Mastering flex and rigid-flex PCBA manufacturing is very important now. These technologies help create smaller, lighter, and better devices. Flexible PCBs use only 10% of the space and weight of regular rigid boards. Smaller size makes assembly easier, cuts material costs, and reduces mistakes. Flex circuits also remove wire routing problems, saving time during testing and fixing. Using these new methods gives you better quality and reliability while keeping costs low.

Key Takeaways

Flex and rigid-flex PCBs are lightweight and save space. They help make devices smaller and easier to put together.

Picking the right materials is important for good performance. Flexible materials like polyimide are great for bending parts.

Testing and making prototypes help ensure good quality. Early checks find problems and save money.

Using quality control steps lowers mistakes and gains customer trust.

Using new tech like automation and green methods improves efficiency and helps the environment.

Understanding Flex and Rigid-Flex PCBs

What Are Flex and Rigid-Flex PCBs?

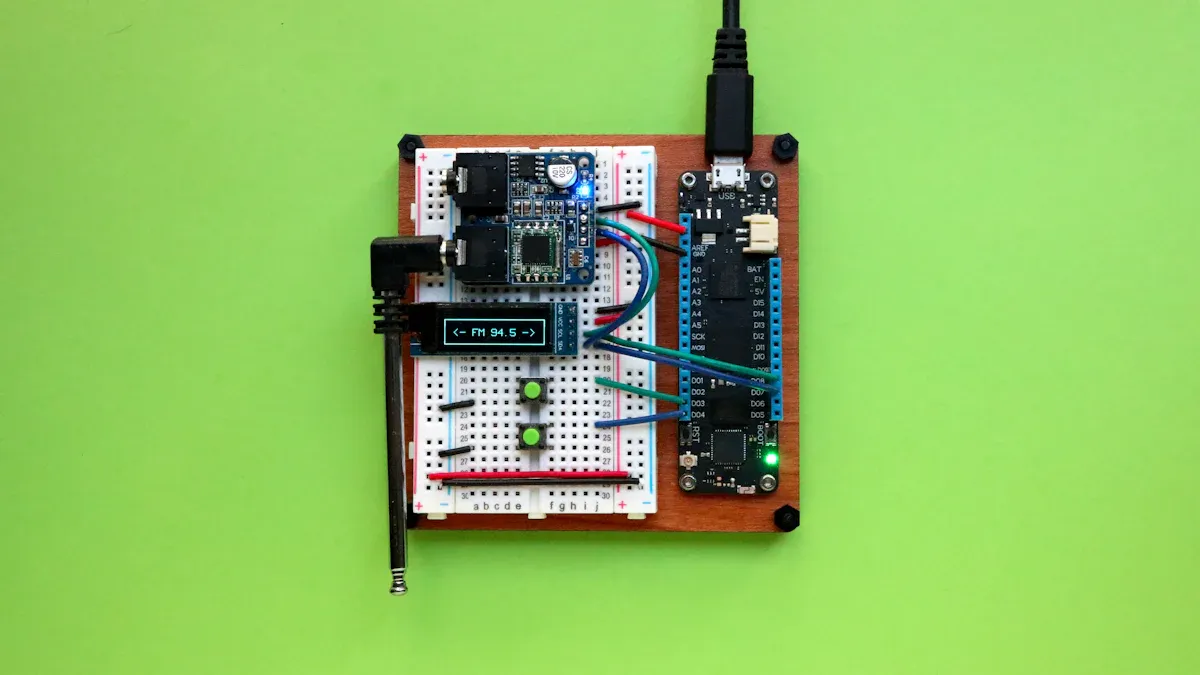

Flex and rigid-flex PCBs are key parts of modern gadgets. Flex PCBs are made from bendable materials like polyimide (PI) or polyester (PET). This lets the whole board bend to fit tight spaces. Rigid-flex PCBs mix stiff materials, like FR4, with flexible layers. These designs let some parts bend while keeping other parts strong.

Type | Materials Used | How It Bends |

|---|---|---|

Flex PCB | Uses flexible materials like PI and PET | The whole board can bend |

Rigid-Flex PCB | Combines stiff (FR4) and flexible materials | Only certain parts with flexible layers can bend |

Rigid-flex PCBs are like a mix of rigid and flexible boards. They can fold or bend often without losing their performance.

