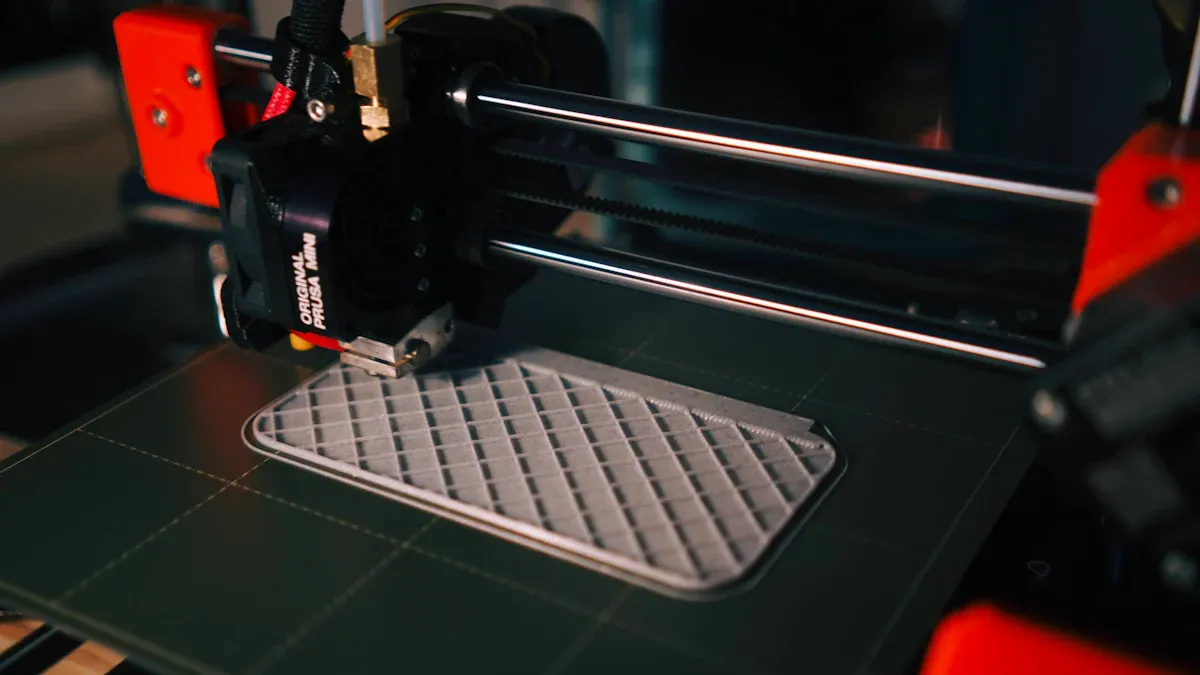

The Role of 3D Printing in Flexible Electronics

3D printing has changed how flexible electronics are made. It allows for detailed designs and easy customization. Unlike older methods, additive manufacturing creates complex shapes with great accuracy. For instance, multi-material 3D printing helps make soft robots and flexible light-up devices that work in tough conditions.

This technology also improves how devices function. Special inks used in 3D printing stick well and make strong, flexible layers. UV crosslinking during printing makes objects stronger and more flexible. These improvements make 3D printed electronics perfect for lightweight and adaptable designs.

Why Flexible 3D Printed Electronics Are Significant Today

Flexible 3D printed electronics are important because they can bend and fit anywhere. They use special inks and materials to create circuits that work in tight spaces. This makes them great for wearable tech, foldable screens, and smart fabrics.

They are lighter and easier to use than traditional electronics. Flexible hybrid electronics mix hard and soft parts for better performance and durability. As people want more portable and multi-use devices, 3D printing becomes even more valuable.

New manufacturing methods, like roll-to-roll processing, make production faster and cheaper. These changes help flexible electronics meet the growing need for lightweight and portable solutions in many industries.

Transforming Industries with Flexible 3D Printed Electronics

Healthcare: Changing Wearable Devices and Smart Implants

Flexible 3D printed electronics are improving healthcare tools like wearables and implants. These devices can track your health as you move. Fitness trackers now predict health problems early, helping with prevention. Smart clothes, like socks that find diabetic foot ulcers, are changing health checks.

Smart implants are another big step forward. Elon Musk’s Neuralink is making implants to treat brain issues. Devices like the Apple Watch track heart rate and oxygen levels. These tools allow doctors to monitor patients remotely, making care easier and faster.

