Electronics projects are always getting better. You need good pcb prototyping. More and more tools for electronics prototyping are being made.

Picking the right pcb prototyping board is very important. It helps your electronics project work well. It saves money. It also helps you learn about PCB designs. This guide looks at the 10 best pcb prototyping boards for 2025. You will find boards that are easy to use. They are also not too expensive. They work for many different electronics projects.

Key Takeaways

Picking the right PCB prototyping board is key. It makes your electronics project work. It also saves you money.

Different boards meet different needs. Breadboards are for quick tests. Perfboards and custom PCBs are for final products.

Think about the material. Think about the number of layers. Consider the cost. Also, think about the timeline. These choices change how much you spend. They also change how fast your project finishes.

Your skill level is important. Your future plans for the project also matter. Beginners can use breadboards. Custom services help with hard designs. These are for making many products.

Understanding PCB Prototyping Boards

What Are PCB Prototyping Boards

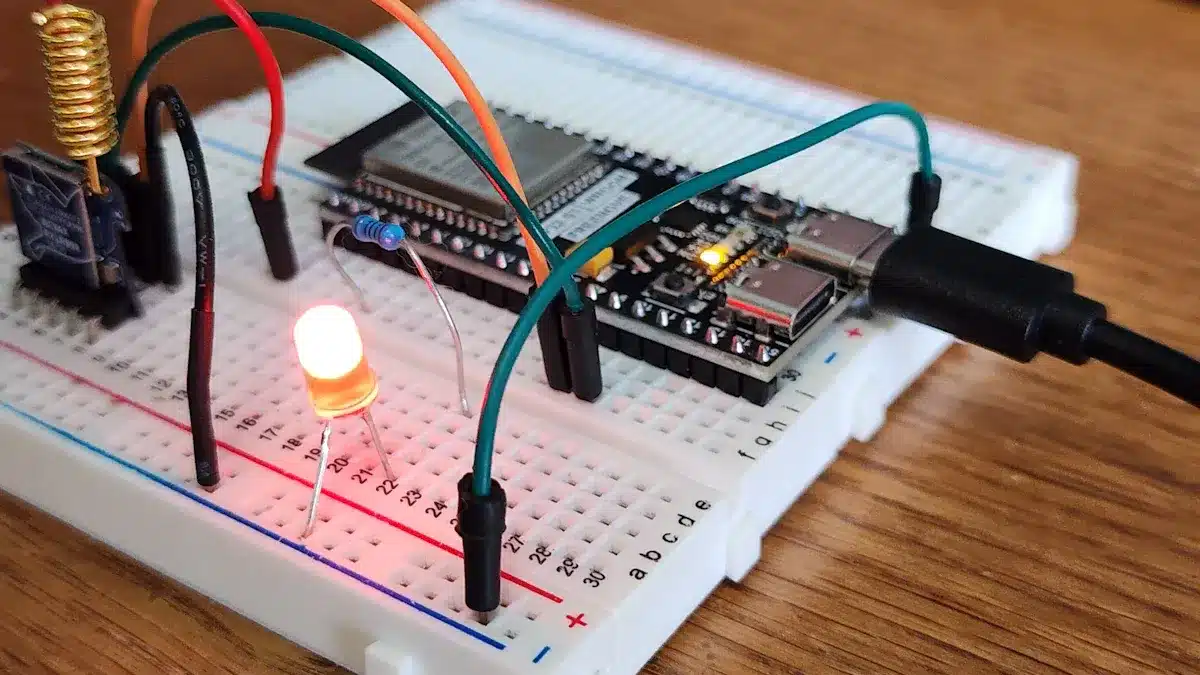

You use a pcb prototyping board to test your electronics designs. These boards help you build circuits. You can check them before making a final printed circuit board. Different types of boards exist. For example, breadboards are great for quick tests. They do not need soldering. But breadboards have limits. They are not good for complex designs. They are also not good for high voltage. It is hard to map out intricate designs on them. This can cause problems later.

Breadboard | Perfboard | Stripboard | |

|---|---|---|---|

Attachment | Solderless (reusable) | Solder | Solder |

Connectivity | Spring clips | Individual holes | Parallel copper strips |

Material | Plastic | Thin sheet with holes | Insulating material |

Flexibility | Good for temporary testing | More freedom | Low cost, faster building |

Complexity | Simple to high-level circuits | Custom connections | Simplifies wiring |

You also have many types of actual PCBs:

Single-sided PCBs: These have one layer of conducting material. Components are on the other side. They are the oldest and simplest type.

Double-sided PCBs: These allow copper and components on both sides. You can make more complex designs.

Flexible PCBs: These use flexible plastic. They fit into small or curved spaces.

Rigid-Flex PCBs: These combine flexible and rigid parts. You can fold or flex them.

HDI PCBs: These offer very dense circuits. They have smaller holes and pads.

LED PCBs: These are for lighting modules. LEDs mount directly onto them.

Why Board Selection Matters

Choosing the right board is very important. It affects how fast you finish. It also affects how much money you spend. For example, using a single panel saves money. It has many identical prototype boards. It reduces labor costs. Assembling 12 boards on one panel is cheaper. It costs less per unit. This method also makes handling easier. Testing is also easier. You can test many boards at once. This speeds up your development. It also lowers errors.

