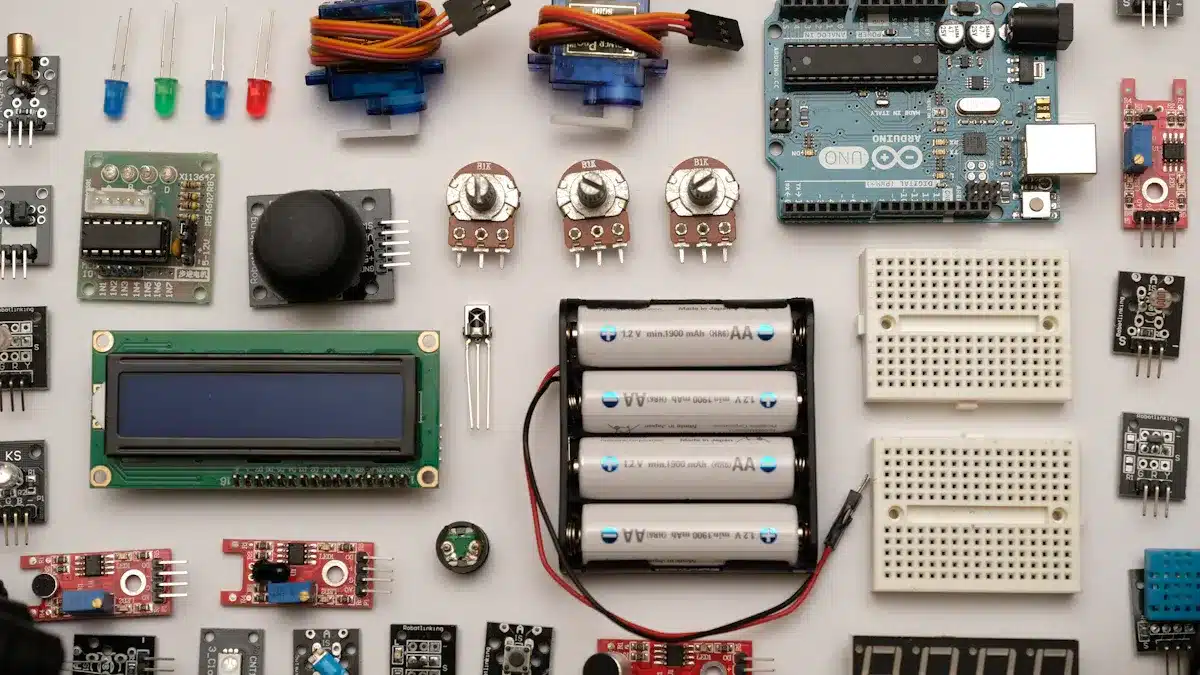

Electronic components PCB are crucial in the design of printed circuit boards. They enhance the performance and intelligence of technology. As we look ahead to 2025, understanding the key electronic components PCB is essential. The global market for electronic components in PCB design is projected to reach USD 484.63 billion in 2024, indicating significant growth across various sectors.

The North America PCB market is expected to expand at a rate exceeding 7.14% from 2025 to 2029.

High-Density Interconnect (HDI) technology is advancing to accommodate the demands of smaller devices and improved networks.

Stay informed about these trends to gain a better understanding of the future of PCB assembly services.

Key Takeaways

Resistors are very important. They control current in circuits. They also protect delicate parts from damage.

Capacitors hold and release energy. They help keep voltage steady. This improves how circuits work.

Diodes let current flow one way only. They protect circuits from reverse polarity and sudden voltage increases.

1. Resistors

Function

Resistors are very important in controlling electric current in circuits. They limit how much current can flow through a circuit. This helps ensure that parts get the right amount of power. This is key for protecting sensitive parts of a printed circuit board (PCB) from damage. Without resistors, circuits could get too much current. This could cause failures or problems.

Applications

You can find resistors in almost every electronic device. They are important in many uses, such as:

Voltage division: Resistors help split voltage levels for different parts.

Current limiting: They protect LEDs and other devices by controlling the current.

Signal conditioning: Resistors change signal levels in audio and communication devices.