The market for medical wearables could double by 2024, reaching $20 billion. This shows how much people want flexible electronics in healthcare. Flexible hybrid electronics, which mix soft and hard parts, make these devices stronger and better.

Automotive: Improving Lightweight Parts and Sensors

Flexible 3D printed electronics are changing cars by making lighter parts and better sensors. In electric cars, these electronics cut weight and save energy. Flexible sensors can be added to many car parts, improving safety and comfort.

For example, these sensors fit on both inside and outside surfaces. They also work well in tough conditions, perfect for cars.

Metric | Description |

|---|---|

Flexibility | |

Durability | Lasts longer, even with regular use. |

Safety | |

User Experience | Makes cars more user-friendly with smart sensors. |

Flexible electronics are key to making better electric cars. Climate concerns and new rules push this change. Additive manufacturing helps create strong, eco-friendly car parts.

Aerospace: Improving Antennas and Structural Electronics

In aerospace, flexible 3D printed electronics are helping with antennas and smart parts. These new ideas make planes and spacecraft lighter but still powerful.

Flexible antennas bend to fit curved surfaces, sending signals better. Smart parts have sensors built into them, reducing extra equipment.

Metric | Value |

|---|---|

Mass of system components | |

Number of elements in array | 256 |

Size of flexible arrays | 30 × 30 cm² |

Minimum radius of curvature | 23 cm |

Power delivered wirelessly | ~80 mW |

Estimated EIRP | 52.7 dBm |

Simulated directivity | ~31 dBi |

Measured directivity | 26.5 dBi |

Half-power beam-width | Nearly identical to simulation |

Distance for beam focusing | 1.5 m |

These changes make aerospace systems smarter and lighter. Additive manufacturing helps build these parts with great detail. Flexible electronics are leading to better, greener aerospace technology.

Consumer Electronics: Changing Foldable Screens and Personalized Devices

Flexible electronics are changing how we use everyday gadgets. Foldable screens and personalized devices are now part of daily life. Flexible batteries and screens let devices bend and adjust easily.

Foldable screens are a big step forward in display technology. These screens use special OLEDs that fold without breaking. They give users a smooth viewing experience. For example, Samsung’s Galaxy Z Fold sold 2 million units in South Korea in one year. This shows people love these new ideas.

Personalized gadgets are another exciting use of flexible electronics. Imagine a smartwatch that fits your wrist perfectly. Or think of a gaming controller made just for your hands. Flexible sensors make this possible by letting devices match your needs. These sensors also improve how gadgets work. They react to touch, pressure, and even heat.

More people around the world want these technologies. Here’s how different places are using foldable screens and custom gadgets:

Region | Example |

|---|---|

South Korea | Samsung’s Galaxy Z Fold sold 2 million units in one year. |

Japan | AR and VR industries drive demand for flexible tech. |

North America | Consumer interest is growing, with a 30% yearly increase expected until 2030. |

Europe | Tech companies focus on energy-saving flexible OLED screens for sustainability. |

These trends show flexible electronics are popular everywhere. New devices are lighter, stronger, and save energy. Flexible tech also leads to foldable laptops, rollable TVs, and wearable screens.

The future of gadgets is all about being adaptable and personal. Flexible electronics make devices fit your needs and improve your experience. Whether it’s a foldable phone or a custom gadget, these innovations are changing technology for the better.

Future Trends in Flexible 3D Printed Electronics

Stretchable and Biocompatible Electronics

Stretchable and biocompatible electronics are changing how flexible devices are used. These gadgets can bend, stretch, and fit odd shapes. This makes them perfect for wearables and healthcare tools. You’ll see them in smart clothes, medical devices, and human-machine systems. They fit well with the body, making them comfy and easy to use.

The need for these technologies is growing fast. The market will grow a lot in the next ten years. This is because of better tech and more remote health monitoring. New ideas like self-repairing materials and hybrid designs are helping. For example, new printing methods now make stretchable circuits that stay strong and flexible.

Did you know? The COVID-19 pandemic sped up research on stretchable electronics. These are now used for touch-free health checks and remote monitoring. This shows their value in today’s healthcare.