Where Are Flex and Rigid-Flex PCBs Used?

Flex and rigid-flex PCBs are used in many industries. They are light and strong, making them great for creative designs. Here are some examples:

Medical Devices: Used in small, reliable tools like pacemakers and scanners.

Wearable Tech: Found in smartwatches and fitness bands for compact designs.

Automotive Systems: Used in car safety systems like ADAS for durability.

Aerospace Technology: Perfect for lightweight designs in satellites and planes.

IoT Devices: Needed for smart home gadgets to stay connected.

These uses show how flexible PCBs help make advanced products.

Why Choose Rigid-Flex PCB Designs?

Rigid-flex PCB designs have many benefits over regular rigid PCBs. They give more space by letting traces go in different directions. This helps make devices smaller by fitting more parts in less space.

Benefit | What It Does |

|---|---|

More layout space | Flex layers allow 3D designs and routing in different directions. |

Better reliability | Handles vibration, shock, and bending; flex layers absorb the stress. |

Smaller designs | Folding lets you fit more parts in tiny spaces. |

Fewer components | Flex layers replace connectors and cables between rigid PCBs. |

Flexible design options | Rigid and flex parts can be shaped for specific needs. |

Faster speeds | High-speed signals can pass through both rigid and flex sections. |

These features make rigid-flex PCBs a top choice for industries needing strong and high-performing designs. Using advanced methods, you can create affordable and long-lasting solutions.

Key Steps in Flex and Rigid-Flex PCBA Manufacturing

Material Selection and Preparation

Picking the right materials is key for making good PCBs. Think about cost, strength, and how they work with the process. Flexible materials like polyimide (PI) are great for bending parts. Rigid sections often use FR-4 for strength. Each material must handle heat or bending based on its job.

Factor | Cost Effect | Things to Think About |

|---|---|---|

Board Size | Keep size small but still functional. | |

Board Thickness | Thicker boards cost more. | Pick thickness based on what the device needs. |

Material Type | Special materials cost extra. | Use FR-4 for rigid parts, PI for flexible ones. |

Number of Layers | More layers mean higher costs. | Simple designs save money. |

Surface Finish | Changes performance and price. | ENIG is reliable but pricier than HASL. |

Good material choices help boards work well and stay affordable. Materials must be cleaned to remove dirt before use. This step helps make strong connections during production.

Design Considerations for Flex-Rigid PCB Manufacturing

Smart design is important for making strong flex-rigid PCBs. Focus on bend radius, material fit, and ease of making. A good design reduces stress on flexible parts and avoids damage from bending.

Material Selection: Pick materials that match for both rigid and flexible parts. They should handle heat and last long.

Bend Radius: Keep the bend radius at least 10 times the flexible layer’s thickness. This stops cracks or peeling.

Design for Manufacturability (DFM): Work with your manufacturer early. Match your design to their tools to avoid problems.

Following these tips helps you make a PCB that works well and saves money.

Prototyping and Testing for Quality Assurance

Prototyping helps test designs before making lots of PCBs. It finds problems early and ensures the design works. Use advanced tests to check reliability.

Testing Method | What It Does | Why It’s Important |

|---|---|---|

Automated Optical Inspection (AOI) | Great for quick production checks. | |

Automated X-Ray Inspection (AXI) | Finds hidden issues in solder joints. | Needed for complex boards in cars or planes. |

Functional Testing (FCT) | Tests if parts work in real-life conditions. | Makes sure everything works before shipping. |

Environmental Testing | Checks how it performs in tough conditions. | Important for cars and aerospace uses. |

Also, have a strong quality program. Do checks before, during, and after making the boards. These steps make sure your PCB is high-quality and reliable.

Production and Assembly Techniques

Making rigid-flex PCBs needs care and accuracy. Each step is important to make sure the boards work well and meet quality standards.