In 2025, new resistor technology will improve their performance in high-density PCB designs. For example, buried resistors are now placed inside PCB layers. This saves space and improves signal quality while lowering electromagnetic interference (EMI).

Here’s a look at some common types of resistors used in PCB design:

Resistor Type | Characteristics | Common Applications |

|---|---|---|

Carbon Film Resistor | Stable, moderate precision | General-purpose electronics, common fixed resistor |

Metal Film Resistor | High precision, low noise | Audio, instrumentation, precision circuits |

Wire-Wound Resistor | High power rating, accurate | Power amplifiers, motor drives, load banks |

Surface Mount Resistor (SMD) | Small size, leadless | Phones, computers, modern electronics |

Thermistor (NTC/PTC) | Temp.-sensitive | Temp. sensors, overcurrent/overheat protection |

Varistor | Voltage-dependent | Surge protectors, power strips |

These resistors serve many industries, including military, medical, and automotive. They allow tighter tolerances and better performance for fast applications like 5G.

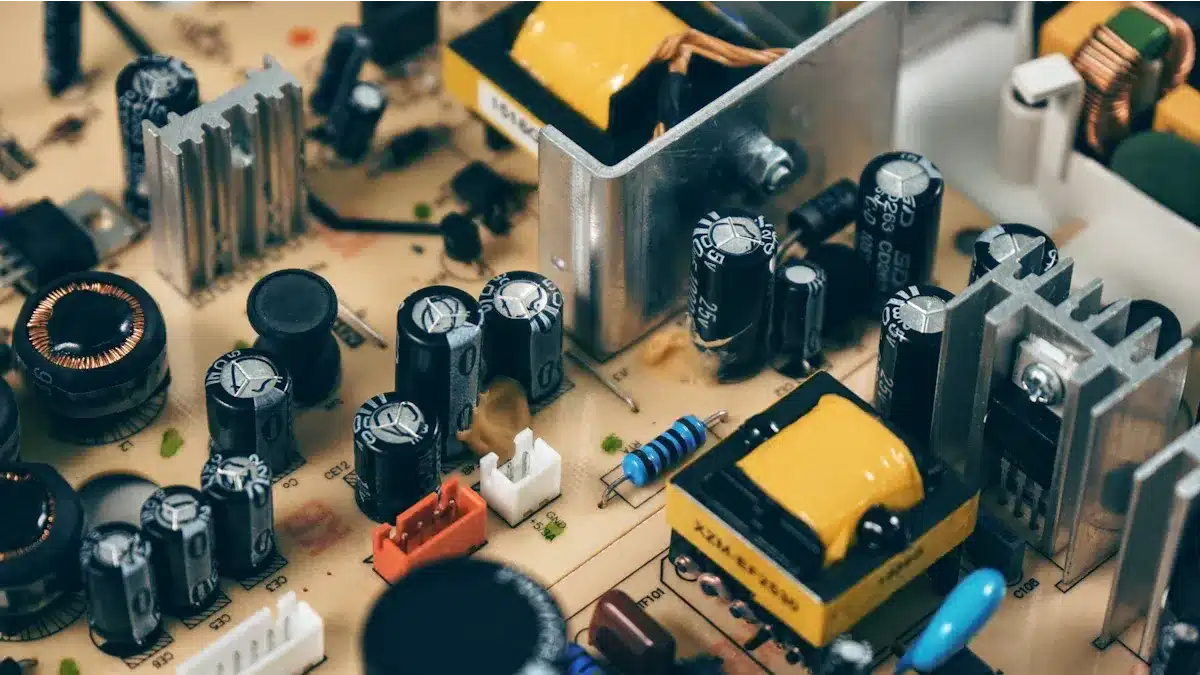

2. Capacitors

Types

Capacitors are important for storing and releasing electrical energy. They help keep voltage steady in electronic circuits. You can find different types of capacitors in modern PCB designs. Each type has special features. Here’s a quick look:

Dielectric Material | Polarity | Typical Capacitance Range | Key Characteristics | Typical Applications | |

|---|---|---|---|---|---|

Ceramic Capacitors | Ceramic compounds (like barium titanate) | Non-polarized | 1pF to 100µF | Low cost, small size, good for high frequencies | General purpose, bypass, decoupling |