Here’s what’s driving this growth:

Aspect | Details |

|---|---|

Market Growth | Big growth expected soon due to better tech and health device demand. |

Applications | Used in healthcare, gadgets, cars, planes, and more. |

Innovations | New printing methods, hybrid designs, and self-repairing materials allow better designs. |

Future Trends | Widespread use expected from 2025 to 2035 in healthcare, smart clothes, and human-machine tools. |

Unique Advantages | Flexible, durable, and fits many shapes, improving wearables and smart fabrics. |

Stretchable and biocompatible electronics are more than a trend. They’re a big step forward in how we use technology.

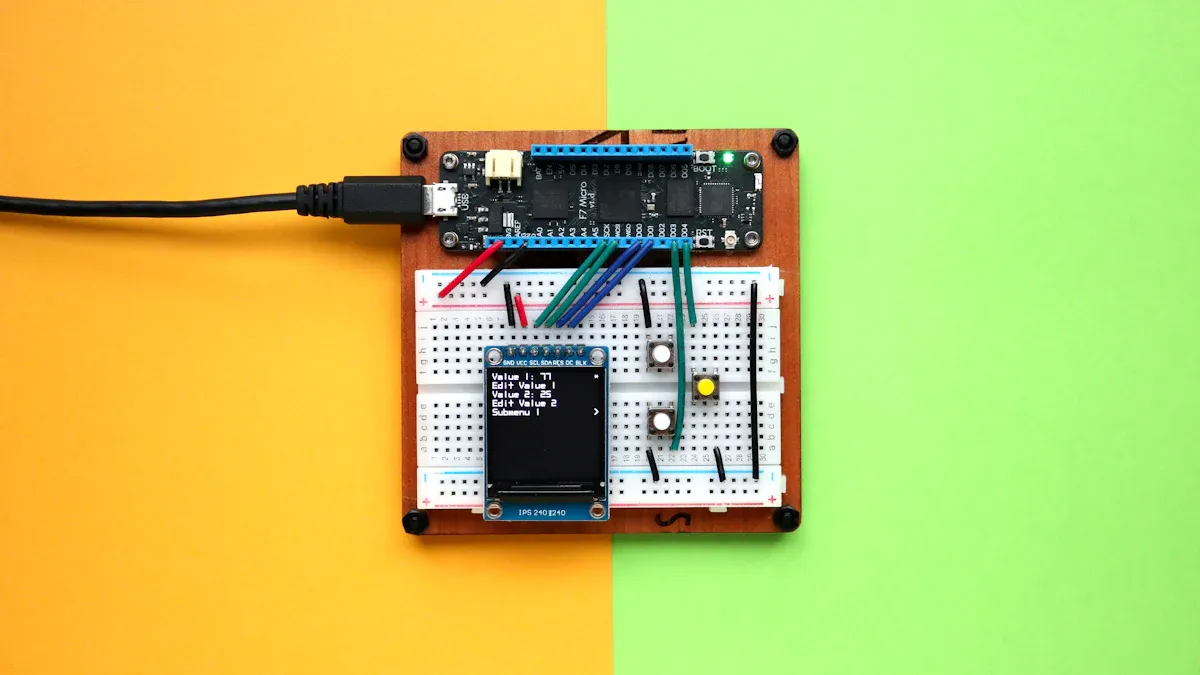

AI and IoT Integration in Printed Flexible Electronics

Adding AI and IoT to printed flexible electronics is changing devices. These tools make systems smarter and more useful. For example, smart socks with deep learning can study your walk. They track activity and even collect energy for IoT uses. These socks help in healthcare, fitness games, and smart homes.

AI makes flexible electronics smarter by analyzing data instantly. IoT connects devices to networks, letting them talk to each other. Imagine a wearable that tracks your health and adjusts your home’s temperature. This is possible now with printed flexible electronics.

These ideas are shaping the future of wearables and smart gadgets. As AI and IoT improve, expect even smarter devices in daily life.

Advancements in Sustainable and High-Performance Materials

Sustainability is key to the future of flexible electronics. Scientists are making materials that work well and are eco-friendly. For instance, biodegradable papers are used to make flexible electronics. These materials work like regular ones but are better for the planet.

Research Insight: A study shows starch-based films could be used in printed electronics. These films are cheap and biodegradable. But it’s still hard to make them work well for printing.

The push for green electronics is growing as industries go eco-friendly. High-tech materials like nano-copper paste and special resins are leading the way. These materials make flexible electronics stronger and better while being kind to the environment.