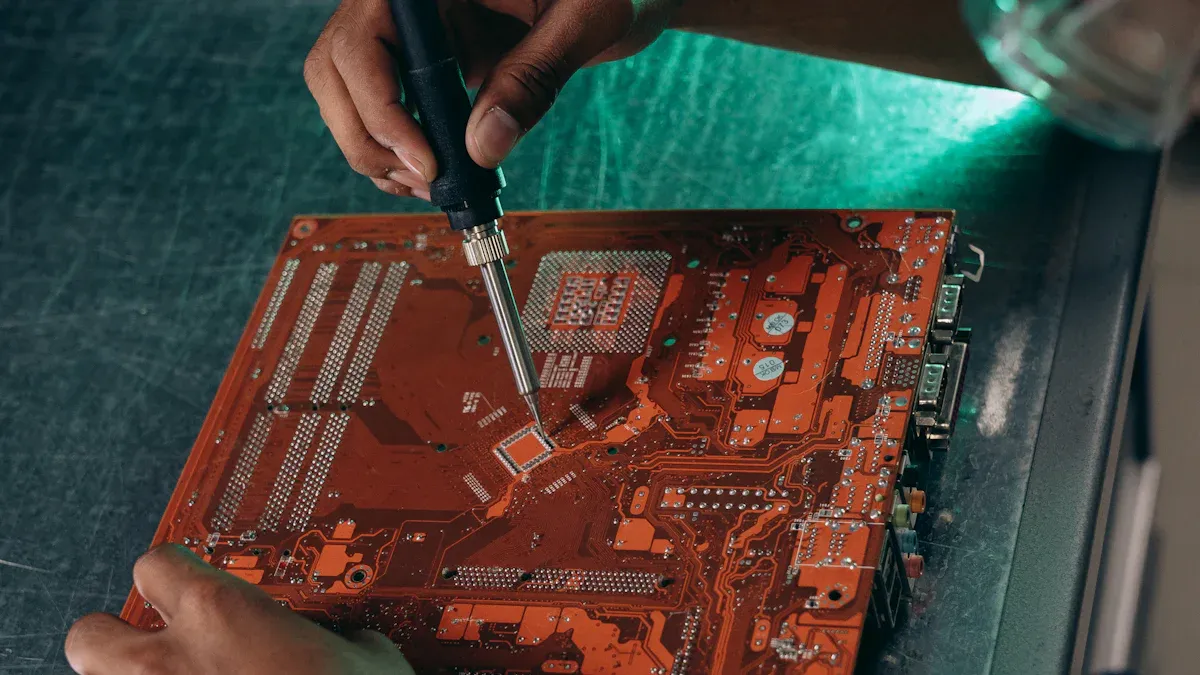

1. Layer Stacking and Lamination

Rigid and flexible layers must be stacked carefully. Misaligned layers can cause problems. Heat and pressure are used to bond the layers together. This process, called lamination, makes the board strong. Using machines for lamination helps avoid mistakes and improves precision.

2. Drilling and Plating

Holes are drilled to connect the layers electrically. Flexible parts need special drilling, like laser drilling, for accuracy. After drilling, a metal layer is added to the holes. This plating step ensures electricity flows properly through the board.

3. Circuit Patterning

The circuit design is added to the board in this step. A light-sensitive material is applied, and light is used to create the pattern. This process, called photolithography, forms the tiny paths for electricity. Clean workspaces are needed to get good results.

4. Component Placement and Soldering

Parts are placed on the board with great care. Machines called pick-and-place systems do this quickly and accurately. Soldering attaches the parts to the board. Reflow soldering is often used because it makes strong connections. Watching the soldering process closely helps avoid problems.

5. Testing and Inspection

Testing checks if the board works correctly. Automated optical inspection (AOI) finds visible issues. Functional testing makes sure the board performs as it should. These tests catch problems early and prevent failures later.

Best Practices for Production and Assembly

To make great rigid-flex PCBs, follow these tips:

Work Efficiently: Cut waste and improve productivity with smart methods.

Use New Tools: Try advanced machines and technology for better results.

Keep Improving: Always look for ways to do things better.

Make Customers Happy: Deliver good products on time to meet their needs.

By following these steps and tips, you can make strong and reliable rigid-flex PCBs.