Electrolytic Capacitors | Aluminum oxide or tantalum oxide | Polarized | 0.1µF to 1F | High capacitance, fairly low cost | Power supply filtering, smoothing |

Tantalum Capacitors | Tantalum pentoxide | Polarized | 0.1µF to 1000µF | High capacitance in a small size, stable | Critical power, filtering in low voltage |

Film Capacitors | Plastic films (like polyester) | Non-polarized | 1nF to 100µF | High precision, stable | Audio circuits, timing |

Supercapacitors | Porous carbon, metal oxides | Polarized | 1F to 1000F+ | Very high capacitance, stores a lot of energy | Energy storage, backup power |

Innovations

New ideas in capacitor technology are changing PCB design. You can now put capacitors inside PCB layers. This makes designs 30-50% smaller. Special dielectric layers with high permittivity let you have more capacitance in less space. This makes PCBs work better.

Also, embedded capacitance is a big new idea. It helps improve design processes and fixes problems with older designs. Tools like CR-8000 help simulate and analyze how embedded capacitance works. These improvements lead to better performance in your PCB layouts.

In 2025, capacitors will keep getting better. They will make electronic components PCB more efficient and useful.

3. Diodes

Function

Diodes are very important in electronic circuits. They let current flow in only one direction. This makes them key for controlling electrical signals. When you connect a diode the right way, it works like a one-way valve for electricity. If the current tries to go the other way, the diode stops it. This helps protect sensitive parts on your printed circuit board (PCB) from damage caused by reverse polarity.

Applications

You can find diodes in many devices and uses. Here are some common types of diodes and what they do:

Rectifier diode: Changes alternating current (AC) to direct current (DC). Models like 1N4001 and 1N5408 can handle high voltages and currents.

Zener diode: Keeps voltage steady and protects circuits from too much voltage.

Schottky diode: Has a low forward voltage drop (0.2 to 0.4V) and switches quickly, making it great for high-frequency uses.

LED: Works as a visual indicator and needs current-limiting resistors to avoid damage.

Photodiode: Turns light into electric current, often used in sensors and communication systems.

Avalanche diode: Protects circuits from high-voltage surges, often used in cars and industrial settings.

In high-frequency PCB designs, diodes help protect circuits a lot. For example, Zener diodes keep voltage steady, while TVS (Transient Voltage Suppressor) diodes manage high surge pulse energies, like those from electrostatic discharge (ESD) events. It is important to place these diodes correctly. You should put ESD diodes near connectors to make sure they respond quickly. This reduces voltage spikes that could damage sensitive integrated circuits.

By knowing how diodes work and where to use them, you can improve the reliability and performance of your electronic components PCB.

4. Transistors

Function

Transistors are very important in today’s electronics. You can think of them as small switches or amplifiers. They control how electrical signals move in your printed circuit board (PCB). When you put voltage on the gate of a transistor, it lets current flow between the source and drain. This helps you turn devices on and off or make signals stronger.

Applications

Transistors are found in many electronic devices. They are key for processing signals, which is important for communication systems. Here are some common types of transistors and their main performance features:

Transistor Type | |

|---|---|

JFET | Drain-Source Breakdown Voltage (BVDS), Gate-Source Voltage (VGS) Range, Drain Current (ID), On-Resistance (RDS(on)), Gate Threshold Voltage (VGS(th)), Capacitances (Ciss, Coss, Crss) |

MOSFET | Drain-Source Breakdown Voltage (BVDS), Gate-Source Voltage (VGS) Range, Drain Current (ID), On-Resistance (RDS(on)), Gate Threshold Voltage (VGS(th)), Capacitances (Ciss, Coss, Crss) |

IGBT | Drain-Source Breakdown Voltage (BVDS), Gate-Source Voltage (VGS) Range, Drain Current (ID), On-Resistance (RDS(on)), Gate Threshold Voltage (VGS(th)), Capacitances (Ciss, Coss, Crss) |