Here’s how new materials are shaping the future:

Bioprinting improvements: New materials help make flexible electronics that work with human tissue.

Eco-friendly focus: Scientists are creating materials that balance performance and sustainability.

Uses: From healthcare to gadgets, green materials are being used everywhere.

Sustainability isn’t just about cutting waste. It’s about blending technology with nature. By using eco-friendly materials, we can build a greener and smarter future.

Mass Customization and Localized Manufacturing

Mass customization and localized manufacturing are changing how things are made. Flexible 3D printed electronics help by making custom products quickly and easily. Now, you can get items made just for you without losing quality or spending too much.

The Power of Mass Customization

Mass customization lets companies make unique items for each person. They still keep the speed and cost benefits of mass production. Flexible electronics make this possible because they can fit many designs. For example, wearables can now be shaped to fit your body better. This makes them more comfortable and useful. People love this because it gives them a personal touch.

Here are some benefits of mass customization with flexible electronics:

Better User Experience: Custom products are easier to use and more enjoyable.

Higher Willingness to Pay: People often pay more for items made just for them.

Smart Production: New tools allow small batches to be made efficiently.

Localized Manufacturing: A Big Change

Localized manufacturing means making products closer to where people live. This saves money on shipping, speeds up delivery, and helps the environment. Flexible 3D printed electronics work well in these setups. They use special materials and methods that are easier to handle locally.

Did you know? Localized manufacturing helps combine flexible electronics with IoT. This creates smart devices for industries like healthcare and cars.

Solving Production Challenges

Making flexible electronics on a large scale isn’t easy. Special materials and methods can cost more. Meeting high demand also needs creative solutions. But new digital tools and hybrid systems are solving these problems.

Problem | Solution |

|---|---|

High Costs | People are willing to pay more for custom products. |

Scaling Up | Flexible systems handle changes without slowing down. |

Special Materials Needed | Digital tools make small-batch production simple and fast. |

The Future of Manufacturing

The future combines mass customization with localized manufacturing. This meets the need for personal products while staying eco-friendly. As technology improves, expect smarter, faster, and greener solutions.

Flexible 3D printed electronics are leading this change. They make it possible to create products just for you. This is a big step forward for industries, opening up endless new ideas and opportunities.

Challenges and Opportunities in Flexible 3D Printed Electronics

Solving Production and Cost Problems

Making more flexible electronics is hard and costs a lot. Special materials and advanced methods make production expensive. For example, mixing aerosol jet printing with laser sintering improves devices but raises costs. Companies are fixing this by combining steps into one system. Using stereolithography with conductive inkjet printing saves time and makes circuits faster.

Producing electronics near customers is another solution. This cuts shipping costs and helps the planet by using less energy. It also reduces waste, making production more eco-friendly. As people want lighter and portable devices, these ideas will make flexible electronics cheaper and easier to get.

Fixing Rules and Standards Issues

Flexible electronics are growing fast, but rules haven’t kept up. Without clear standards, it’s hard to make safe and high-quality products. Countries like China are working on rules for testing and safety checks. These rules focus on risks, especially for medical devices made with 3D printing.

Groups are teaming up to create global rules. For example, IPC and NIST are helping set guidelines for flexible electronics. They’re working on things like testing how long products last and measuring conductive layers. Following these rules will make sure products are safe and work well.

Growing Markets and Teaming Up Across Industries

Flexible electronics have big chances to grow. More people want portable and eco-friendly devices, opening doors for teamwork between industries. Studies show:

Source | Key Insights |

|---|---|

SNS Insider | Lightweight devices boost growth and encourage teamwork. |

Cognitive Market Research | Growth creates chances for new partnerships and markets. |

Markets and Markets | New technology brings exciting opportunities for collaboration. |

Industries like healthcare, cars, and gadgets can work together. For example, adding sensors to smart clothes or wearable devices creates new ideas. By teaming up, industries can make cool products and help the planet at the same time.

Driving Innovation Through Research and Development

Research and development (R&D) are key to improving flexible 3D printed electronics. Investing in R&D helps create new ideas and change industries. It focuses on better materials, smarter production, and exciting new uses.