Best Practices for Flex and Rigid-Flex PCBA Manufacturing

Ensuring Quality Control Throughout the Process

Quality control is very important in making flex and rigid-flex PCBs. It helps products work well and meet high standards. Using smart methods can lower mistakes and make work faster.

Poka-Yoke: Use tools that stop errors during production. For example, design tools that only let parts fit the right way.

Standardized Work: Write down each step of the process. This keeps things consistent and avoids differences between batches.

Continuous Improvement (CI): Ask your team to find ways to improve. Small fixes can make big changes over time.

Six Sigma: Use data to find and fix problems. This method aims for nearly perfect results.

Lean Manufacturing Principles: Remove waste and extra steps. This saves time and materials.

These practices help keep quality high during production. Good quality control reduces mistakes and builds trust with customers.

Managing Costs Without Sacrificing Performance

Keeping costs low while making good products is important. Smart strategies can save money and avoid waste.

Strategy | How It Helps |

|---|---|

Material Selection | CEM materials cost less and work well. Picking the right materials avoids expensive problems. |

Production Automation | Machines cut labor costs and work faster. Automation improves efficiency and saves money. |

Quality Control Measures | Catching problems early saves money on fixing mistakes. |

Choose materials that are strong but not too expensive. For example, CEM materials cost less but still work well. Use machines to do repetitive tasks quickly and accurately. This lowers labor costs and speeds up production. Also, check for problems early to avoid costly fixes later. These steps help balance cost and performance.

Avoiding Common Design and Manufacturing Errors

Mistakes in design or production can cause delays and bad products. Knowing common errors helps you avoid them and improve your process.

Type of Error | What Happens |

|---|---|

Parts in the wrong spot can cause problems. | |

Routing Errors | Bad signal paths can lead to malfunctions. |

Power Distribution Errors | Too much power or uneven voltage can damage the board. |

Thermal Management Errors | Poor heat control can overheat and harm the board. |

To avoid these problems, place parts carefully. Use machines to make sure parts are in the right spot. Plan signal paths well to prevent short circuits. Check power needs to avoid overloading. Use heat sinks or special holes to control heat. Fixing these issues makes boards stronger and more reliable. This saves time and money while making better products.

Challenges and Solutions in Flex and Rigid-Flex PCB Manufacturing

Solving Material and Design Problems

Material and design issues can affect how well rigid flex PCBs work. Fix these problems early to make sure they last longer. Flexible PCBs may have ZIF connection problems due to bad designs or mistakes in production. These problems can cause devices to stop working or fail completely. To prevent this, test the circuit designs carefully and check alignment during assembly.

Heat and physical stress can also damage microvias. These stresses might cause cracks or layers to separate. Choose materials that can handle tough conditions. For example, testing shows that picking the right materials and settings improves durability. Always follow bend radius rules to stop copper from cracking or hardening.

Tip: Work with your manufacturer early to match your design to their tools. This lowers mistakes and improves the quality of your rigid flex PCB.

Handling Production and Assembly Challenges

Making rigid flex PCBs is a detailed process that needs accuracy. If layers are not aligned during bonding, the board may not work. High accuracy is key to avoiding these problems. Skilled workers and special tools are needed for complex designs.

Challenge | What It Means |

|---|---|

Complex Manufacturing Steps | Joining flexible and rigid layers takes careful work. |

Need for Precision | Misaligned parts can cause problems during assembly. |

High Material Costs | Special materials and tools make production more expensive. |

Longer Production Time | Making rigid flex PCBs takes more time than regular rigid boards. |

To fix these issues, use strong quality checks. Smart designs, like good layer stacking and circuit layouts, can make things easier. Using automated machines can also improve accuracy and reduce mistakes.

Making Rigid Flex PCBs Strong for Tough Conditions

Rigid flex PCBs often work in extreme places, like very hot or wet areas. To make them last, pick the right materials and test them well. For example, materials should meet V-0 flammability ratings to stay safe from fire risks.

Important Factor | What It Does |

|---|---|

V-Rating | Rates how fire-safe the material is; V-0 is required for safety. |

Max Operating Temperature | Shows the highest temperature the board can handle without failing. |

Comparative Tracking Index (CTI) | Tests how well the material resists electrical damage in tough conditions. |

Good heat control is also important to stop overheating. Use heat sinks or thermal vias to spread heat away from the board. Testing during the prototype stage can find weak spots and make sure the board works well under stress.