HEMT | Drain-Source Breakdown Voltage (BVDS), Gate-Source Voltage (VGS) Range, Drain Current (ID), On-Resistance (RDS(on)), Gate Threshold Voltage (VGS(th)), Capacitances (Ciss, Coss, Crss) |

GaN FET | Drain-Source Breakdown Voltage (BVDS), Gate-Source Voltage (VGS) Range, Drain Current (ID), On-Resistance (RDS(on)), Gate Threshold Voltage (VGS(th)), Capacitances (Ciss, Coss, Crss) |

New technology has made transistors smaller and better at processing signals on PCBs. This means more components can fit on a PCB, saving space. It helps create smaller PCBs, which is important for portable devices and aerospace systems. Shorter signal paths and fewer unwanted effects improve signal quality and reduce losses.

In 2025, transistors will keep getting better, making electronic components PCB more efficient and powerful.

5. Inductors

Function

Inductors are very important in electronic circuits. They store energy in a magnetic field. When current goes through an inductor, it makes a magnetic field around it. This magnetic field holds energy. The inductor can release this energy when the current goes down. This ability to store and release energy is why inductors are needed for managing electrical signals in many uses.

Applications

Inductors are often used in power supply circuits. They help keep voltage and current steady. This makes sure that electronic parts work well. Here are some main uses of inductors in power supply circuits:

Application | Description |

|---|---|

Inductors hold electrical energy and let it go when needed for buffering. | |

Filtering | They work with capacitors to remove high-frequency noise and improve stability. |

Current Stabilization | They keep output current steady in switching power supplies and DC-DC converters. |

EMI Suppression | They reduce electromagnetic interference to protect other devices. |

Inductors come in different types with various core materials and inductance values. For example, ferrite cores work well for high-frequency uses, while iron cores can handle more inductance and current. Here’s a quick look at common inductance values and core materials used in PCB inductors for 2025:

Core Type | Characteristics | Application Scenarios |

|---|---|---|

Ferrite Core | Good for high-frequency uses, cuts losses and boosts efficiency | RF circuits or fast switching regulators |

Iron Core | Good for uses needing higher inductance and current handling | Power inductors for low-frequency power uses |

Picking the right inductor for your printed circuit board (PCB) design can really affect performance. Knowing how inductors work and where to use them will help you make better and more reliable electronic components PCB.

6. Transformers

Function

Transformers are very important for changing voltage. They change voltage levels to fit the needs of different parts in a circuit. This helps power move efficiently through your printed circuit board (PCB). Transformers also keep parts separate. They protect sensitive components from high voltages and noise.

Here’s a quick look at what transformers do:

Function | Description |

|---|---|

Voltage Alteration | Changes voltage levels to fit circuit needs, helping power transfer well. |

Electrical Separation | Keeps different parts of a circuit safe from high voltages and noise. |

Impedance Alignment | Helps power transfer better and reduces signal reflections, especially in audio and communication. |

Signal Conditioning | Changes voltage and current to make sure circuit stages work together. |

Galvanic Isolation | Separates circuits to stop direct electrical contact, which cuts down noise and ground loops. |

Applications

Transformers are used in many places, especially in power systems. They help your electronic components PCB work well. When you design your PCB, think about how the size and efficiency of transformers affect layout and energy flow. More efficient transformers need careful design to reduce losses. This can change the size and weight of the transformer, which might require changes in your PCB layout.

Here are some important points about transformer size and efficiency:

Bigger transformers make the overall size and weight larger, needing layout changes.

Larger size means more heat management is needed to avoid overheating.

EMI problems get worse with bigger transformers, needing extra shielding and grounding.

By knowing what transformers do and where they are used, you can improve the performance and reliability of your electronic components PCB.