Key Areas of R&D in Flexible Electronics

Material Innovation:

Scientists are making better materials for flexible electronics. For example, conductive inks with tiny particles improve how electricity flows. These materials make devices stronger and more efficient.Advanced Manufacturing Techniques:

R&D works on improving how products are made. Methods like multi-material 3D printing allow for detailed designs. These techniques also cut waste and are better for the environment.Exploring New Applications:

Flexible electronics can be used in many new ways. For instance, stretchable sensors help prosthetics, and foldable solar panels work in space. These ideas show how R&D solves real-world problems.

Tip: Keep learning about new R&D trends. Reading reports and studies can show you new opportunities.

Benefits of Investing in R&D

Faster Innovation: New products and ideas are developed quicker.

Competitive Edge: Companies that focus on R&D often lead their fields.

Eco-Friendly Solutions: Research helps create greener technologies for the planet.

Focusing on R&D helps grow flexible 3D printed electronics. It drives new ideas and ensures success in a fast-changing world.

The Path Forward for Flexible 3D Printed Electronics

How Businesses Can Use Flexible Electronics

Using flexible electronics needs a clear plan. Companies should match their goals with proven methods to succeed. For example, the Balanced Scorecard links business tasks to the company’s vision. McKinsey’s Strategic Horizons helps balance short-term and long-term growth. These tools guide businesses to mix new ideas with practical choices.

Framework Name | What It Does |

|---|---|

Balanced Scorecard | Connects daily work to the company’s goals and vision. |

McKinsey’s Strategic Horizons | Helps plan for both quick wins and future growth. |

Value Disciplines | Focuses on giving customers special value in a niche market. |

Stakeholder Theory | Highlights the role of all stakeholders in decision-making. |

Businesses should also focus on what customers want. Flexible electronics, like wearables, allow for custom-made products. By offering value and staying creative, companies can lead in this fast-changing market.

Working Together to Create New Ideas

Teamwork is key to improving flexible electronics. Companies can join forces with schools, startups, or even rivals to share ideas and tools. These partnerships help test new uses and make current technologies better.

For instance, working with universities gives access to advanced research. Partnering with startups lets companies try new ideas quickly. Together, they can cut costs and launch products faster. Partnerships also bring chances to use flexible electronics in areas like healthcare or cars.

Tip: Choose partners who share your goals. Good teamwork can lead to amazing breakthroughs.

Preparing for Success with Skilled People and Tools

To succeed with flexible electronics, companies need trained workers and modern tools. Hiring experts in materials, 3D printing, and electronics design keeps businesses competitive. Training current staff in these skills also helps.

Having the right equipment matters too. Investing in top-quality 3D printers and eco-friendly materials ensures better products. Local factories can lower costs and speed up delivery. These steps improve operations and make companies leaders in the field.

Note: Strong investments today help businesses face future challenges and opportunities.

Flexible 3D printed electronics are changing industries with amazing uses. They are helping areas like healthcare and aerospace with new ideas. The market for printed sensors may grow to $4.5 billion by 2030. This is because of better biosensors, temperature sensors, and image sensors. These changes show how useful they can be in many fields.

Using flexible 3D printed electronics now can keep you ahead. They support sustainability and allow for custom designs. These technologies bring smarter, lighter, and better solutions. They are shaping a future full of connected and creative possibilities.

FAQ

What are flexible 3D printed electronics?

Flexible 3D printed electronics are bendable gadgets made with special 3D printing. They use soft materials and conductive inks to create light circuits. These are found in wearables, foldable screens, and medical tools.

How do flexible 3D printed electronics benefit industries?

They help industries make light, custom, and energy-saving products. For example, they improve health trackers, foldable devices, and car sensors. Their flexibility works well for creative designs in many fields.

Are flexible 3D printed electronics eco-friendly?

Yes, many use green materials like biodegradable bases and energy-saving methods. These reduce waste and support eco-friendly production, helping global green goals.

Can flexible electronics replace traditional electronics?

Flexible electronics work with traditional ones but don’t fully replace them. They are great for light, bendable designs, while traditional ones suit rigid, high-power needs.

What challenges do flexible 3D printed electronics face?

Making more, cutting costs, and meeting rules are big challenges. But better materials, new methods, and teamwork are solving these problems.

See Also

Exploring the Benefits and Drawbacks of Flex PCBA Today

The Importance of Tailored PCBA Production in Today’s Electronics

Emerging Innovations in PCB and PCBA Design for Tomorrow