Note: Regular checks and maintenance can help your rigid flex PCB last longer, even in tough environments.

Innovations in Flex and Rigid-Flex PCBA Manufacturing

New Trends in Flex-Rigid PCB Production

The way we make rigid-flex PCBs is changing fast. Companies are using new ideas to create smaller and better devices. Here are some exciting updates in the industry:

Advanced Materials: Special materials like Teflon and Rogers 4000 are used for military tools. They improve signal quality.

Smaller Designs: Tiny designs with more parts fit into less space.

Robots and Automation: Machines work faster and make fewer mistakes.

AI Technology: AI helps save money and makes better decisions.

IoT Growth: IoT devices need strong and energy-saving PCBs.

Cybersecurity Focus: Protecting PCBs from hackers is now a big priority.

Better Testing: New tests find problems early, ensuring great quality.

These changes show why keeping up with new tech is so important in flex-rigid PCB production.

Using Smart Tech in PCB Manufacturing

Automation is making rigid-flex PCB production faster and smarter. Tools like AI and robots are improving how things are made. For example:

Machines like AOI systems find mistakes quickly and accurately.

AI predicts when machines need fixing, saving time.

Live monitoring keeps the assembly process running smoothly.

Technology | How It Helps |

|---|---|

Faster Methods | Speeds up production and increases output. |

Robots | Finds mistakes and reduces waste. |

AI Systems | Cuts costs and makes assembly more efficient. |

Adding these tools improves quality and meets the needs of today’s electronics.

Eco-Friendly PCB Manufacturing

Making rigid-flex PCBs is becoming more eco-friendly. Companies are using green methods to help the planet. Here are some ways they’re doing it:

Green Practice | How It Helps the Environment |

|---|---|

Lowers harmful gas emissions by 70%. | |

Additive manufacturing | Cuts material waste by 40%. |

Easy-to-take-apart designs | Lets 90% of parts be reused. |

Recycling materials | Uses 60% less raw material. |

These steps not only help the Earth but also save money. By going green, companies can make great products while protecting the planet.

Learning how to make flex and rigid-flex PCBs needs key steps. Designing PCBs smartly helps make them faster and cheaper. Using panels wisely saves materials, and picking a good maker saves money and time. Solving problems like material limits and using new ideas like robots and green methods keeps you ahead in the market.

By using these tips, you can make better PCBs, improve quality, and meet industry needs. Start using these ideas now to get better results in your work.

FAQ

What is the difference between flex and rigid-flex PCBs?

Flex PCBs are fully bendable, while rigid-flex PCBs mix stiff and flexible layers. Flex PCBs can fold completely, making them great for small spaces. Rigid-flex PCBs are strong but allow certain parts to bend while keeping other sections firm.

How do you ensure the durability of rigid-flex PCBs?

To make rigid-flex PCBs last, use strong materials and follow bend rules. Pick materials that handle heat and stress well. Test often during production to catch and fix problems early.

Why is prototyping important in PCB manufacturing?

Prototyping lets you check designs before making many PCBs. It finds mistakes, ensures everything works, and saves money by avoiding big errors. This step makes sure the final product is high-quality and works as planned.

What industries benefit most from rigid-flex PCBs?

Industries like healthcare, cars, planes, and gadgets use these PCBs a lot. They are perfect for small, light, and tough designs, like pacemakers, car safety systems, satellites, and smartwatches.

How can you reduce costs in PCB manufacturing?

Save money by picking affordable materials, using machines, and designing smartly. Choose materials like CEM, improve workflows, and work with manufacturers early to avoid costly changes.

Tip: Always balance saving money with keeping the product high-quality.

See Also

Exploring The Benefits And Challenges Of Flex PCBA

Why PCBA Manufacturing Skills Are Crucial For Electronics

A Deep Dive Into PCBA Manufacturing And Assembly

Emerging Trends In PCB And PCBA Design And Production

The Significance Of Custom PCBA Manufacturing In Electronics