Board selection also impacts your project timeline. It impacts costs. Board size, layer count, and material choice affect expenses. Larger boards mean more materials. More layers mean more materials. They also mean more manufacturing steps. This increases costs. A small 2-layer pcb might cost $5. A larger one could be $40 or more. Going from 2-layer to 4-layer boards can double costs. It can even triple them. You can save money. Make your board smaller. Use fewer layers. Choose materials like FR-4. This can cut prototyping costs by up to 50%. But faster delivery times cost more. You must balance speed and budget.

Key Factors for Choosing a Board

When you pick a pcb for your electronics project, consider several key factors.

Material Selection: The material you choose affects performance. It also affects cost. Materials like FR4, polyimide, or Rogers have different properties. They can increase expenses.

Layer Count: More layers improve signal quality. But they add complexity. They add cost to manufacturing.

Cost and Timeline: You must balance cost and time. Complex designs will cost more. Needing a fast turnaround will cost more. Plan your budget carefully. Plan your timeline carefully. This helps you use resources well. It also helps you avoid delays.

When your project needs a professional touch, custom pcb services are the answer. These services turn your design into a finished pcb. You get compact, reliable, and repeatable boards. This is crucial for final product prototypes or small-batch production.

Many companies offer these services. JLCPCB, PCBWay, and OSH Park are popular choices. For quick-turn PCB prototype manufacturing, you can also look at us-based pcb manufacturers. Advanced Circuits and Sierra Circuits are top pcb manufacturers in usa. Foxtronics EMS also offers us-based pcb manufacturers services for fast-turn PCB prototyping. Pentalogix provides us-based pcb manufacturers with less restrictive design rules for quick-turn prototypes. PCBWay also offers quick turn time PCB prototyping.

The cost for a custom pcb varies. Simple two-layer boards might cost $50 to $200. More complex multilayer boards can range from $300 to $1000. Turnaround times are usually 2 to 10 business days. Rush orders can be as fast as 24 hours. Standard orders might take 10-15 business days. These top pcb manufacturers in usa offer various service levels. Basic PCB fabrication costs $50 to $500. Rapid PCB prototyping for urgent projects ranges from $100 to $1,000. PCB prototypes with assembly can cost $200 to $2,000 or more. Choosing us-based pcb manufacturers often means reliable service. These top pcb manufacturers in usa help validate your designs quickly.

Picking the Right PCB Prototyping Board

Matching Board to Project Needs

Your board choice must fit your project. Some electronics need special materials. This is true for high-frequency signals. Regular FR4 materials are not enough. You need special ones. Examples are Rogers 4000 series. Others are Isola Tachyon or Panasonic Megtron. These materials have low dielectric loss. They also have controlled impedance. This makes sure signals travel well. A steady and small Dielectric Constant (Dk) is key. It stops signal delays. A small dissipation factor (DF) also helps. It keeps the signal speed good. You must also control impedance. This means careful design. Traces and ground planes are important. This is vital for your pcb.

Budget and Reusability

Think about your money. Also, think about reusing your board. Ready-made boards cost less at first. They are good for quick checks. They are also good for small electronics projects. Custom boards cost more to design at first. These are called NRE costs. They can be from $5,000 to $150,000. But, each unit costs less later. This is for mass production. A custom design saves money. This is true if you make many units.

Criteria | Custom Board | Off-the-shelf Board |

|---|---|---|

Budget | Higher upfront | Lower upfront |

Timeline | Flexible/long-term | Need it fast |

Volume | High-volume | Low-volume or test market |

Cost | Higher upfront design, lower per-unit at scale | Lower upfront, higher per-unit over time |

Skill Level and Learning Curve

Your skill level helps you choose. Beginners can start with breadboards. They are easy to use. Harder electronics projects might need other boards. These include universal pcb prototyping boards. FPGA development boards are another option. These need more experience. They give you more control.

Future Scalability and Production

Think about your project’s future. How will it grow for production? Your prototyping board choice matters. It helps you check designs early. You can test parts. You can make changes. This gets your product to market faster. It also lowers costs later. Finding and fixing problems early saves money. It stops delays in making many products. Using one company for both steps helps. It makes talking easier. It keeps quality the same. This means faster final pcbs.

Choosing the right PCB prototyping board is very important. It helps your electronics project. You learned about many different boards. Each board works for different projects. Think about what your project needs. Think about your money. Think about what you can do. This smart choice helps you create new things faster. It makes your ideas real.

FAQ

What is the best PCB prototyping board for beginners?

Start with a breadboard. It needs no soldering. You can connect parts fast. You can disconnect parts fast. This helps you learn easily. You can test ideas quickly.

When should you use custom PCB prototype services?

Use custom services for hard designs. They are good for final product tests. Custom boards are strong. They are also small. They are key for small-batch making.

Can you reuse PCB prototyping boards?

Yes, you can reuse some boards.

Breadboards are fully reusable. Just pull out parts.

Perfboards and stripboards are less reusable. You solder parts onto them. Taking solder off is hard.

How do you choose between a breadboard and a perfboard?

Use a breadboard for quick tests. It uses no solder. Choose a perfboard for lasting circuits. You solder parts onto it. Perfboards are stronger than breadboards.

Tip: Breadboards are great for first ideas. Perfboards are better for a stronger test model.

See Also

Streamlined Rapid PCBA: Accelerating Your Electronic Project Development with Ease

The Indispensable Role of PCBA Prototyping in Driving Electronic Innovation Forward

Exploring Flexible PCBA: Key Advantages and Hurdles in Contemporary Electronics

Essential Insights: Understanding PCBA Prototypes and Their Diverse Practical Applications

Mastering PCBA Assembly: Ten Expert Tips for Efficiency and Cost Savings

good