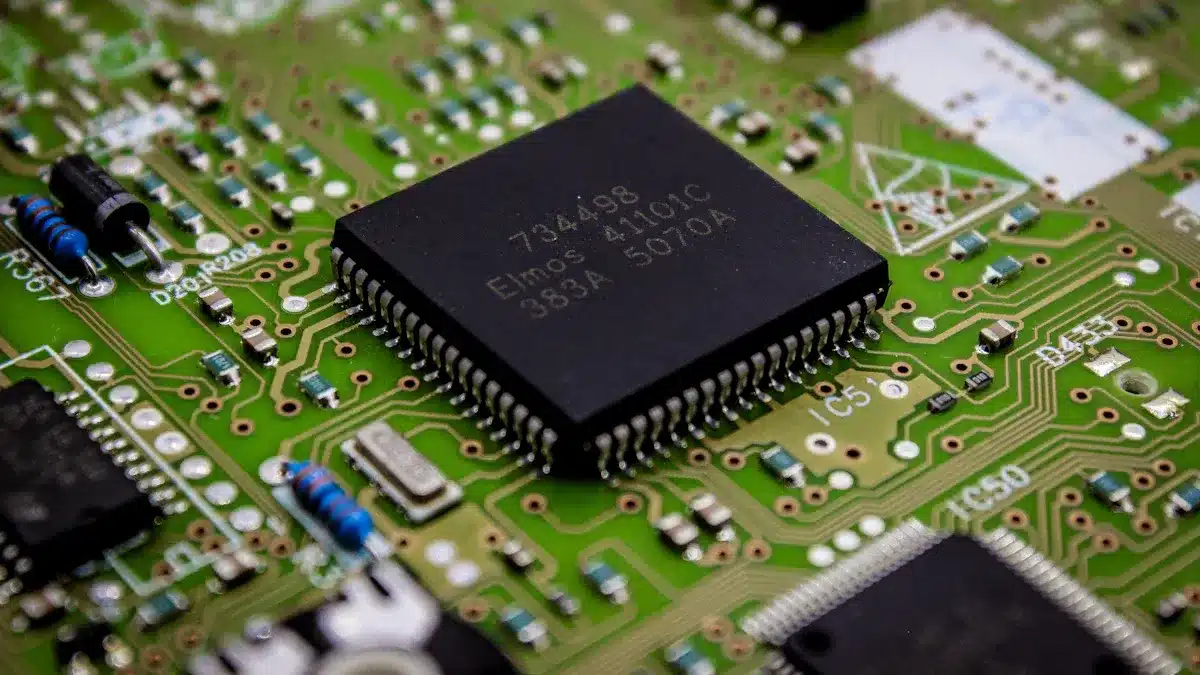

7. Integrated Circuits (ICs)

Function

Integrated Circuits (ICs) are chips that combine many functions. This means you can do different tasks without using many parts. ICs can process data and amplify signals. Using ICs makes your printed circuit board (PCB) design simpler. It also cuts down the number of parts you need.

Applications

ICs are very important in today’s electronics. They come in different types, each with special jobs. Here’s a quick look at the most common types of ICs used in PCB design:

Type of ICs | Description |

|---|---|

Digital ICs | Handle discrete signals, great for computing, logic tasks, and storing data. |

Analog ICs | Work with continuous signals, used for things like audio boosting and power control. |

Mixed ICs | Combine both digital and analog functions, used in complex tasks like ADC and DAC. |

You can find digital ICs in microprocessors, memory devices, and communication tools. Analog ICs are often in audio amplifiers and medical devices. Mixed ICs are key in smartphones and car systems.

ICs greatly affect the size and performance of PCBs. The move to advanced high-density interconnects (HDI) has raised wiring density in small areas. Multi-layer boards (MLB) use two or more inner layers in a compact way, improving functionality. Also, IC substrates like FC-CSP and FC-BGA connect chips to PCBs. This creates a network that helps make things smaller. This means you can design smaller, more efficient electronic components PCB that work better.

8. Relays

Function

Relays are very important for controlling powerful devices. They work like switches that open and close circuits using low-power signals. When a small current goes through the relay, it lets a larger current flow in another circuit. This helps you control powerful devices safely without touching them directly.

Applications

You can find relays in many uses, especially in electronic components PCB. Here are some common types of relays used in PCB applications:

High Power PCB Relays: Made for high-power uses, these relays can handle a lot of current and usually need air cooling.

Low Power PCB Relays: Made for low-power uses, these relays manage less current but still work well.

Relays also give electrical separation in sensitive PCB circuits. They provide galvanic isolation, which is very important for safety. This means they keep control and load circuits apart. By doing this, relays stop high voltages from harming sensitive parts. Here are some key benefits of using relays for isolation:

They help switch between low and high voltage safely.

They lower the chance of electric shock.

They protect sensitive parts from damage.

In 2025, relays will still be very important for keeping your printed circuit board designs safe and reliable. Knowing how they work and where to use them will help you make better choices in your projects.

9. Connectors

Function

Connectors are very important for making strong links between parts of your printed circuit board (PCB). They help signals and power move easily from one part to another. Without connectors, your electronic devices would not work well. You depend on connectors to make sure everything works together smoothly.

Applications

Connectors are used in many areas across different industries. Here are some common types of connectors and where they are used:

USB Connectors: Found in computers and phones for data transfer and charging.

HDMI Connectors: Used in audio-visual devices for sending high-definition video and sound.

RJ45 Connectors: Important for networking, connecting devices to local area networks (LANs).

Power Connectors: Supply power to devices, helping them run well.

As technology improves, you will see new trends in connector technology:

Faster data rates: People want quicker data speeds because of growing AI and IoT needs.

Higher, faster power throughput: There is a need for better energy transfer, especially for electric vehicles (EVs) and renewable energy.

Smaller components: Making things smaller is a trend in many fields, needing more compact designs.

Contactless connectivity: This new technology allows movement without wires and removes the need for manual connections.

These trends will change how connectors work in your electronic components PCB, making them better and more flexible.

10. Crystals & Oscillators

Function

Crystals and oscillators are very important for timing. They create exact frequencies that help your electronic devices stay in sync. You can think of them as the heartbeat of your printed circuit board (PCB). When you need precise timing, these parts make sure everything works well.

Applications

You can find crystals and oscillators in many electronic devices. They are key for uses like:

Microcontrollers: They help keep accurate timing for tasks.

Communication devices: They make sure signals are sent and received at the right times.

Consumer electronics: They keep clocks and timers running correctly.

Here’s a table showing common frequency ranges and uses for crystals and oscillators:

Frequency Range | Specific Frequencies | Common Applications |

|---|---|---|

Low (32 kHz to 1 MHz) | 32.768 kHz | Quartz wristwatches, Real-time clock modules |

100 kHz to 1 MHz | N/A | RFID systems, Consumer electronics |

Intermediate (1 to 10 MHz) | 4 to 8 MHz | Microcontrollers, TV remote controls |

10 MHz | N/A | Digital circuits, Communication devices |

High (10 to 100 MHz) | 20 to 40 MHz | Microprocessors, Wireless devices |

100 MHz | N/A | Fast digital circuits, High-speed ADCs |

Very High (Above 100 MHz) | 125 to 200 MHz | Advanced communication systems, Ethernet |

Above 200 MHz | N/A | Radar systems, Satellite communication |

To keep your circuits accurate and reliable, consider these tips:

Use proper grounding and shielding to keep performance high.

Place decoupling capacitors near the power pin of the crystal oscillator for steady operation.

By knowing how important crystals and oscillators are, you can improve the performance of your electronic components PCB.

To sum up, important electronic parts for PCBs, like resistors, capacitors, and diodes, are key for the future of printed circuit board technology. The global PCB market is expected to hit about USD 85.4 billion in 2025. So, it’s good to keep up with new changes in these parts. Use trends like smaller sizes, flexible designs, and eco-friendly materials to improve your projects.

FAQ

What are electronic components PCB?

Electronic components PCB are important parts found in printed circuit boards. They help manage electrical signals and power in devices.

Why are resistors important in PCB design?

Resistors control current flow, keeping sensitive parts on your printed circuit board safe. They make sure devices get the right voltage and avoid damage.

How do capacitors improve circuit performance?

Capacitors hold and release energy, keeping voltage steady. They reduce noise and make your electronic components PCB work better.

See Also

Streamlined PCBA Solutions for Your Electronics Projects

The Importance of Custom PCBA Production in Today’s Electronics

Essential PCBA Components and Their Primary Roles Explained